How to Use Stepper Motor (Bipolar): Examples, Pinouts, and Specs

Design with Stepper Motor (Bipolar) in Cirkit Designer

Design with Stepper Motor (Bipolar) in Cirkit DesignerIntroduction

A bipolar stepper motor is an electromechanical component capable of precise position control. It operates on the principle of magnetism and energizes coil pairs in a sequence to rotate the motor shaft in discrete steps. With a full rotation divided into a number of equal steps, stepper motors are commonly used in applications requiring accurate positioning such as 3D printers, CNC machines, and robotics.

Explore Projects Built with Stepper Motor (Bipolar)

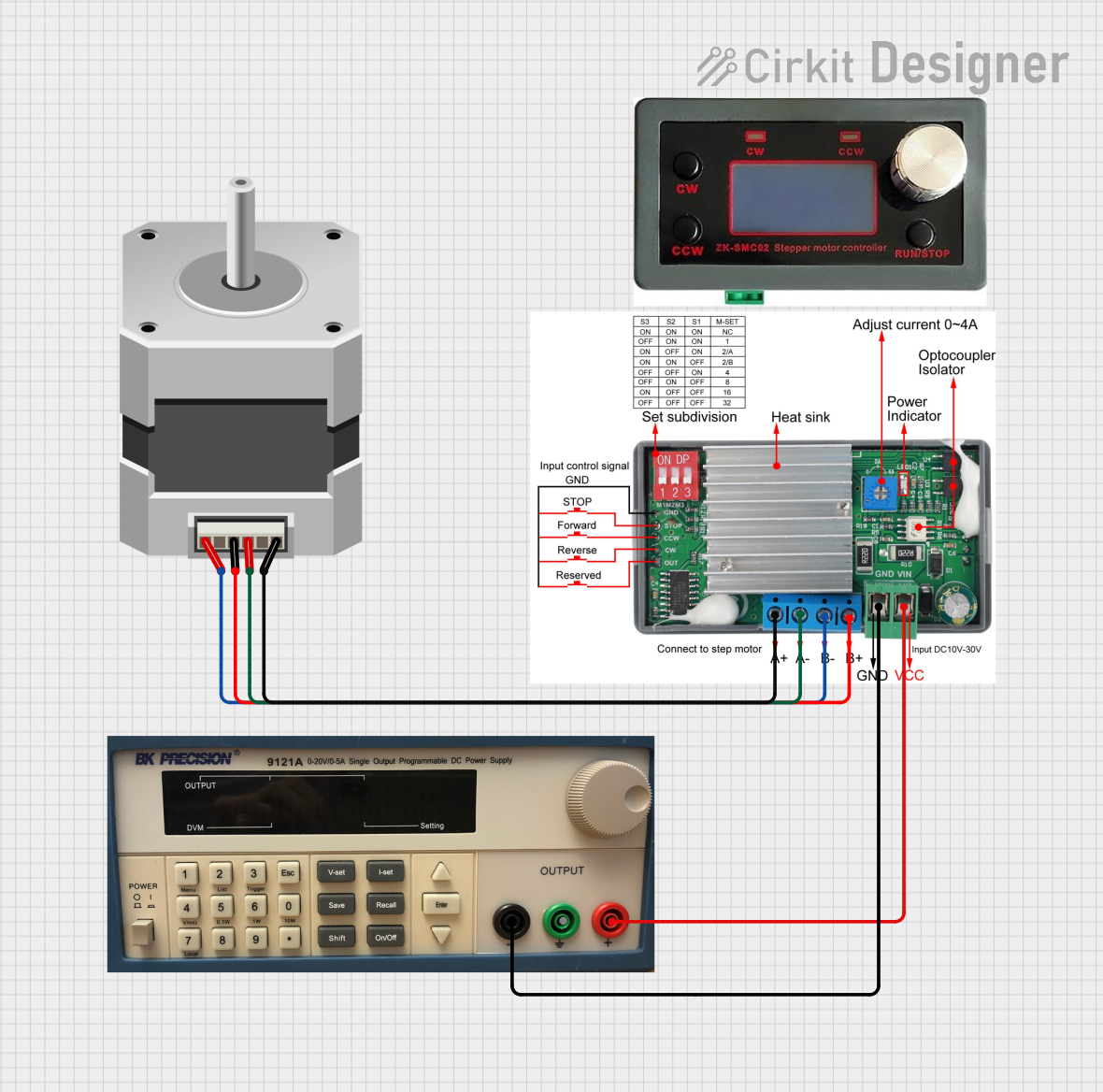

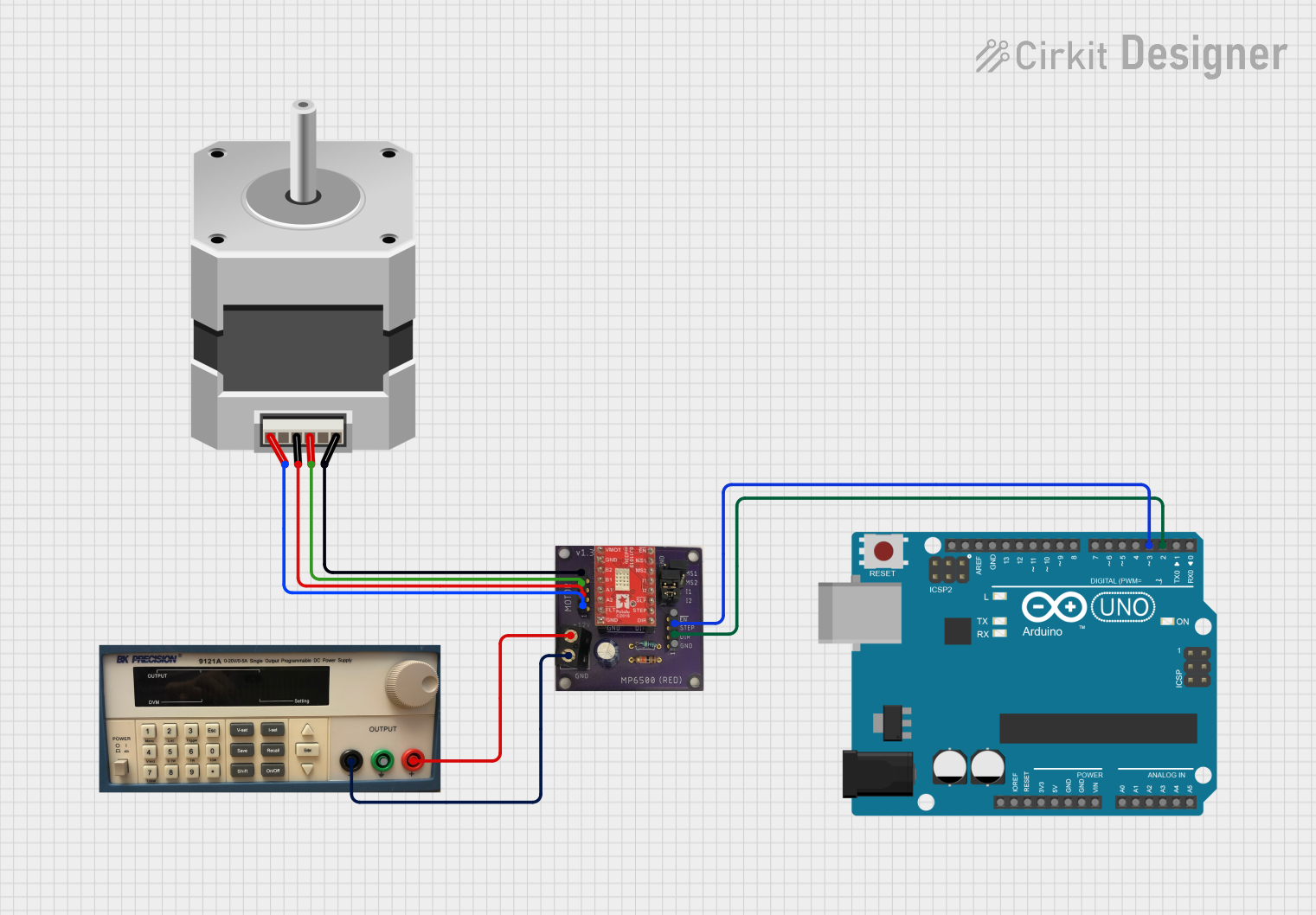

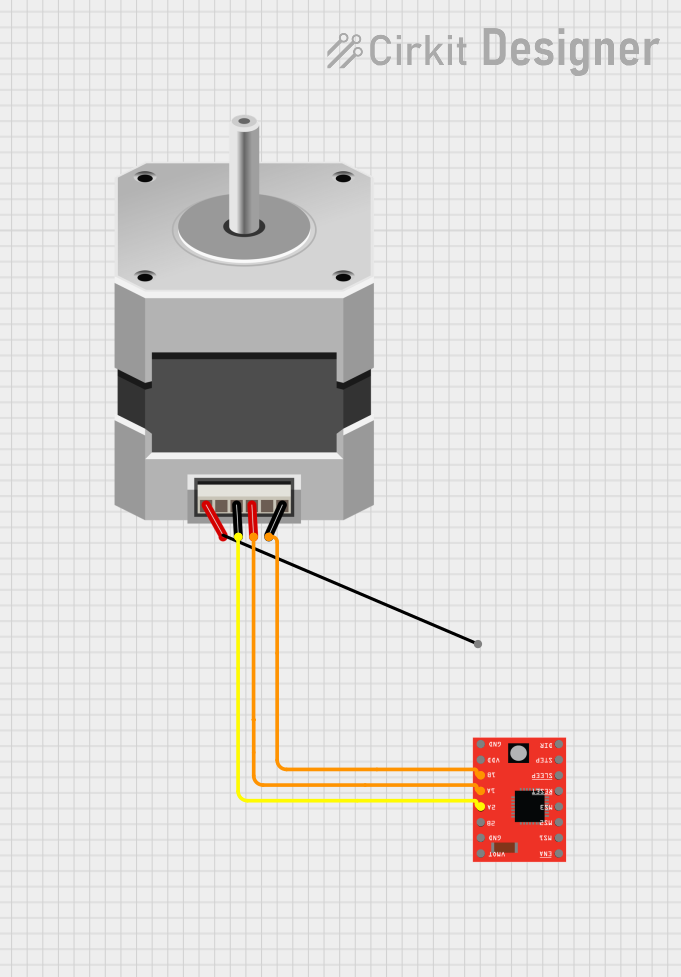

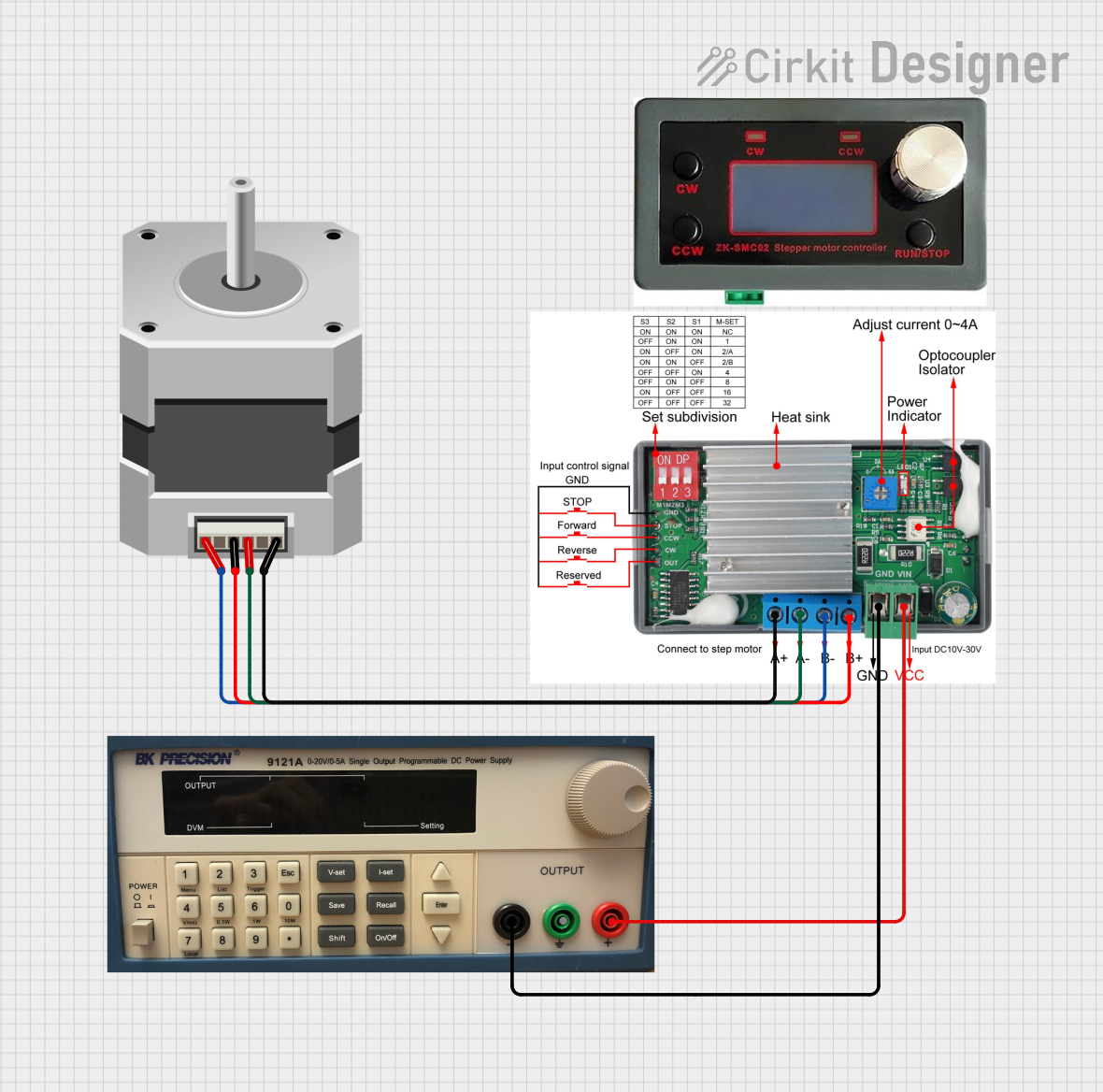

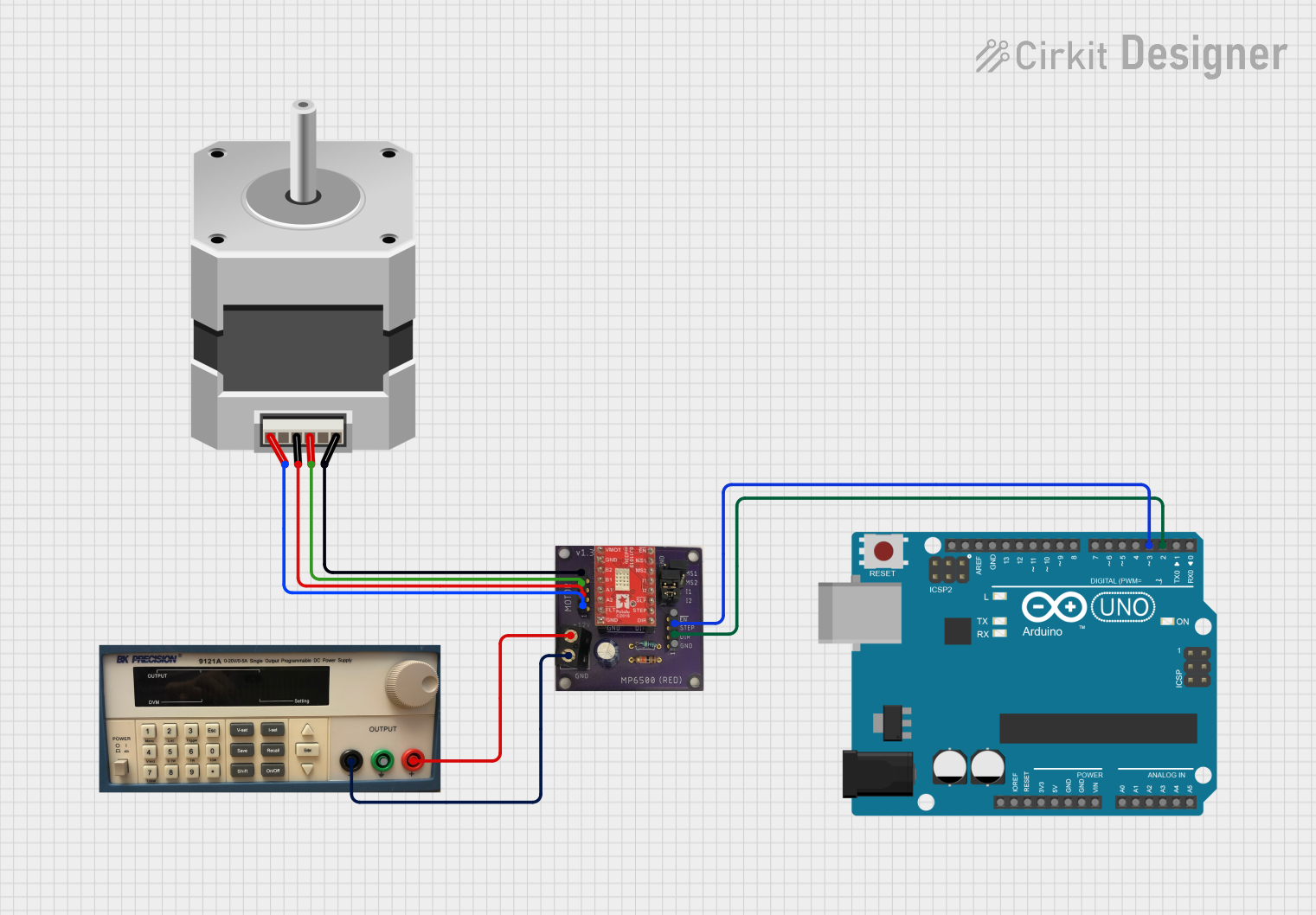

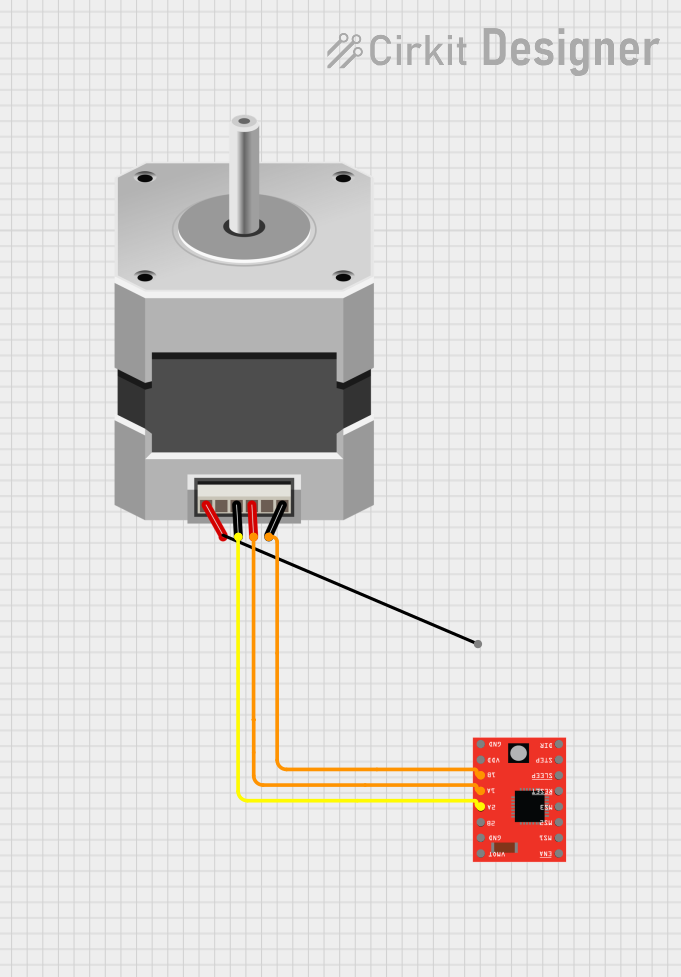

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with Stepper Motor (Bipolar)

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerTechnical Specifications

General Characteristics

- Step Angle: Typically 1.8 degrees per step (200 steps per revolution)

- Rated Voltage: Varies, often between 2V to 4V

- Rated Current: Varies, often between 500mA to 2A per phase

- Resistance per Phase: Depends on the model, often a few ohms

- Inductance per Phase: Depends on the model, often a few mH

Pin Configuration and Descriptions

| Pin Number | Description | Notes |

|---|---|---|

| 1 | Coil A1 | Connect to a motor driver output |

| 2 | Coil A2 | Connect to a motor driver output |

| 3 | Coil B1 | Connect to a motor driver output |

| 4 | Coil B2 | Connect to a motor driver output |

Usage Instructions

Connecting to a Circuit

- Motor Driver: Use a dedicated stepper motor driver capable of handling the motor's voltage and current requirements.

- Power Supply: Ensure the power supply matches the voltage and current specifications of the stepper motor.

- Microcontroller: Connect the motor driver inputs to a microcontroller like an Arduino UNO for control signals.

Best Practices

- Current Limiting: Adjust the current limit on the motor driver to match the rated current of the motor to prevent overheating.

- Microstepping: Use microstepping if your driver supports it to achieve smoother motion and higher resolution.

- Decoupling Capacitors: Place capacitors close to the motor driver's power supply pins to filter noise and voltage spikes.

Example Code for Arduino UNO

#include <Stepper.h>

// Change these values based on your motor's specifications

const int stepsPerRevolution = 200; // typically 200 steps for a 1.8 degree stepper

const int motorPin1 = 8; // Coil A1

const int motorPin2 = 9; // Coil A2

const int motorPin3 = 10; // Coil B1

const int motorPin4 = 11; // Coil B2

// Initialize the stepper library

Stepper myStepper(stepsPerRevolution, motorPin1, motorPin3, motorPin2, motorPin4);

void setup() {

myStepper.setSpeed(60); // Set the speed to 60 RPM

}

void loop() {

myStepper.step(stepsPerRevolution); // Move one revolution in one direction

delay(500);

myStepper.step(-stepsPerRevolution); // Move one revolution in the other direction

delay(500);

}

Troubleshooting and FAQs

Common Issues

- Motor Does Not Rotate: Check wiring connections, ensure the power supply is adequate, and verify that the motor driver is functioning.

- Motor Vibrates but Does Not Rotate: This may indicate a misalignment of steps. Check the sequence of control signals from the microcontroller.

- Motor Overheats: Ensure the current limit on the motor driver matches the motor's specifications. Overheating can also occur if the motor is stalled or overloaded.

FAQs

Q: Can I run a bipolar stepper motor without a driver? A: No, a bipolar stepper motor requires a driver to control the current in each coil.

Q: How do I reverse the direction of the motor? A: To reverse the direction, reverse the sequence of control signals or use the stepper library's step function with a negative number of steps.

Q: What is the difference between a bipolar and a unipolar stepper motor? A: A bipolar stepper motor has two coils and requires a change in the direction of current flow to change the magnetic field, while a unipolar stepper motor has an additional center tap on each coil and does not require current reversal.

Remember to always refer to the specific datasheet of your stepper motor model for precise specifications and wiring instructions.