How to Use HW-131: Examples, Pinouts, and Specs

Design with HW-131 in Cirkit Designer

Design with HW-131 in Cirkit DesignerIntroduction

The HW-131 is a high-power, high-speed switching diode that serves as a critical component in modern electronic circuits. Its primary function is to allow current to flow in one direction, known as the forward direction, while blocking current in the reverse direction. This diode is particularly known for its fast switching speeds and low forward voltage drop, making it suitable for high-frequency applications and efficient rectification processes. Common applications of the HW-131 include:

- Power supply units

- High-frequency inverters

- Signal demodulation

- Voltage clamping

- Protection circuits

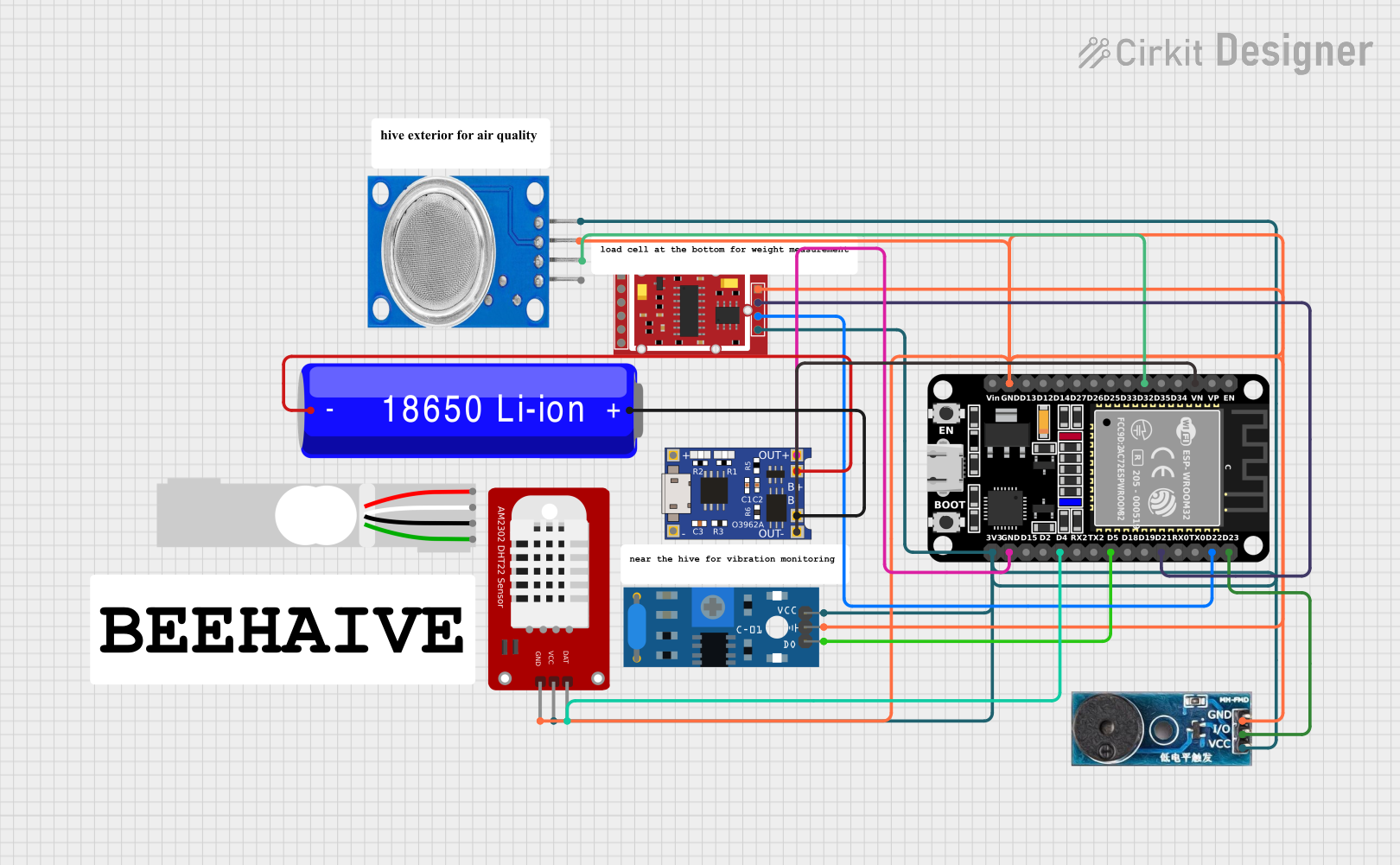

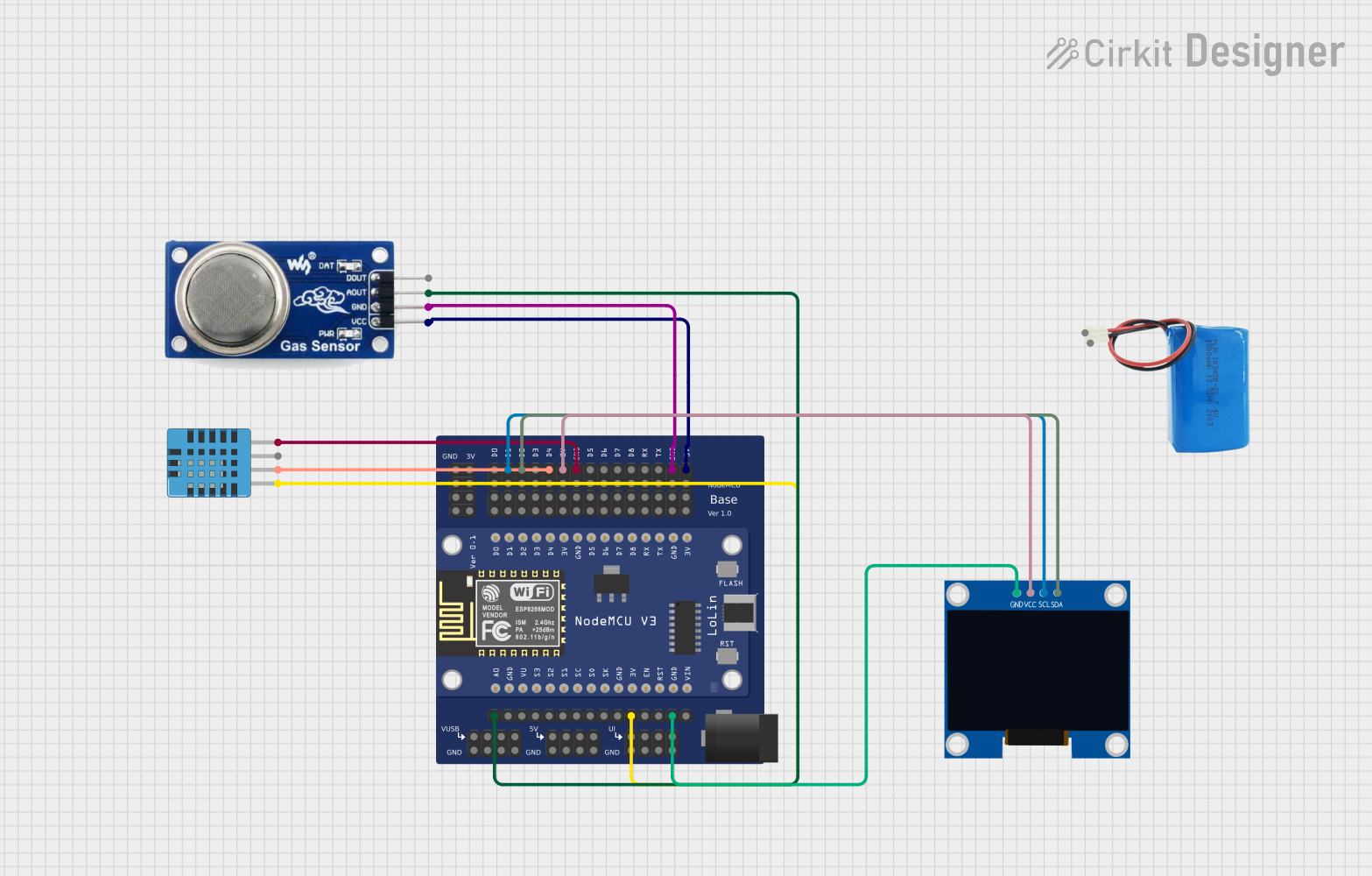

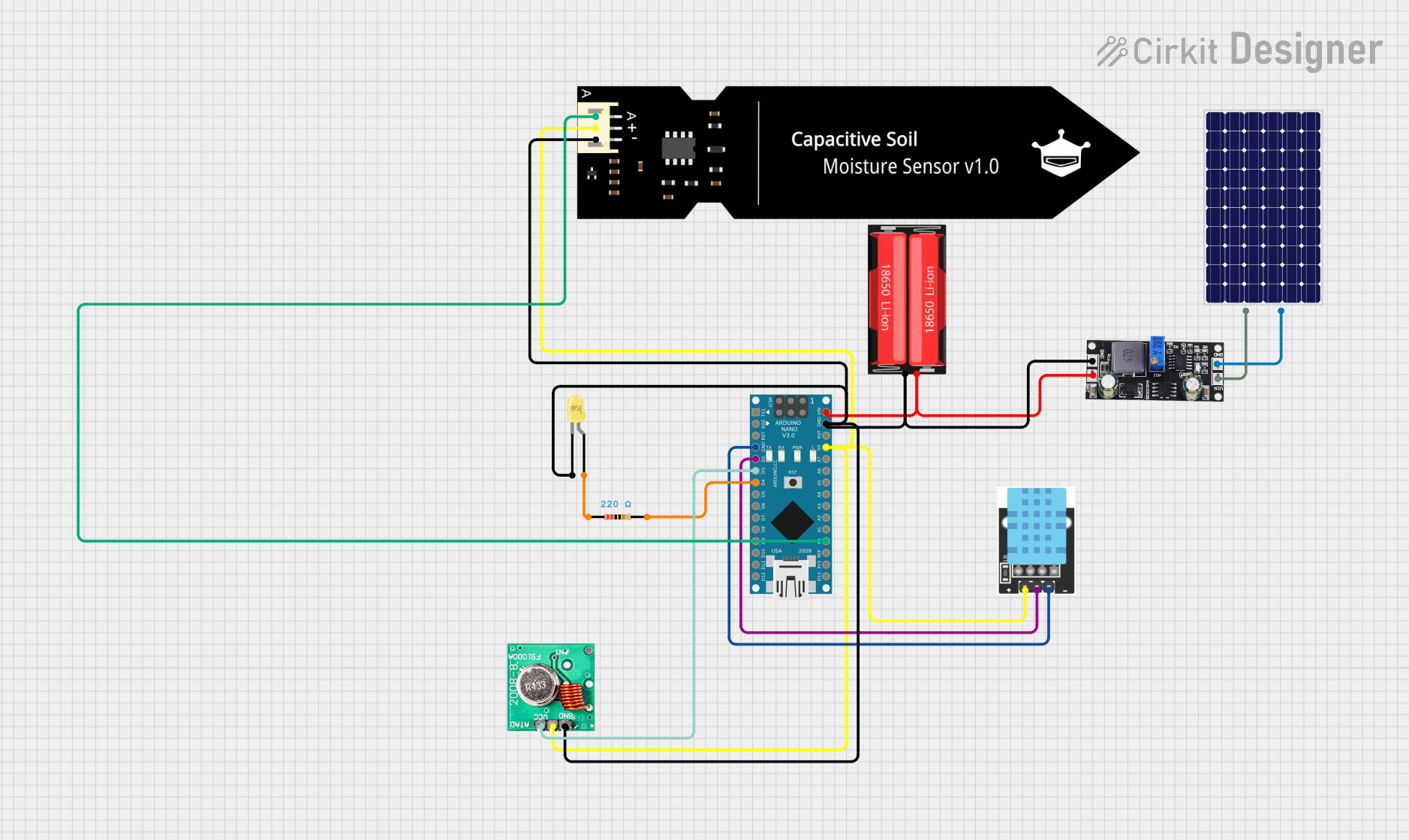

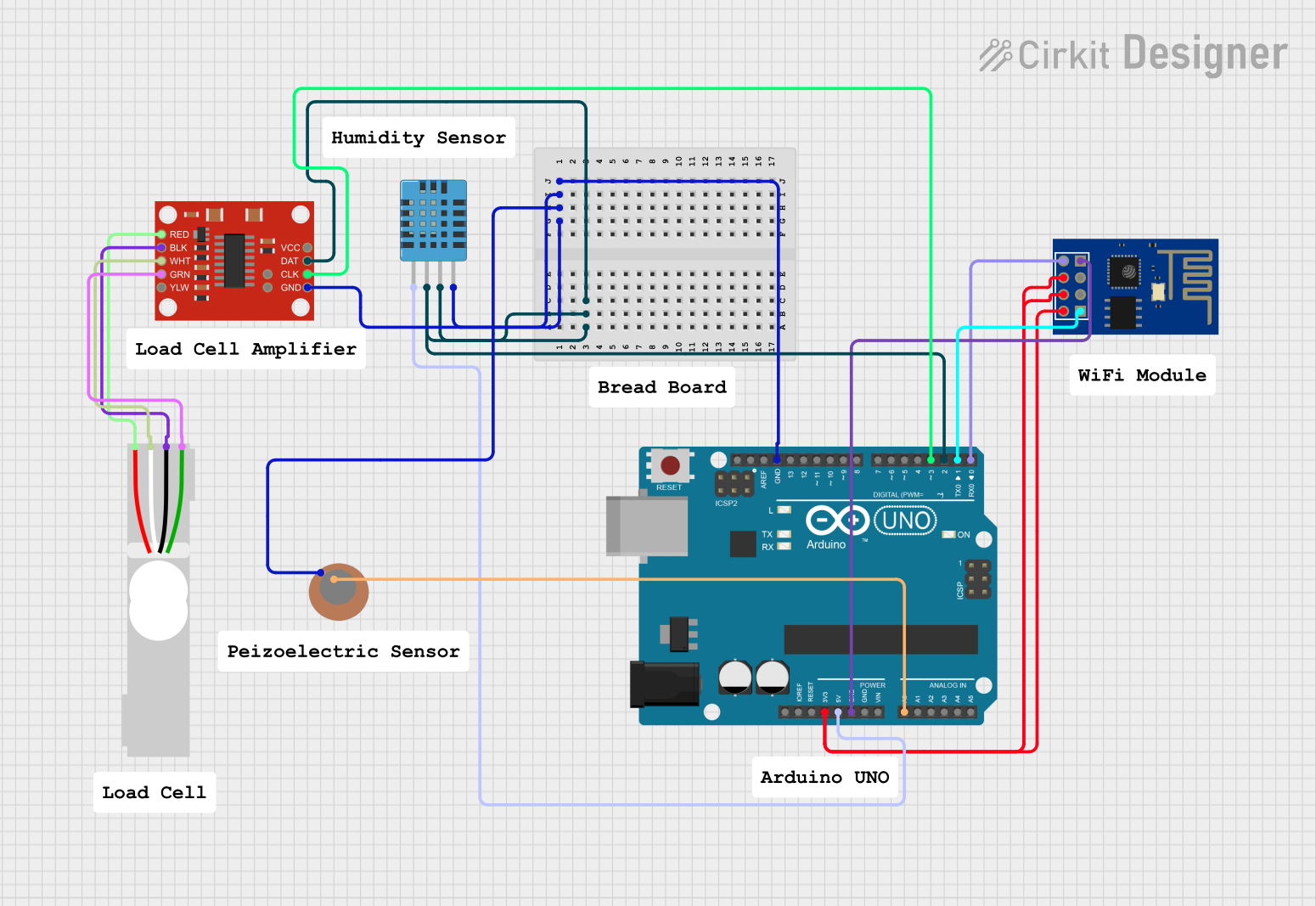

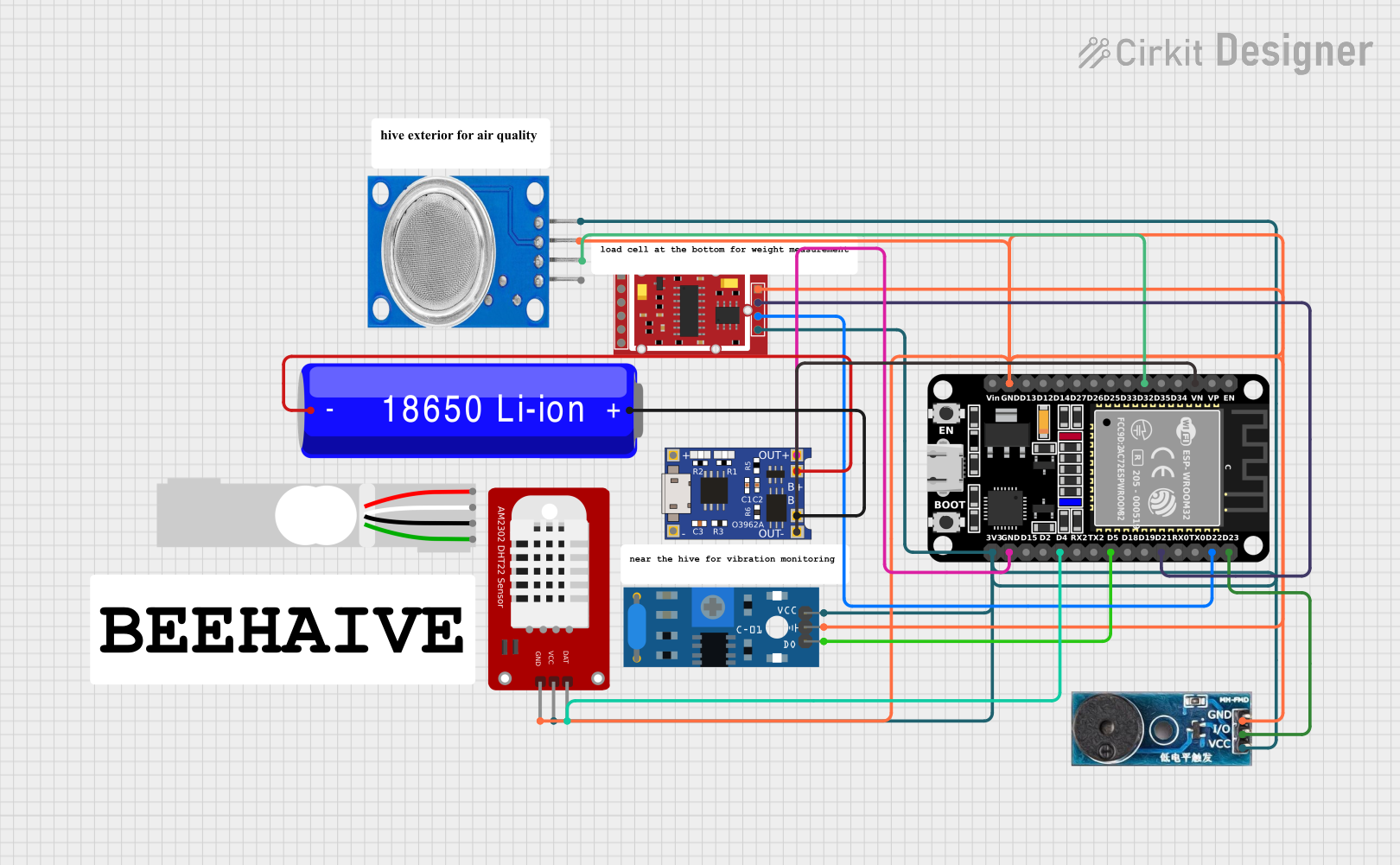

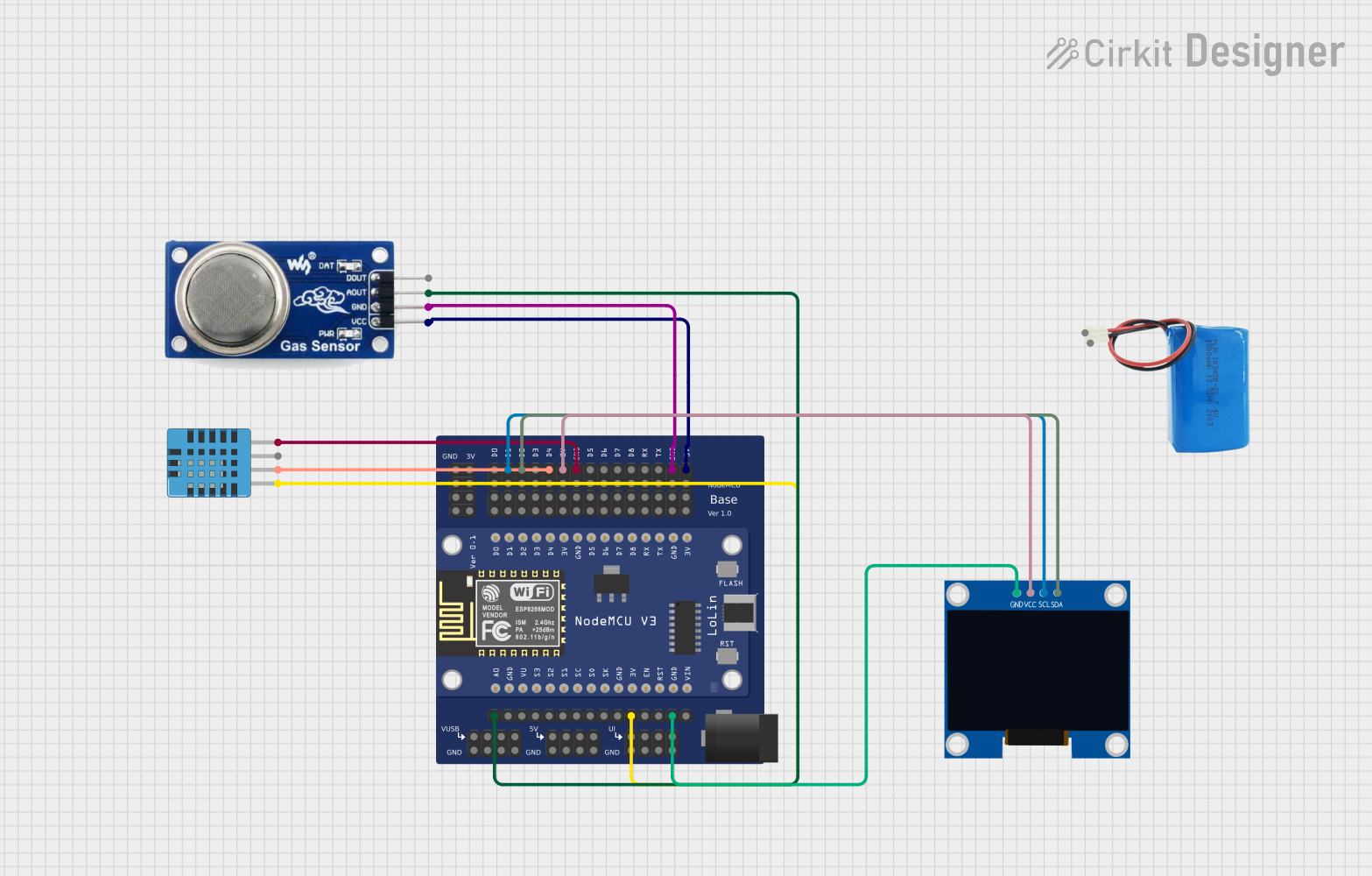

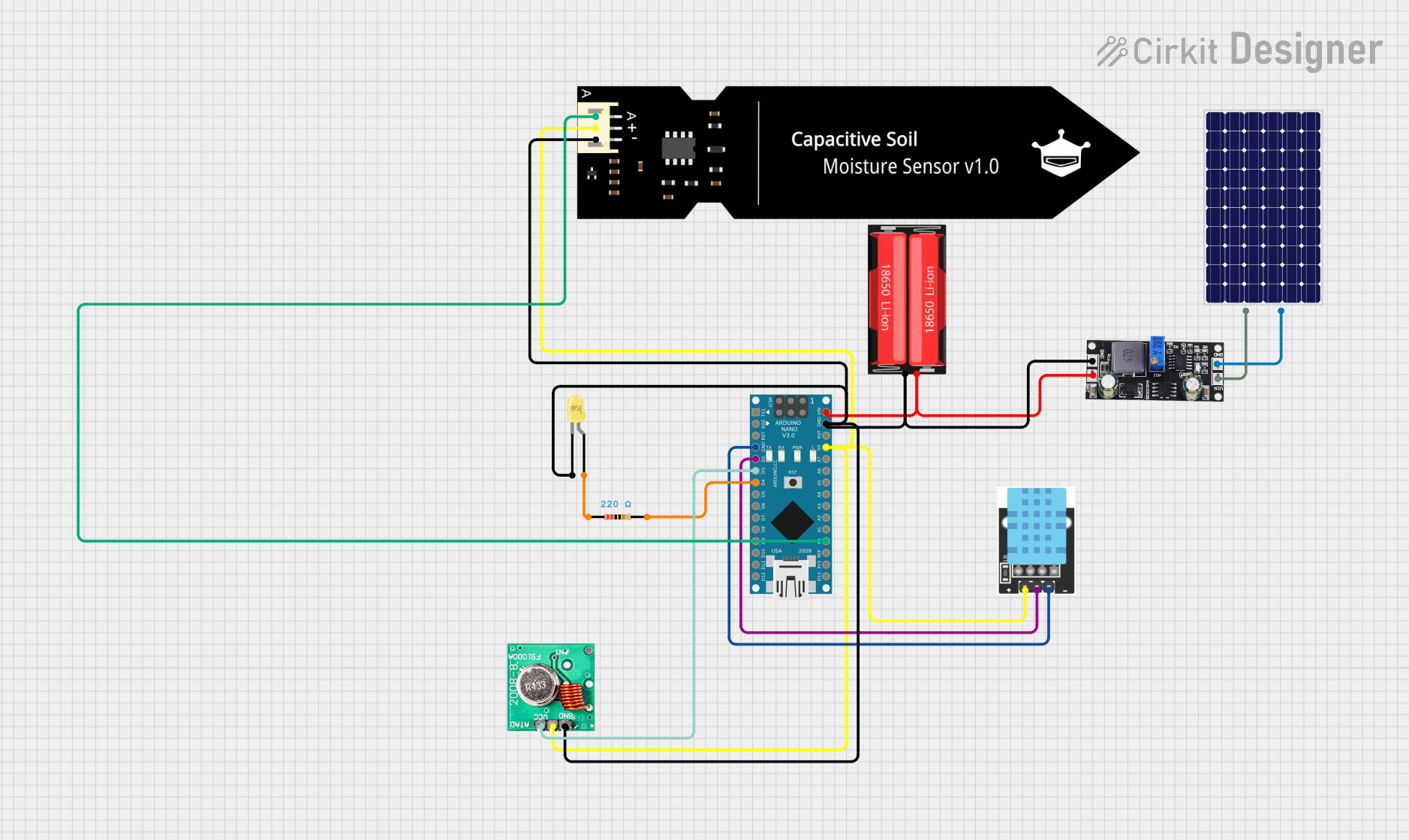

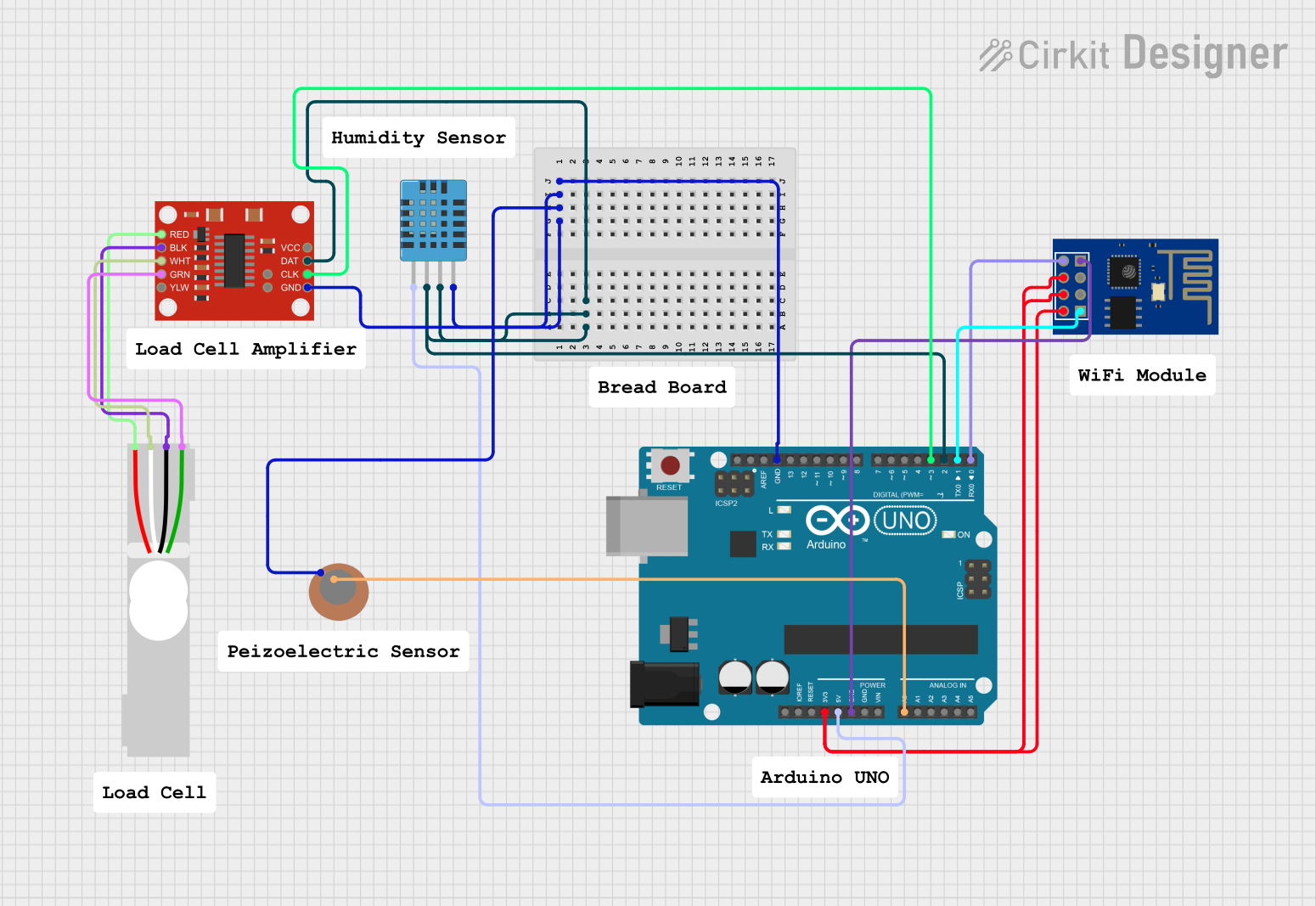

Explore Projects Built with HW-131

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with HW-131

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerTechnical Specifications

Key Technical Details

| Parameter | Value | Description |

|---|---|---|

| Maximum Repetitive Reverse Voltage (Vrrm) | 100 V | The maximum voltage the diode can withstand in the reverse direction without breakdown. |

| Average Forward Current (Ifav) | 1 A | The maximum average current the diode can conduct in the forward direction. |

| Non-Repetitive Peak Forward Surge Current (Ifsm) | 30 A | The maximum current the diode can conduct in the forward direction for a short time (typically 8.3 ms). |

| Forward Voltage Drop (Vf) | 1.0 V @ If = 1 A | The voltage drop across the diode when conducting the rated forward current. |

| Reverse Recovery Time (trr) | 50 ns | The time it takes for the diode to switch from conducting to blocking state. |

| Operating Junction Temperature (Tj) | -55°C to +150°C | The range of temperatures over which the diode can operate without damage. |

Pin Configuration and Descriptions

The HW-131 diode has two terminals:

| Pin | Name | Description |

|---|---|---|

| 1 | Anode | The terminal through which current enters when the diode is forward-biased. |

| 2 | Cathode | The terminal through which current exits when the diode is forward-biased. |

Usage Instructions

How to Use the HW-131 in a Circuit

Identify the Anode and Cathode: Ensure you correctly identify the anode and cathode terminals of the HW-131. The anode is typically marked by a longer lead or a color band.

Forward Bias Connection: Connect the anode to the positive side of the power source and the cathode to the negative side to forward bias the diode.

Reverse Bias Protection: To use the HW-131 as a protection diode, connect it in reverse bias across the load or power supply terminals.

Heat Management: If operating near the maximum rated current, consider using a heat sink to dissipate excess heat and prevent thermal overload.

Important Considerations and Best Practices

- Always verify the orientation of the diode before powering the circuit.

- Do not exceed the maximum ratings specified in the technical specifications to avoid damaging the diode.

- Use a current-limiting resistor if necessary to prevent the diode from exceeding its average forward current rating.

- When using the diode in high-speed switching applications, ensure the circuit design accounts for the reverse recovery time.

Troubleshooting and FAQs

Common Issues and Solutions

- Diode Not Conducting: Check for correct polarity. Ensure the anode is connected to the positive voltage and the cathode to the negative.

- Excessive Heat Generation: Verify that the current through the diode does not exceed the average forward current rating. Consider using a heat sink.

- Unexpected Voltage Drops: Ensure that the forward voltage drop of the diode is accounted for in the circuit design.

FAQs

Q: Can the HW-131 be used for AC rectification? A: Yes, the HW-131 can be used in bridge rectifiers for AC to DC conversion, provided the frequency and current ratings are within the diode's specifications.

Q: What is the significance of the reverse recovery time? A: The reverse recovery time affects the efficiency of the diode in high-speed switching applications. A shorter recovery time allows for faster switching.

Q: How can I test the HW-131 diode? A: You can test the diode using a multimeter set to the diode test function. You should see a low resistance in the forward direction and high resistance in the reverse.

Example Code for Arduino UNO

The following example demonstrates how to use the HW-131 diode to protect an Arduino UNO input from negative voltage spikes.

// There is no specific code required for the diode itself, as it is a passive component.

// However, the following example shows how to set up an input pin with a pull-up resistor

// and use the HW-131 diode for protection.

void setup() {

pinMode(2, INPUT_PULLUP); // Set digital pin 2 as an input with an internal pull-up resistor

}

void loop() {

// Read the state of the pin

int pinState = digitalRead(2);

// The HW-131 diode would be connected across the input pin (cathode to pin, anode to ground)

// to protect against negative voltage spikes that could potentially damage the Arduino pin.

// Your application logic here

}

Remember, the diode is a passive component and does not require code to operate. The example above is to illustrate how the diode might be incorporated into an Arduino project for input protection.