How to Use Motor Driver: Examples, Pinouts, and Specs

Design with Motor Driver in Cirkit Designer

Design with Motor Driver in Cirkit DesignerIntroduction

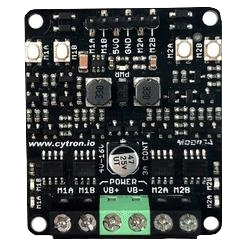

The Maker MDD3A Motor Driver is a versatile and powerful electronic device designed to control and drive the motion of motors. It is capable of handling high current and voltage, making it suitable for a wide range of applications including robotics, industrial automation, and hobbyist projects. The MDD3A allows for precise control over the speed and direction of DC motors, stepper motors, and servo motors.

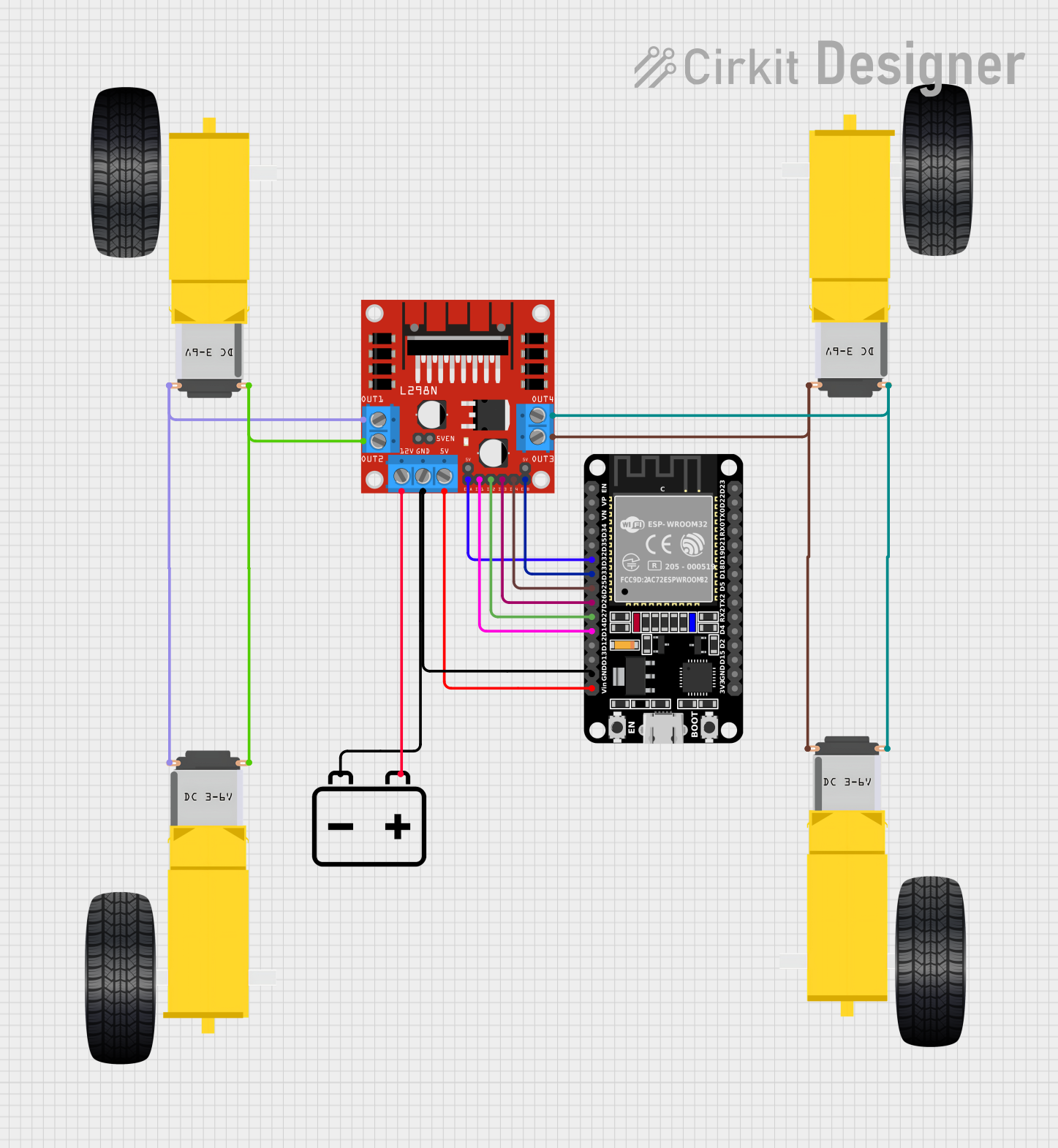

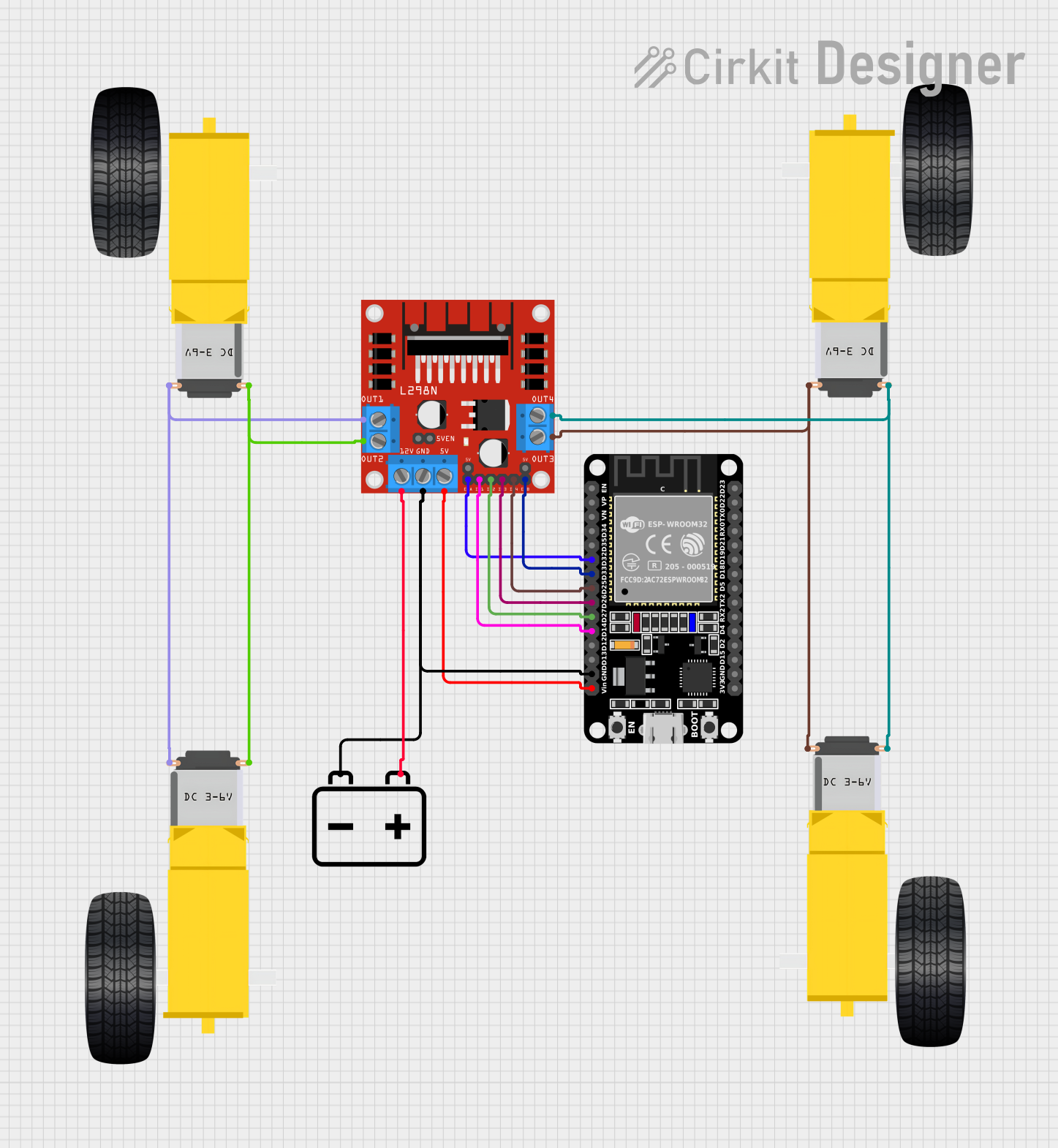

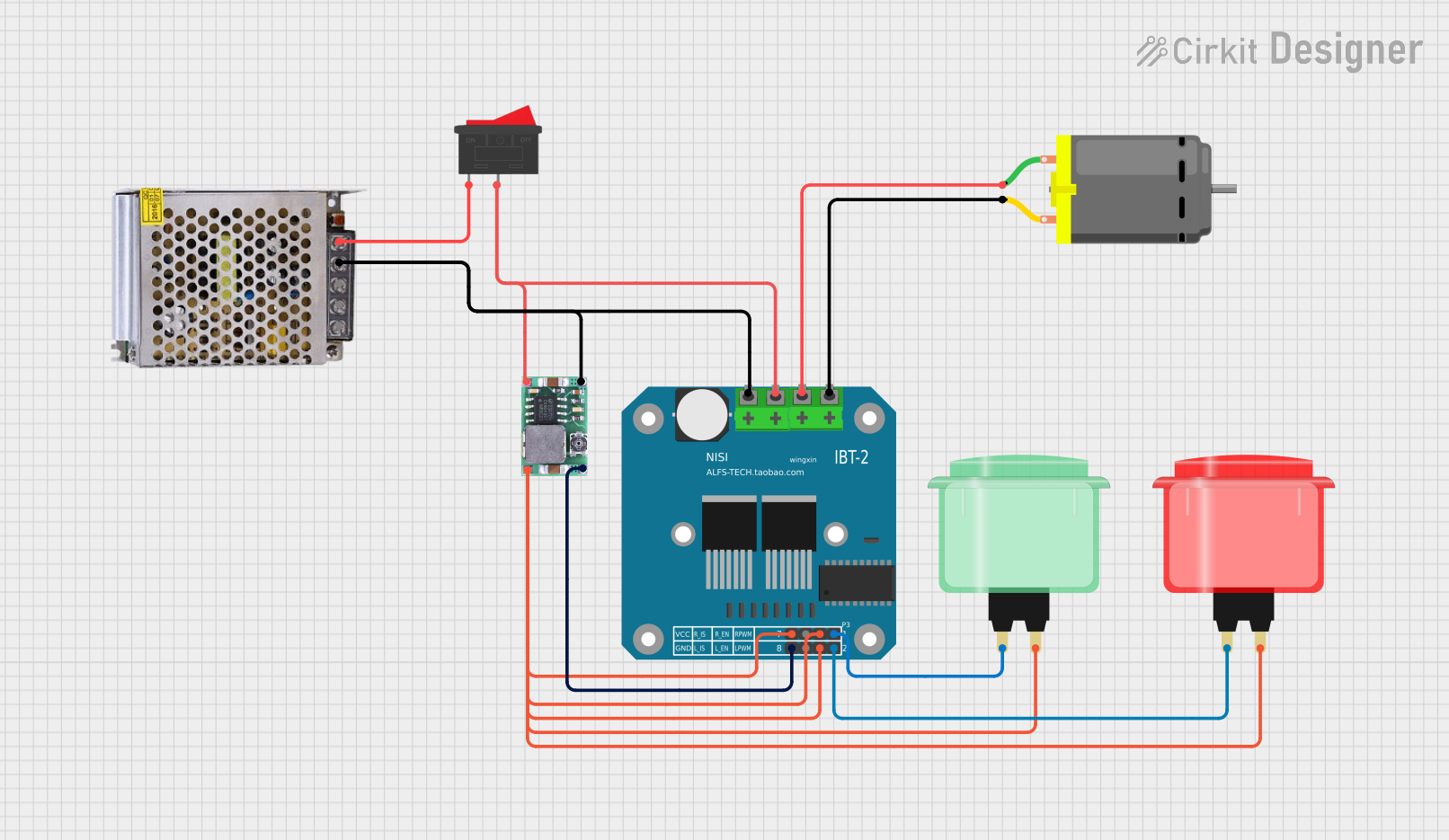

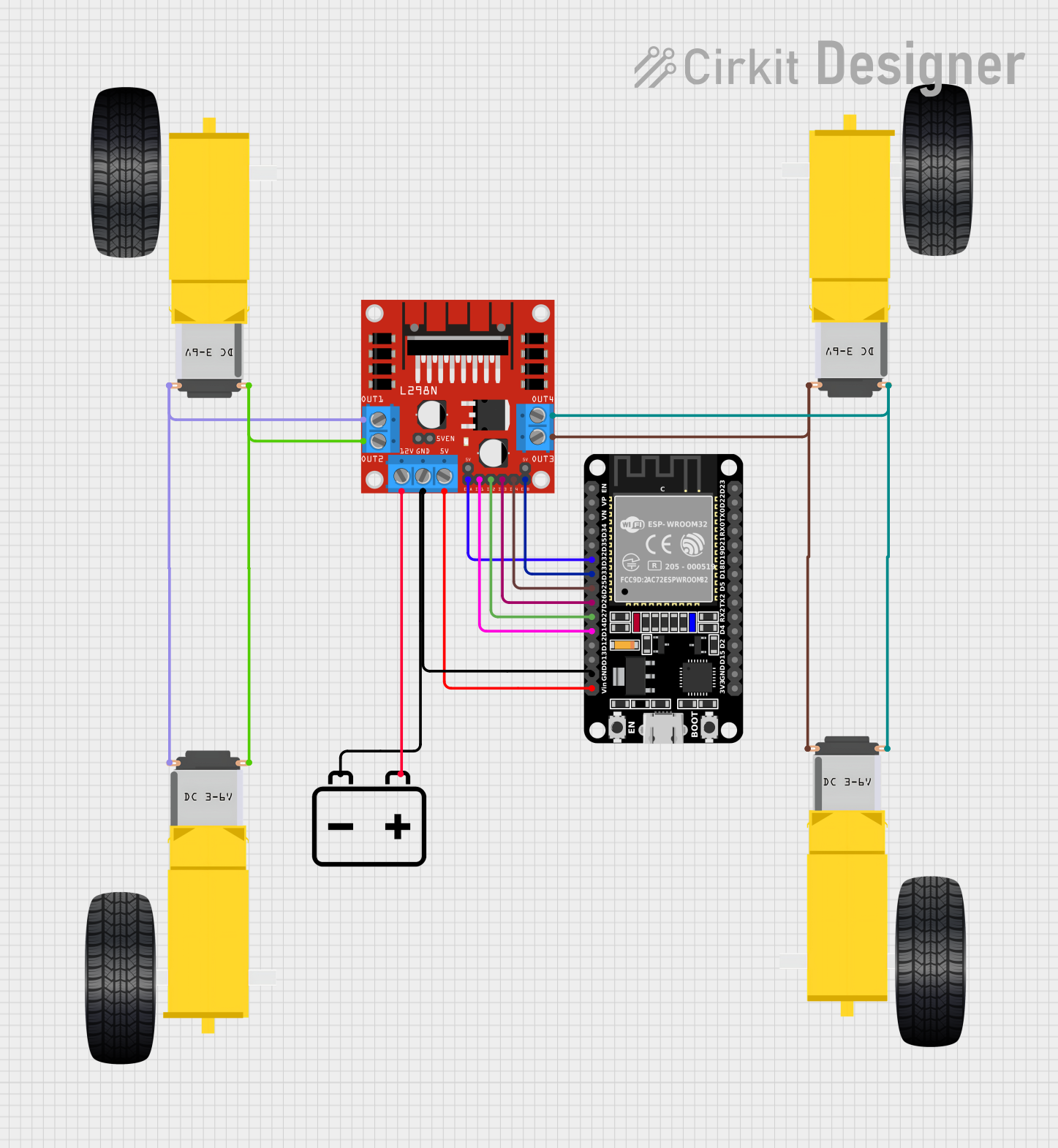

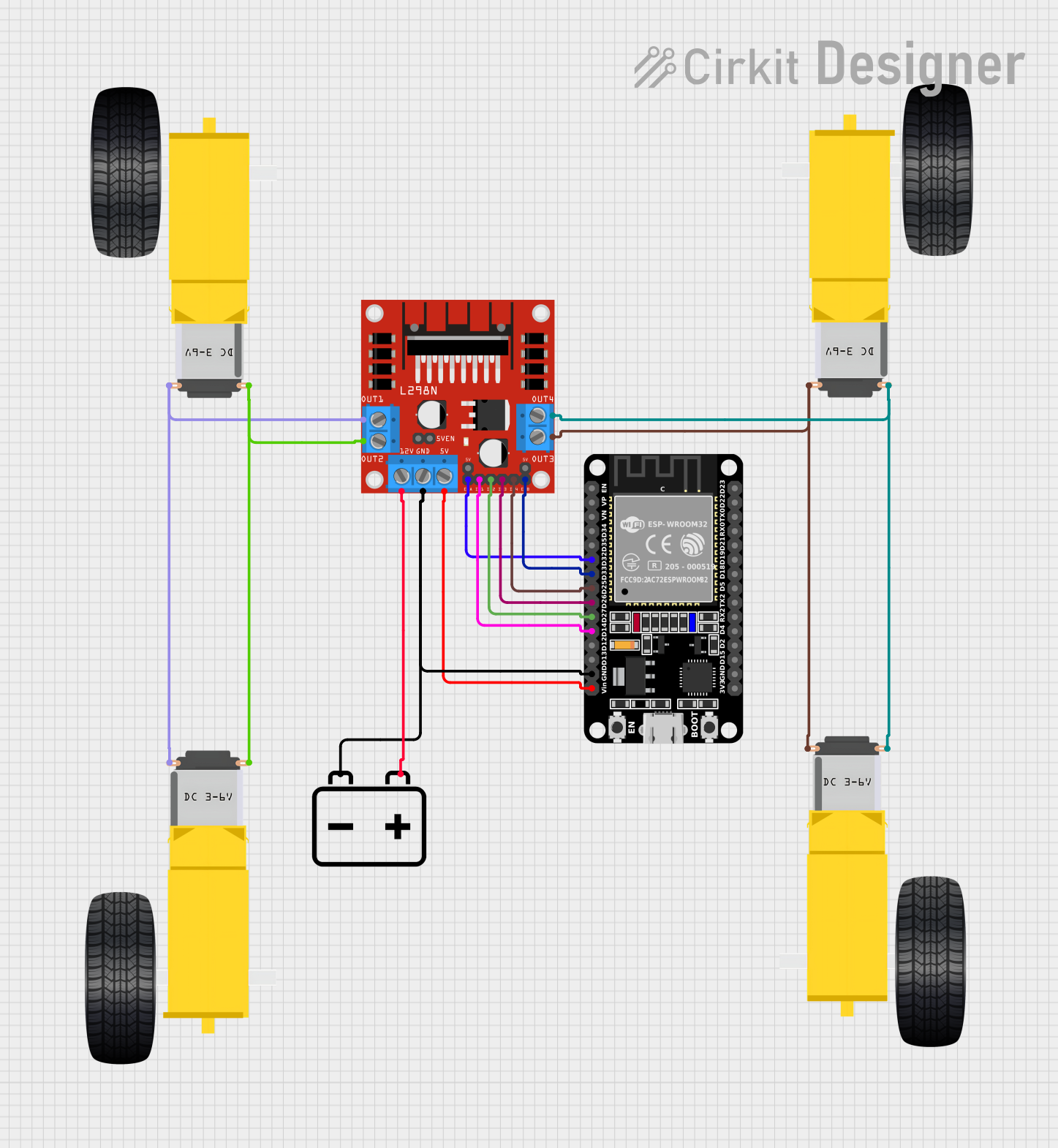

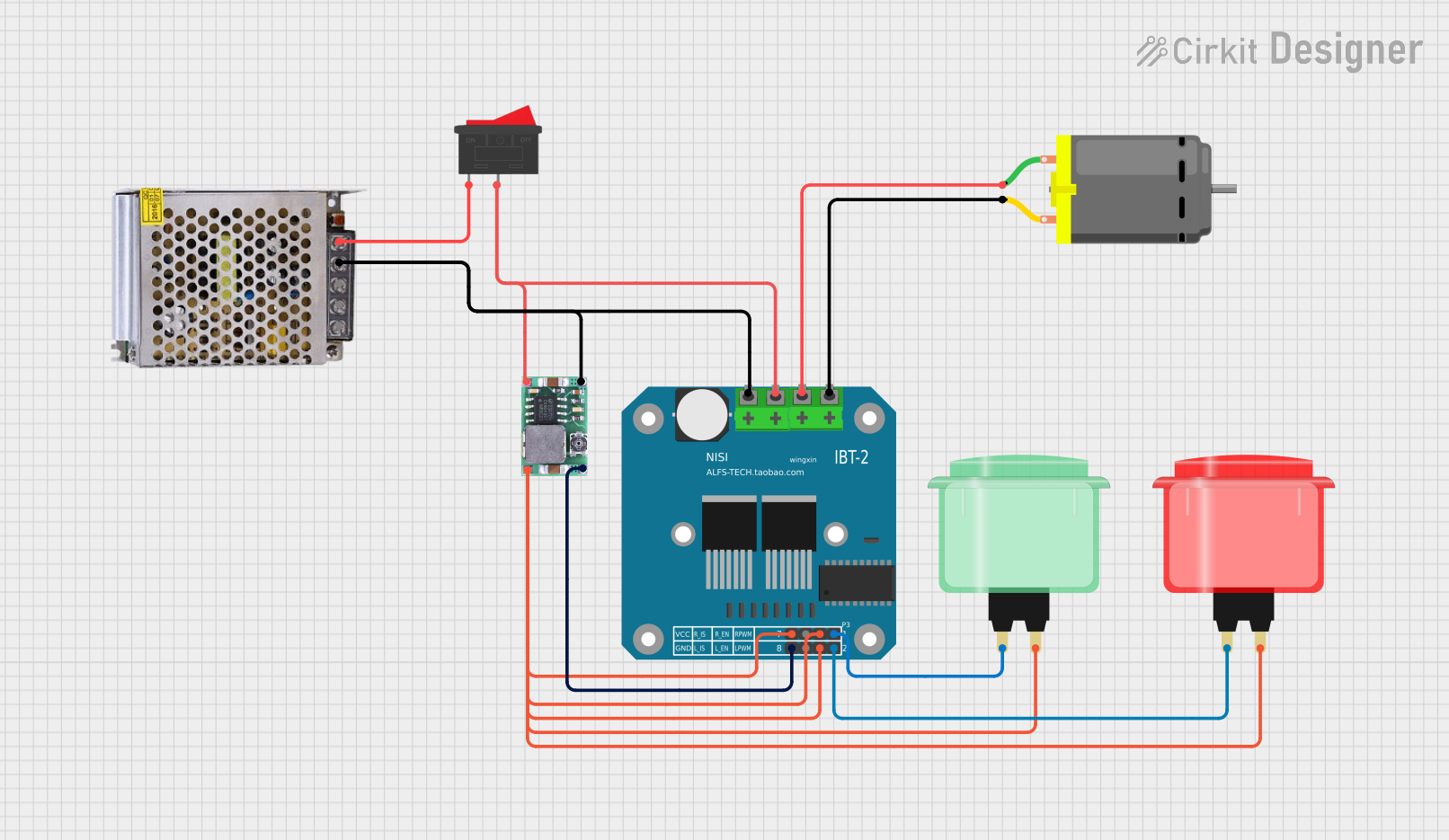

Explore Projects Built with Motor Driver

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with Motor Driver

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications and Use Cases

- Robotics: Driving wheels or actuator motors.

- CNC machines: Controlling stepper motors for precise movements.

- Electric vehicles: Managing propulsion and steering motors.

- Hobby projects: Controlling motors in RC cars, drones, and more.

Technical Specifications

Key Technical Details

- Operating Voltage: 5V to 30V

- Continuous Current: Up to 3A per channel

- Peak Current: Up to 6A per channel (short duration)

- Control Signal Input Voltage: 3.3V to 5V (TTL compatible)

- Control Modes: Direction/Speed (PWM), Forward/Reverse, Brake

Pin Configuration and Descriptions

| Pin Number | Pin Name | Description |

|---|---|---|

| 1 | VM | Motor power supply (5V-30V) |

| 2 | GND | Ground connection |

| 3 | VCC | Logic power supply (5V) |

| 4 | AIN1 | Input control A1 |

| 5 | AIN2 | Input control A2 |

| 6 | PWMA | PWM input for speed control of motor A |

| 7 | STBY | Standby mode (active low) |

| 8 | BIN1 | Input control B1 |

| 9 | BIN2 | Input control B2 |

| 10 | PWMB | PWM input for speed control of motor B |

| 11 | AOUT1 | Motor A output 1 |

| 12 | AOUT2 | Motor A output 2 |

| 13 | BOUT1 | Motor B output 1 |

| 14 | BOUT2 | Motor B output 2 |

Usage Instructions

How to Use the MDD3A in a Circuit

Power Connections:

- Connect the motor power supply to the VM and GND pins.

- Connect the logic power supply to the VCC and GND pins.

Motor Connections:

- Connect your motor to the AOUT1 and AOUT2 pins for motor A, or BOUT1 and BOUT2 for motor B.

Control Signal Connections:

- Connect your control signals (e.g., from an Arduino) to the AIN1, AIN2, PWMA, BIN1, BIN2, and PWMB pins as required.

Enable the Driver:

- Set the STBY pin to high to enable the driver.

Important Considerations and Best Practices

- Ensure that the power supply voltage and current do not exceed the specifications.

- Use appropriate heat sinks if operating near the maximum current rating.

- Always provide a common ground between the logic source (e.g., Arduino) and the motor driver.

- Use PWM signals for speed control and digital signals to set the direction.

Example Code for Arduino UNO

// Define motor driver pins

#define AIN1 2

#define AIN2 3

#define PWMA 5 // PWM pin for speed control

void setup() {

// Set motor driver pins as outputs

pinMode(AIN1, OUTPUT);

pinMode(AIN2, OUTPUT);

pinMode(PWMA, OUTPUT);

}

void loop() {

// Set motor A direction to forward

digitalWrite(AIN1, HIGH);

digitalWrite(AIN2, LOW);

// Set motor A speed to 50%

analogWrite(PWMA, 127); // PWM value between 0 (0%) and 255 (100%)

delay(2000); // Run motor for 2 seconds

// Stop motor A

digitalWrite(AIN1, LOW);

digitalWrite(AIN2, LOW);

delay(1000); // Wait for 1 second

}

Troubleshooting and FAQs

Common Issues

- Motor not running: Check power supply connections, ensure STBY pin is high, and verify control signals.

- Motor running hot: Reduce the load or current, check for proper ventilation and heat sinking.

- Inconsistent motor speed: Ensure PWM signal is stable and within the correct voltage range.

Solutions and Tips for Troubleshooting

- Double-check wiring and connections for any loose or incorrect connections.

- Use a multimeter to verify the voltage levels at the power supply and control pins.

- If using PWM for speed control, ensure the frequency is within the acceptable range for the motor driver.

FAQs

Q: Can I control two motors independently with the MDD3A? A: Yes, the MDD3A has two channels, allowing for independent control of two motors.

Q: What is the maximum frequency for the PWM signal? A: The MDD3A can typically handle PWM frequencies up to 25kHz. Check the datasheet for exact specifications.

Q: Can I use the MDD3A with a microcontroller operating at 3.3V logic? A: Yes, the control signal input voltage is compatible with 3.3V logic levels.

For further assistance, please refer to the Maker MDD3A datasheet or contact technical support.