How to Use magnetic contactor: Examples, Pinouts, and Specs

Design with magnetic contactor in Cirkit Designer

Design with magnetic contactor in Cirkit DesignerIntroduction

A magnetic contactor is an electromechanical switch used for switching an electrical power circuit. It is essentially a heavy-duty relay with higher current ratings, used for controlling electric motors and other high-power loads in industrial and commercial applications. Contactors come in various sizes and configurations, but they all operate on the same basic principle: an electromagnetic coil is energized to create a magnetic field, which pulls in a set of contacts to make or break the circuit.

Explore Projects Built with magnetic contactor

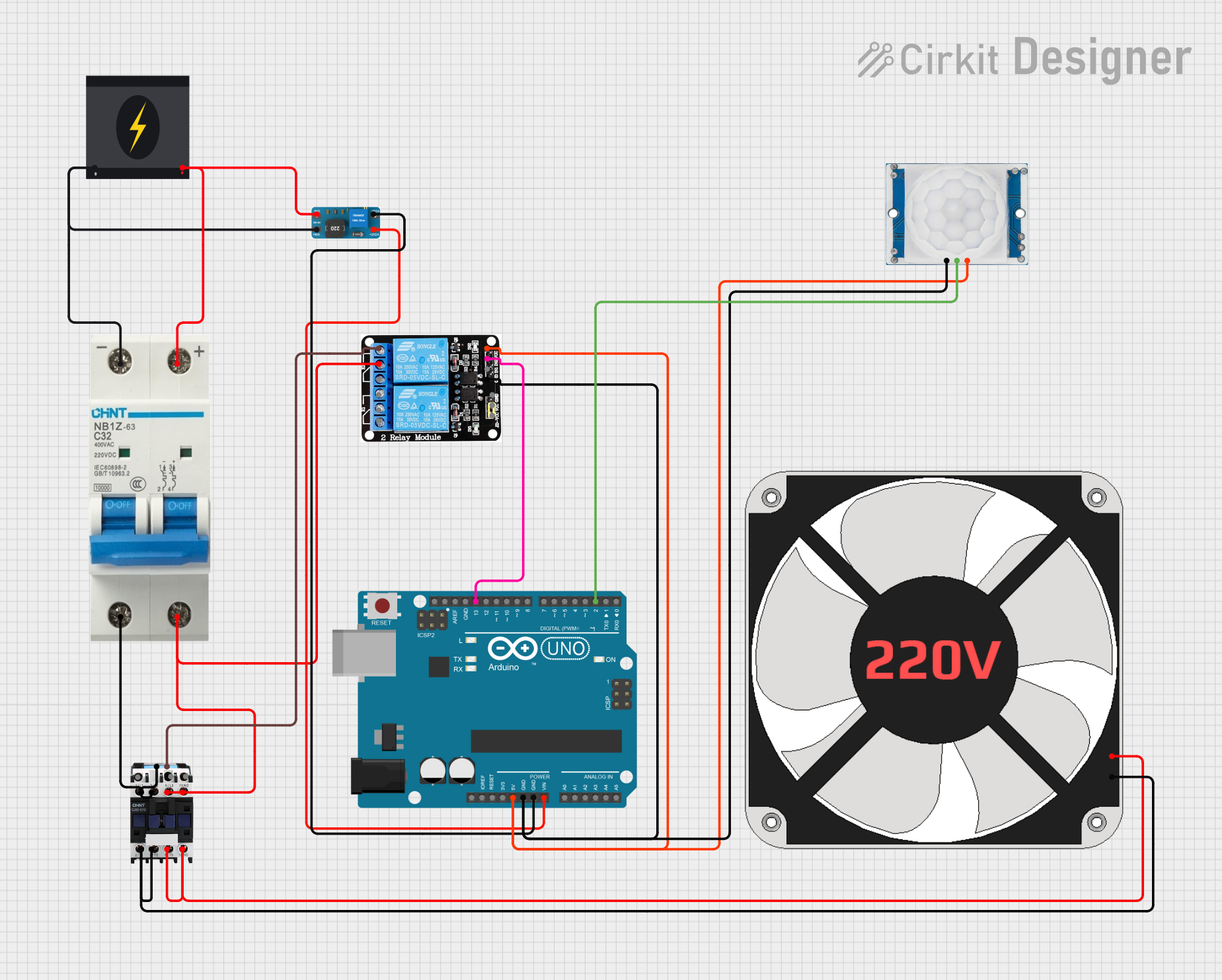

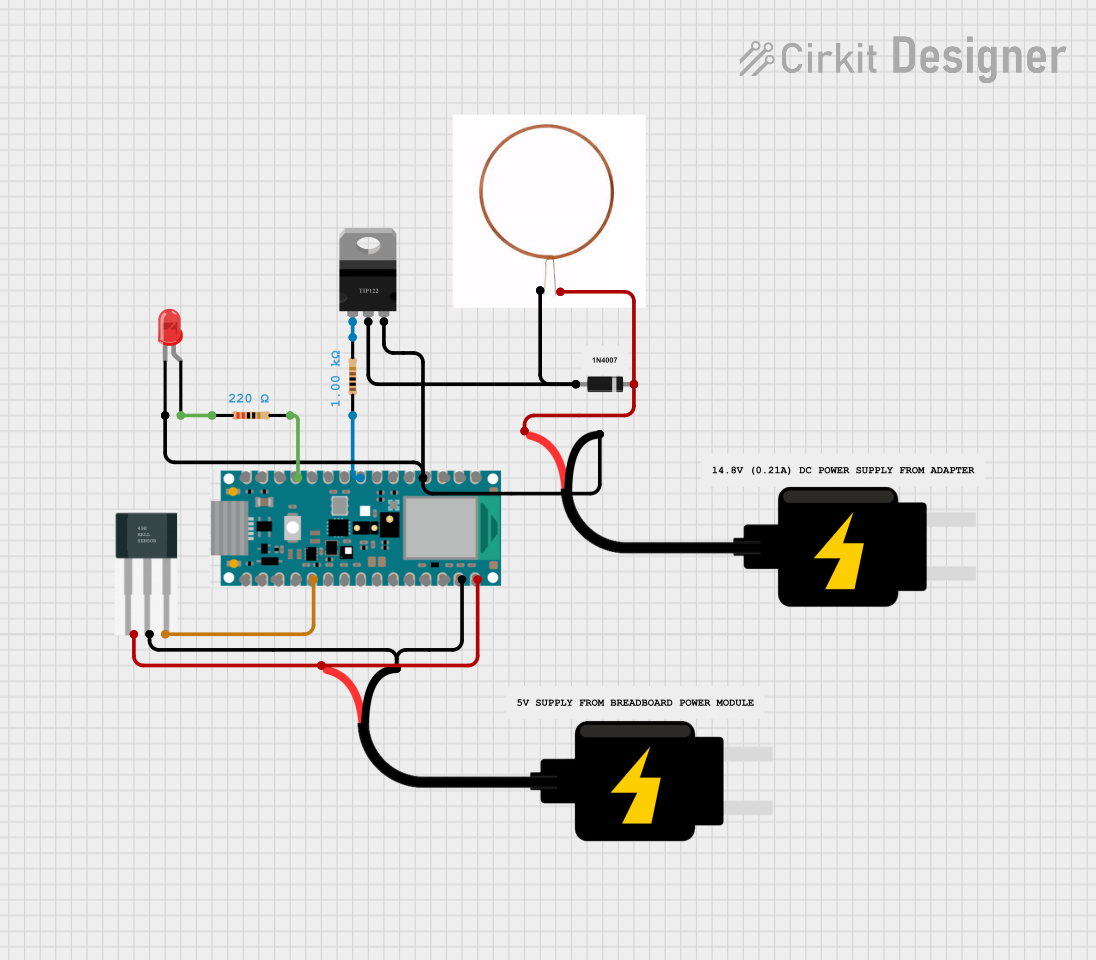

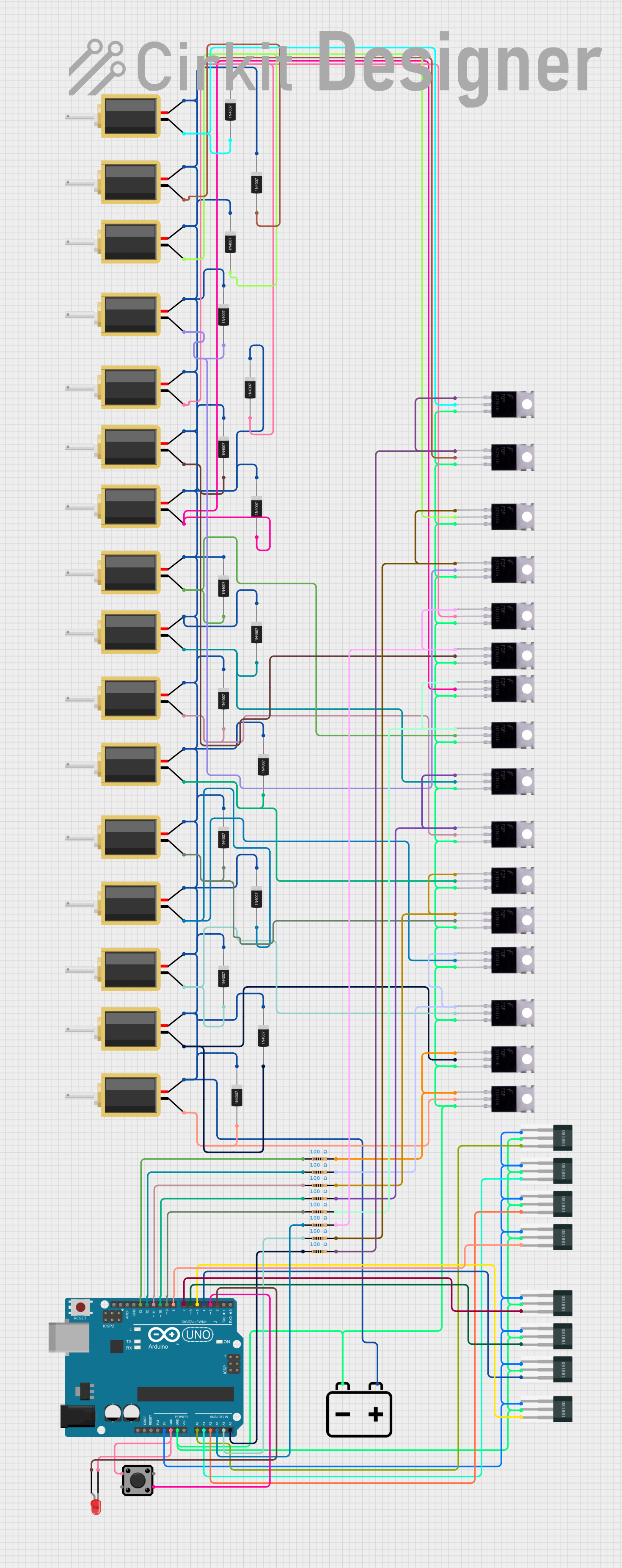

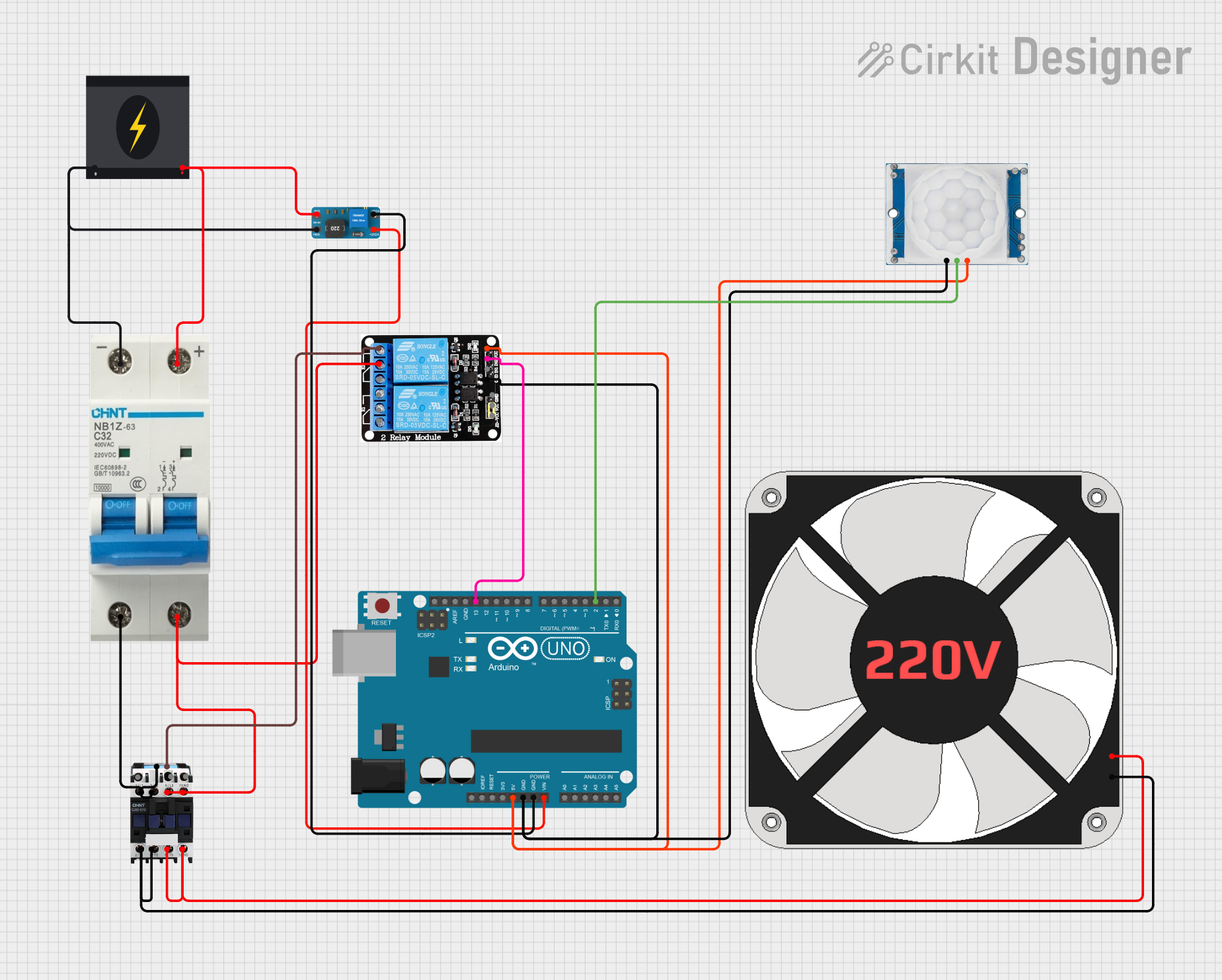

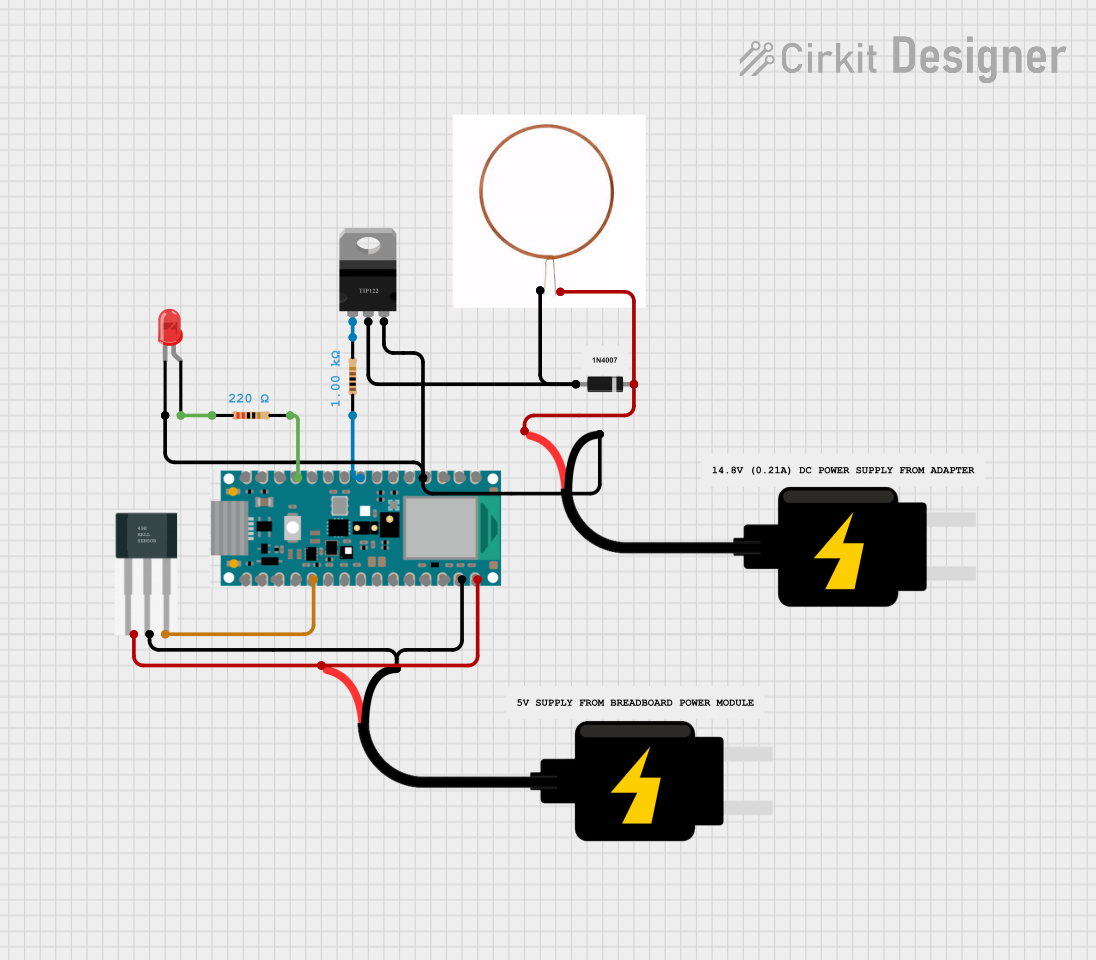

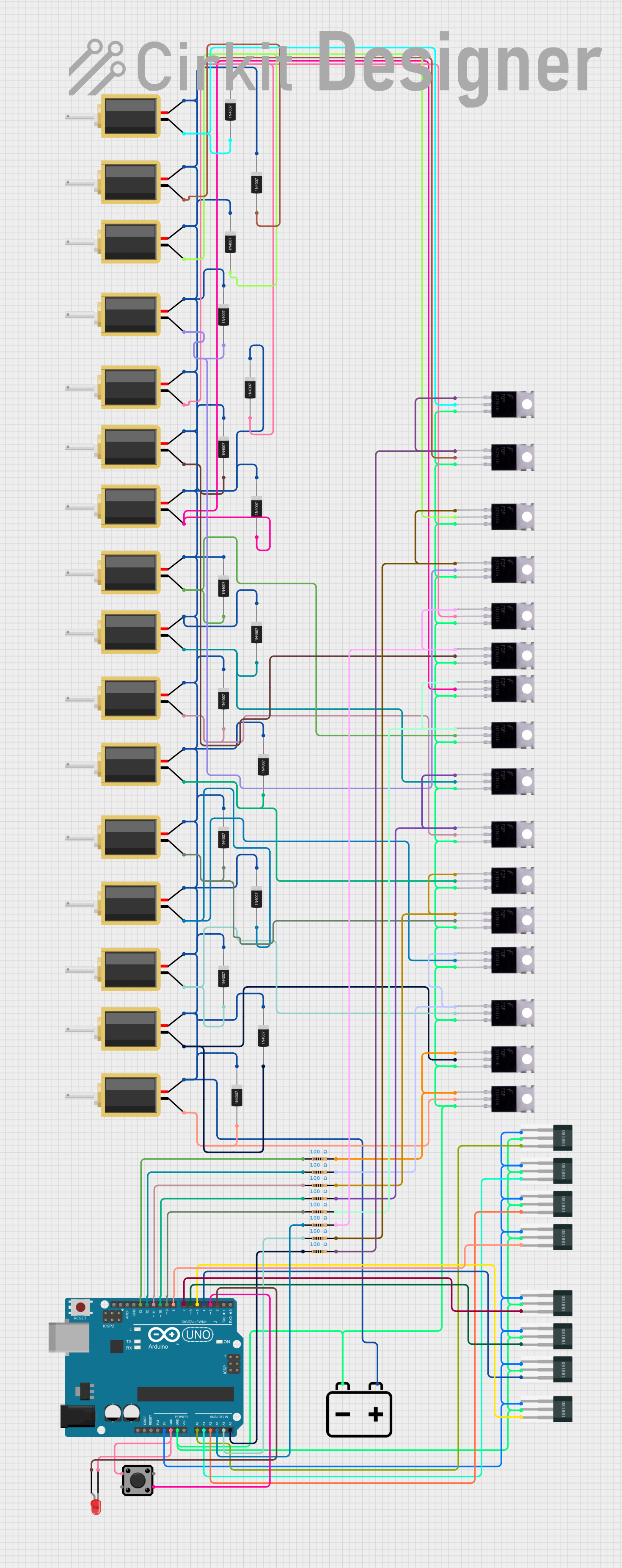

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with magnetic contactor

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications and Use Cases

- Motor control and starting

- Lighting control systems

- Heating systems

- Power supply control

- Automation systems

Technical Specifications

Key Technical Details

- Rated Voltage: The maximum voltage the contactor can handle.

- Rated Current: The maximum current the contactor can conduct.

- Power Ratings: The maximum power the contactor can switch.

- Coil Voltage: The operating voltage of the electromagnetic coil.

- Contact Configuration: Normally open (NO) or normally closed (NC).

Pin Configuration and Descriptions

| Pin Number | Description | Type |

|---|---|---|

| 1 | Coil Positive | Input |

| 2 | Coil Negative | Input |

| 3 | Common Contact | Output |

| 4 | Normally Open (NO) | Output |

| 5 | Normally Closed (NC) | Output |

Usage Instructions

How to Use the Component in a Circuit

- Power Supply: Ensure that the coil is supplied with the correct voltage as per the contactor's specifications.

- Load Connection: Connect the load to the NO or NC contacts depending on whether you want the load to be energized when the coil is activated or not.

- Control Signal: Use a control signal (e.g., from a push button or a control relay) to energize the coil.

Important Considerations and Best Practices

- Always de-energize the circuit before working on it.

- Use appropriate cable sizes for the load to prevent overheating.

- Ensure that the contactor's ratings exceed the requirements of the load.

- Regularly inspect the contactor for signs of wear or damage.

Troubleshooting and FAQs

Common Issues Users Might Face

- Contactor Does Not Operate: Check the coil voltage and control circuit.

- Contacts Not Making Proper Connection: Inspect for dirt or damage on the contacts.

- Overheating: Ensure the load does not exceed the contactor's ratings.

Solutions and Tips for Troubleshooting

- Verify that the control circuit is supplying the correct voltage to the coil.

- Clean or replace contacts if they are dirty or damaged.

- Check for loose connections and tighten them to ensure proper conductivity.

FAQs

Q: Can a magnetic contactor be used for DC applications? A: Yes, but ensure the contactor is rated for DC operation.

Q: How often should a contactor be inspected? A: It depends on the usage, but generally every 6 to 12 months.

Q: What is the difference between a contactor and a relay? A: Contactors are designed for high-power applications, while relays are used for lower power signals.

Example Code for Arduino UNO

// Example code to control a magnetic contactor with an Arduino UNO

// Note: This is a conceptual example. A real-world application may require

// additional components and considerations for safety and functionality.

const int contactorCoilPin = 7; // The digital pin connected to the contactor coil

void setup() {

pinMode(contactorCoilPin, OUTPUT); // Set the contactor coil pin as an output

}

void loop() {

digitalWrite(contactorCoilPin, HIGH); // Energize the coil to close the contacts

delay(5000); // Keep the contacts closed for 5 seconds

digitalWrite(contactorCoilPin, LOW); // De-energize the coil to open the contacts

delay(5000); // Keep the contacts open for 5 seconds

}

Note: The above code assumes the use of a low-voltage contactor that can be directly driven by an Arduino output pin. In practice, contactors require higher currents and voltages to operate, so a driver circuit or an intermediate relay is typically needed to interface with the Arduino. Always consult the contactor's datasheet and ensure all safety protocols are followed when interfacing with high-power devices.