How to Use NEMA 23 : Examples, Pinouts, and Specs

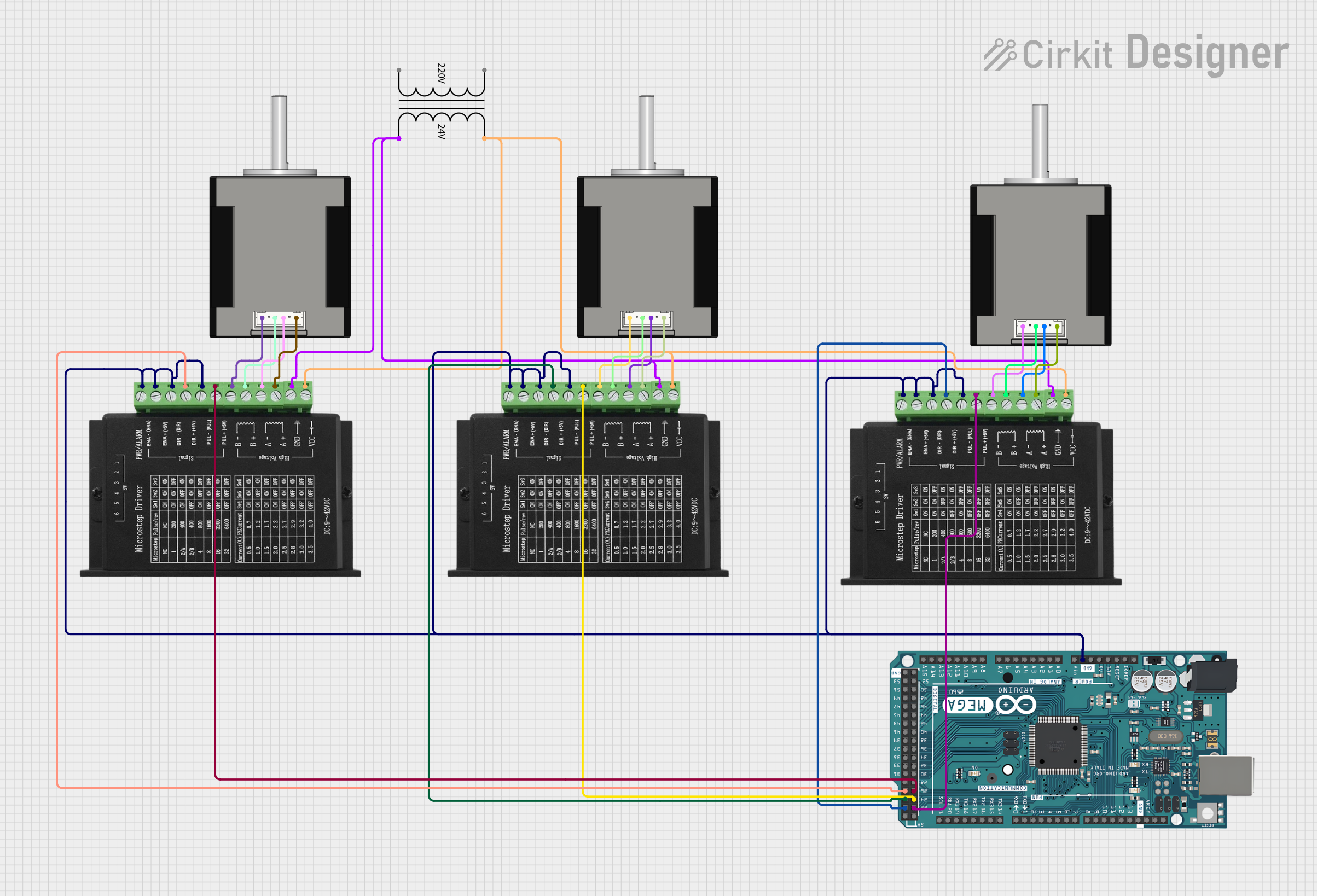

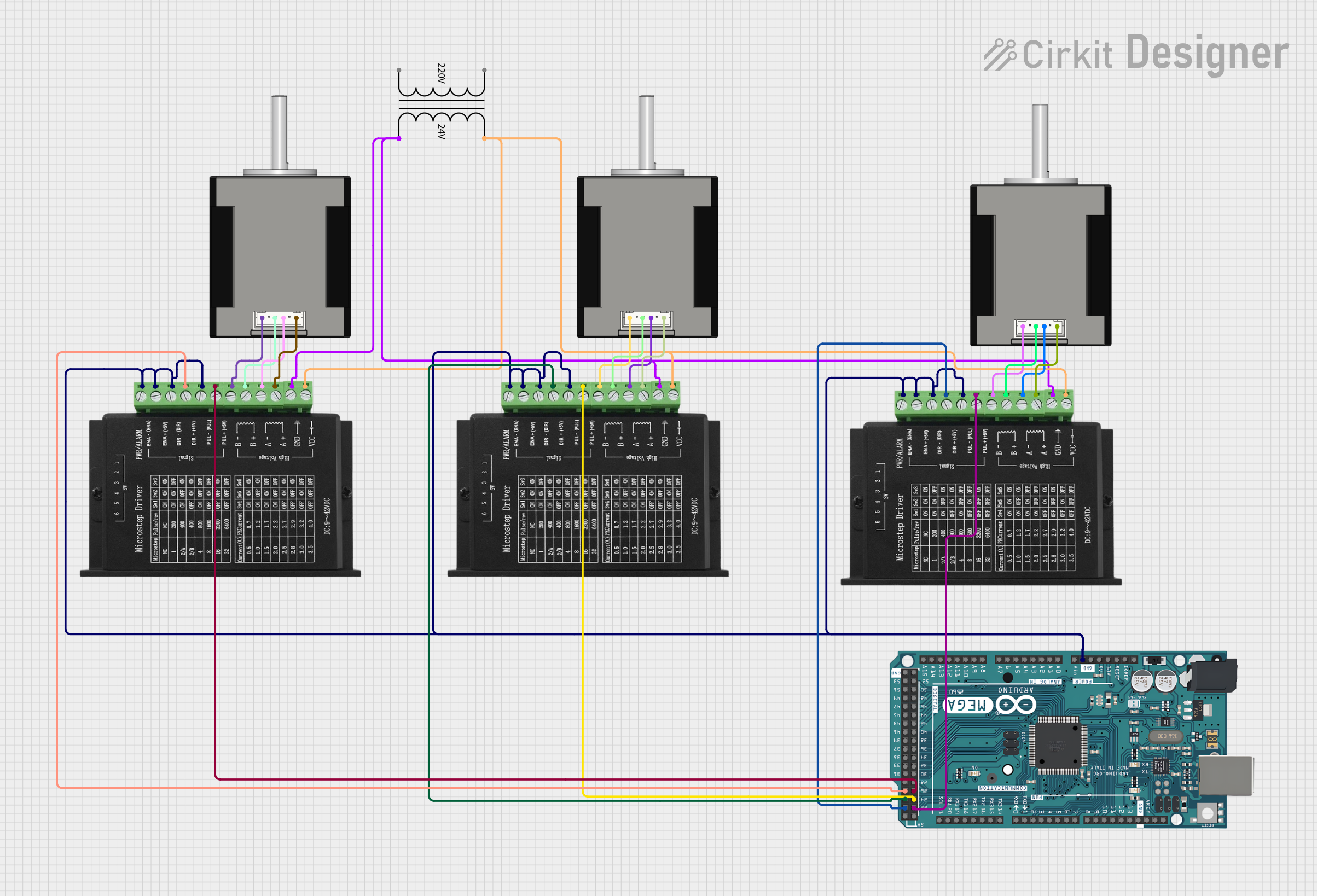

Design with NEMA 23 in Cirkit Designer

Design with NEMA 23 in Cirkit DesignerIntroduction

The NEMA 23 stepper motor is a widely used actuator that converts electrical pulses into discrete mechanical movements. The motor's name, NEMA 23, refers to its frame size, which is 2.3 inches (approximately 58.4 mm) square on the face. This type of motor is commonly employed in CNC machines, 3D printers, robotics, and other precision motion control applications due to its balance of torque, speed, and size.

Explore Projects Built with NEMA 23

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with NEMA 23

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerTechnical Specifications

General Characteristics

- Frame Size: 2.3 inches (58.4 mm)

- Step Angle: Typically 1.8 degrees (200 steps per revolution)

- Rated Voltage: Varies by model

- Rated Current: Varies by model

- Holding Torque: Varies by model

- Shaft Diameter: Typically 1/4 inch (6.35 mm)

Pin Configuration and Descriptions

| Pin Number | Description | Notes |

|---|---|---|

| 1 | Coil A+ | Connect to motor driver A+ |

| 2 | Coil A- | Connect to motor driver A- |

| 3 | Coil B+ | Connect to motor driver B+ |

| 4 | Coil B- | Connect to motor driver B- |

| 5 | (Optional) Encoder A | Only on models with encoders |

| 6 | (Optional) Encoder B | Only on models with encoders |

| 7 | (Optional) Encoder Index | Only on models with encoders |

| 8 | (Optional) Encoder GND | Only on models with encoders |

Note: The pin configuration may vary slightly depending on the manufacturer. Always consult the datasheet for your specific motor model.

Usage Instructions

Connecting to a Circuit

- Motor Driver: Use a suitable stepper motor driver that can handle the motor's rated current and voltage.

- Power Supply: Ensure the power supply matches the requirements of the motor and driver.

- Microcontroller: Connect the driver's control inputs to a microcontroller, such as an Arduino UNO, for pulse generation.

Best Practices

- Current Limiting: Adjust the current limit on the motor driver to match the motor's rated current to prevent overheating.

- Microstepping: Use microstepping for smoother motion and higher resolution.

- Heat Management: Employ heat sinks or cooling systems if the motor operates at high currents for extended periods.

Example Arduino Code

#include <Stepper.h>

// Change these values based on your motor's specifications

const int stepsPerRevolution = 200; // typically 200 steps for a 1.8 degree step angle

// Wiring:

// Connect the motor's four wires to the driver, and then connect the driver to the following pins:

// Arduino pins 8, 9, 10, 11 are connected to motor driver inputs

Stepper myStepper(stepsPerRevolution, 8, 10, 9, 11);

void setup() {

myStepper.setSpeed(60); // Set the motor speed to 60 RPM

}

void loop() {

myStepper.step(stepsPerRevolution); // Move one revolution in one direction

delay(500);

myStepper.step(-stepsPerRevolution); // Move one revolution in the other direction

delay(500);

}

Note: The above code is a simple example to control a NEMA 23 stepper motor using the Arduino Stepper library. Adjust the pin numbers and parameters according to your specific setup.

Troubleshooting and FAQs

Common Issues

- Motor Does Not Rotate: Check wiring connections, ensure the power supply and driver are functioning, and verify that the control signals are being sent from the microcontroller.

- Motor Vibrates but Does Not Rotate: This may indicate a misalignment of steps or incorrect wiring. Double-check the sequence of connections and the step angle settings.

- Overheating: If the motor gets too hot, reduce the current on the driver, improve ventilation, or add a heat sink.

FAQs

Q: Can I run a NEMA 23 motor directly from an Arduino? A: No, the Arduino cannot supply enough current or voltage. Use a dedicated motor driver.

Q: What is the maximum speed of a NEMA 23 stepper motor? A: The maximum speed varies by model and setup, but it is generally around 1000 RPM.

Q: How do I determine the correct power supply for my motor? A: Check the motor's rated voltage and current, and select a power supply that can provide at least those values.

Q: Can I use a NEMA 23 motor for vertical applications? A: Yes, but ensure the motor has enough holding torque to prevent back driving when power is off.

Note: This documentation is for informational purposes only. Always consult the specific datasheet and technical resources provided by the manufacturer for your particular NEMA 23 stepper motor model.