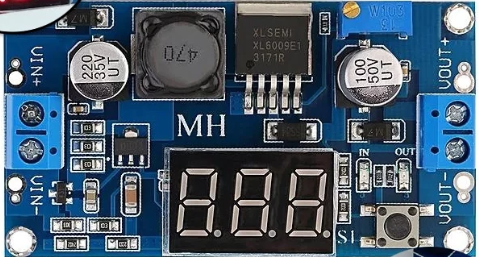

How to Use STEP UP: Examples, Pinouts, and Specs

Design with STEP UP in Cirkit Designer

Design with STEP UP in Cirkit DesignerIntroduction

A step-up converter, also known as a boost converter, is a type of DC-DC converter that increases the input voltage to a higher output voltage while maintaining power balance. This component is widely used in applications where the available voltage is insufficient to power a load or device. By efficiently stepping up the voltage, it ensures that devices can operate at their required voltage levels without the need for larger or more expensive power sources.

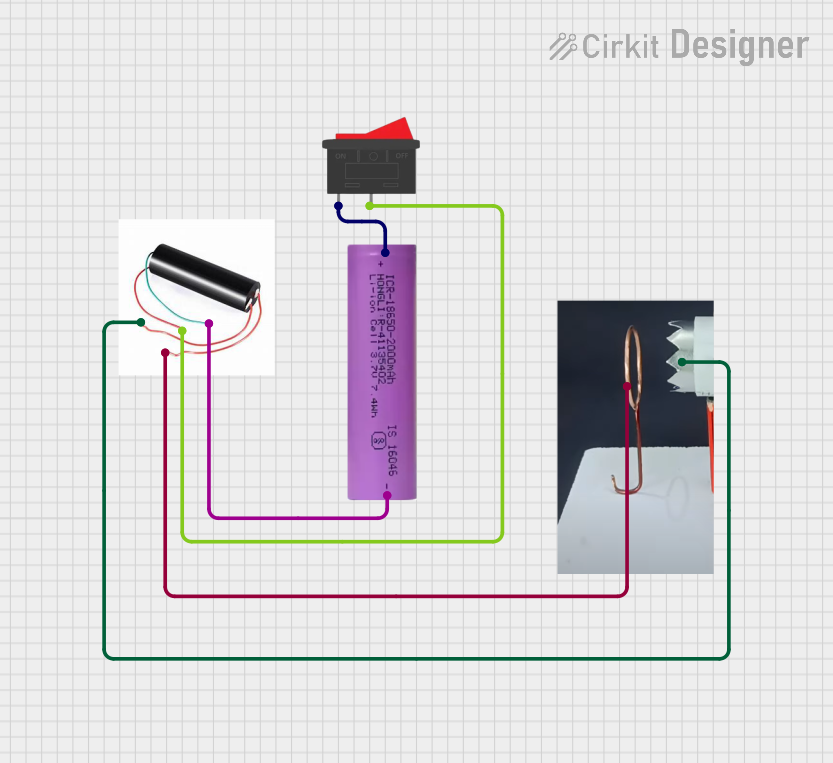

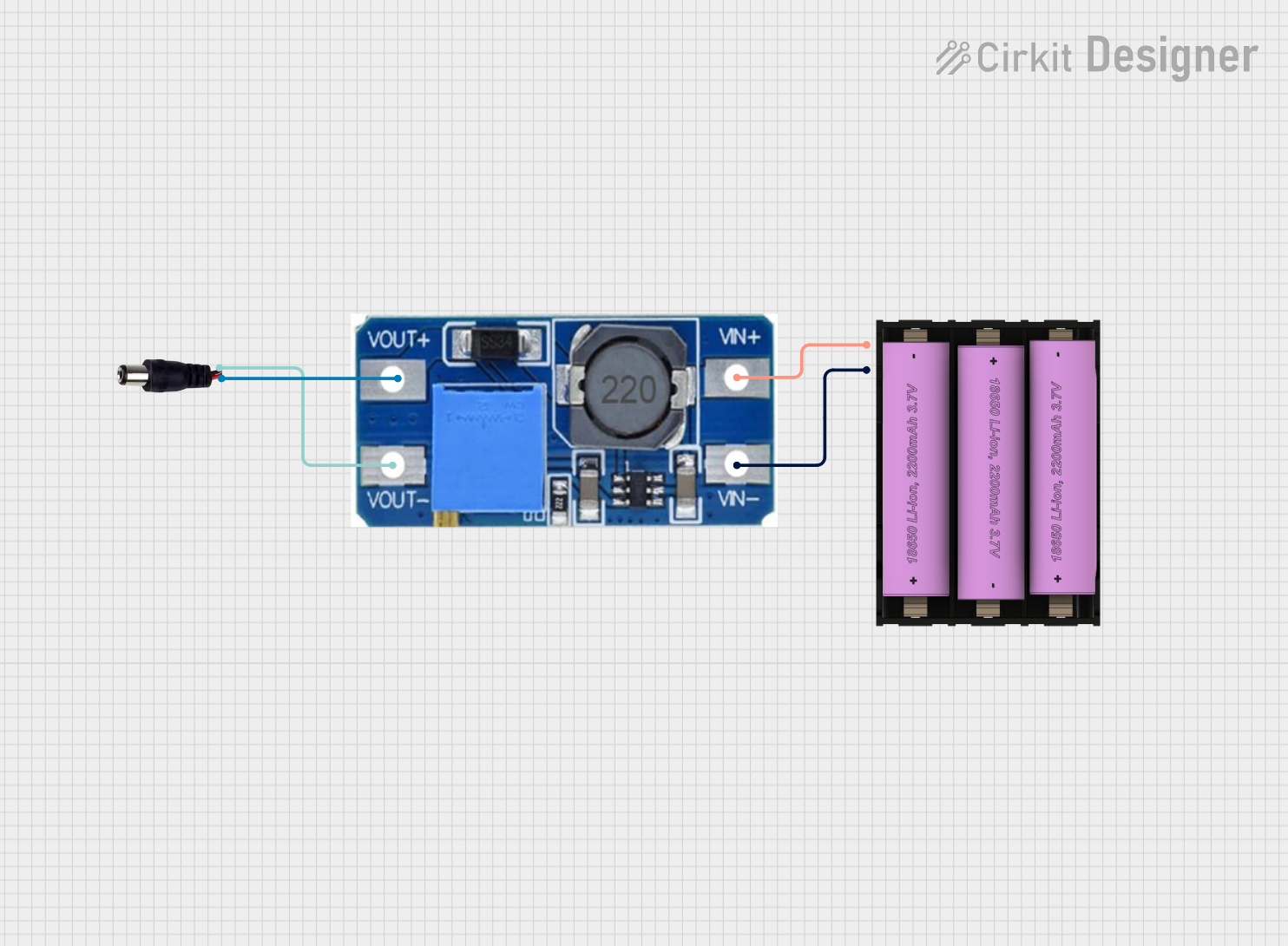

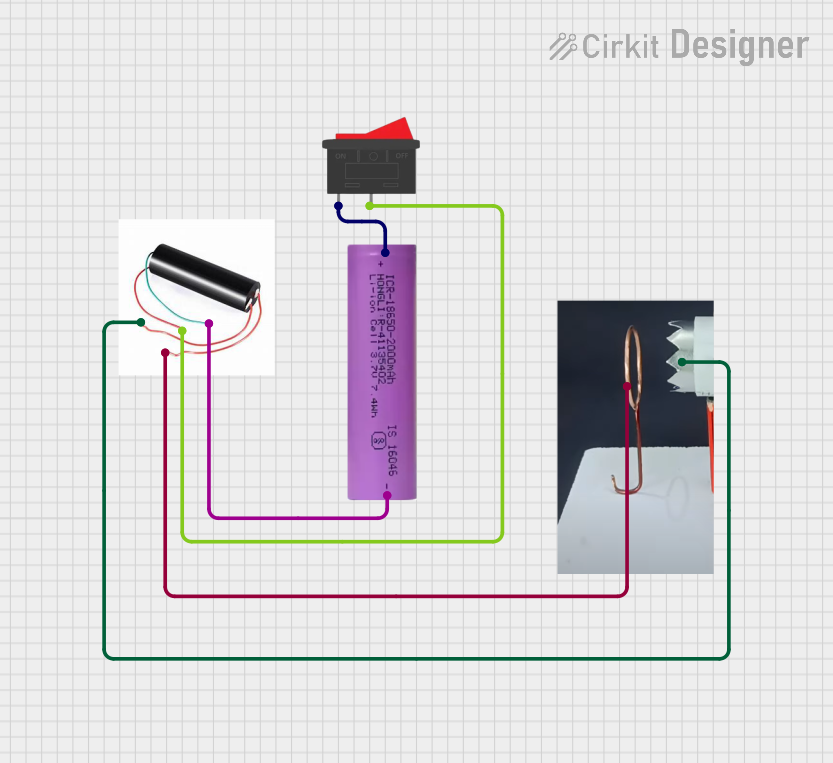

Explore Projects Built with STEP UP

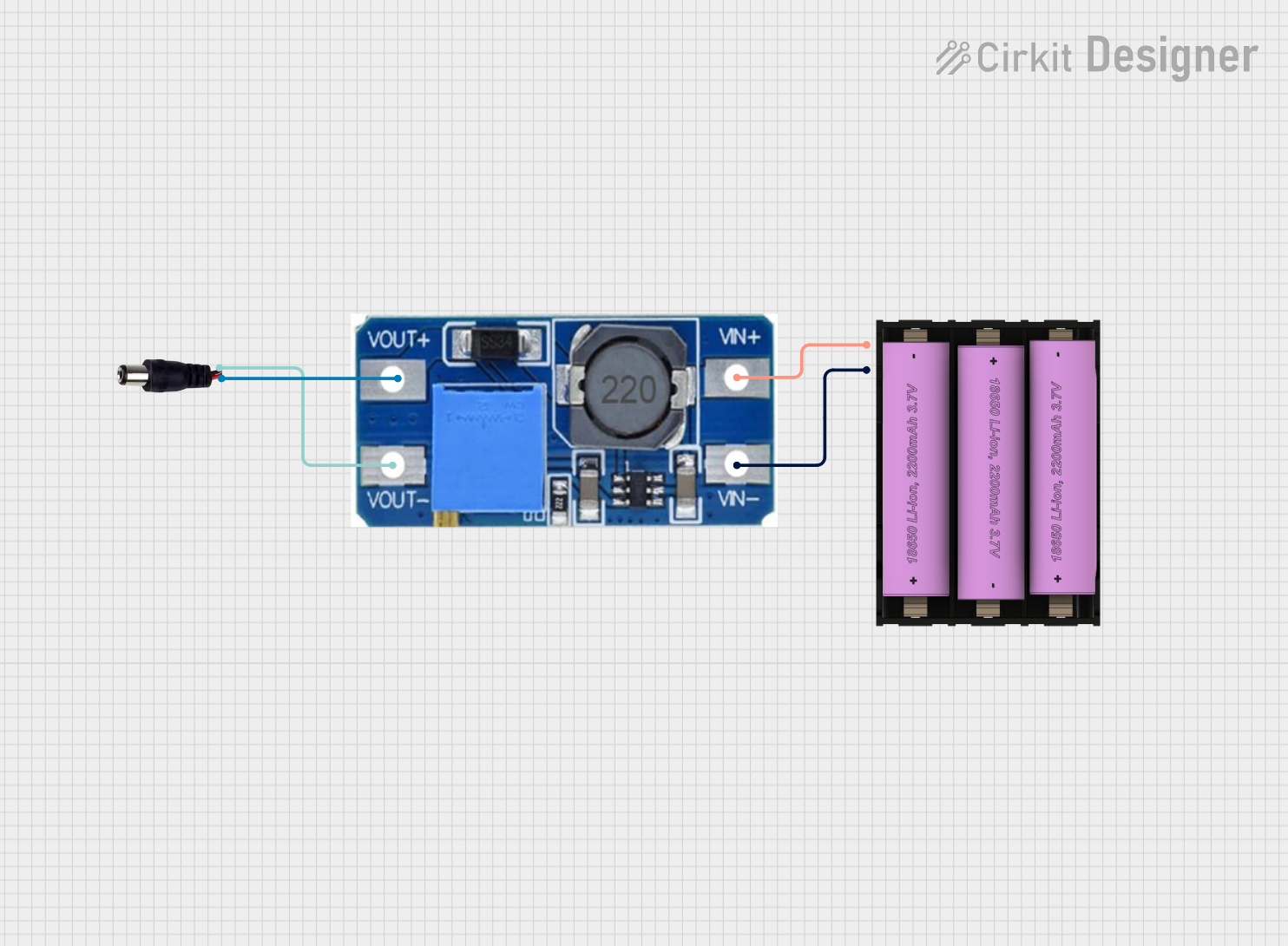

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with STEP UP

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications and Use Cases

- Powering devices requiring higher voltage from low-voltage batteries (e.g., 3.7V Li-ion to 12V).

- Solar power systems to boost panel output voltage.

- LED drivers for high-power LEDs.

- USB power banks to step up battery voltage to 5V.

- Industrial and automotive applications requiring voltage conversion.

Technical Specifications

Below are the general technical specifications for a typical step-up converter. Note that specific models may vary, so always refer to the datasheet of the exact component you are using.

| Parameter | Value |

|---|---|

| Input Voltage Range | 2V to 24V (varies by model) |

| Output Voltage Range | 5V to 48V (varies by model) |

| Output Current | Up to 5A (depending on the design) |

| Efficiency | Up to 95% (depending on load and input) |

| Switching Frequency | 100 kHz to 1 MHz |

| Operating Temperature | -40°C to +85°C |

Pin Configuration and Descriptions

The pinout of a step-up converter module may vary depending on the design, but a typical module includes the following pins:

| Pin Name | Description |

|---|---|

| VIN | Input voltage pin. Connect the lower voltage source. |

| GND | Ground pin. Connect to the ground of the circuit. |

| VOUT | Output voltage pin. Provides the boosted voltage. |

| EN (optional) | Enable pin. Used to turn the module on/off. |

| FB (optional) | Feedback pin. Used for voltage regulation. |

Usage Instructions

How to Use the Component in a Circuit

Connect the Input Voltage (VIN):

Attach the positive terminal of your power source to the VIN pin and the negative terminal to the GND pin. Ensure the input voltage is within the specified range of the step-up converter.Connect the Output Load (VOUT):

Connect the load (e.g., motor, LED, or other devices) to the VOUT pin and its ground to the GND pin.Adjust the Output Voltage (if applicable):

Some step-up converters have a potentiometer for adjusting the output voltage. Use a small screwdriver to turn the potentiometer clockwise or counterclockwise to increase or decrease the output voltage, respectively.Enable the Module (if applicable):

If the module has an EN (enable) pin, ensure it is connected to a HIGH signal (e.g., 3.3V or 5V) to activate the converter. Leaving it unconnected or LOW may disable the module.

Important Considerations and Best Practices

- Input Voltage Range: Ensure the input voltage is within the specified range. Exceeding the maximum input voltage can damage the module.

- Output Voltage Adjustment: Use a multimeter to measure the output voltage while adjusting the potentiometer to avoid overvoltage.

- Heat Dissipation: For high-power applications, ensure proper heat dissipation by adding a heatsink or active cooling if necessary.

- Capacitor Placement: Place input and output capacitors close to the module to reduce voltage ripple and improve stability.

- Current Limit: Do not exceed the maximum output current rating of the module to prevent overheating or damage.

Example: Using a Step-Up Converter with Arduino UNO

Below is an example of using a step-up converter to power a 12V motor from a 5V Arduino UNO power supply.

Circuit Connections:

- Connect the Arduino's 5V pin to the VIN pin of the step-up converter.

- Connect the GND pin of the Arduino to the GND pin of the step-up converter.

- Adjust the step-up converter to output 12V using the potentiometer.

- Connect the VOUT pin of the step-up converter to the positive terminal of the motor.

- Connect the motor's negative terminal to the GND pin of the step-up converter.

Arduino Code:

// Example code to control a 12V motor using a step-up converter

// and an Arduino UNO with a PWM signal.

const int motorPin = 9; // PWM pin connected to motor driver

void setup() {

pinMode(motorPin, OUTPUT); // Set motor pin as output

}

void loop() {

// Gradually increase motor speed

for (int speed = 0; speed <= 255; speed++) {

analogWrite(motorPin, speed); // Write PWM signal to motor

delay(20); // Wait 20ms before increasing speed

}

// Gradually decrease motor speed

for (int speed = 255; speed >= 0; speed--) {

analogWrite(motorPin, speed); // Write PWM signal to motor

delay(20); // Wait 20ms before decreasing speed

}

}

Troubleshooting and FAQs

Common Issues and Solutions

No Output Voltage:

- Cause: Input voltage is too low or not connected properly.

- Solution: Verify the input voltage is within the specified range and connections are secure.

Output Voltage is Incorrect:

- Cause: Potentiometer is not adjusted correctly.

- Solution: Use a multimeter to measure the output voltage and adjust the potentiometer.

Overheating:

- Cause: Exceeding the current limit or poor heat dissipation.

- Solution: Reduce the load current or add a heatsink to the module.

High Voltage Ripple:

- Cause: Insufficient input/output capacitors.

- Solution: Add low-ESR capacitors close to the input and output pins.

FAQs

Q: Can I use a step-up converter to power sensitive electronics?

A: Yes, but ensure the output voltage is stable and within the tolerance range of the device. Adding capacitors can help reduce voltage ripple.

Q: What happens if I exceed the input voltage range?

A: Exceeding the input voltage range can damage the module. Always check the datasheet for the maximum input voltage.

Q: Can I use a step-up converter to charge batteries?

A: It is not recommended unless the converter is specifically designed for battery charging, as it may not provide proper current regulation.

Q: How do I calculate the efficiency of the step-up converter?

A: Efficiency (%) = (Output Power / Input Power) × 100. Measure the input and output voltage and current to calculate power.