How to Use sw1801p: Examples, Pinouts, and Specs

Design with sw1801p in Cirkit Designer

Design with sw1801p in Cirkit DesignerIntroduction

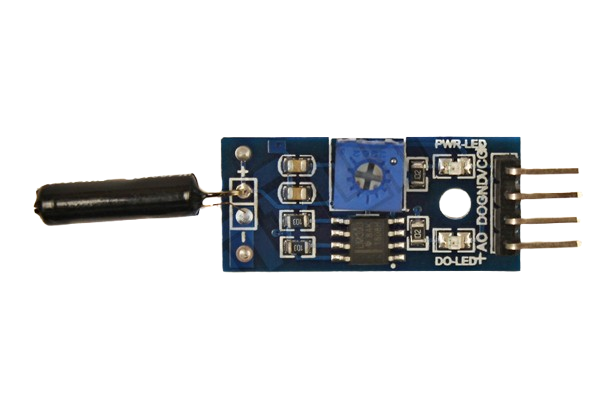

The SW1801P is a surface-mount SPDT (Single Pole Double Throw) switch designed for low-power applications. Its compact design makes it ideal for use in space-constrained environments. This versatile switch is commonly employed in signal routing, control circuits, and other applications requiring reliable switching between two outputs.

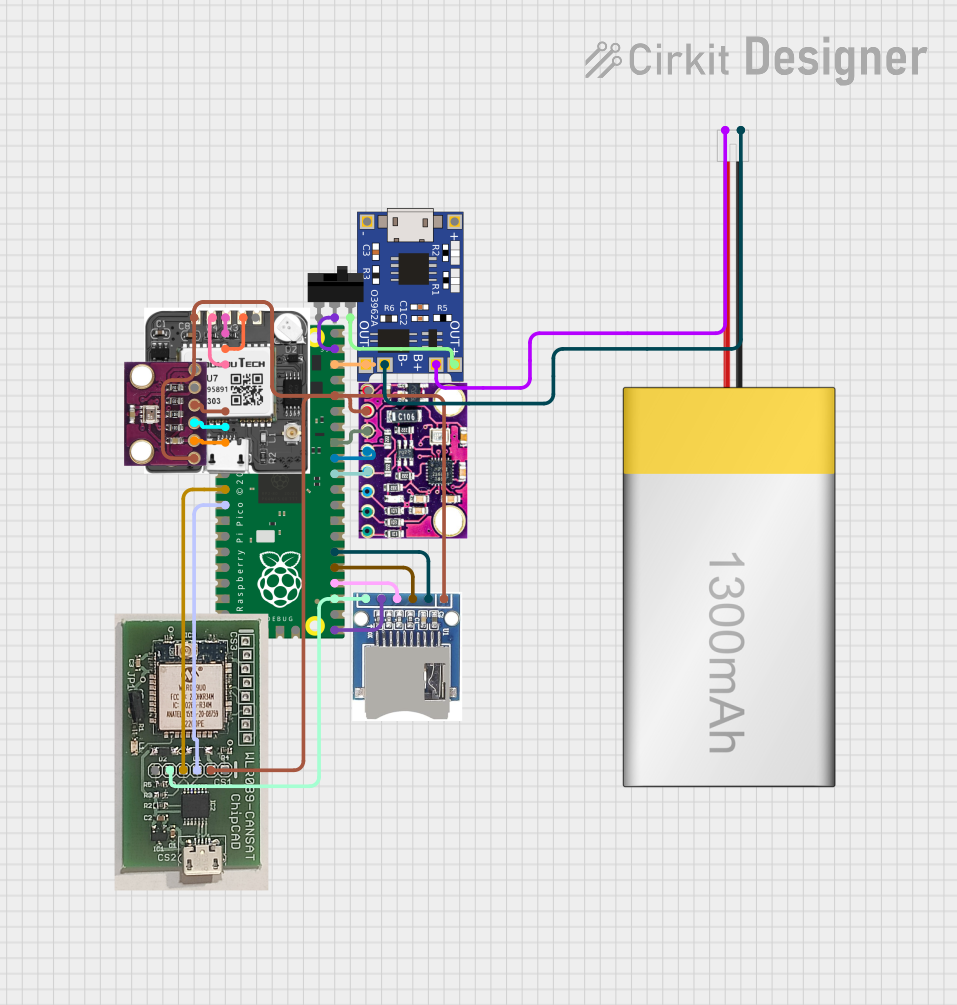

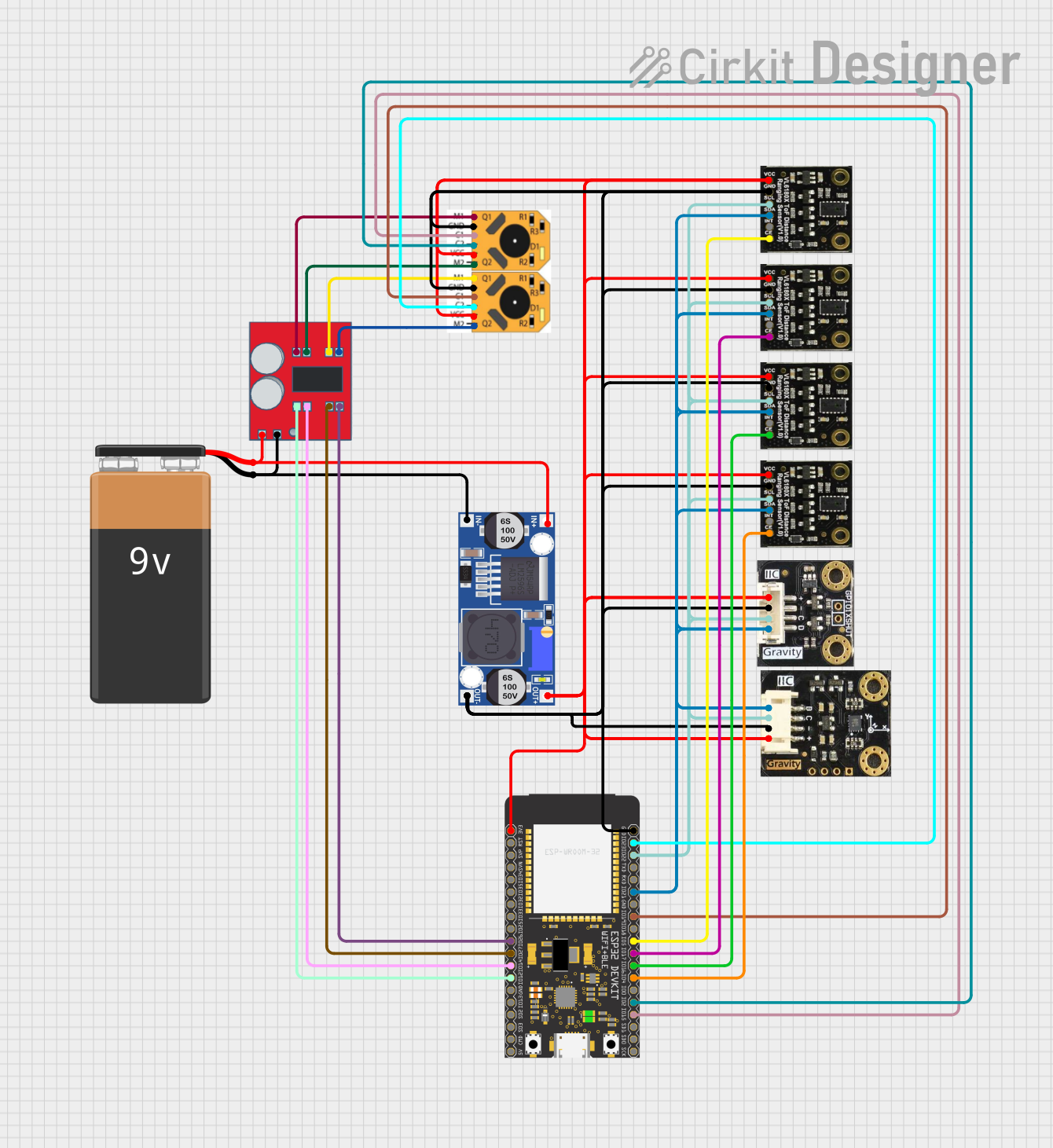

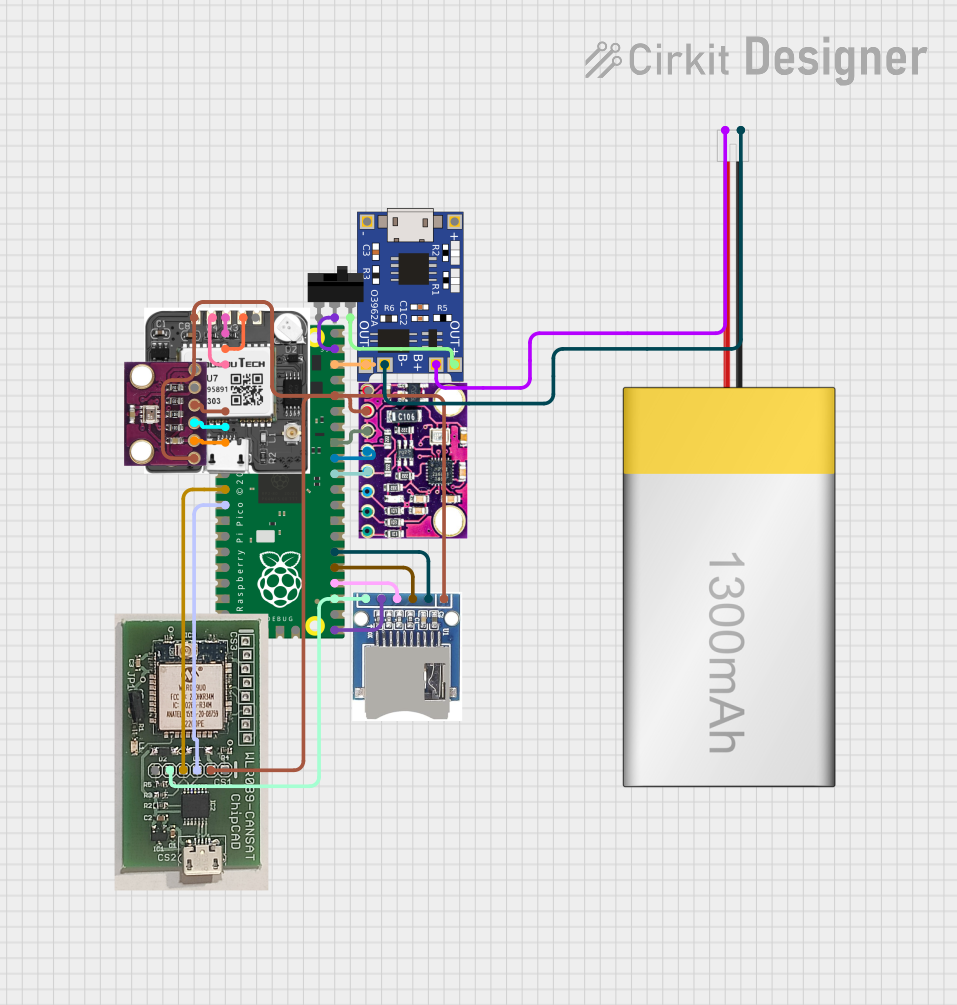

Explore Projects Built with sw1801p

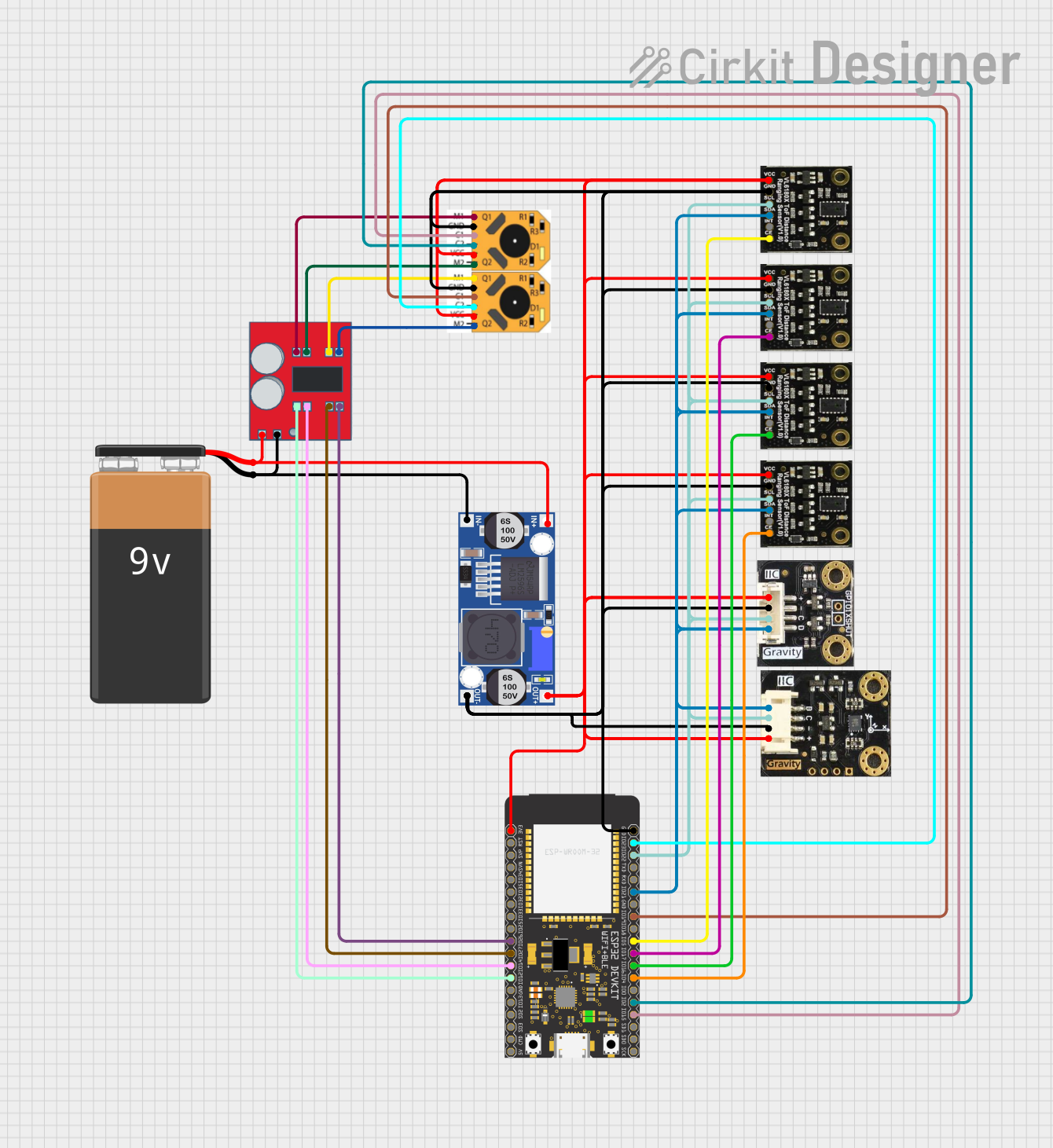

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with sw1801p

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications and Use Cases

- Signal routing in communication devices

- Control circuits in embedded systems

- Audio and video signal switching

- Low-power switching in portable electronics

- Test and measurement equipment

Technical Specifications

The SW1801P is designed to operate efficiently in low-power environments. Below are its key technical details:

Key Specifications

| Parameter | Value |

|---|---|

| Switch Type | SPDT (Single Pole Double Throw) |

| Operating Voltage | 1.8V to 5.5V |

| Maximum Current Rating | 100mA |

| Contact Resistance | ≤ 100 mΩ |

| Insulation Resistance | ≥ 100 MΩ |

| Operating Temperature | -40°C to +85°C |

| Package Type | Surface Mount (SMD) |

Pin Configuration and Descriptions

The SW1801P has three pins, as described in the table below:

| Pin Number | Name | Description |

|---|---|---|

| 1 | Common (C) | The common terminal connected to the input. |

| 2 | Output 1 | The first output terminal. |

| 3 | Output 2 | The second output terminal. |

Usage Instructions

The SW1801P is straightforward to use in a circuit. Below are the steps and considerations for integrating it into your design:

How to Use the SW1801P in a Circuit

- Identify the Pins: Refer to the pin configuration table to identify the Common (C), Output 1, and Output 2 pins.

- Connect the Common Pin: Connect the Common (C) pin to the input signal or voltage source.

- Connect the Output Pins: Connect Output 1 and Output 2 to the desired output circuits or devices.

- Control the Switching: Use an external control mechanism (e.g., a microcontroller or manual switch) to toggle between Output 1 and Output 2.

Important Considerations and Best Practices

- Voltage and Current Ratings: Ensure the input voltage and current do not exceed the specified maximum ratings (5.5V and 100mA, respectively).

- PCB Design: As the SW1801P is a surface-mount device, ensure your PCB design includes appropriate SMD pads for soldering.

- Signal Integrity: For high-frequency signals, minimize trace lengths to reduce signal degradation.

- Debouncing: If the switch is used in a mechanical system, consider implementing debouncing techniques in your circuit or software to avoid false triggering.

Example: Using SW1801P with Arduino UNO

The SW1801P can be controlled using an Arduino UNO to toggle between two outputs. Below is an example circuit and code:

Circuit Description

- Connect the Common (C) pin to a signal source (e.g., 5V).

- Connect Output 1 and Output 2 to two LEDs with appropriate current-limiting resistors.

- Use a digital pin on the Arduino to control the switching mechanism.

Arduino Code

// Define the control pin for the SW1801P

const int controlPin = 7;

// Define the output pins for the LEDs

const int led1 = 8;

const int led2 = 9;

void setup() {

// Set the control pin as output

pinMode(controlPin, OUTPUT);

// Set the LED pins as outputs

pinMode(led1, OUTPUT);

pinMode(led2, OUTPUT);

// Initialize the switch to Output 1

digitalWrite(controlPin, LOW);

digitalWrite(led1, HIGH);

digitalWrite(led2, LOW);

}

void loop() {

// Toggle the switch every 2 seconds

digitalWrite(controlPin, HIGH); // Switch to Output 2

digitalWrite(led1, LOW);

digitalWrite(led2, HIGH);

delay(2000);

digitalWrite(controlPin, LOW); // Switch back to Output 1

digitalWrite(led1, HIGH);

digitalWrite(led2, LOW);

delay(2000);

}

Troubleshooting and FAQs

Common Issues and Solutions

Switch Not Functioning Properly

- Cause: Incorrect pin connections.

- Solution: Double-check the pin configuration and ensure proper connections.

Signal Degradation

- Cause: Long PCB traces or high-frequency signals.

- Solution: Minimize trace lengths and use proper grounding techniques.

Overheating

- Cause: Exceeding the maximum current or voltage ratings.

- Solution: Ensure the input voltage is within 1.8V to 5.5V and the current does not exceed 100mA.

Intermittent Switching

- Cause: Mechanical noise or lack of debouncing.

- Solution: Implement software or hardware debouncing techniques.

FAQs

Q: Can the SW1801P handle AC signals?

A: The SW1801P is primarily designed for low-power DC applications. For AC signals, ensure the voltage and current ratings are not exceeded.

Q: Is the SW1801P suitable for high-frequency signals?

A: Yes, but care must be taken to minimize trace lengths and maintain signal integrity.

Q: Can I use the SW1801P in a high-temperature environment?

A: The SW1801P operates reliably within a temperature range of -40°C to +85°C. Ensure the ambient temperature does not exceed this range.