How to Use DRV 8835 Motor Driver: Examples, Pinouts, and Specs

Design with DRV 8835 Motor Driver in Cirkit Designer

Design with DRV 8835 Motor Driver in Cirkit DesignerIntroduction

The DRV 8835 is a dual H-bridge motor driver manufactured by Pololu, designed for controlling DC motors and stepper motors. It supports motor supply voltages ranging from 0V to 11V and can deliver up to 1.2A continuous current per channel (or 1.5A peak). This compact and efficient motor driver is ideal for robotics, automation, and other motor control applications.

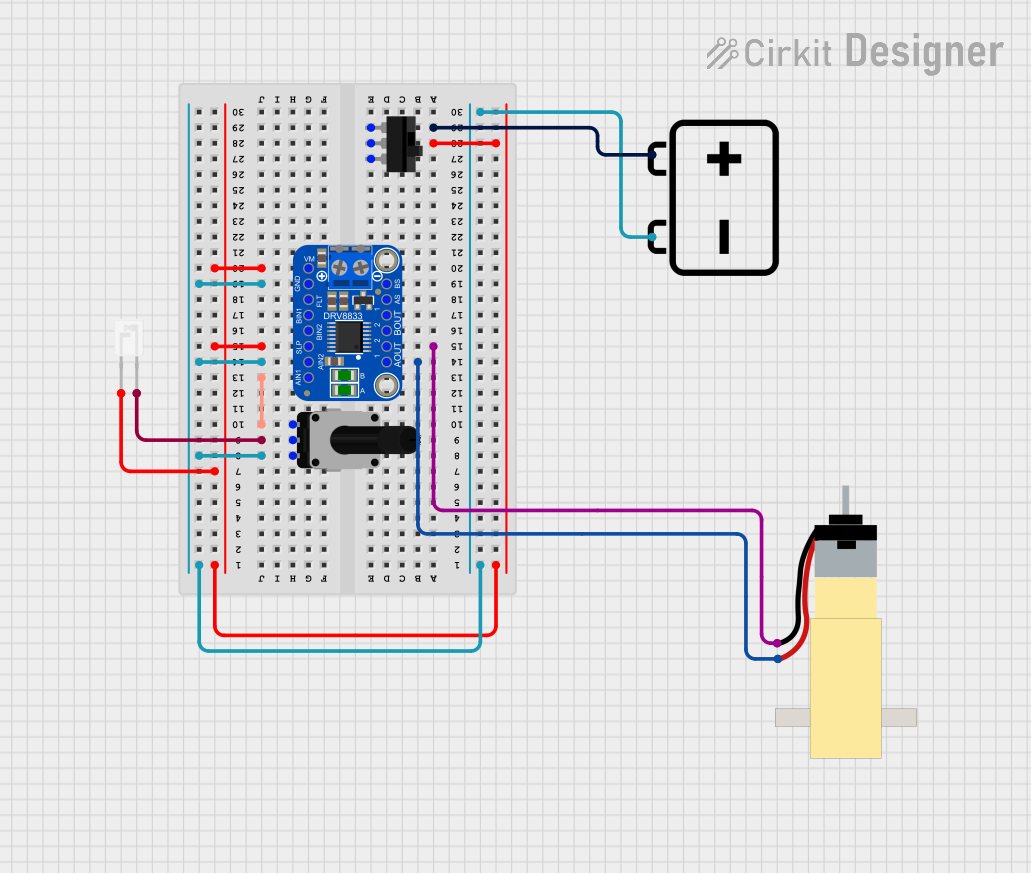

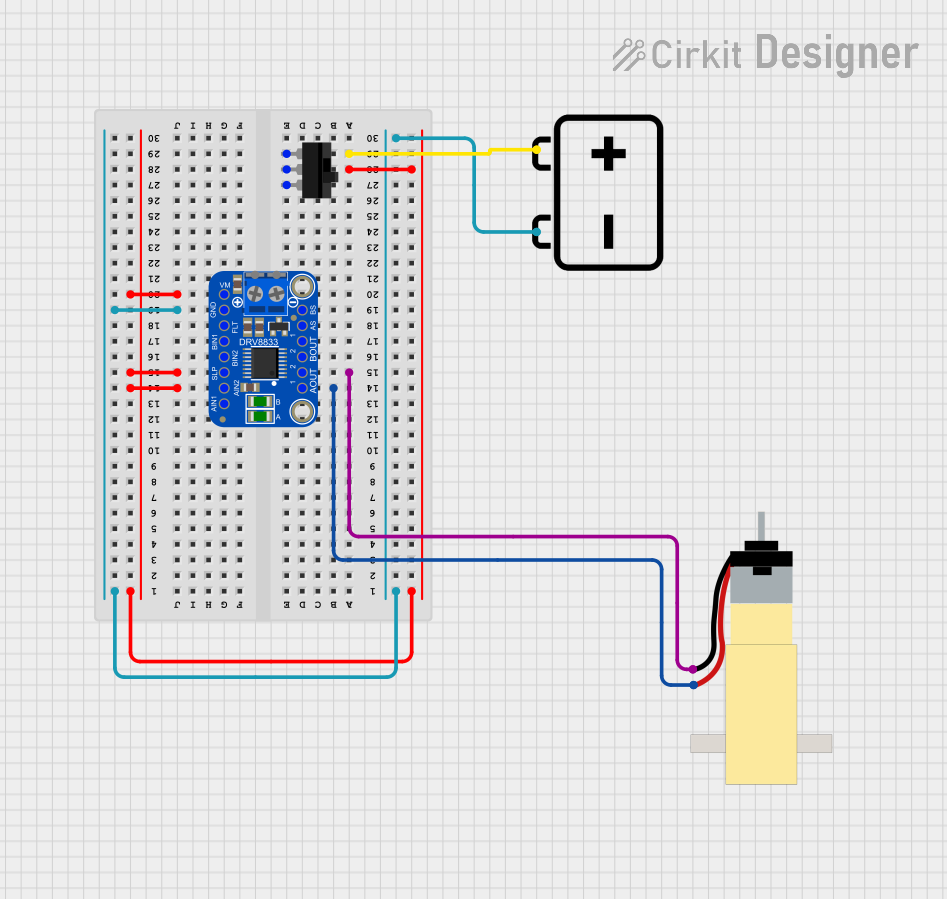

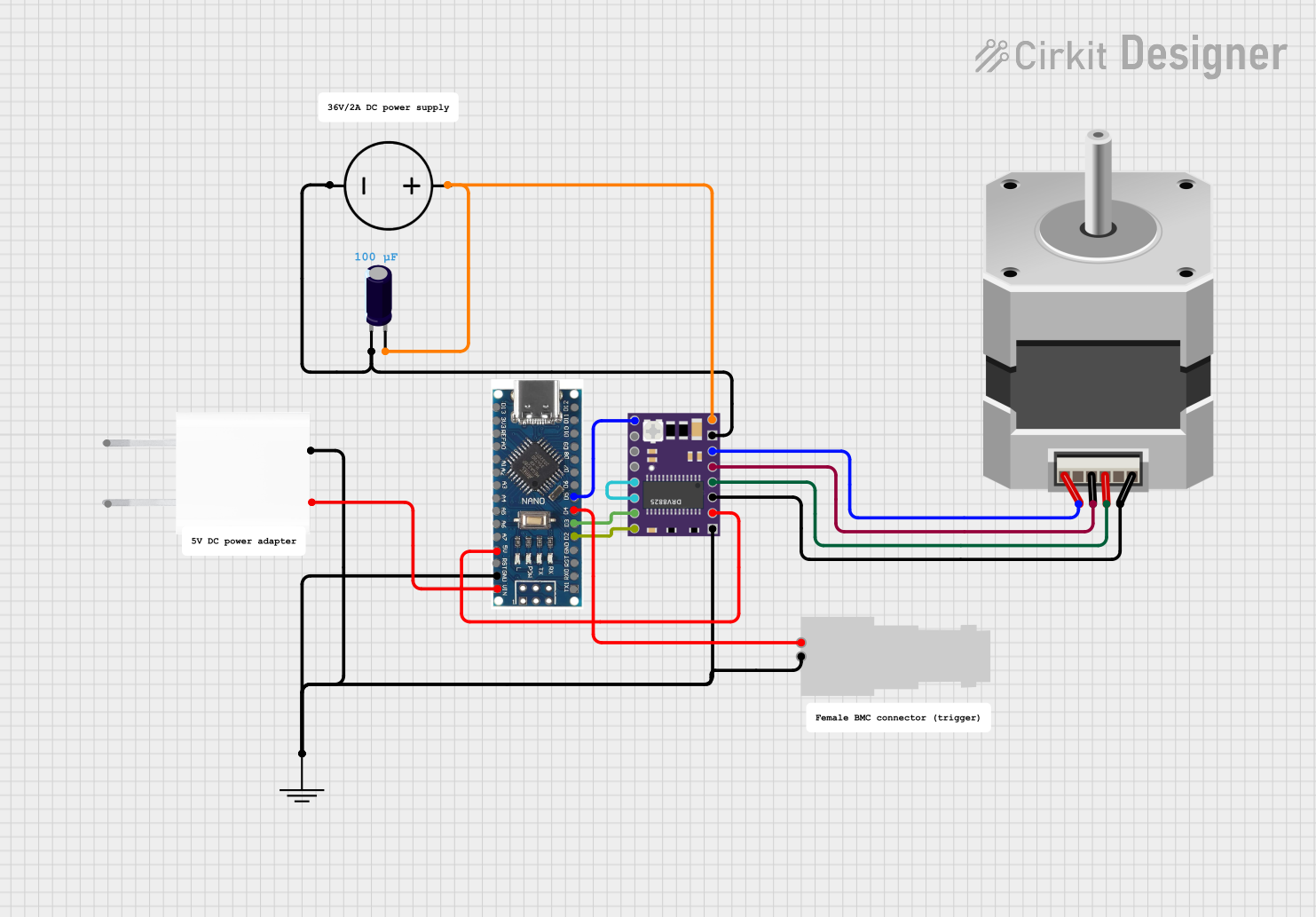

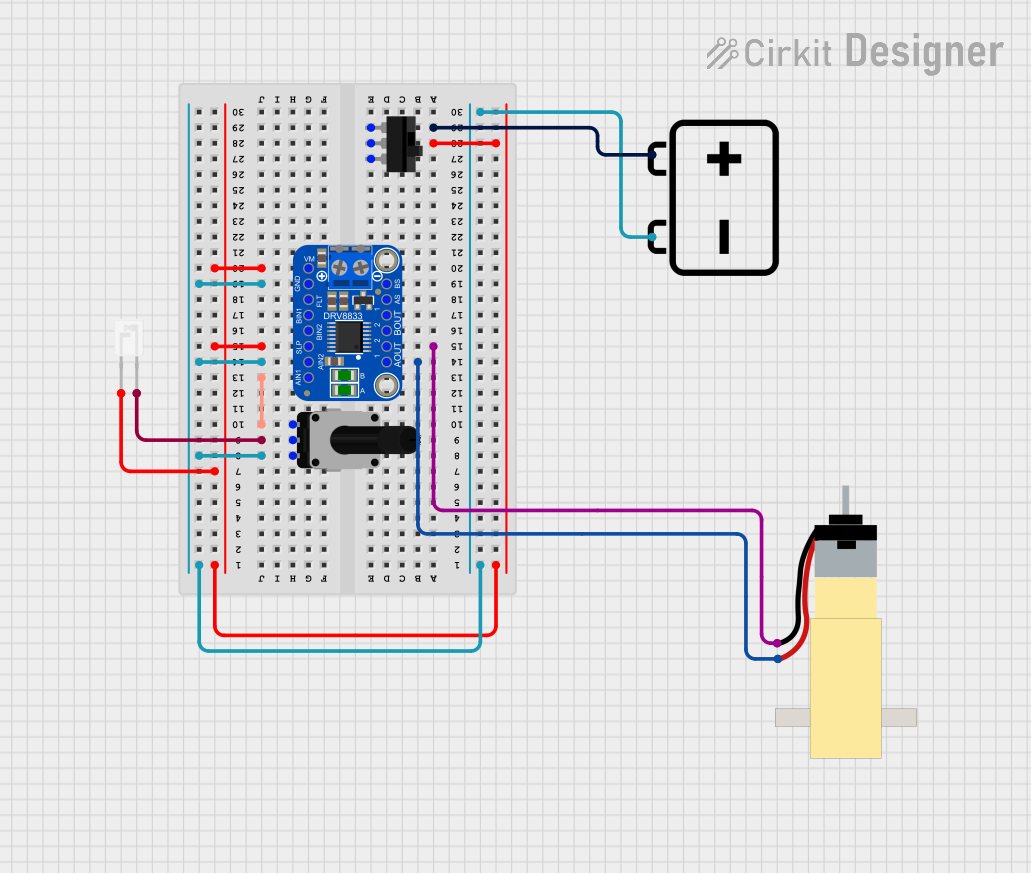

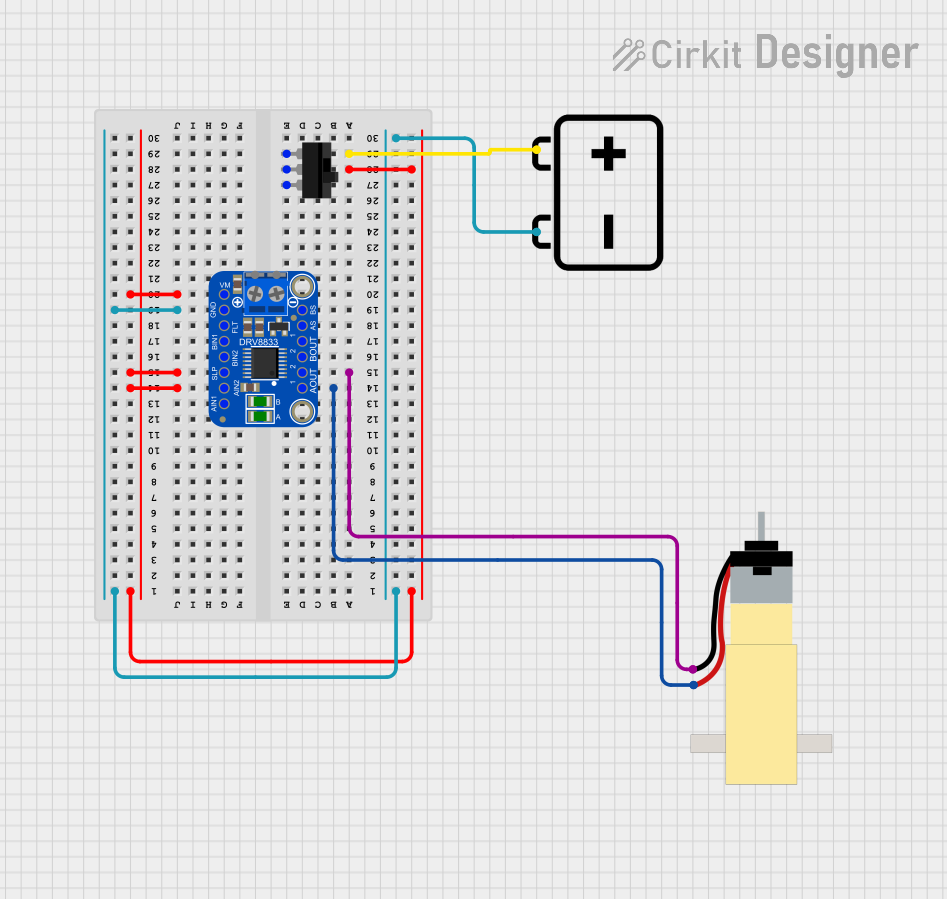

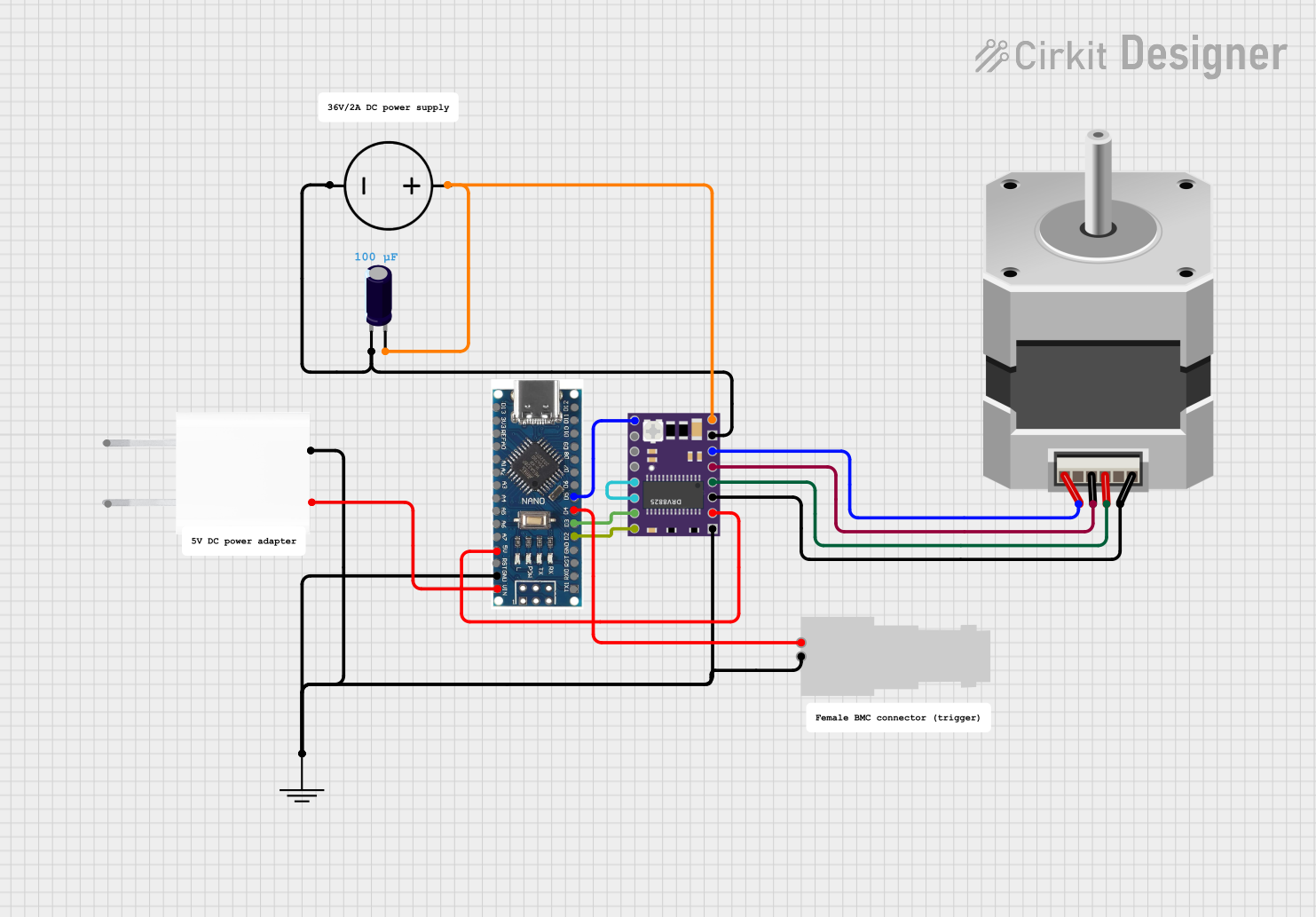

Explore Projects Built with DRV 8835 Motor Driver

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with DRV 8835 Motor Driver

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications and Use Cases

- Robotics: Driving wheels or actuators in small robots

- Automation: Controlling conveyor belts or small mechanisms

- DIY Projects: Building motorized toys or gadgets

- Stepper Motor Control: Driving small stepper motors in CNC machines or 3D printers

Technical Specifications

The following table outlines the key technical details of the DRV 8835 motor driver:

| Parameter | Value |

|---|---|

| Motor Supply Voltage (VM) | 0V to 11V |

| Logic Voltage (VCC) | 1.8V to 7V |

| Continuous Current per H-Bridge | 1.2A |

| Peak Current per H-Bridge | 1.5A |

| Control Interface | PWM or PHASE/ENABLE |

| Protection Features | Overcurrent, Thermal Shutdown |

| Dimensions | 0.6" × 0.8" × 0.1" (15mm × 20mm × 3mm) |

Pin Configuration and Descriptions

The DRV 8835 motor driver has the following pinout:

| Pin | Name | Description |

|---|---|---|

| 1 | VM | Motor power supply (0V to 11V). Connect to the positive terminal of the motor. |

| 2 | GND | Ground connection. Common ground for logic and motor power. |

| 3 | AIN1 | Input 1 for motor A. Used for direction or PWM control. |

| 4 | AIN2 | Input 2 for motor A. Used for direction or PWM control. |

| 5 | BIN1 | Input 1 for motor B. Used for direction or PWM control. |

| 6 | BIN2 | Input 2 for motor B. Used for direction or PWM control. |

| 7 | VCC | Logic power supply (1.8V to 7V). |

| 8 | AOUT1 | Output 1 for motor A. Connect to one terminal of motor A. |

| 9 | AOUT2 | Output 2 for motor A. Connect to the other terminal of motor A. |

| 10 | BOUT1 | Output 1 for motor B. Connect to one terminal of motor B. |

| 11 | BOUT2 | Output 2 for motor B. Connect to the other terminal of motor B. |

Usage Instructions

How to Use the DRV 8835 in a Circuit

Power Connections:

- Connect the motor power supply (VM) to the VM pin. Ensure the voltage is within the 0V to 11V range.

- Connect the logic power supply (VCC) to the VCC pin. Ensure the voltage is within the 1.8V to 7V range.

- Connect the GND pin to the ground of your power supply.

Motor Connections:

- For motor A, connect its terminals to AOUT1 and AOUT2.

- For motor B, connect its terminals to BOUT1 and BOUT2.

Control Signals:

- Use the AIN1 and AIN2 pins to control motor A.

- Use the BIN1 and BIN2 pins to control motor B.

- Apply PWM signals to these pins for speed control, or use them in a PHASE/ENABLE configuration for direction and speed control.

Enable the Driver:

- Ensure the control signals are within the logic voltage range (1.8V to 7V).

- Use a microcontroller (e.g., Arduino UNO) to generate the control signals.

Important Considerations and Best Practices

- Current Limiting: Ensure the motor's current draw does not exceed the driver's maximum continuous current rating (1.2A per channel).

- Heat Dissipation: If operating near the maximum current, consider adding a heatsink or improving ventilation to prevent thermal shutdown.

- Decoupling Capacitors: Place a capacitor (e.g., 100µF) across the VM and GND pins to stabilize the motor power supply.

- Avoid Reverse Polarity: Ensure correct polarity for both the motor and logic power supplies to prevent damage.

Example Code for Arduino UNO

Below is an example of how to control two DC motors using the DRV 8835 with an Arduino UNO:

// Define motor control pins

const int AIN1 = 3; // Motor A input 1 (PWM)

const int AIN2 = 4; // Motor A input 2

const int BIN1 = 5; // Motor B input 1 (PWM)

const int BIN2 = 6; // Motor B input 2

void setup() {

// Set motor control pins as outputs

pinMode(AIN1, OUTPUT);

pinMode(AIN2, OUTPUT);

pinMode(BIN1, OUTPUT);

pinMode(BIN2, OUTPUT);

}

void loop() {

// Example: Drive motor A forward at 50% speed

analogWrite(AIN1, 128); // PWM signal (0-255)

digitalWrite(AIN2, LOW); // Set direction

// Example: Drive motor B backward at 75% speed

digitalWrite(BIN1, LOW); // Set direction

analogWrite(BIN2, 192); // PWM signal (0-255)

delay(2000); // Run motors for 2 seconds

// Stop both motors

digitalWrite(AIN1, LOW);

digitalWrite(AIN2, LOW);

digitalWrite(BIN1, LOW);

digitalWrite(BIN2, LOW);

delay(2000); // Wait for 2 seconds

}

Troubleshooting and FAQs

Common Issues and Solutions

Motors Not Running:

- Verify that the motor power supply (VM) and logic power supply (VCC) are connected and within the specified voltage ranges.

- Check the control signals (AIN1, AIN2, BIN1, BIN2) to ensure they are being correctly generated by the microcontroller.

Driver Overheating:

- Ensure the motor's current draw does not exceed 1.2A per channel.

- Improve ventilation or add a heatsink to the driver.

Erratic Motor Behavior:

- Add a decoupling capacitor (e.g., 100µF) across the VM and GND pins to stabilize the power supply.

- Check for loose or incorrect wiring connections.

Arduino Code Not Working:

- Verify that the correct pins are defined in the code and connected to the driver.

- Ensure the Arduino is powered and properly uploading the code.

FAQs

Q: Can the DRV 8835 drive stepper motors?

A: Yes, the DRV 8835 can drive small stepper motors by controlling both H-bridges. You will need to generate the appropriate step and direction signals.

Q: What happens if the motor draws more than 1.2A?

A: The driver includes overcurrent protection and will shut down temporarily to prevent damage. Reduce the motor load or use a motor with lower current requirements.

Q: Can I use the DRV 8835 with a 3.3V microcontroller?

A: Yes, the DRV 8835 supports logic voltages as low as 1.8V, making it compatible with 3.3V systems.