How to Use 6-60V 400W DC Three-Phase Brushless Motor Speed Controller: Examples, Pinouts, and Specs

Design with 6-60V 400W DC Three-Phase Brushless Motor Speed Controller in Cirkit Designer

Design with 6-60V 400W DC Three-Phase Brushless Motor Speed Controller in Cirkit DesignerIntroduction

The 6-60V 400W DC Three-Phase Brushless Motor Speed Controller (Manufacturer: RANSANX, Part ID: B0F1YGJ48F) is a versatile and efficient device designed to regulate the speed and direction of three-phase brushless DC (BLDC) motors. It operates within a wide voltage range of 6 to 60 volts and supports a maximum power output of 400 watts, making it suitable for a variety of applications.

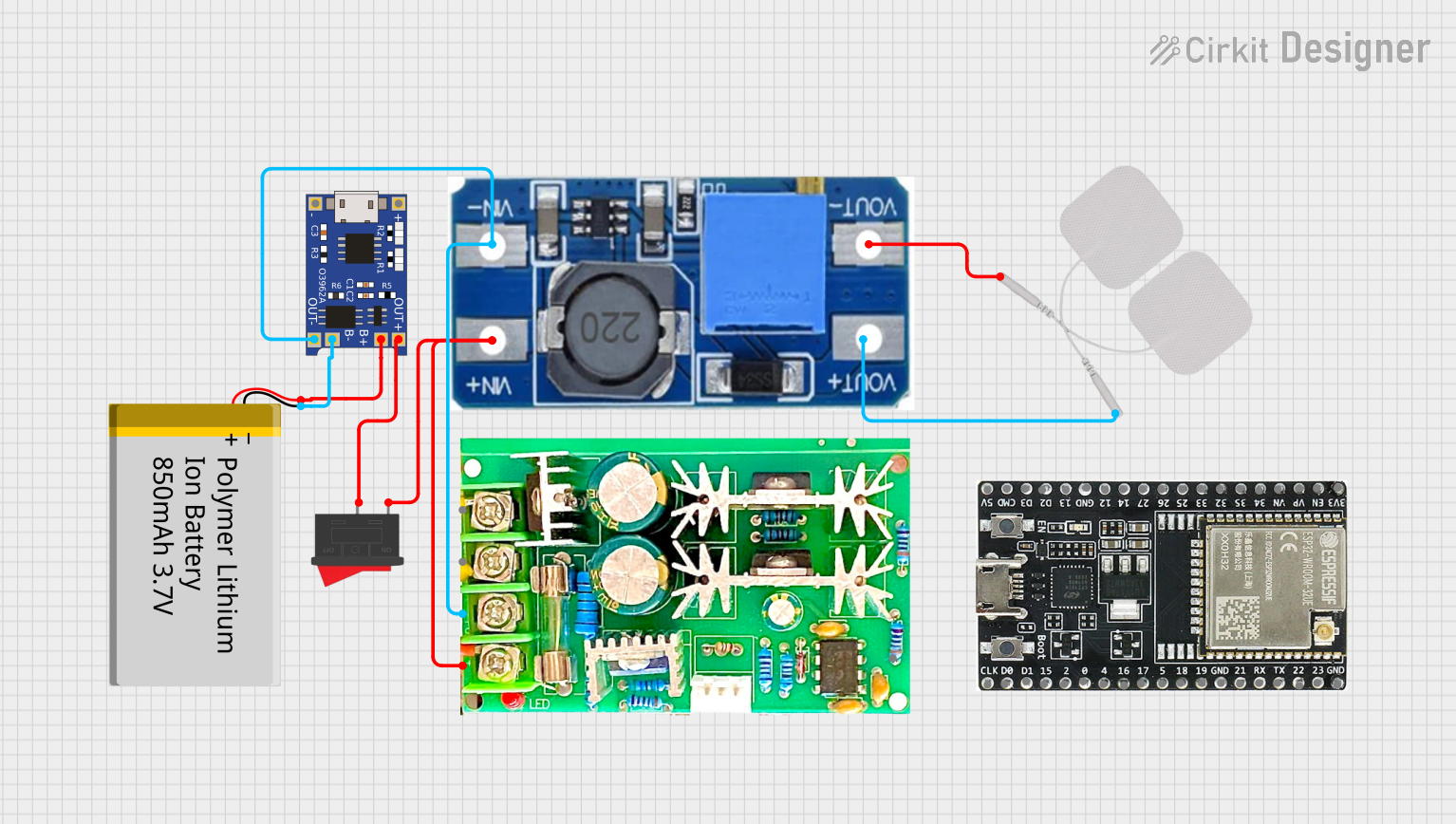

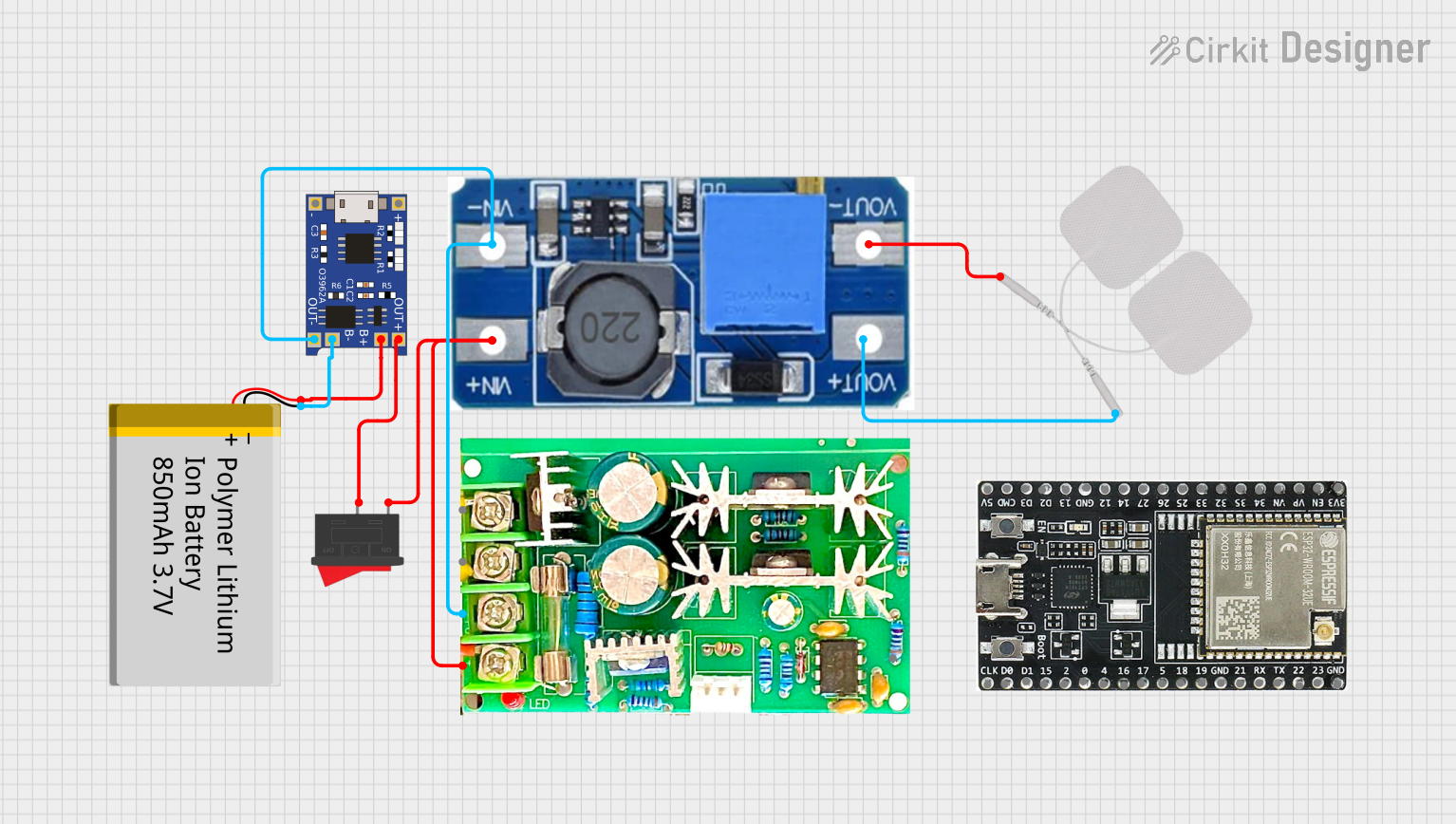

Explore Projects Built with 6-60V 400W DC Three-Phase Brushless Motor Speed Controller

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with 6-60V 400W DC Three-Phase Brushless Motor Speed Controller

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications and Use Cases

- Electric bicycles and scooters

- RC vehicles and drones

- Industrial automation systems

- Conveyor belts and robotic arms

- Fans, pumps, and other motor-driven devices

This controller is ideal for projects requiring precise motor speed control, high efficiency, and reliable operation.

Technical Specifications

Key Technical Details

| Parameter | Specification |

|---|---|

| Input Voltage Range | 6V to 60V DC |

| Maximum Power Output | 400W |

| Motor Type Supported | Three-phase brushless DC motor |

| Control Mode | PWM (Pulse Width Modulation) |

| Speed Adjustment Range | 0% to 100% |

| Direction Control | Forward and reverse supported |

| Operating Temperature | -20°C to 50°C |

| Dimensions | 85mm x 60mm x 28mm |

Pin Configuration and Descriptions

The controller has several input and output connections for power, motor, and control signals. Below is the pin configuration:

Power and Motor Connections

| Pin Label | Description |

|---|---|

+V |

Positive DC input (6V to 60V) |

-V |

Negative DC input (ground) |

U |

Motor phase U connection |

V |

Motor phase V connection |

W |

Motor phase W connection |

Control Signal Connections

| Pin Label | Description |

|---|---|

PWM |

PWM input for speed control |

DIR |

Direction control input (forward/reverse) |

GND |

Ground for control signals |

Usage Instructions

How to Use the Component in a Circuit

- Power Supply Connection: Connect a DC power supply (6V to 60V) to the

+Vand-Vterminals. Ensure the power supply can provide sufficient current for the motor's operation. - Motor Connection: Connect the three-phase brushless DC motor to the

U,V, andWterminals. Ensure the motor's voltage and power ratings are compatible with the controller. - Control Signal Connection:

- Connect a PWM signal (e.g., from a microcontroller) to the

PWMpin to control the motor speed. - Use the

DIRpin to set the motor's direction. A HIGH signal typically sets forward direction, while a LOW signal sets reverse direction. - Connect the

GNDpin to the ground of the control signal source.

- Connect a PWM signal (e.g., from a microcontroller) to the

- Speed Adjustment: Adjust the PWM duty cycle to control the motor speed. A higher duty cycle corresponds to a higher speed.

Important Considerations and Best Practices

- Voltage Compatibility: Ensure the input voltage matches the motor's operating voltage range.

- Heat Dissipation: The controller may generate heat during operation. Use proper heat sinks or cooling mechanisms if necessary.

- Wiring: Use appropriate wire gauges for power and motor connections to handle the current without overheating.

- Startup Testing: Test the setup with a low-speed setting initially to verify proper operation before increasing the speed.

Example: Using with Arduino UNO

The controller can be easily interfaced with an Arduino UNO for motor speed and direction control. Below is an example code snippet:

// Define pins for PWM and direction control

const int pwmPin = 9; // PWM output pin

const int dirPin = 8; // Direction control pin

void setup() {

pinMode(pwmPin, OUTPUT); // Set PWM pin as output

pinMode(dirPin, OUTPUT); // Set direction pin as output

// Set initial direction to forward

digitalWrite(dirPin, HIGH);

}

void loop() {

// Gradually increase motor speed

for (int speed = 0; speed <= 255; speed++) {

analogWrite(pwmPin, speed); // Set PWM duty cycle

delay(20); // Wait for 20ms

}

// Gradually decrease motor speed

for (int speed = 255; speed >= 0; speed--) {

analogWrite(pwmPin, speed); // Set PWM duty cycle

delay(20); // Wait for 20ms

}

// Reverse motor direction

digitalWrite(dirPin, LOW); // Set direction to reverse

delay(1000); // Wait for 1 second

// Repeat the process

}

Troubleshooting and FAQs

Common Issues and Solutions

Motor Does Not Start:

- Check the power supply voltage and ensure it is within the specified range.

- Verify all connections, especially the motor phase wires (

U,V,W). - Ensure the PWM signal is being generated correctly.

Motor Runs in the Wrong Direction:

- Check the

DIRpin signal. Toggle the signal to change the direction. - Verify the motor phase connections (

U,V,W) are correct.

- Check the

Overheating:

- Ensure proper ventilation or use a heat sink for the controller.

- Check for excessive current draw from the motor.

Inconsistent Speed Control:

- Verify the PWM signal's frequency and duty cycle.

- Ensure the ground (

GND) of the controller and the control signal source are connected.

FAQs

Q: Can this controller be used with a single-phase motor?

A: No, this controller is specifically designed for three-phase brushless DC motors.

Q: What is the recommended PWM frequency?

A: A PWM frequency between 1 kHz and 20 kHz is typically recommended for smooth motor operation.

Q: Can I use this controller with a battery-powered system?

A: Yes, as long as the battery voltage is within the 6V to 60V range and can supply sufficient current.

Q: Is reverse braking supported?

A: No, this controller does not support active braking. It only controls speed and direction.

This documentation provides a comprehensive guide to using the 6-60V 400W DC Three-Phase Brushless Motor Speed Controller effectively. For further assistance, refer to the manufacturer's datasheet or contact RANSANX support.