How to Use 12V Air Pump: Examples, Pinouts, and Specs

Design with 12V Air Pump in Cirkit Designer

Design with 12V Air Pump in Cirkit DesignerIntroduction

The DEWIN 12V Air Pump (Part ID: Pump) is a compact and efficient device designed to compress air and inflate various objects such as tires, balloons, air mattresses, and other inflatable items. Powered by a 12V DC power supply, this air pump is ideal for portable and automotive applications, offering convenience and reliability in a wide range of scenarios.

Explore Projects Built with 12V Air Pump

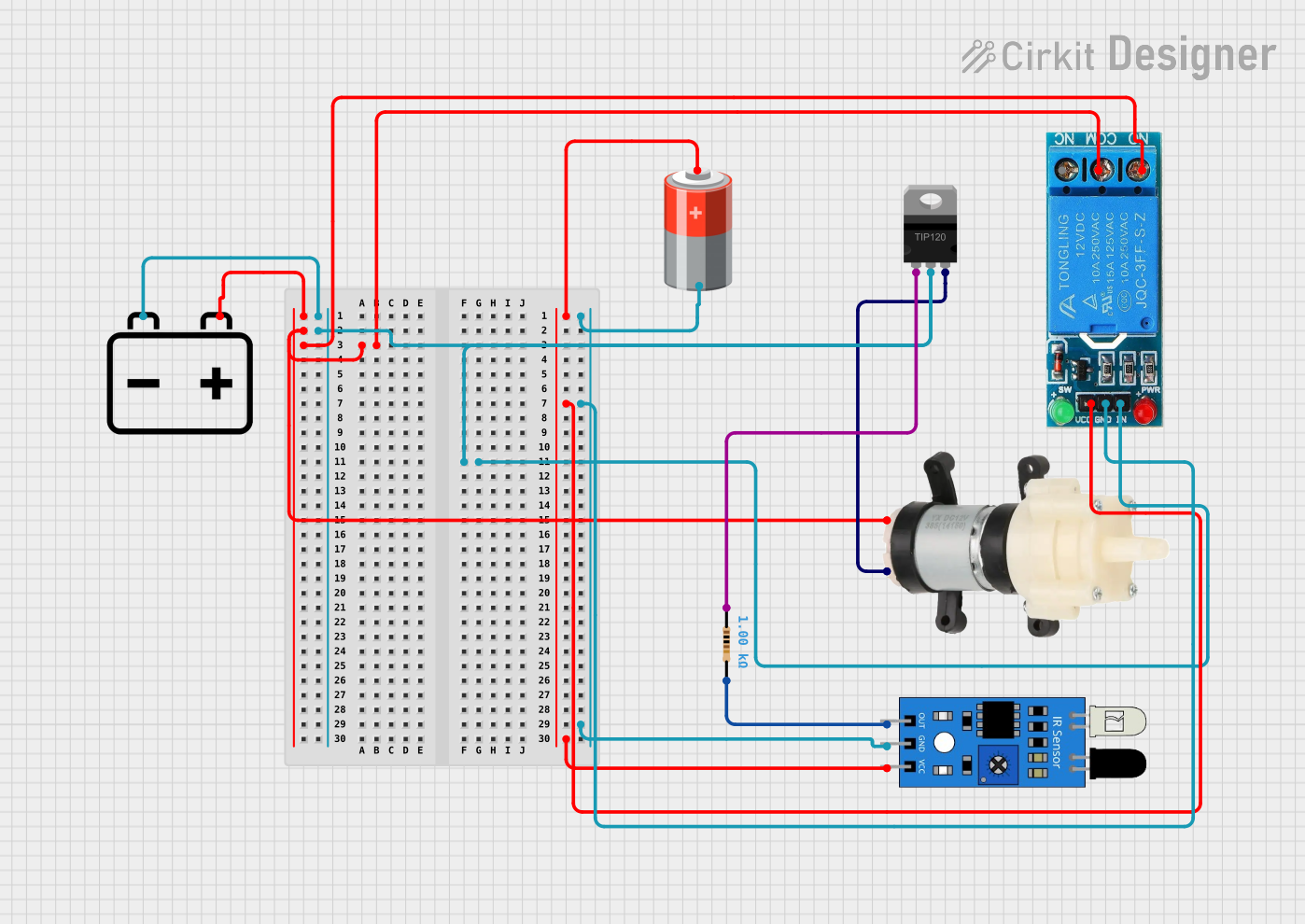

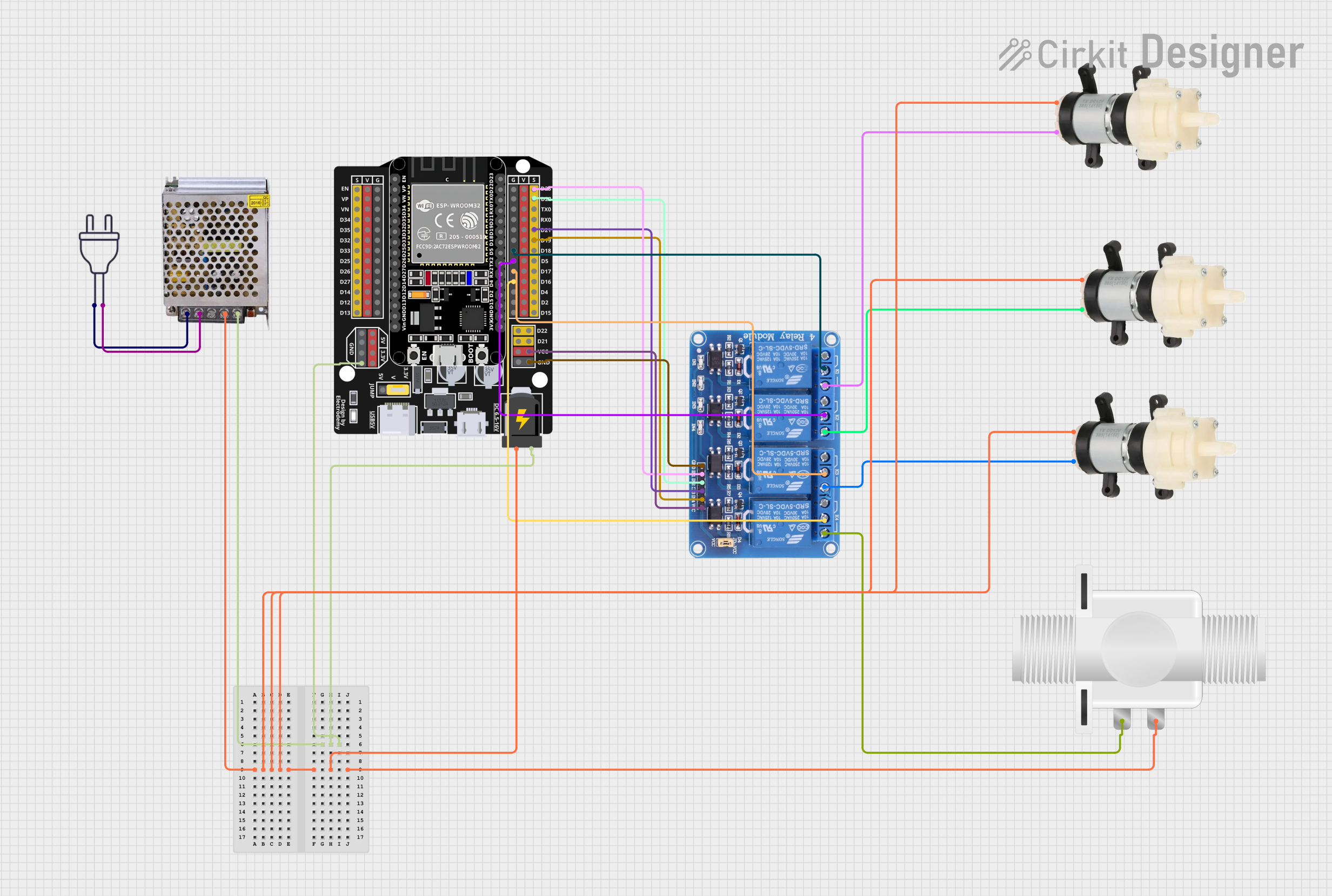

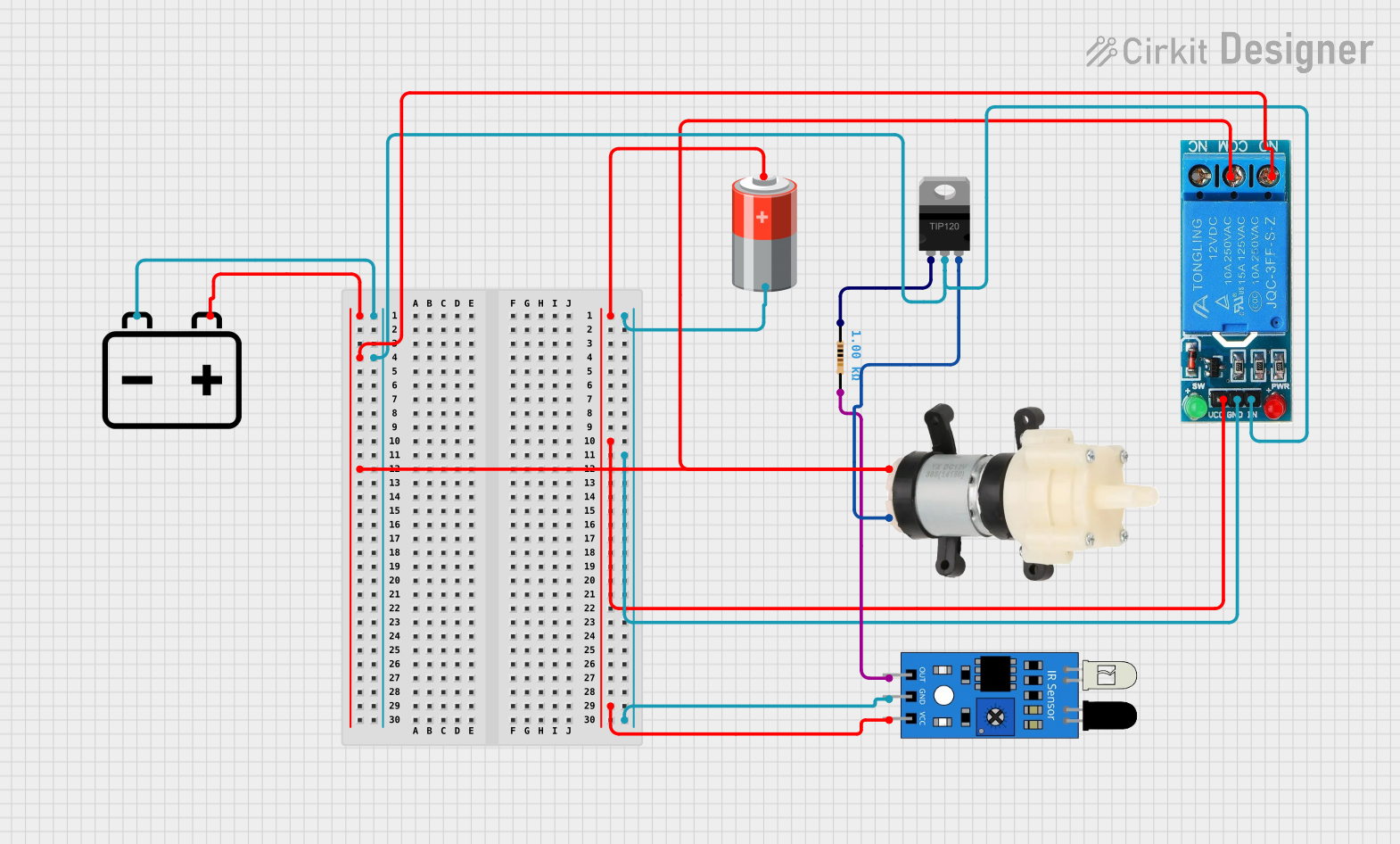

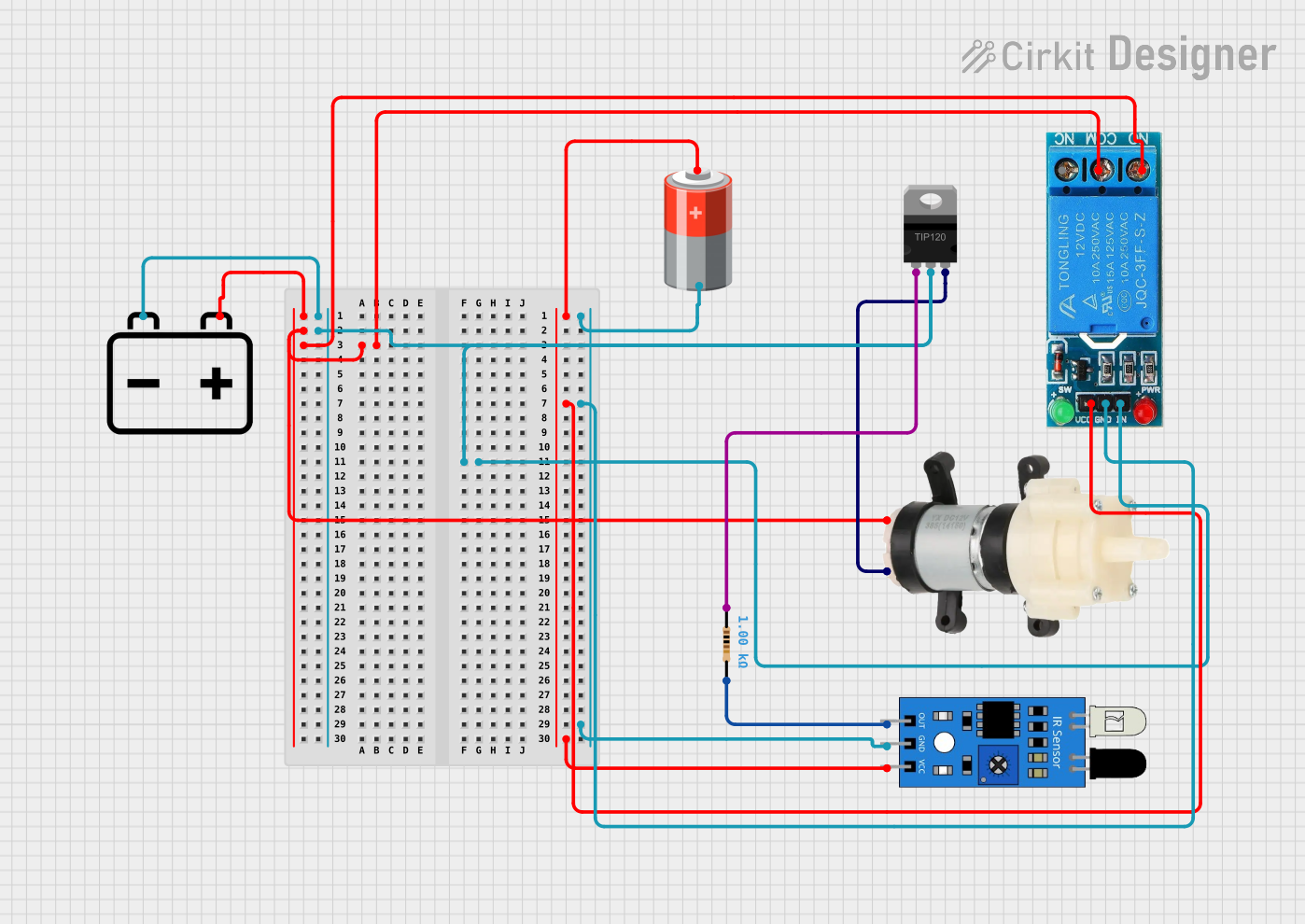

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with 12V Air Pump

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications and Use Cases

- Inflating car, bike, or motorcycle tires

- Filling air mattresses, inflatable pools, or camping gear

- Inflating sports equipment such as basketballs or soccer balls

- General-purpose air compression tasks in DIY projects

Technical Specifications

The following table outlines the key technical details of the DEWIN 12V Air Pump:

| Parameter | Specification |

|---|---|

| Operating Voltage | 12V DC |

| Current Consumption | 3A (typical) |

| Maximum Pressure | 120 PSI |

| Air Flow Rate | 25 liters per minute (L/min) |

| Dimensions | 150mm x 80mm x 60mm |

| Weight | 0.8 kg |

| Noise Level | ≤ 65 dB |

| Operating Temperature | -10°C to 60°C |

| Connector Type | DC barrel jack or alligator clips |

Pin Configuration and Descriptions

The DEWIN 12V Air Pump has a simple two-wire connection for power input:

| Pin/Connection | Description |

|---|---|

| Red Wire (+) | Positive terminal (12V DC) |

| Black Wire (-) | Negative terminal (Ground) |

Usage Instructions

How to Use the 12V Air Pump in a Circuit

- Power Supply: Connect the red wire to the positive terminal of a 12V DC power source and the black wire to the ground terminal. Ensure the power supply can provide at least 3A of current.

- Switch Control: Optionally, include a switch in series with the red wire to control the pump's operation.

- Load Connection: Attach the air pump's nozzle securely to the object you wish to inflate.

- Operation: Turn on the power supply or switch to activate the pump. Monitor the inflation process to avoid over-pressurizing the object.

Important Considerations and Best Practices

- Power Source: Use a stable 12V DC power supply capable of delivering at least 3A to ensure proper operation.

- Heat Management: Avoid running the pump continuously for more than 10 minutes to prevent overheating. Allow the pump to cool down between uses.

- Pressure Monitoring: Use a pressure gauge to monitor the inflation process and avoid exceeding the maximum pressure rating of the object being inflated.

- Polarity Check: Ensure correct polarity when connecting the wires to prevent damage to the pump.

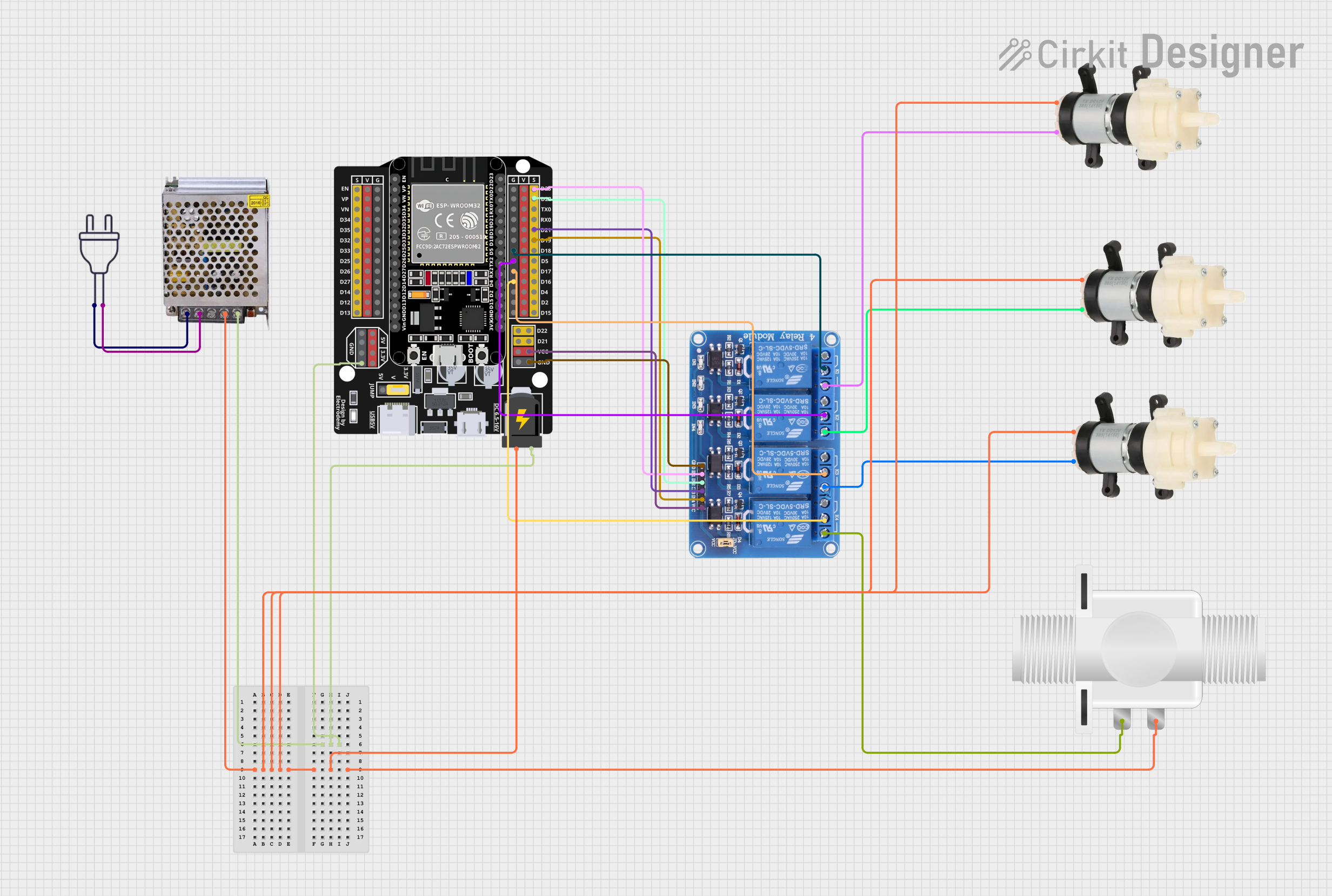

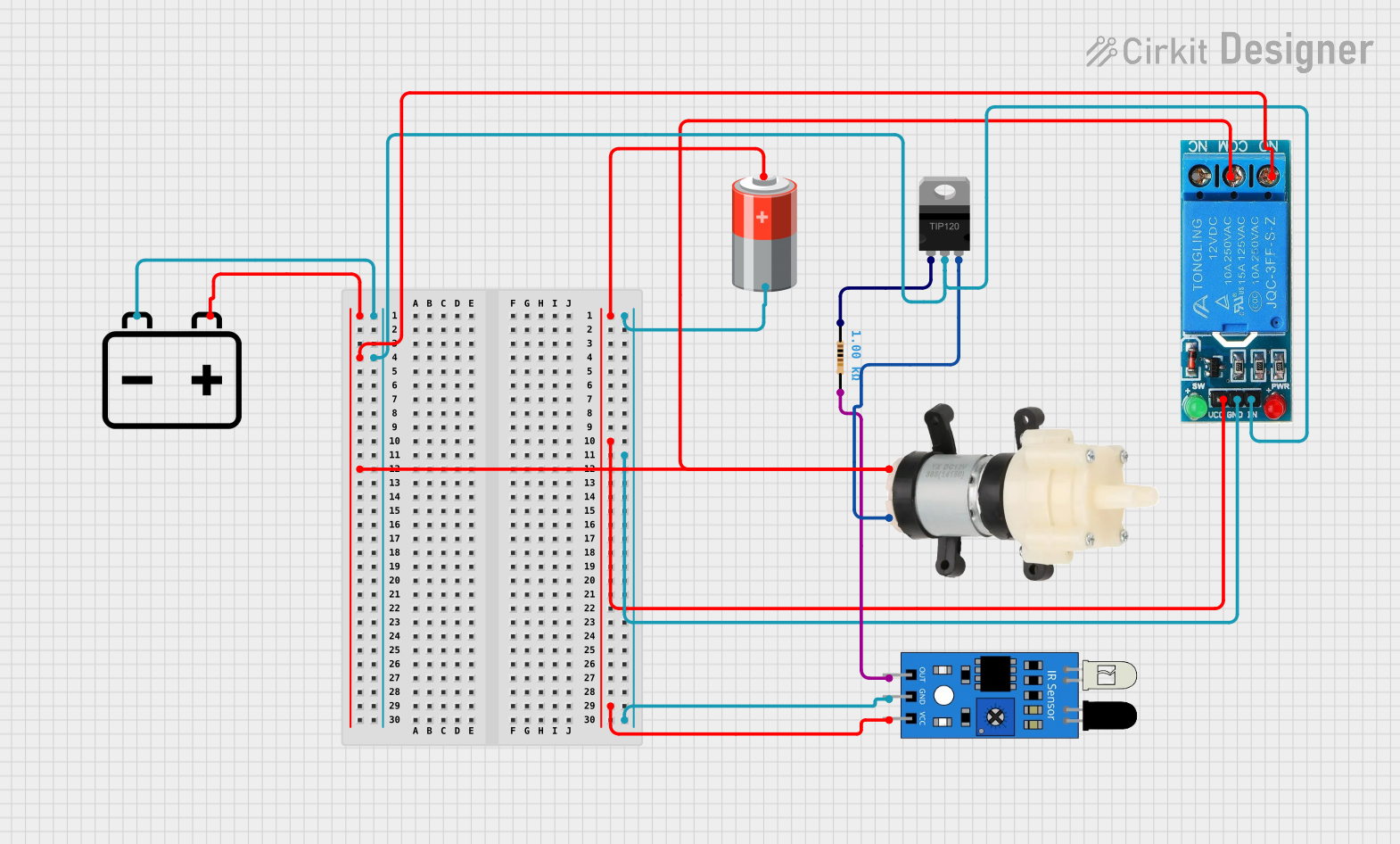

Example: Controlling the Air Pump with an Arduino UNO

The DEWIN 12V Air Pump can be controlled using an Arduino UNO and a relay module. Below is an example circuit and code:

Circuit Diagram

- Connect the red wire of the pump to the NO (Normally Open) terminal of the relay.

- Connect the COM (Common) terminal of the relay to the 12V DC power supply.

- Connect the black wire of the pump to the ground terminal of the power supply.

- Connect the relay module's control pin to Arduino pin 7.

Arduino Code

// This code demonstrates how to control the DEWIN 12V Air Pump using an Arduino UNO

// and a relay module. The pump will turn on for 5 seconds and then turn off.

const int relayPin = 7; // Pin connected to the relay module

void setup() {

pinMode(relayPin, OUTPUT); // Set the relay pin as an output

digitalWrite(relayPin, LOW); // Ensure the relay is off at startup

}

void loop() {

digitalWrite(relayPin, HIGH); // Turn on the pump

delay(5000); // Keep the pump on for 5 seconds

digitalWrite(relayPin, LOW); // Turn off the pump

delay(10000); // Wait for 10 seconds before repeating

}

Troubleshooting and FAQs

Common Issues and Solutions

Pump Does Not Start

- Cause: Insufficient power supply or incorrect wiring.

- Solution: Verify that the power supply provides 12V DC and at least 3A. Check the wiring for proper connections and polarity.

Pump Overheats

- Cause: Prolonged operation without cooling.

- Solution: Limit the pump's runtime to 10 minutes and allow it to cool before restarting.

Low Air Pressure

- Cause: Blocked or loose nozzle connection.

- Solution: Ensure the nozzle is securely attached and free of obstructions.

Excessive Noise

- Cause: Loose mounting or worn components.

- Solution: Secure the pump to a stable surface and inspect for wear or damage.

FAQs

Q: Can I use the pump with a car battery?

A: Yes, the pump can be powered directly from a 12V car battery using alligator clips.Q: Is the pump waterproof?

A: No, the pump is not waterproof. Avoid exposing it to water or moisture.Q: Can the pump be used for vacuum applications?

A: No, this pump is designed for air compression and inflation only.Q: What is the maximum runtime for the pump?

A: The pump should not be operated continuously for more than 10 minutes to prevent overheating.