How to Use Engine with gearbox 6 VDC 200rpm up: Examples, Pinouts, and Specs

Design with Engine with gearbox 6 VDC 200rpm up in Cirkit Designer

Design with Engine with gearbox 6 VDC 200rpm up in Cirkit DesignerIntroduction

The Engine with Gearbox 6 VDC 200rpm is a compact and efficient motor designed for applications requiring low-speed, high-torque output. This motor operates on a 6-volt direct current (VDC) supply and is equipped with a gearbox that reduces the motor's speed to 200 revolutions per minute (rpm). The integrated gearbox enhances the torque output, making it suitable for driving mechanical systems that require precise and powerful motion.

Explore Projects Built with Engine with gearbox 6 VDC 200rpm up

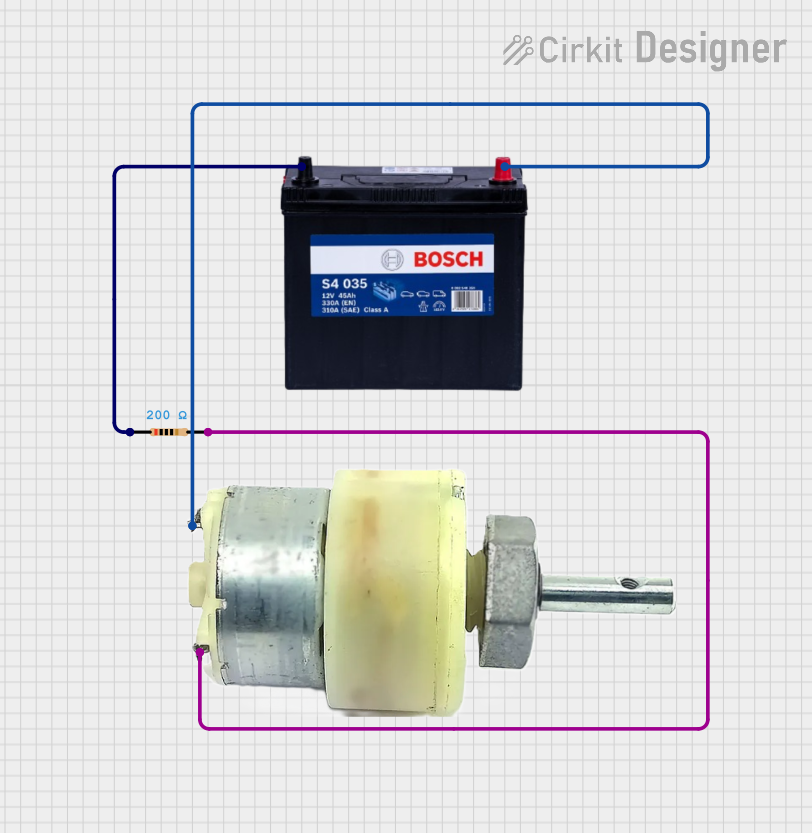

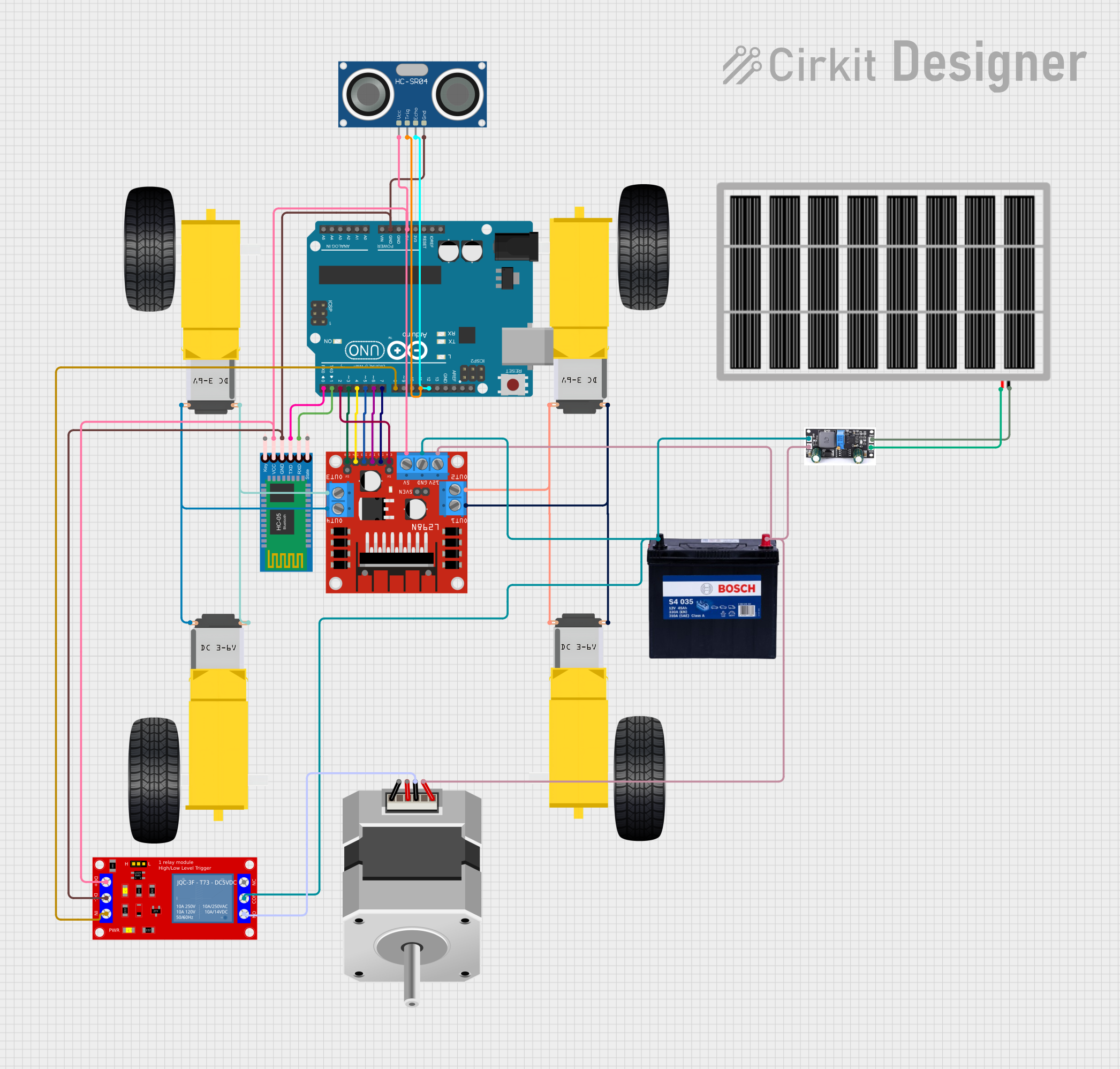

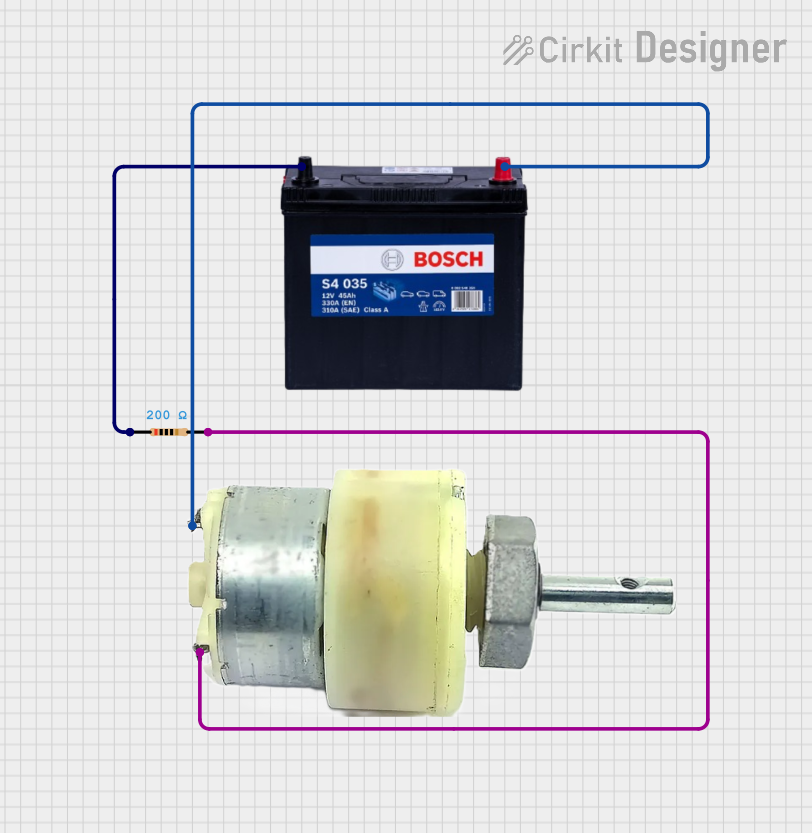

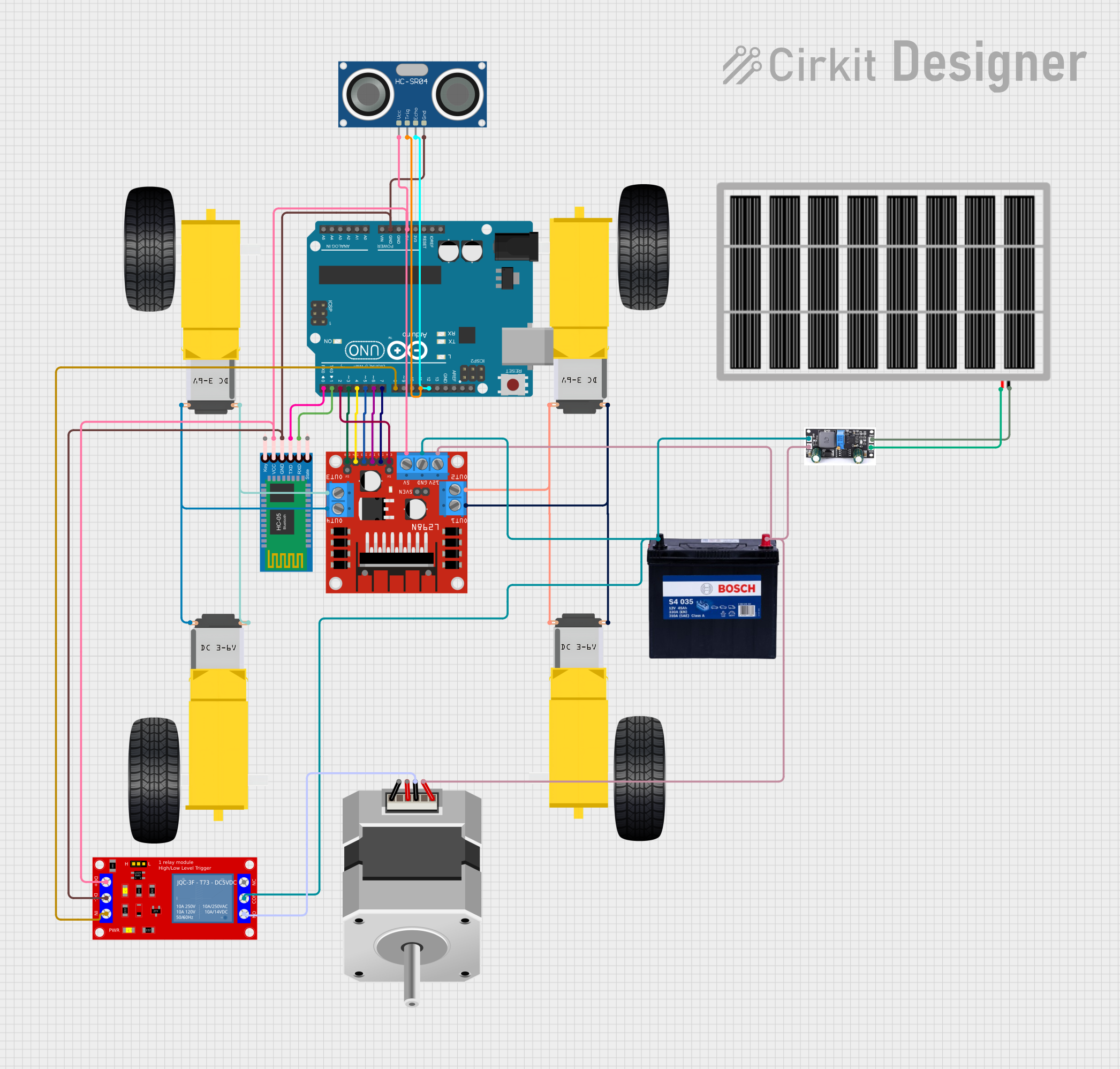

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with Engine with gearbox 6 VDC 200rpm up

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications and Use Cases

- Robotics: Driving wheels, arms, or other moving parts in robots.

- Conveyor systems: Powering small conveyor belts for material handling.

- Automated mechanisms: Used in vending machines, door openers, and other automated systems.

- DIY projects: Ideal for hobbyists building custom mechanical systems or vehicles.

Technical Specifications

Below are the key technical details of the Engine with Gearbox 6 VDC 200rpm:

| Parameter | Specification |

|---|---|

| Operating Voltage | 6 VDC |

| No-load Speed | 200 rpm |

| Gearbox Ratio | Typically 1:30 (varies by model) |

| Stall Torque | ~2.5 kg·cm (varies by load) |

| No-load Current | ~150 mA |

| Stall Current | ~1.2 A |

| Shaft Diameter | 6 mm |

| Motor Dimensions | ~35 mm x 25 mm x 20 mm |

| Weight | ~50 g |

Pin Configuration and Descriptions

The motor typically has two terminals for electrical connections:

| Pin/Terminal | Description |

|---|---|

| Positive (+) | Connect to the positive terminal of the power supply. |

| Negative (-) | Connect to the negative terminal of the power supply. |

Note: The motor's direction of rotation can be reversed by swapping the polarity of the connections.

Usage Instructions

How to Use the Component in a Circuit

- Power Supply: Connect the motor to a 6 VDC power source. Ensure the power supply can provide sufficient current (at least 1.2 A for stall conditions).

- Polarity: Connect the positive terminal of the power supply to the motor's positive terminal and the negative terminal to the motor's negative terminal.

- Direction Control: To reverse the motor's rotation, swap the positive and negative connections.

- Motor Driver: For precise control (e.g., speed or direction), use a motor driver such as the L298N or L293D. These drivers allow integration with microcontrollers like Arduino.

Important Considerations and Best Practices

- Current Limiting: Use a current-limiting resistor or a motor driver with built-in protection to prevent damage during stall conditions.

- Heat Management: Prolonged operation at high torque may cause the motor to heat up. Allow for adequate cooling or limit continuous operation.

- Load Matching: Ensure the load does not exceed the motor's torque rating to avoid stalling or damage.

- Power Supply: Use a stable and regulated 6 VDC power source to ensure consistent performance.

Example: Connecting to an Arduino UNO

To control the motor with an Arduino UNO, you can use an L298N motor driver. Below is an example code to control the motor's speed and direction:

// Example code to control a 6 VDC motor with gearbox using Arduino and L298N

// Define motor control pins

const int ENA = 9; // PWM pin for speed control

const int IN1 = 8; // Direction control pin 1

const int IN2 = 7; // Direction control pin 2

void setup() {

// Set motor control pins as outputs

pinMode(ENA, OUTPUT);

pinMode(IN1, OUTPUT);

pinMode(IN2, OUTPUT);

}

void loop() {

// Rotate motor in one direction

digitalWrite(IN1, HIGH); // Set IN1 high

digitalWrite(IN2, LOW); // Set IN2 low

analogWrite(ENA, 128); // Set speed (0-255, 128 = ~50% speed)

delay(3000); // Run for 3 seconds

// Stop the motor

analogWrite(ENA, 0); // Set speed to 0

delay(1000); // Wait for 1 second

// Rotate motor in the opposite direction

digitalWrite(IN1, LOW); // Set IN1 low

digitalWrite(IN2, HIGH); // Set IN2 high

analogWrite(ENA, 128); // Set speed (0-255, 128 = ~50% speed)

delay(3000); // Run for 3 seconds

// Stop the motor

analogWrite(ENA, 0); // Set speed to 0

delay(1000); // Wait for 1 second

}

Note: Ensure the L298N motor driver is powered with a 6 VDC supply and properly connected to the motor and Arduino.

Troubleshooting and FAQs

Common Issues and Solutions

Motor Not Spinning

- Cause: Insufficient power supply or incorrect wiring.

- Solution: Verify the power supply voltage and current. Check the wiring for proper connections.

Motor Spins in the Wrong Direction

- Cause: Polarity of the connections is reversed.

- Solution: Swap the positive and negative connections to reverse the direction.

Motor Overheating

- Cause: Prolonged operation at high torque or insufficient cooling.

- Solution: Reduce the load or provide adequate cooling. Avoid continuous operation at maximum torque.

Motor Stalls Under Load

- Cause: Load exceeds the motor's torque rating.

- Solution: Reduce the load or use a motor with a higher torque rating.

Noisy Operation

- Cause: Gearbox lubrication is insufficient or worn out.

- Solution: Apply appropriate lubrication to the gearbox if possible.

FAQs

Can I use a higher voltage power supply?

- No, using a voltage higher than 6 VDC may damage the motor or gearbox.

Can this motor be used for precise positioning?

- This motor is not designed for precise positioning. For such applications, consider using a stepper motor or a servo motor.

What is the maximum load this motor can handle?

- The motor can handle loads up to its stall torque (~2.5 kg·cm). Exceeding this may cause stalling or damage.

Can I control this motor without a motor driver?

- Yes, but a motor driver is recommended for better control and protection. Directly connecting the motor to a power supply allows only basic on/off operation.

This documentation provides all the necessary details to effectively use the Engine with Gearbox 6 VDC 200rpm in your projects.