How to Use m5 stack ultrasonic: Examples, Pinouts, and Specs

Design with m5 stack ultrasonic in Cirkit Designer

Design with m5 stack ultrasonic in Cirkit DesignerIntroduction

The M5Stack Ultrasonic is a compact sensor module designed to measure distances using ultrasonic waves. It emits high-frequency sound waves and calculates the time it takes for the echo to return, providing accurate distance measurements. This module is widely used in robotics, automation, and IoT projects for tasks such as obstacle detection, proximity sensing, and distance measurement.

Explore Projects Built with m5 stack ultrasonic

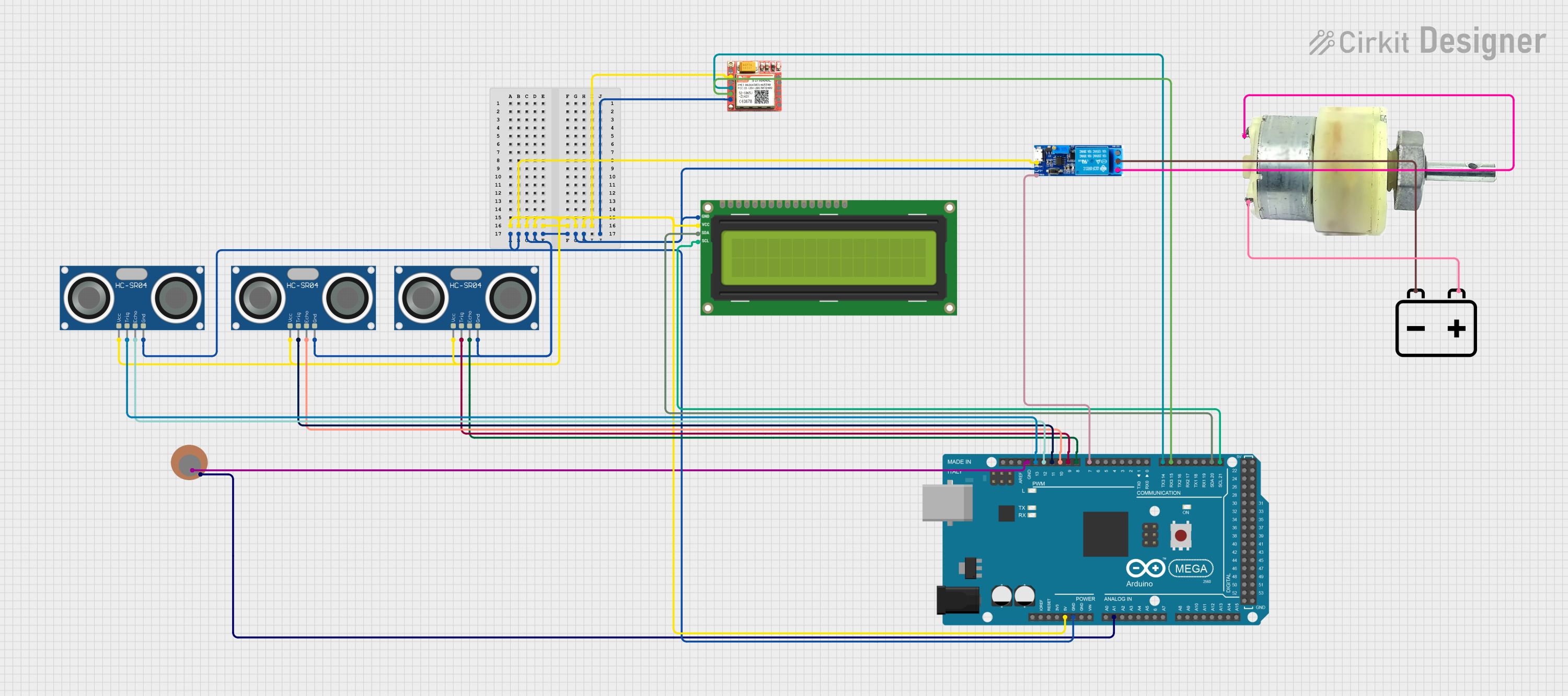

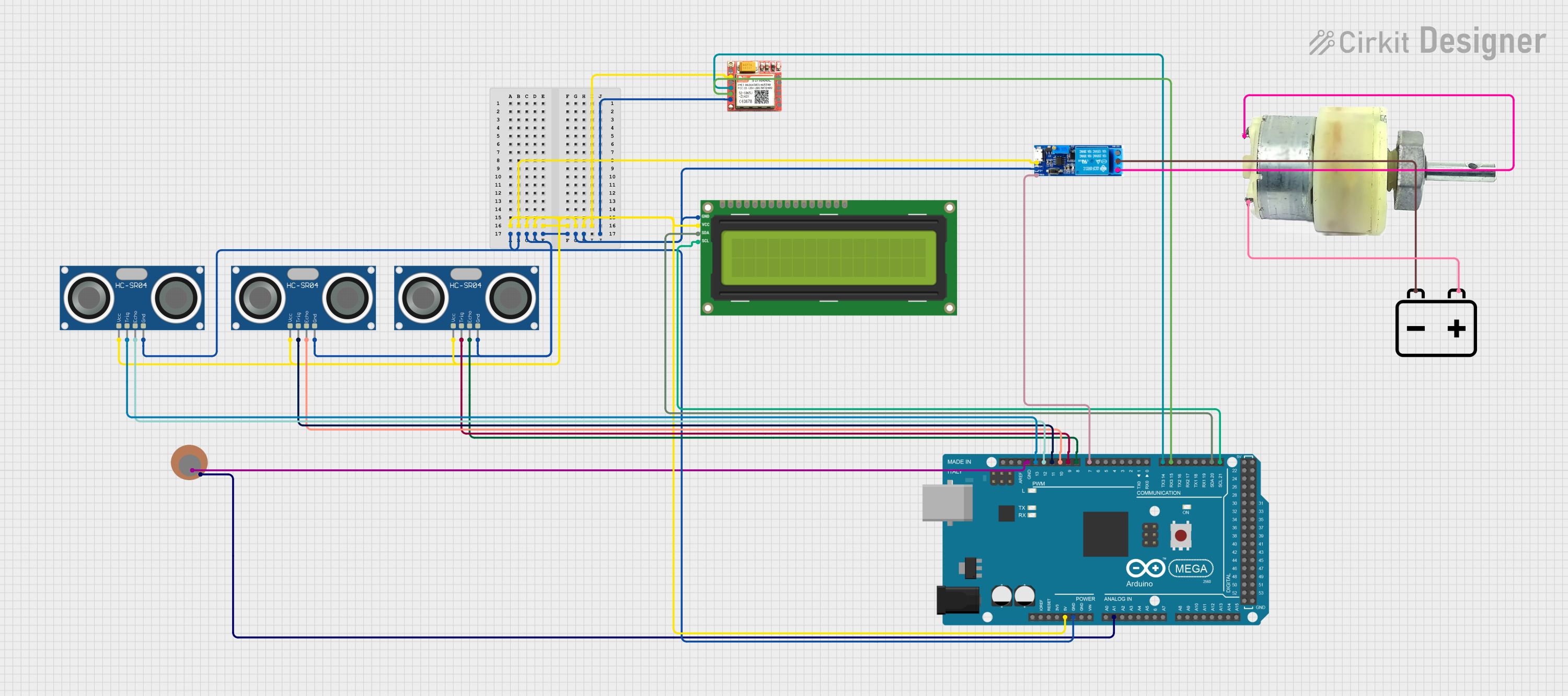

Open Project in Cirkit Designer

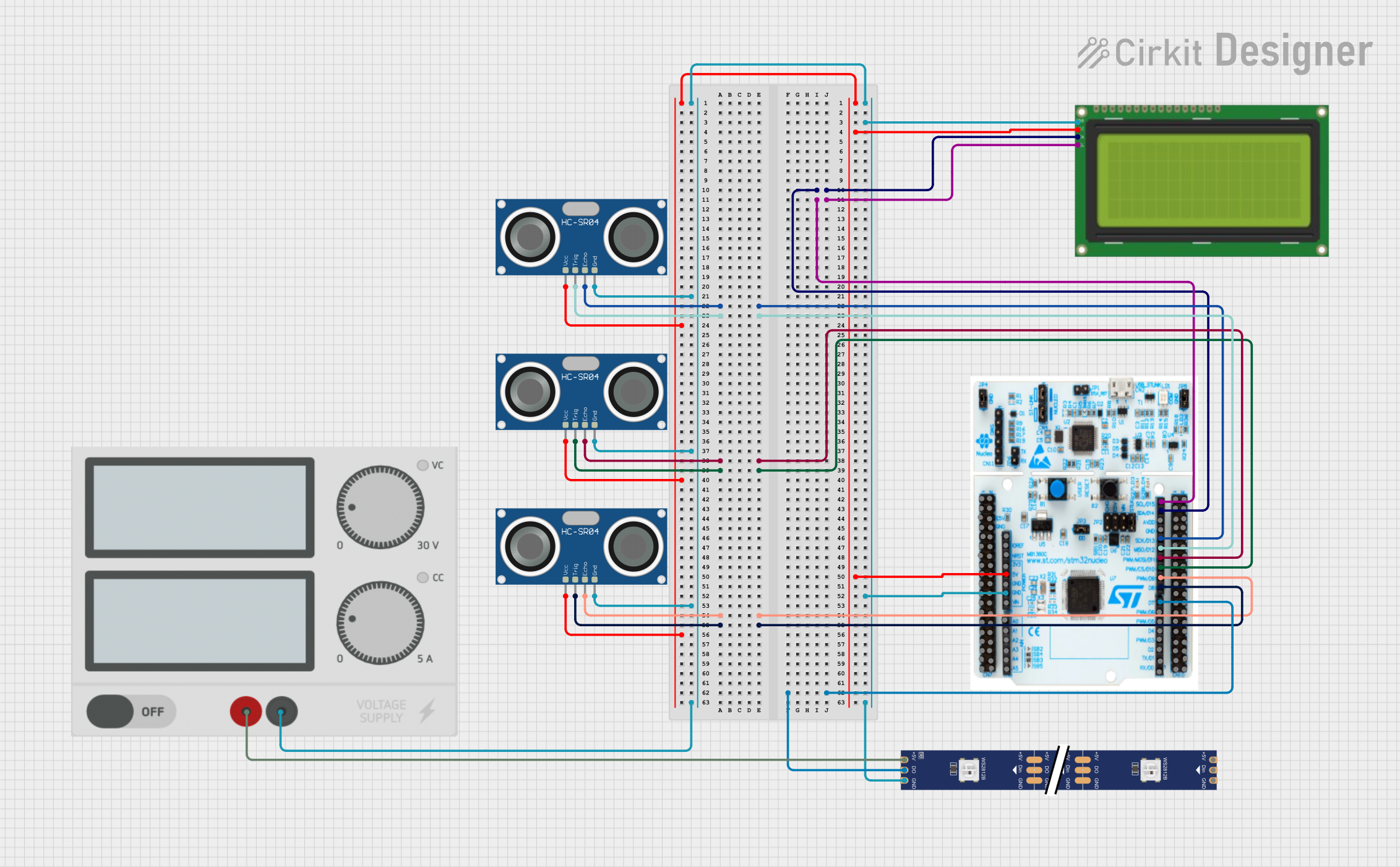

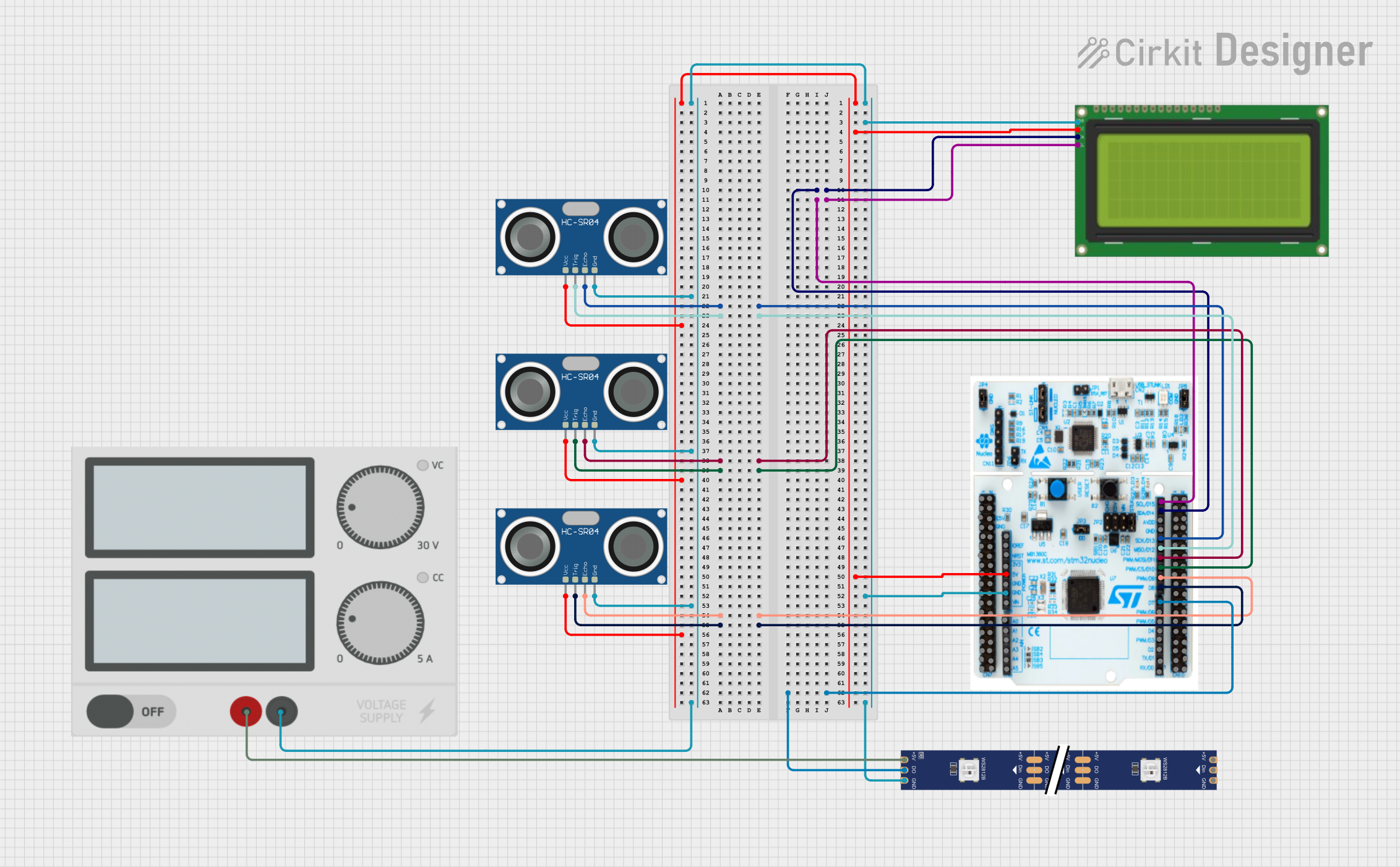

Open Project in Cirkit Designer

Open Project in Cirkit Designer

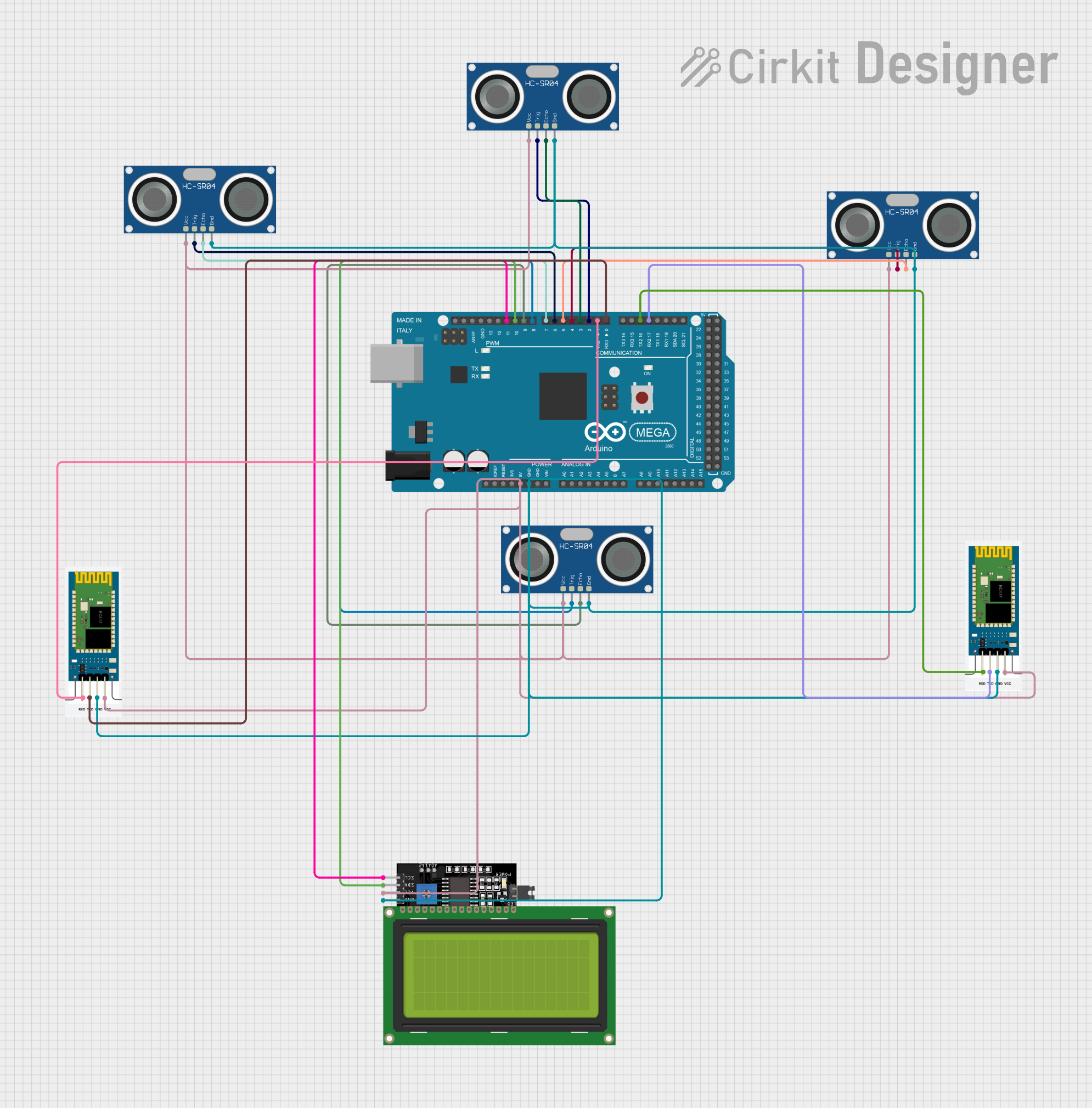

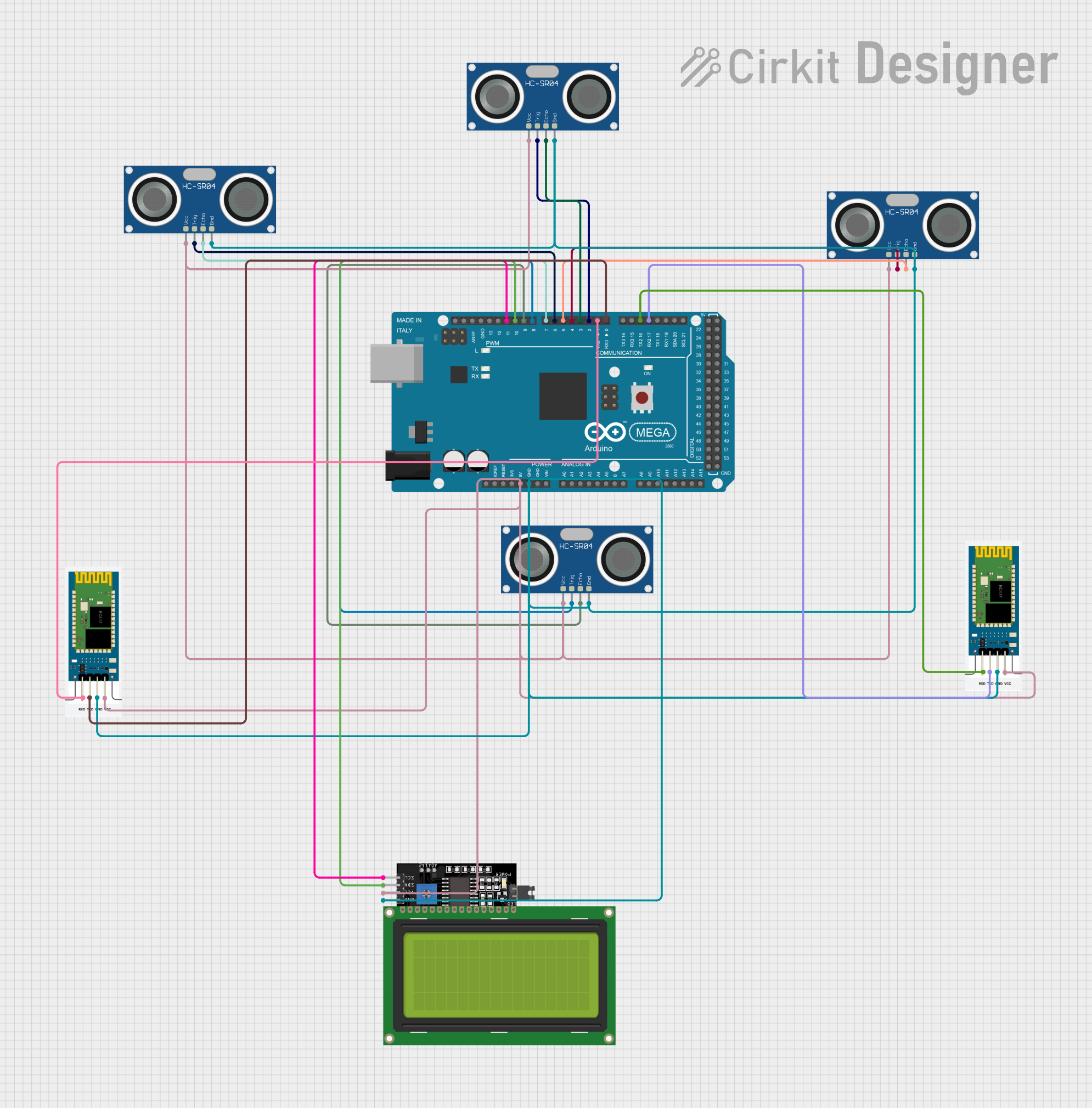

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with m5 stack ultrasonic

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications and Use Cases

- Obstacle detection in robotics

- Distance measurement in automation systems

- Proximity sensing in IoT devices

- Level monitoring in tanks or containers

- Smart parking systems

Technical Specifications

The M5Stack Ultrasonic module is designed for ease of use and reliable performance. Below are its key technical details:

Key Technical Details

- Operating Voltage: 3.3V to 5V

- Operating Current: < 15mA

- Measuring Range: 2cm to 400cm

- Accuracy: ±3mm

- Signal Type: Digital pulse

- Communication Protocol: GPIO (Trigger and Echo pins)

- Dimensions: 32mm x 24mm x 8mm

Pin Configuration and Descriptions

The M5Stack Ultrasonic module has a simple 4-pin interface. Below is the pinout:

| Pin | Name | Description |

|---|---|---|

| 1 | VCC | Power supply pin (3.3V to 5V) |

| 2 | TRIG | Trigger pin. Sends a 10µs pulse to initiate distance measurement. |

| 3 | ECHO | Echo pin. Outputs a pulse width proportional to the measured distance. |

| 4 | GND | Ground pin. Connect to the ground of the power supply. |

Usage Instructions

The M5Stack Ultrasonic module is straightforward to use in a circuit. Below are the steps and best practices for integrating it into your project.

How to Use the Component in a Circuit

Connect the Pins:

- Connect the VCC pin to a 3.3V or 5V power source.

- Connect the GND pin to the ground of your circuit.

- Connect the TRIG pin to a GPIO pin on your microcontroller (e.g., Arduino).

- Connect the ECHO pin to another GPIO pin on your microcontroller.

Trigger the Sensor:

- Send a 10µs HIGH pulse to the TRIG pin to initiate a measurement.

Read the Echo:

- Measure the duration of the HIGH pulse on the ECHO pin. This duration corresponds to the time taken for the ultrasonic wave to travel to the object and back.

Calculate the Distance:

- Use the formula:

[ \text{Distance (cm)} = \frac{\text{Pulse Duration (µs)} \times 0.034}{2} ] The factor 0.034 represents the speed of sound in cm/µs, and the division by 2 accounts for the round trip.

- Use the formula:

Important Considerations and Best Practices

- Ensure the sensor is mounted securely and aligned properly for accurate measurements.

- Avoid placing the sensor near reflective surfaces that may cause inaccurate readings.

- Use a decoupling capacitor (e.g., 10µF) across the VCC and GND pins to reduce noise.

- If using with an Arduino, ensure the GPIO pins are configured as input and output correctly.

Example Code for Arduino UNO

Below is an example code snippet to use the M5Stack Ultrasonic module with an Arduino UNO:

// Define pins for the ultrasonic sensor

const int trigPin = 9; // TRIG pin connected to digital pin 9

const int echoPin = 10; // ECHO pin connected to digital pin 10

void setup() {

// Initialize serial communication for debugging

Serial.begin(9600);

// Set TRIG pin as output and ECHO pin as input

pinMode(trigPin, OUTPUT);

pinMode(echoPin, INPUT);

}

void loop() {

// Send a 10µs HIGH pulse to the TRIG pin

digitalWrite(trigPin, LOW);

delayMicroseconds(2);

digitalWrite(trigPin, HIGH);

delayMicroseconds(10);

digitalWrite(trigPin, LOW);

// Measure the duration of the HIGH pulse on the ECHO pin

long duration = pulseIn(echoPin, HIGH);

// Calculate the distance in cm

float distance = (duration * 0.034) / 2;

// Print the distance to the Serial Monitor

Serial.print("Distance: ");

Serial.print(distance);

Serial.println(" cm");

// Wait for a short period before the next measurement

delay(500);

}

Troubleshooting and FAQs

Common Issues Users Might Face

No Output or Incorrect Readings:

- Cause: Loose or incorrect wiring.

- Solution: Double-check all connections and ensure the pins are connected as per the pinout table.

Fluctuating Distance Measurements:

- Cause: Electrical noise or interference.

- Solution: Add a decoupling capacitor across the VCC and GND pins to stabilize the power supply.

Sensor Not Responding:

- Cause: Incorrect trigger pulse or faulty sensor.

- Solution: Ensure the TRIG pin receives a 10µs HIGH pulse. Test the sensor with a different microcontroller.

Inaccurate Measurements:

- Cause: Reflective or irregular surfaces.

- Solution: Ensure the target surface is perpendicular to the sensor for accurate readings.

Solutions and Tips for Troubleshooting

- Use a multimeter to verify the voltage at the VCC pin.

- Test the sensor in a controlled environment to rule out external factors.

- If using long wires, consider using shielded cables to reduce noise.

- Update your microcontroller's firmware or libraries if compatibility issues arise.

By following this documentation, you can effectively integrate the M5Stack Ultrasonic module into your projects and troubleshoot common issues with ease.