How to Use h-bridge motor driver: Examples, Pinouts, and Specs

Design with h-bridge motor driver in Cirkit Designer

Design with h-bridge motor driver in Cirkit DesignerIntroduction

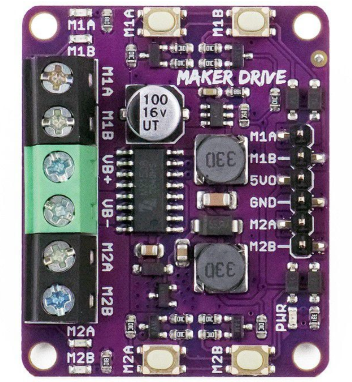

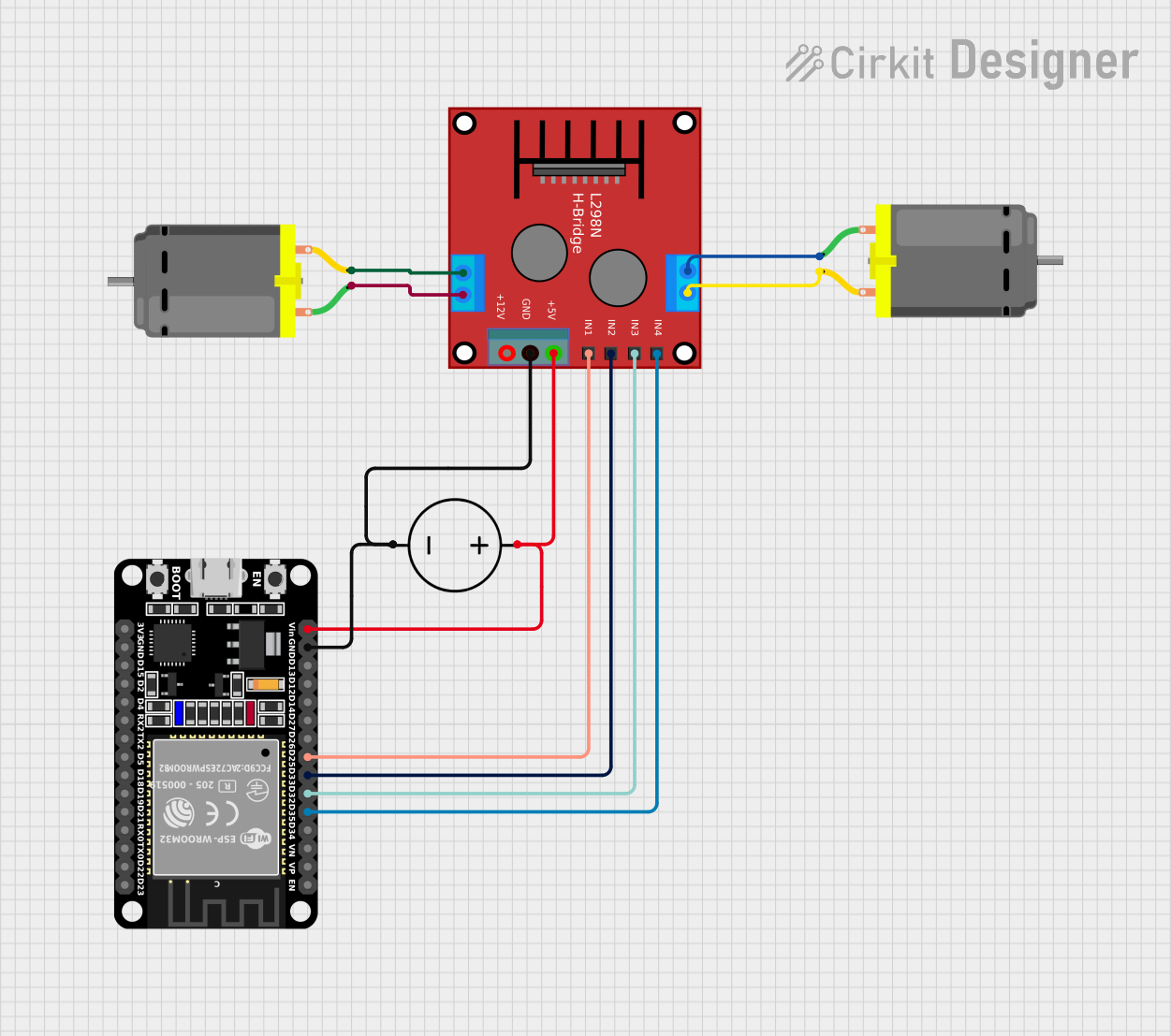

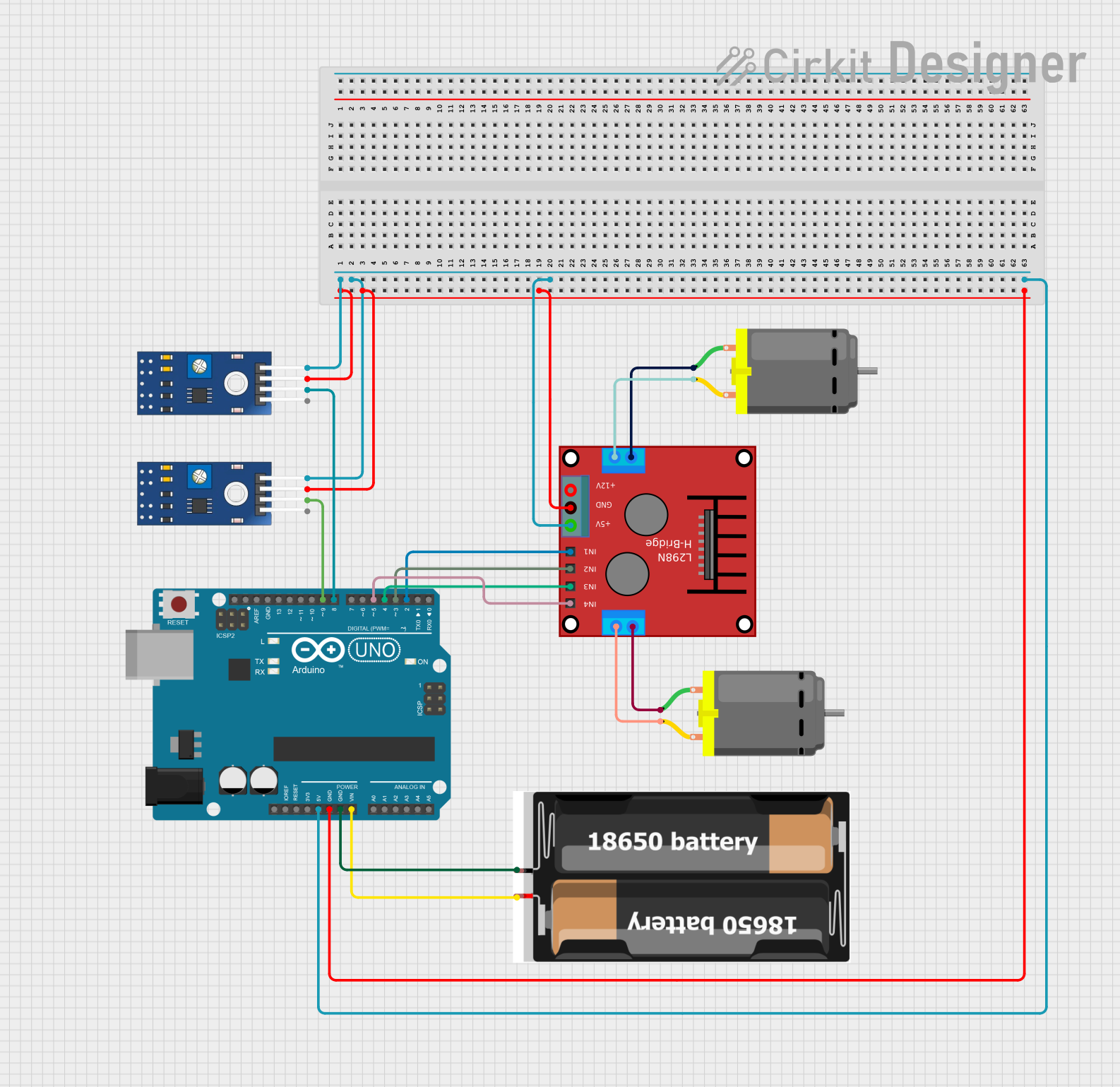

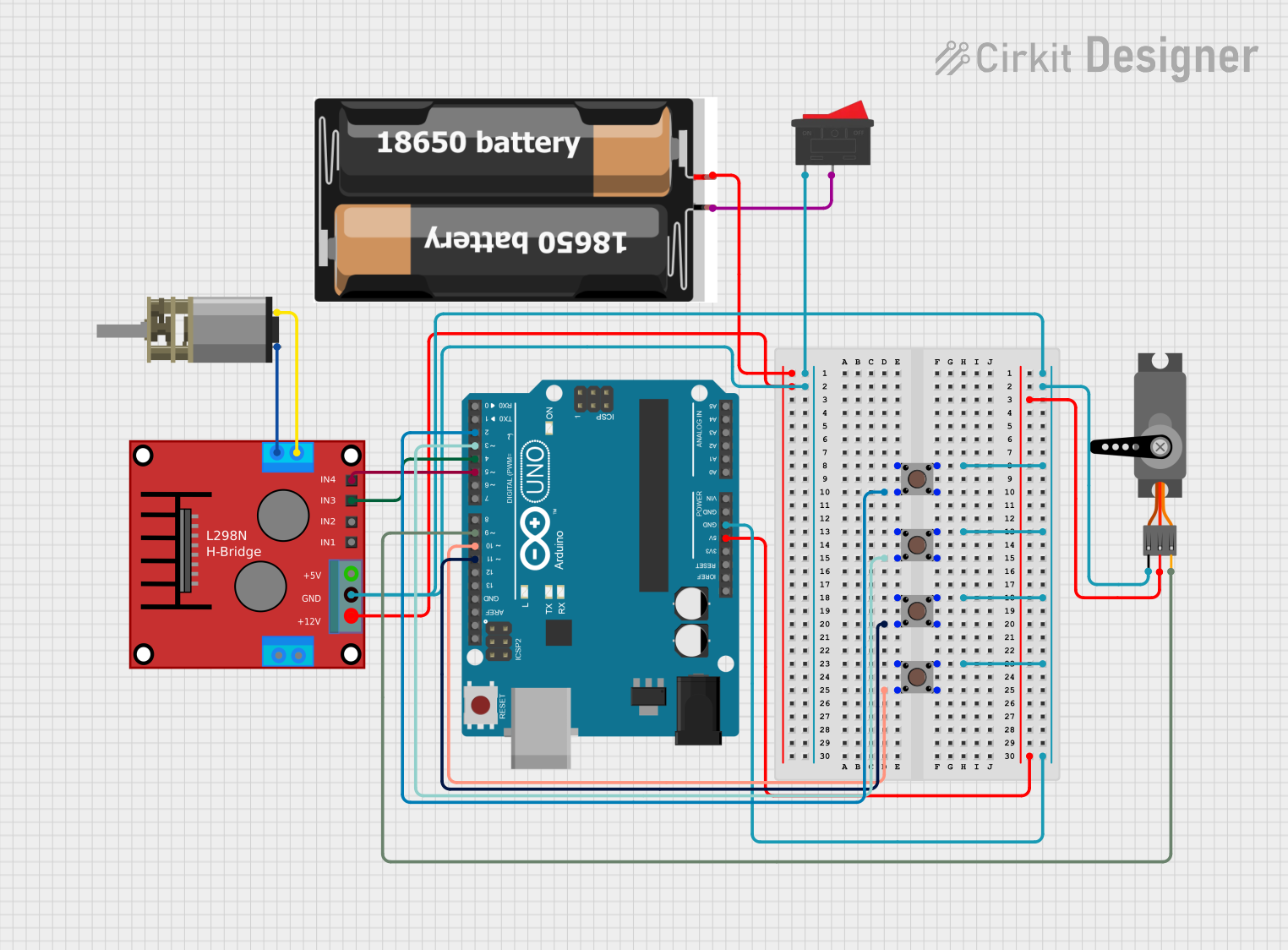

The H-Bridge Motor Driver (Manufacturer: Maker Drive, Part ID: MOTOR DRIVER) is an electronic circuit designed to control the direction and speed of DC motors. By enabling voltage to be applied across a motor in either direction, it allows for forward, reverse, and braking operations. This makes it an essential component in robotics, automation, and other motor control applications.

Explore Projects Built with h-bridge motor driver

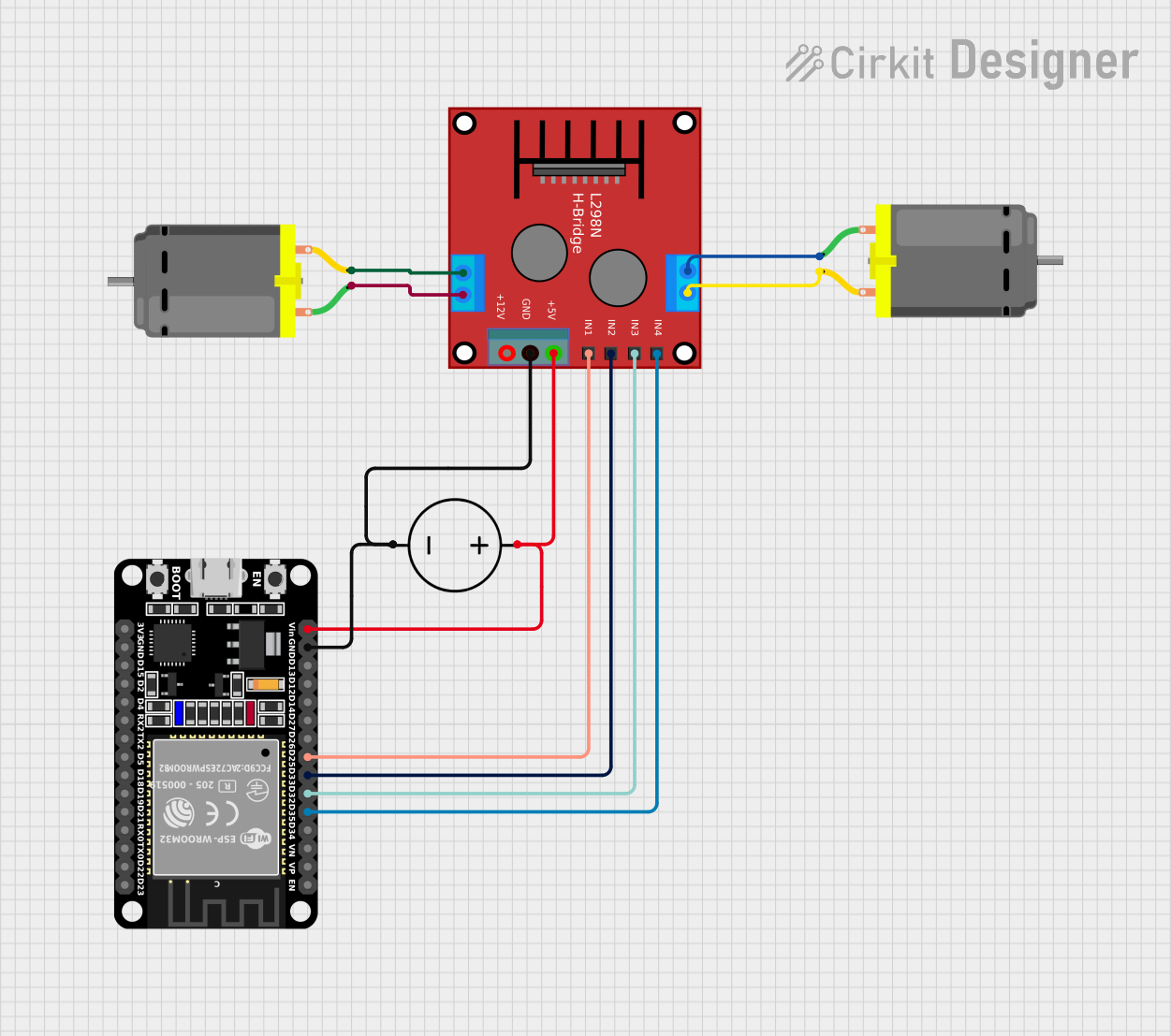

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

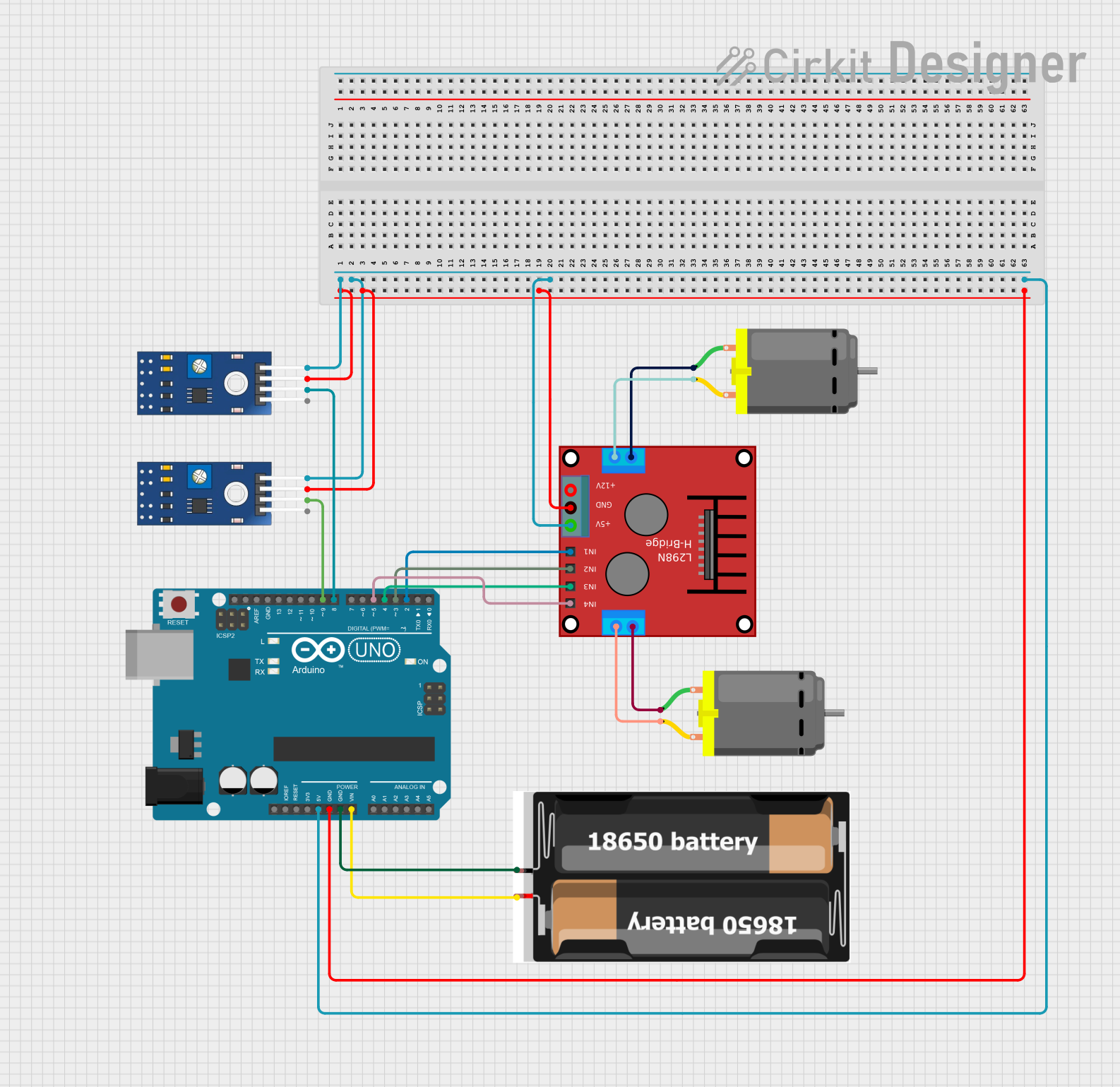

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

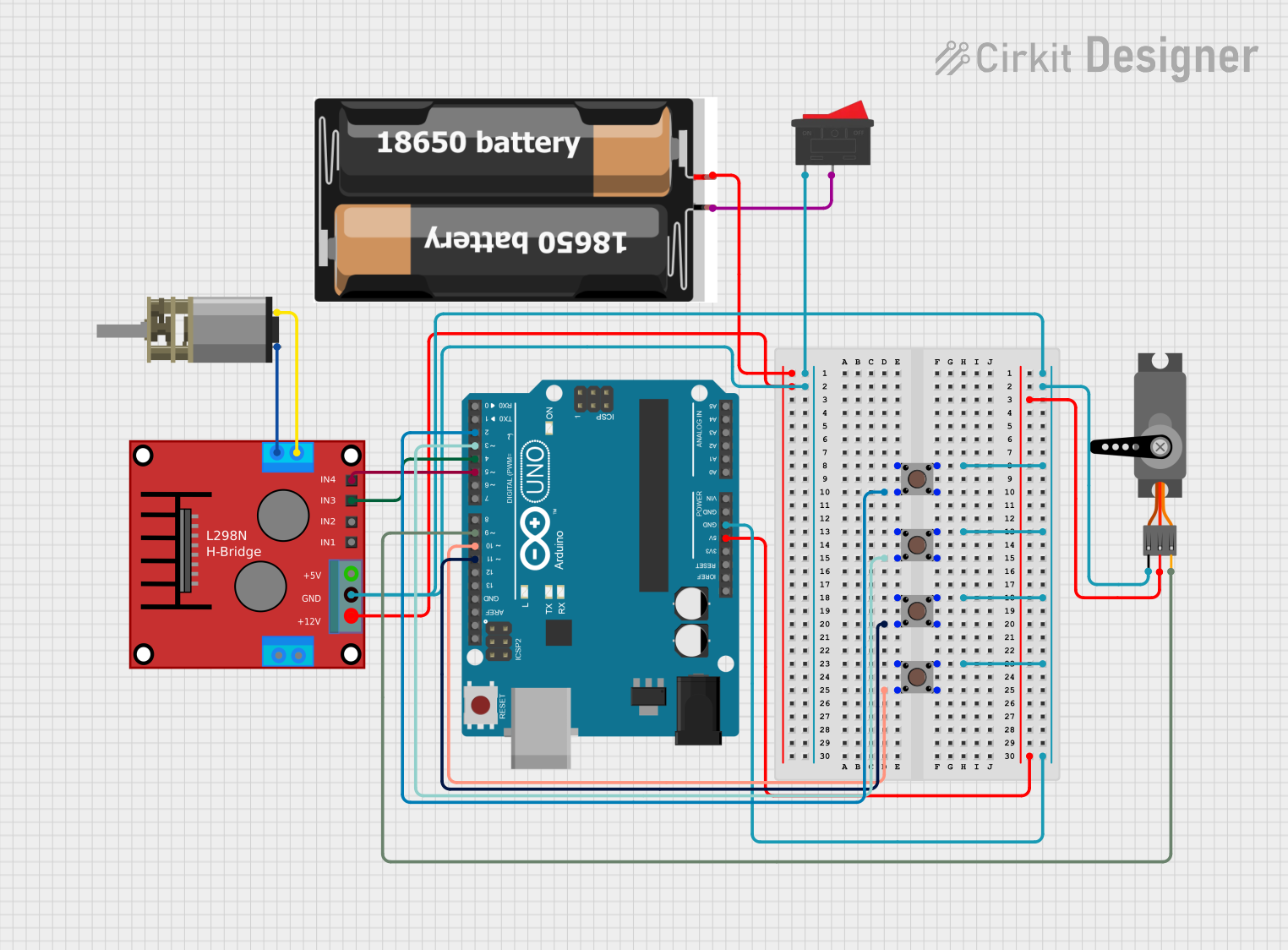

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with h-bridge motor driver

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications and Use Cases

- Robotics: Controlling the movement of robot wheels or arms.

- Automation: Driving conveyor belts or actuators.

- Remote-controlled vehicles: Enabling forward and reverse motion.

- DIY projects: Motorized systems such as fans, doors, or small vehicles.

Technical Specifications

The following table outlines the key technical details of the Maker Drive H-Bridge Motor Driver:

| Parameter | Value |

|---|---|

| Operating Voltage | 5V to 12V |

| Maximum Output Current | 1.5A per channel (continuous) |

| Peak Current | 2A per channel (short duration) |

| Logic Voltage | 3.3V or 5V (compatible with MCUs) |

| Number of Channels | 2 (dual motor control) |

| Control Inputs | IN1, IN2, ENA (per channel) |

| Output Terminals | OUT1, OUT2 (per channel) |

| Protection Features | Overcurrent and thermal shutdown |

Pin Configuration and Descriptions

The H-Bridge Motor Driver has the following pin configuration:

Input Pins

| Pin Name | Description |

|---|---|

| IN1 | Input signal to control motor direction (Channel 1). |

| IN2 | Input signal to control motor direction (Channel 1). |

| ENA | Enable pin for Channel 1 (PWM for speed control). |

| IN3 | Input signal to control motor direction (Channel 2). |

| IN4 | Input signal to control motor direction (Channel 2). |

| ENB | Enable pin for Channel 2 (PWM for speed control). |

Output Pins

| Pin Name | Description |

|---|---|

| OUT1 | Motor output terminal 1 (Channel 1). |

| OUT2 | Motor output terminal 2 (Channel 1). |

| OUT3 | Motor output terminal 1 (Channel 2). |

| OUT4 | Motor output terminal 2 (Channel 2). |

Power Pins

| Pin Name | Description |

|---|---|

| VCC | Power supply input (5V to 12V). |

| GND | Ground connection. |

Usage Instructions

How to Use the Component in a Circuit

- Connect Power Supply:

- Connect the VCC pin to a power source (5V to 12V) and GND to ground.

- Connect the Motor:

- Attach the motor terminals to the output pins (OUT1 and OUT2 for Channel 1, OUT3 and OUT4 for Channel 2).

- Control Inputs:

- Use IN1 and IN2 to control the direction of the motor for Channel 1. Similarly, use IN3 and IN4 for Channel 2.

- Apply a PWM signal to ENA (Channel 1) or ENB (Channel 2) to control motor speed.

- Microcontroller Interface:

- Connect the control pins (IN1, IN2, ENA, etc.) to the GPIO pins of a microcontroller (e.g., Arduino UNO).

Important Considerations and Best Practices

- Ensure the power supply voltage matches the motor's operating voltage.

- Use appropriate heat sinks or cooling if operating near the maximum current rating.

- Avoid short circuits between output terminals to prevent damage.

- Use pull-down resistors on control pins to avoid floating states when the microcontroller is powered off.

Example Code for Arduino UNO

Below is an example code to control a DC motor using the H-Bridge Motor Driver:

// Define control pins for Channel 1

const int IN1 = 9; // Direction control pin 1

const int IN2 = 8; // Direction control pin 2

const int ENA = 10; // Speed control (PWM) pin

void setup() {

// Set control pins as outputs

pinMode(IN1, OUTPUT);

pinMode(IN2, OUTPUT);

pinMode(ENA, OUTPUT);

}

void loop() {

// Rotate motor forward

digitalWrite(IN1, HIGH); // Set IN1 high

digitalWrite(IN2, LOW); // Set IN2 low

analogWrite(ENA, 128); // Set speed to 50% (PWM value: 128)

delay(2000); // Run for 2 seconds

// Rotate motor backward

digitalWrite(IN1, LOW); // Set IN1 low

digitalWrite(IN2, HIGH); // Set IN2 high

analogWrite(ENA, 128); // Set speed to 50% (PWM value: 128)

delay(2000); // Run for 2 seconds

// Stop motor

digitalWrite(IN1, LOW); // Set IN1 low

digitalWrite(IN2, LOW); // Set IN2 low

analogWrite(ENA, 0); // Set speed to 0

delay(2000); // Wait for 2 seconds

}

Troubleshooting and FAQs

Common Issues and Solutions

Motor Does Not Turn On:

- Check the power supply voltage and connections.

- Ensure the ENA/ENB pins are receiving a valid PWM signal.

- Verify that the motor is properly connected to the output terminals.

Motor Spins in the Wrong Direction:

- Swap the IN1 and IN2 signals (or IN3 and IN4 for Channel 2).

- Verify the logic levels sent to the control pins.

Overheating of the Driver:

- Ensure the current drawn by the motor does not exceed the driver's maximum rating.

- Use a heat sink or cooling fan if necessary.

No Response from the Motor Driver:

- Check for loose connections or damaged wires.

- Verify that the microcontroller is correctly programmed and powered.

FAQs

Q: Can I use this driver with a 3.3V microcontroller?

A: Yes, the driver is compatible with both 3.3V and 5V logic levels.

Q: Can I control two motors simultaneously?

A: Yes, the driver supports dual-channel operation, allowing independent control of two motors.

Q: What happens if I connect the motor terminals incorrectly?

A: The motor may not function as expected. Ensure proper wiring to avoid damage to the driver or motor.

Q: Can I use this driver for stepper motors?

A: No, this driver is designed for DC motors. Use a dedicated stepper motor driver for stepper motors.