How to Use CNC SHIELD V3: Examples, Pinouts, and Specs

Design with CNC SHIELD V3 in Cirkit Designer

Design with CNC SHIELD V3 in Cirkit DesignerIntroduction

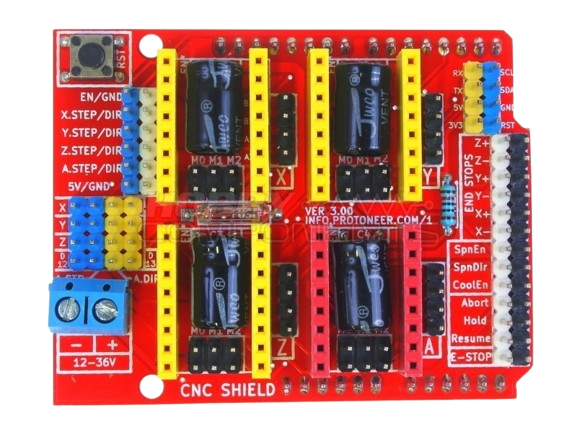

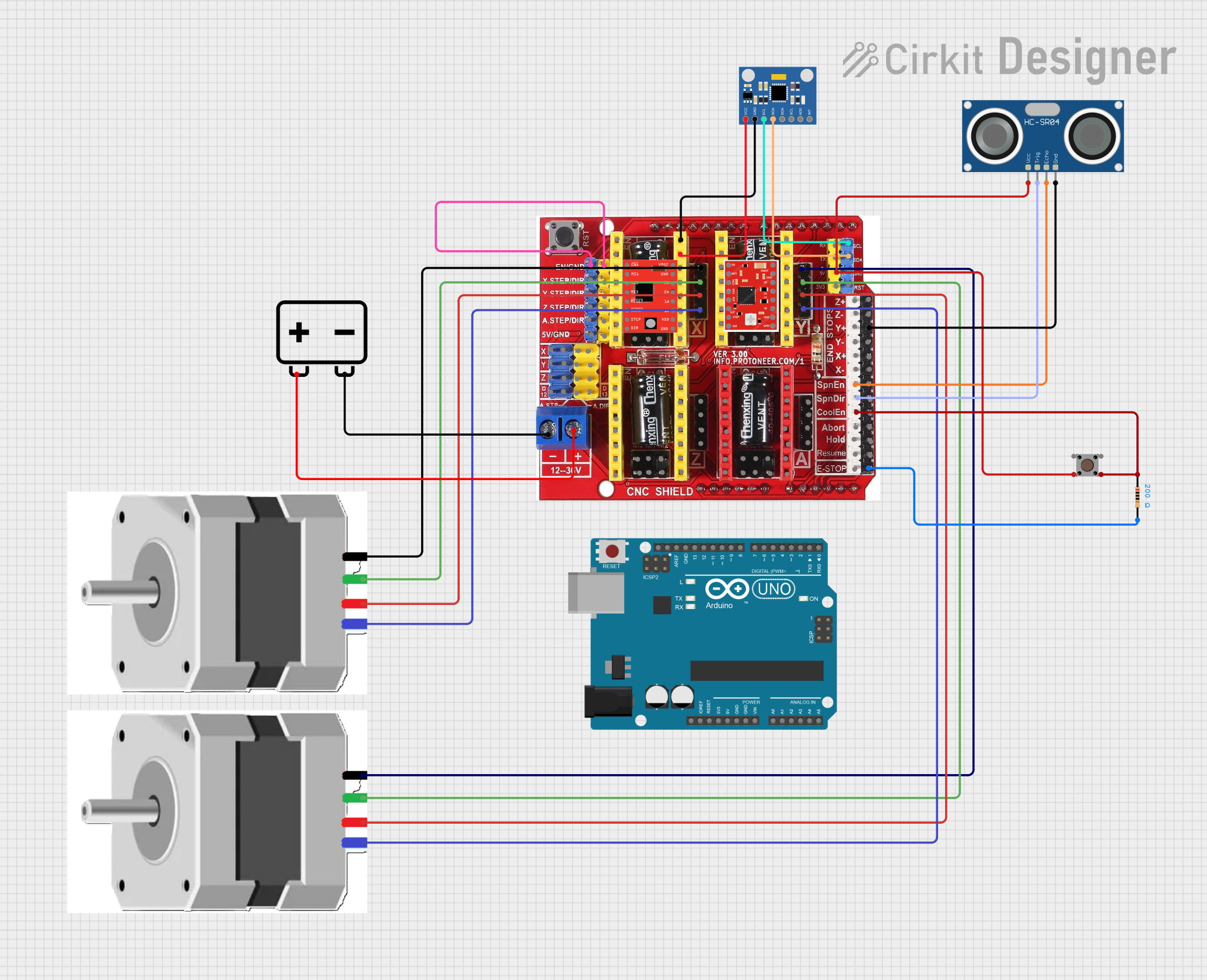

The CNC SHIELD V3, manufactured by INFO PROTONER (Part ID: CNC SHIELD), is a versatile control board designed for CNC machines, 3D printers, and laser engravers. It provides an efficient and user-friendly interface for controlling stepper motors, endstops, and other peripherals. The shield is compatible with Arduino boards, making it an excellent choice for hobbyists and professionals alike. Its modular design allows for easy integration of stepper motor drivers and other components, enabling precise control of motion systems.

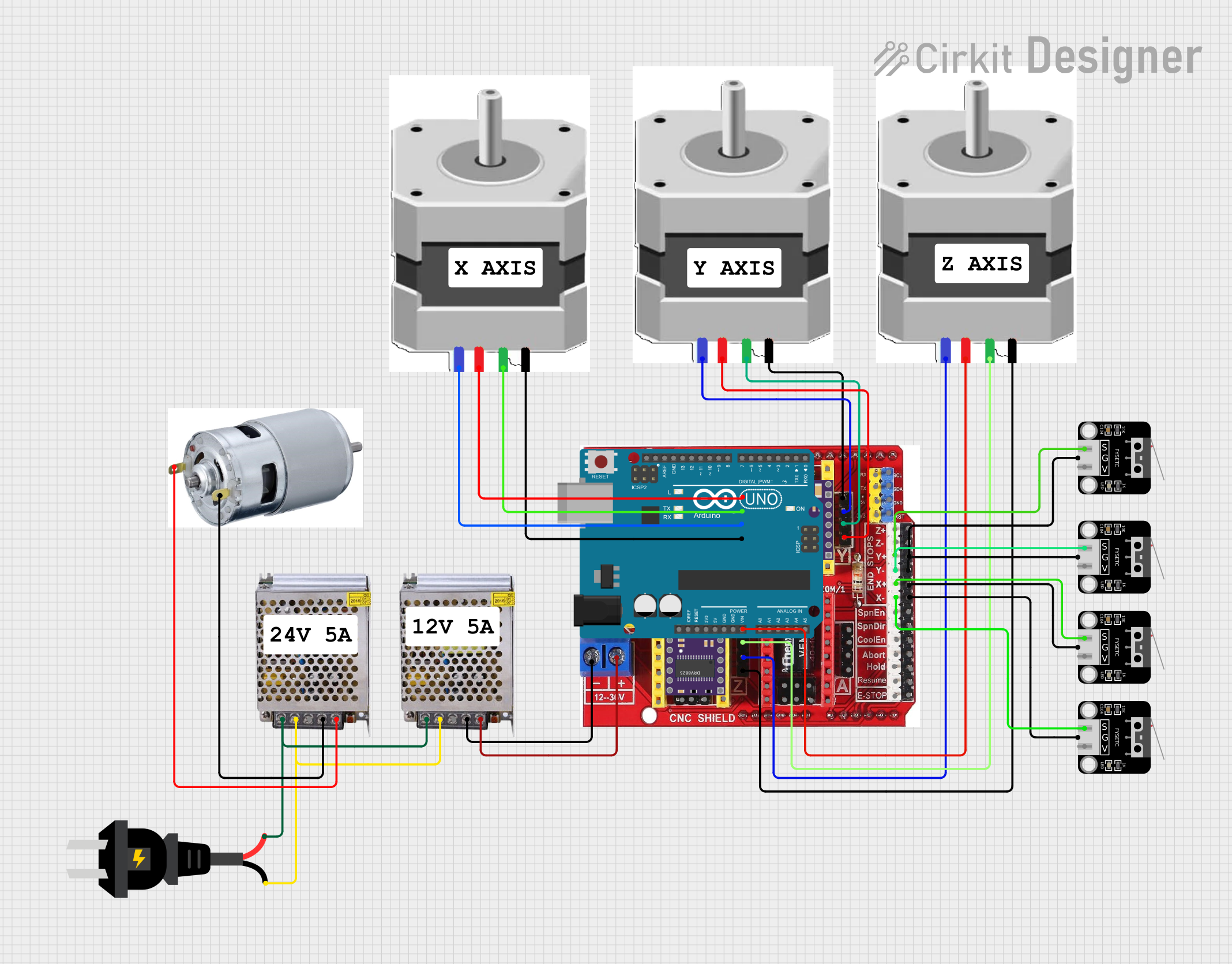

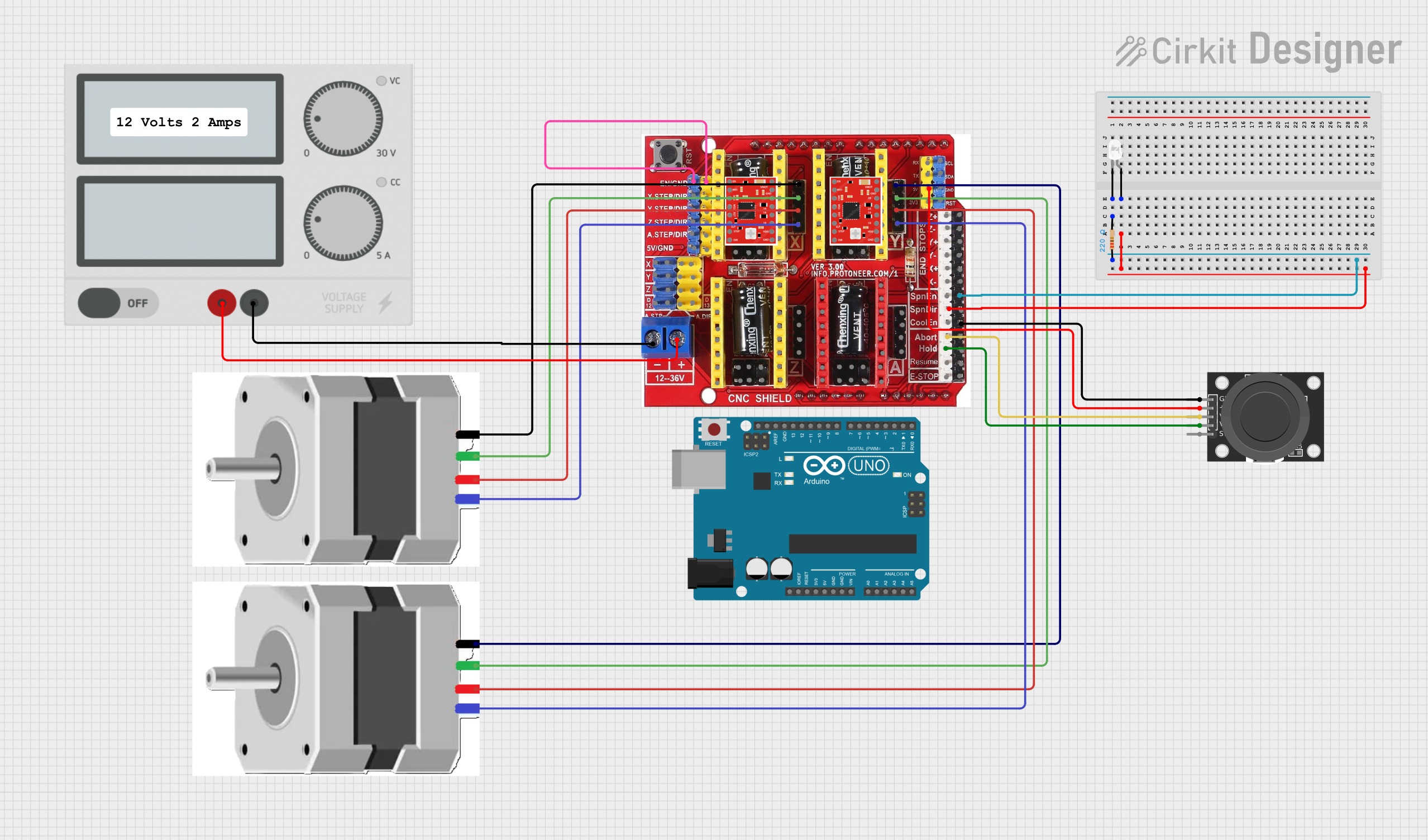

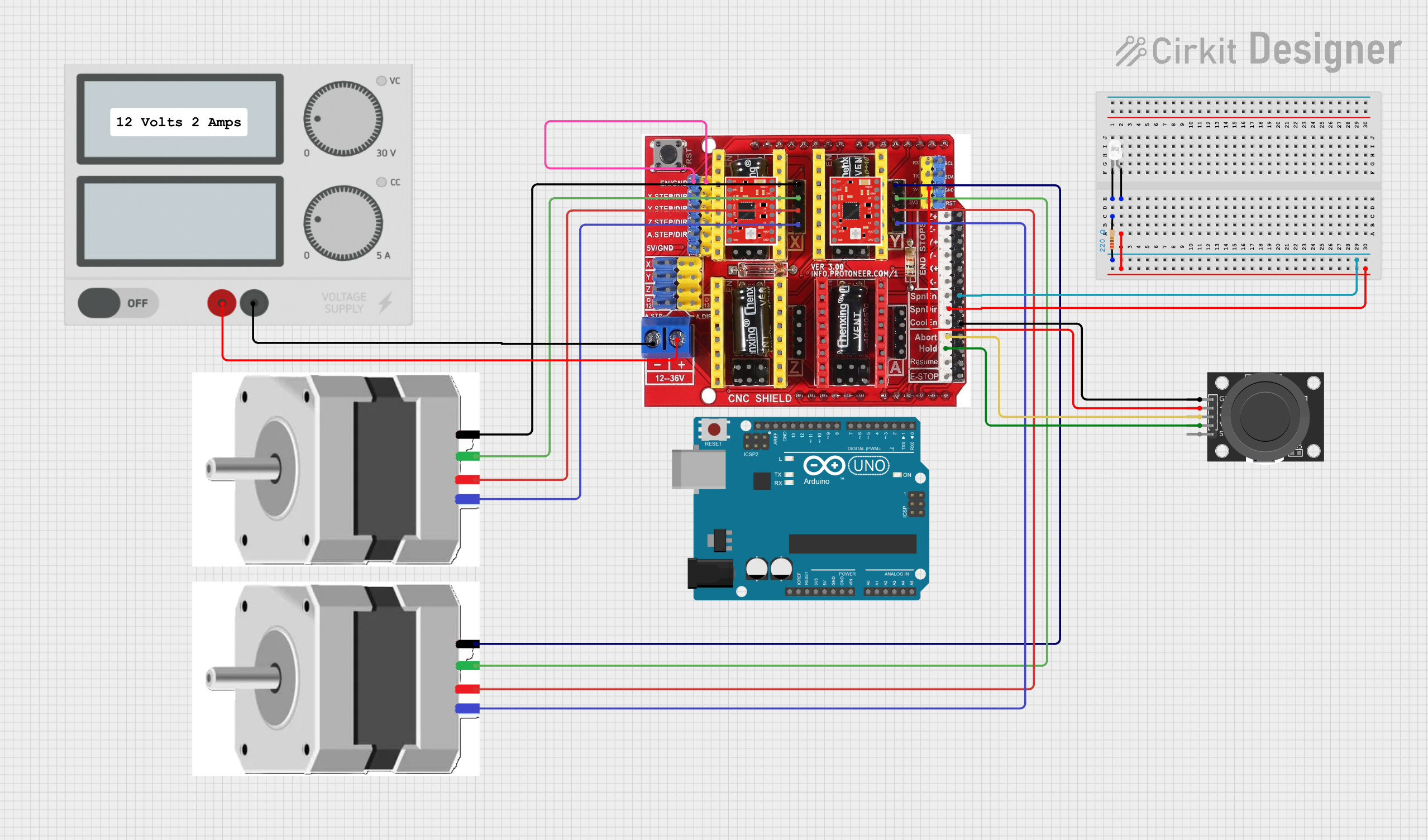

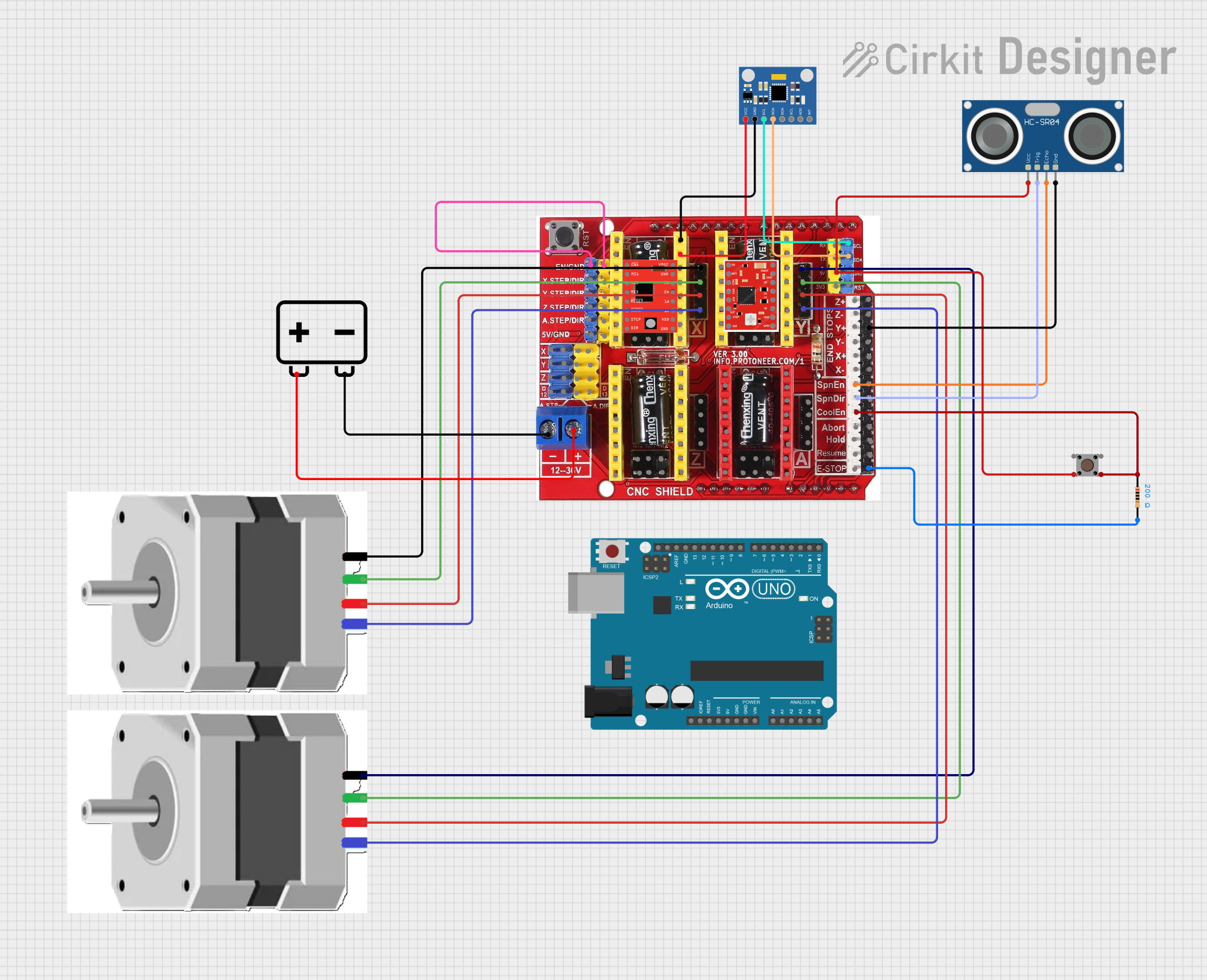

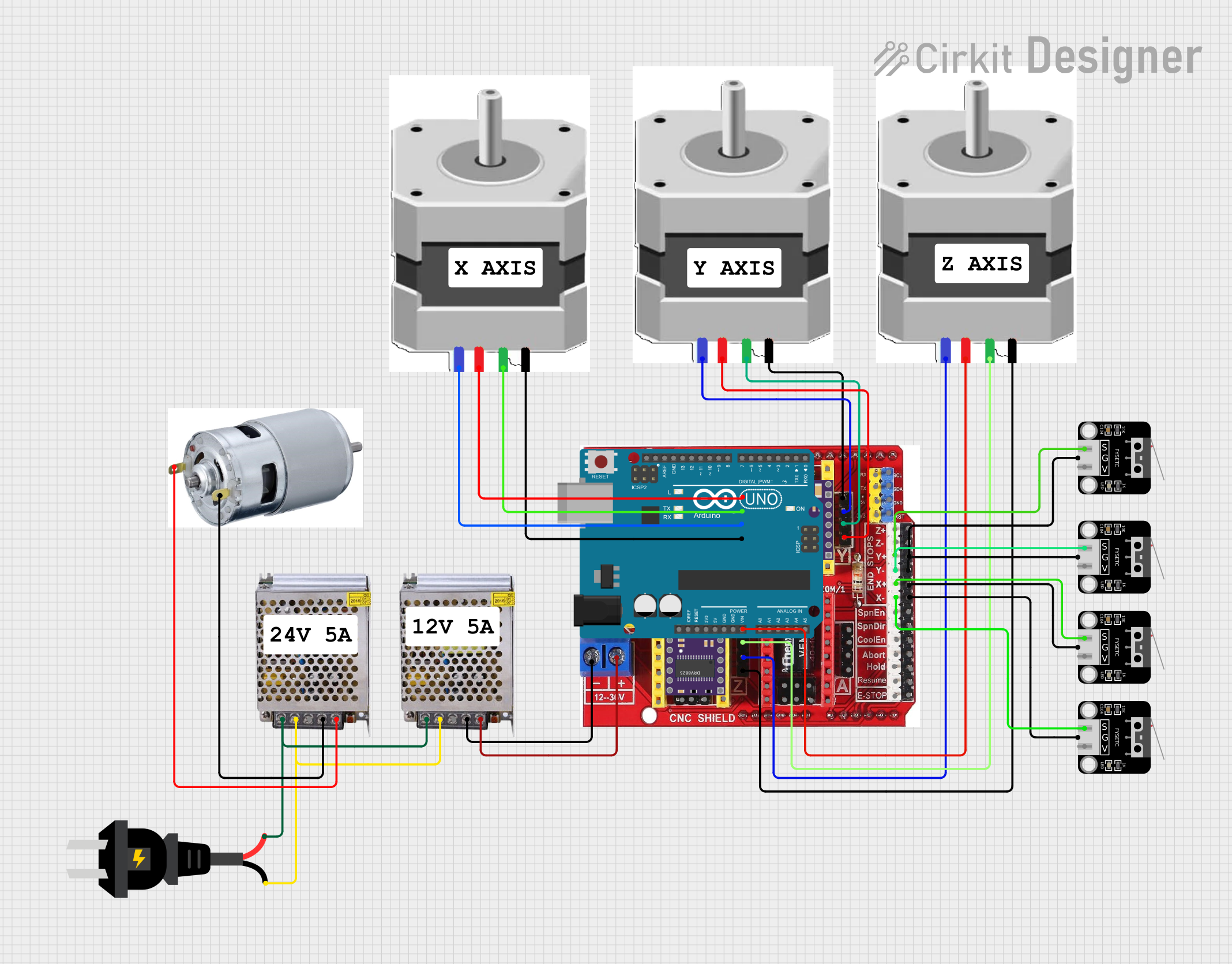

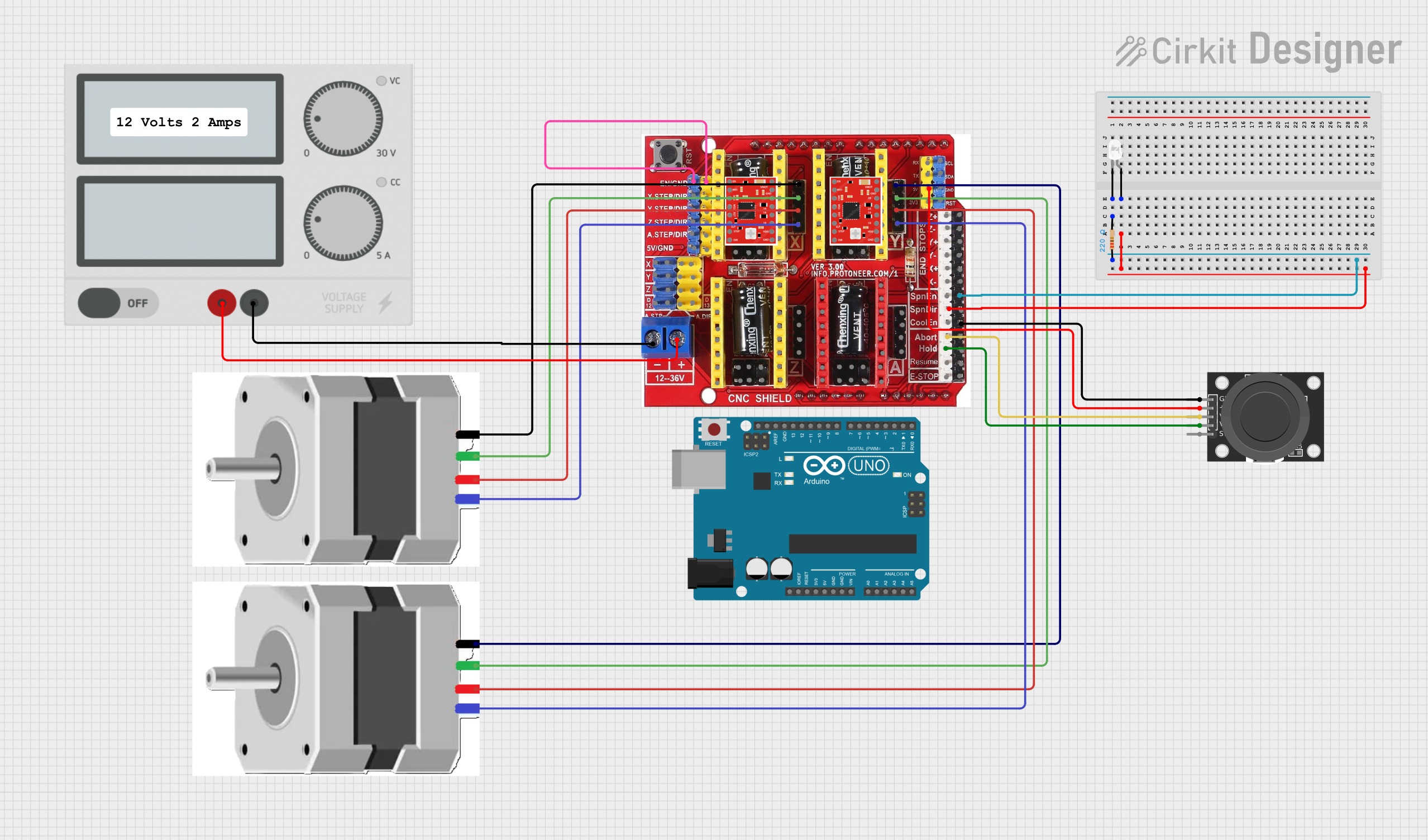

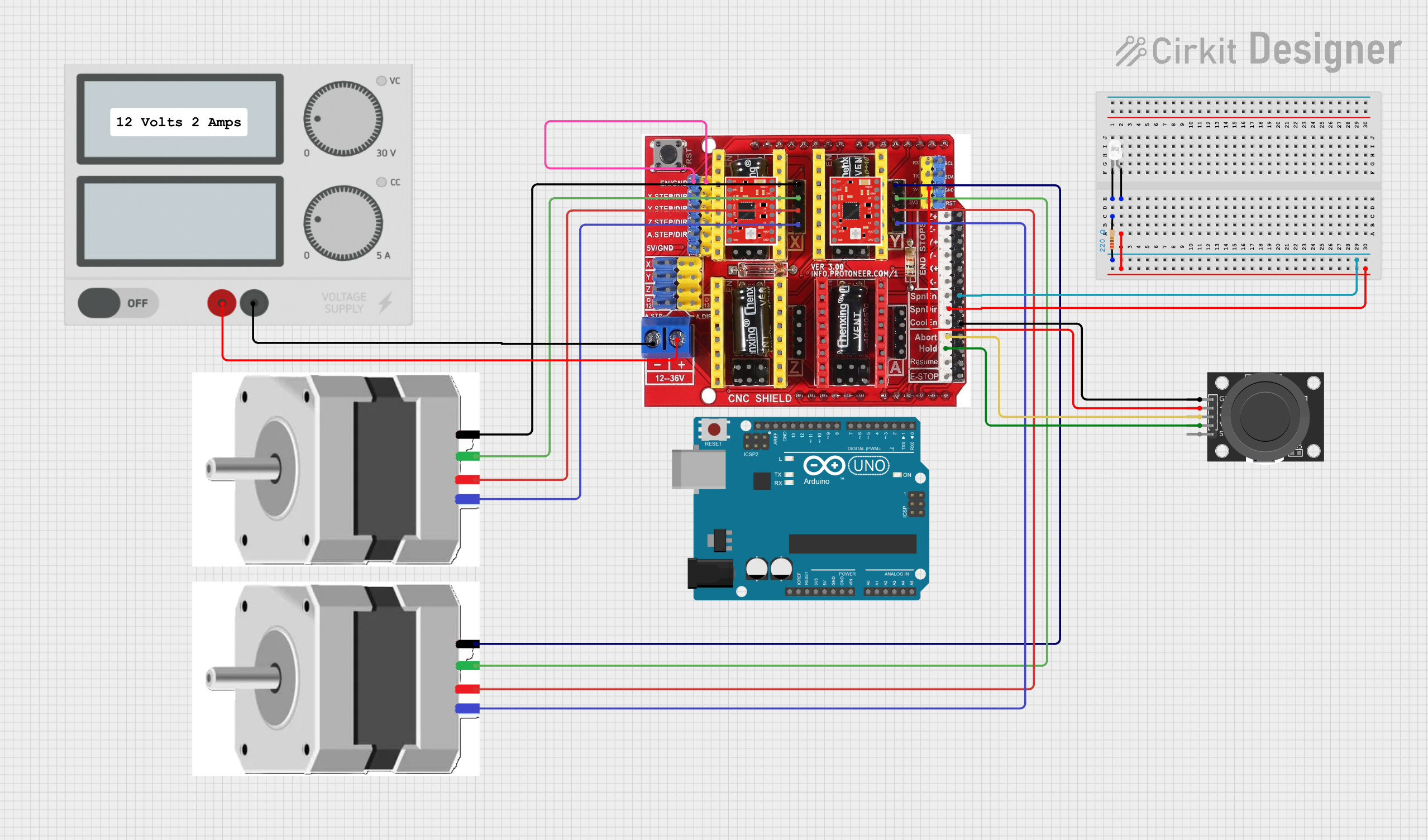

Explore Projects Built with CNC SHIELD V3

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with CNC SHIELD V3

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications and Use Cases

- CNC milling machines

- 3D printers

- Laser engravers and cutters

- Robotics and automation projects

- DIY motion control systems

Technical Specifications

The CNC SHIELD V3 is designed to work seamlessly with Arduino boards, such as the Arduino UNO. Below are the key technical details and pin configurations:

Key Technical Details

- Input Voltage: 12V to 36V (via external power supply for stepper motors)

- Logic Voltage: 5V (provided by the Arduino board)

- Stepper Motor Drivers Supported: A4988, DRV8825, and compatible drivers

- Number of Axes: 4 (X, Y, Z, and A)

- Microstepping Support: Configurable via jumpers (Full, 1/2, 1/4, 1/8, 1/16, etc.)

- Endstop Connections: 6 (2 per axis for X, Y, and Z)

- Spindle/Accessory Control: PWM output for spindle speed control

- Dimensions: 68mm x 53mm (fits standard Arduino UNO footprint)

Pin Configuration and Descriptions

The CNC SHIELD V3 has a straightforward pin layout for easy connectivity. Below is a table describing the key pins and their functions:

| Pin Name | Description |

|---|---|

| X-STEP, Y-STEP, Z-STEP, A-STEP | Step pulse input for X, Y, Z, and A axes (connected to stepper drivers) |

| X-DIR, Y-DIR, Z-DIR, A-DIR | Direction control input for X, Y, Z, and A axes |

| EN (Enable) | Enables or disables all stepper drivers |

| X-END, Y-END, Z-END | Endstop inputs for X, Y, and Z axes (min and max positions) |

| SPN-EN | Spindle enable signal |

| SPN-DIR | Spindle direction control |

| PWM | Pulse-width modulation output for spindle speed control |

| VCC, GND | Power supply pins for logic (5V) |

| Motor Power Input | External power input for stepper motors (12V to 36V) |

Usage Instructions

How to Use the CNC SHIELD V3 in a Circuit

- Connect the Shield to an Arduino UNO:

- Align the CNC SHIELD V3 with the Arduino UNO and carefully plug it into the Arduino's headers.

- Install Stepper Motor Drivers:

- Insert compatible stepper motor drivers (e.g., A4988 or DRV8825) into the designated sockets. Ensure correct orientation by matching the "Enable" pin on the driver with the "EN" pin on the shield.

- Connect Stepper Motors:

- Attach the stepper motors to the X, Y, Z, and A axis motor output terminals.

- Connect Endstops:

- Wire the endstop switches to the X-END, Y-END, and Z-END pins. Use normally open (NO) or normally closed (NC) switches as required.

- Power the Shield:

- Connect an external power supply (12V to 36V) to the motor power input terminal. Ensure the power supply can handle the current requirements of your stepper motors.

- Upload Firmware:

- Install GRBL firmware on the Arduino UNO using the Arduino IDE. GRBL is an open-source motion control firmware compatible with the CNC SHIELD V3.

- Connect to a Computer:

- Use a USB cable to connect the Arduino UNO to your computer. Use software like Universal G-code Sender (UGS) to send G-code commands to the shield.

Important Considerations and Best Practices

- Cooling: Use heatsinks and/or a cooling fan for the stepper motor drivers to prevent overheating during operation.

- Microstepping Configuration: Set the desired microstepping mode using the jumpers under each stepper driver.

- Power Supply: Ensure the external power supply voltage matches the requirements of your stepper motors.

- Firmware Settings: Configure GRBL settings (e.g., steps/mm, max feed rate) to match your machine's specifications.

Example Code for Arduino UNO

Below is an example of how to control a stepper motor connected to the X-axis using the CNC SHIELD V3:

// Example code to control a stepper motor on the X-axis using CNC SHIELD V3

// Ensure GRBL firmware is installed for full functionality

#define X_STEP_PIN 2 // Pin for X-axis step signal

#define X_DIR_PIN 5 // Pin for X-axis direction signal

#define ENABLE_PIN 8 // Pin to enable stepper drivers

void setup() {

pinMode(X_STEP_PIN, OUTPUT); // Set X_STEP_PIN as output

pinMode(X_DIR_PIN, OUTPUT); // Set X_DIR_PIN as output

pinMode(ENABLE_PIN, OUTPUT); // Set ENABLE_PIN as output

digitalWrite(ENABLE_PIN, LOW); // Enable stepper drivers

}

void loop() {

digitalWrite(X_DIR_PIN, HIGH); // Set direction to forward

for (int i = 0; i < 200; i++) { // Move 200 steps (1 revolution for 1.8° stepper)

digitalWrite(X_STEP_PIN, HIGH); // Generate step pulse

delayMicroseconds(500); // Step pulse duration

digitalWrite(X_STEP_PIN, LOW); // End step pulse

delayMicroseconds(500); // Delay between steps

}

delay(1000); // Wait 1 second before reversing direction

digitalWrite(X_DIR_PIN, LOW); // Set direction to reverse

for (int i = 0; i < 200; i++) { // Move 200 steps in reverse

digitalWrite(X_STEP_PIN, HIGH);

delayMicroseconds(500);

digitalWrite(X_STEP_PIN, LOW);

delayMicroseconds(500);

}

delay(1000); // Wait 1 second before repeating

}

Troubleshooting and FAQs

Common Issues and Solutions

Stepper Motors Not Moving:

- Cause: Incorrect wiring or loose connections.

- Solution: Double-check motor connections and ensure the stepper drivers are properly seated.

Overheating Stepper Drivers:

- Cause: Insufficient cooling or excessive current settings.

- Solution: Attach heatsinks and/or a cooling fan. Adjust the current limit on the stepper drivers.

Endstops Not Detected:

- Cause: Incorrect wiring or faulty switches.

- Solution: Verify endstop connections and test the switches with a multimeter.

GRBL Not Responding:

- Cause: Firmware not installed or incorrect settings.

- Solution: Reinstall GRBL firmware and verify configuration settings.

FAQs

Can I use the CNC SHIELD V3 with other Arduino boards?

- Yes, the shield is compatible with Arduino boards that have the same pinout as the Arduino UNO.

What stepper motor drivers are recommended?

- The A4988 and DRV8825 drivers are commonly used and fully compatible with the CNC SHIELD V3.

How do I control the spindle speed?

- Use the PWM pin to send a pulse-width modulation signal to the spindle controller.

Can I use the A-axis for a rotary tool?

- Yes, the A-axis can be configured for a rotary tool or as a clone of another axis.

By following this documentation, you can effectively set up and use the CNC SHIELD V3 for your motion control projects.