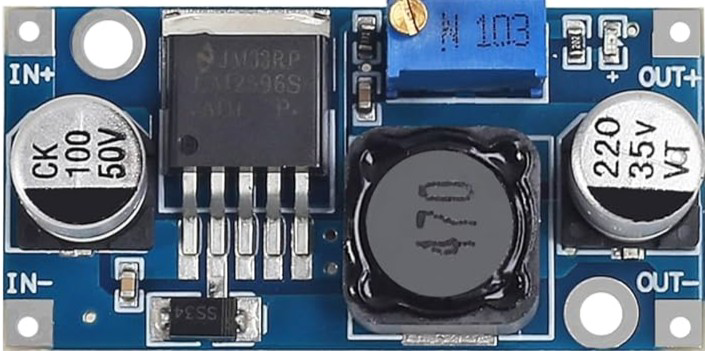

How to Use LM2526 DC-DC Buck Converter: Examples, Pinouts, and Specs

Design with LM2526 DC-DC Buck Converter in Cirkit Designer

Design with LM2526 DC-DC Buck Converter in Cirkit DesignerIntroduction

The LM2526 is a step-down voltage regulator, commonly referred to as a DC-DC buck converter. It efficiently converts a higher input voltage to a lower output voltage, making it ideal for powering devices with lower voltage requirements. This component is widely used in applications such as battery-powered systems, industrial equipment, and embedded systems where energy efficiency and stable voltage regulation are critical.

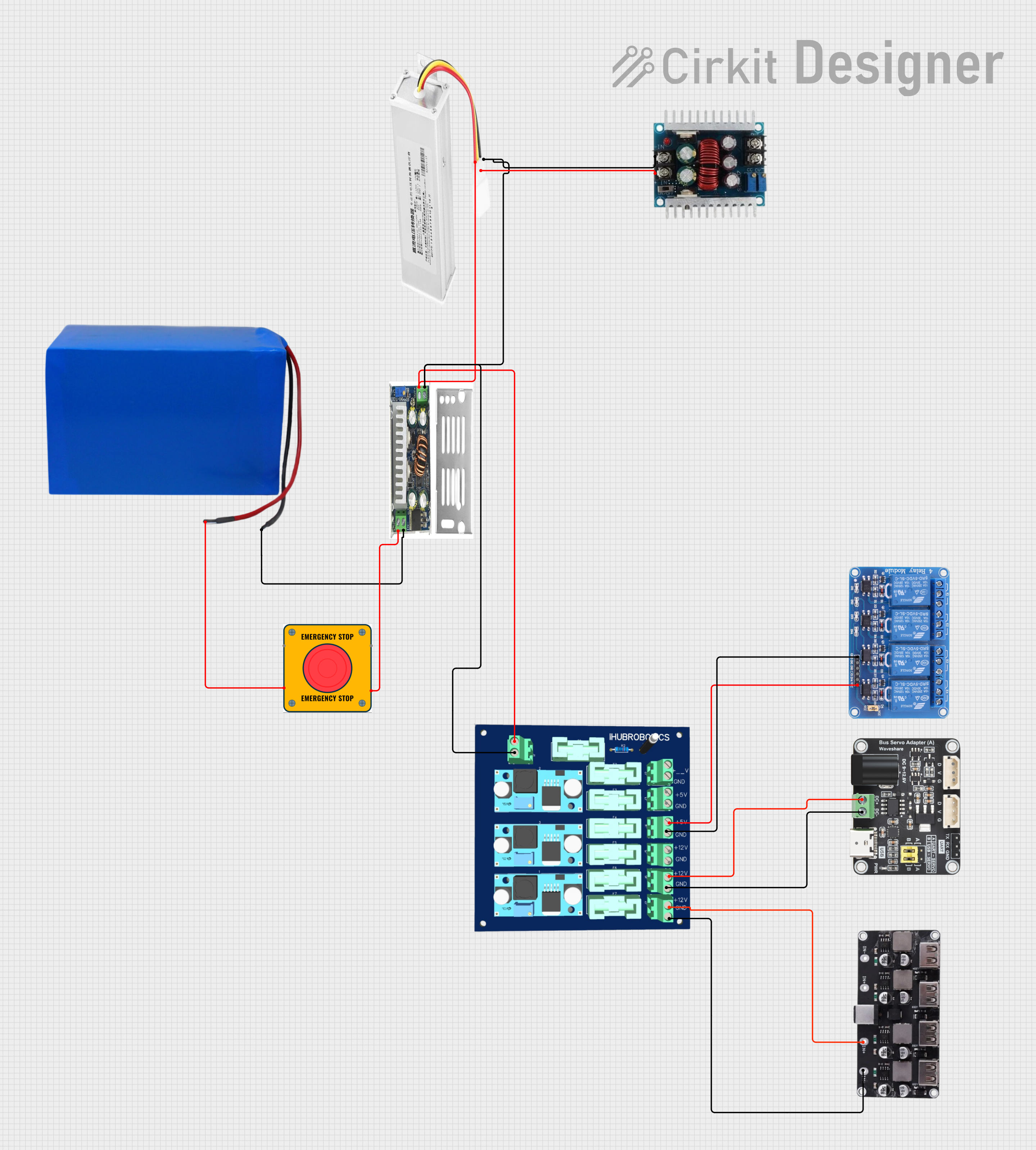

Explore Projects Built with LM2526 DC-DC Buck Converter

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with LM2526 DC-DC Buck Converter

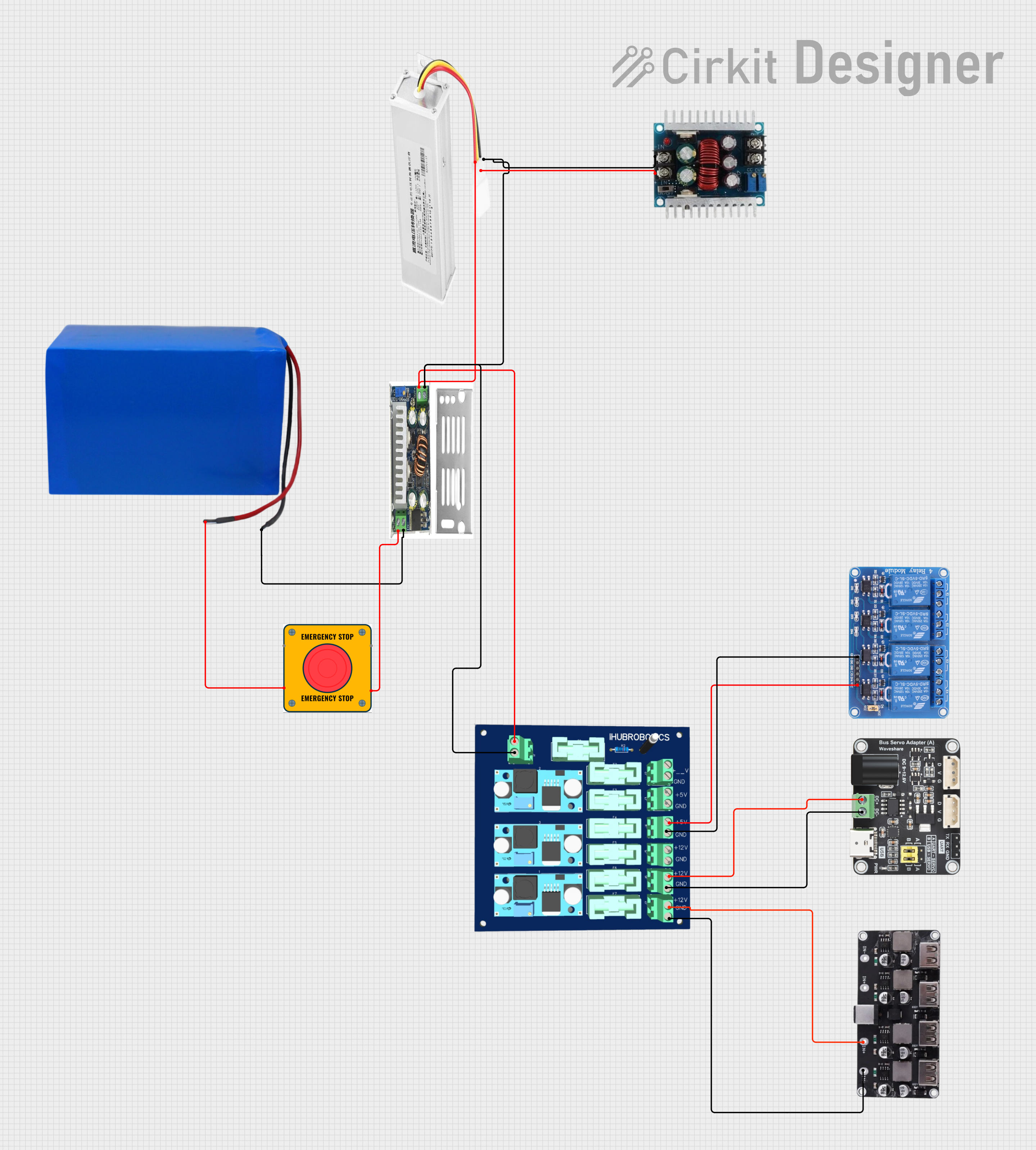

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications:

- Powering microcontrollers and sensors in embedded systems

- Voltage regulation in battery-powered devices

- Industrial automation and control systems

- LED drivers and lighting systems

- Consumer electronics requiring stable low-voltage power

Technical Specifications

Key Technical Details:

- Input Voltage Range: 4.5V to 40V

- Output Voltage Range: Adjustable from 1.23V to 37V

- Output Current: Up to 3A (depending on external components and thermal conditions)

- Efficiency: Up to 90% (depending on load and input/output voltage)

- Switching Frequency: 150 kHz (fixed)

- Thermal Shutdown Protection: Yes

- Overcurrent Protection: Yes

- Package Type: TO-220 or TO-263 (varies by manufacturer)

Pin Configuration and Descriptions:

The LM2526 typically comes in a 5-pin package. Below is the pinout and description:

| Pin Number | Pin Name | Description |

|---|---|---|

| 1 | VIN | Input voltage pin. Connect to the higher input voltage (4.5V to 40V). |

| 2 | GND | Ground pin. Connect to the system ground. |

| 3 | VOUT | Output voltage pin. Provides the regulated lower voltage. |

| 4 | FB | Feedback pin. Used to set the output voltage via an external resistor divider. |

| 5 | EN | Enable pin. Used to turn the converter on or off. |

Usage Instructions

How to Use the LM2526 in a Circuit:

- Input Voltage: Connect the input voltage (VIN) to the VIN pin. Ensure the input voltage is within the specified range (4.5V to 40V).

- Output Voltage Adjustment: Use a resistor divider network connected to the FB pin to set the desired output voltage. The output voltage can be calculated using the formula: [ V_{OUT} = V_{REF} \times \left(1 + \frac{R1}{R2}\right) ] where ( V_{REF} ) is 1.23V (internal reference voltage), and ( R1 ) and ( R2 ) are the resistors in the divider.

- Output Capacitor: Connect a low-ESR capacitor (e.g., 100 µF) to the VOUT pin to stabilize the output voltage.

- Inductor Selection: Choose an inductor with appropriate current rating and inductance value to ensure efficient operation.

- Enable Pin: Connect the EN pin to VIN or a control signal to enable the converter. Pulling this pin low disables the converter.

- Ground Connection: Ensure all ground connections are properly connected to the GND pin.

Important Considerations:

- Thermal Management: Use a heatsink or ensure proper ventilation if the converter operates at high currents.

- Input Capacitor: Place a ceramic capacitor (e.g., 10 µF) close to the VIN pin to reduce input voltage ripple.

- PCB Layout: Minimize the trace length between the VIN, VOUT, and GND pins to reduce noise and improve efficiency.

- Load Regulation: Ensure the load does not exceed the maximum current rating (3A).

Example: Using LM2526 with Arduino UNO

The LM2526 can be used to power an Arduino UNO by stepping down a 12V input to 5V. Below is an example circuit and Arduino code to demonstrate its use.

Circuit:

- Connect a 12V DC power supply to the VIN pin.

- Set the output voltage to 5V using a resistor divider on the FB pin.

- Connect the VOUT pin to the Arduino UNO's 5V pin.

- Connect the GND pin to the Arduino's GND.

Arduino Code:

// Example code to blink an LED using Arduino UNO powered by LM2526

// The LM2526 provides a stable 5V to the Arduino UNO.

const int ledPin = 13; // Built-in LED pin on Arduino UNO

void setup() {

pinMode(ledPin, OUTPUT); // Set the LED pin as an output

}

void loop() {

digitalWrite(ledPin, HIGH); // Turn the LED on

delay(1000); // Wait for 1 second

digitalWrite(ledPin, LOW); // Turn the LED off

delay(1000); // Wait for 1 second

}

Troubleshooting and FAQs

Common Issues and Solutions:

No Output Voltage:

- Cause: The EN pin is not connected or is pulled low.

- Solution: Ensure the EN pin is connected to VIN or a high logic level.

Output Voltage is Incorrect:

- Cause: Incorrect resistor values in the feedback network.

- Solution: Recalculate the resistor values using the output voltage formula and verify connections.

Excessive Heat:

- Cause: High current load or insufficient cooling.

- Solution: Use a heatsink or improve ventilation. Ensure the load does not exceed 3A.

High Output Ripple:

- Cause: Insufficient output capacitance or poor PCB layout.

- Solution: Use a low-ESR capacitor and minimize trace lengths.

Converter Not Starting:

- Cause: Input voltage is below 4.5V.

- Solution: Verify the input voltage and ensure it is within the specified range.

FAQs:

Q: Can the LM2526 be used for 3.3V output?

- A: Yes, the LM2526 can be configured for 3.3V output by selecting appropriate resistor values for the feedback network.

Q: What is the maximum efficiency of the LM2526?

- A: The LM2526 can achieve up to 90% efficiency, depending on the input/output voltage and load conditions.

Q: Can I use the LM2526 without an inductor?

- A: No, an inductor is essential for the buck converter to function properly and maintain efficiency.

Q: Is the LM2526 suitable for battery-powered applications?

- A: Yes, the LM2526 is highly efficient and suitable for battery-powered systems where energy conservation is important.