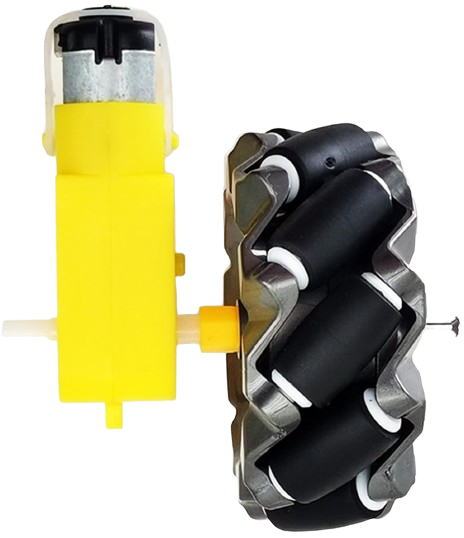

How to Use motor and wheels: Examples, Pinouts, and Specs

Design with motor and wheels in Cirkit Designer

Design with motor and wheels in Cirkit DesignerIntroduction

- The motor and wheels assembly is a fundamental component for building mobile robotic systems. It typically consists of a DC motor or stepper motor attached to wheels, enabling movement and navigation. This setup is widely used in robotics, remote-controlled vehicles, and automation projects.

- Common applications include robotic cars, conveyor systems, automated guided vehicles (AGVs), and educational robotics kits.

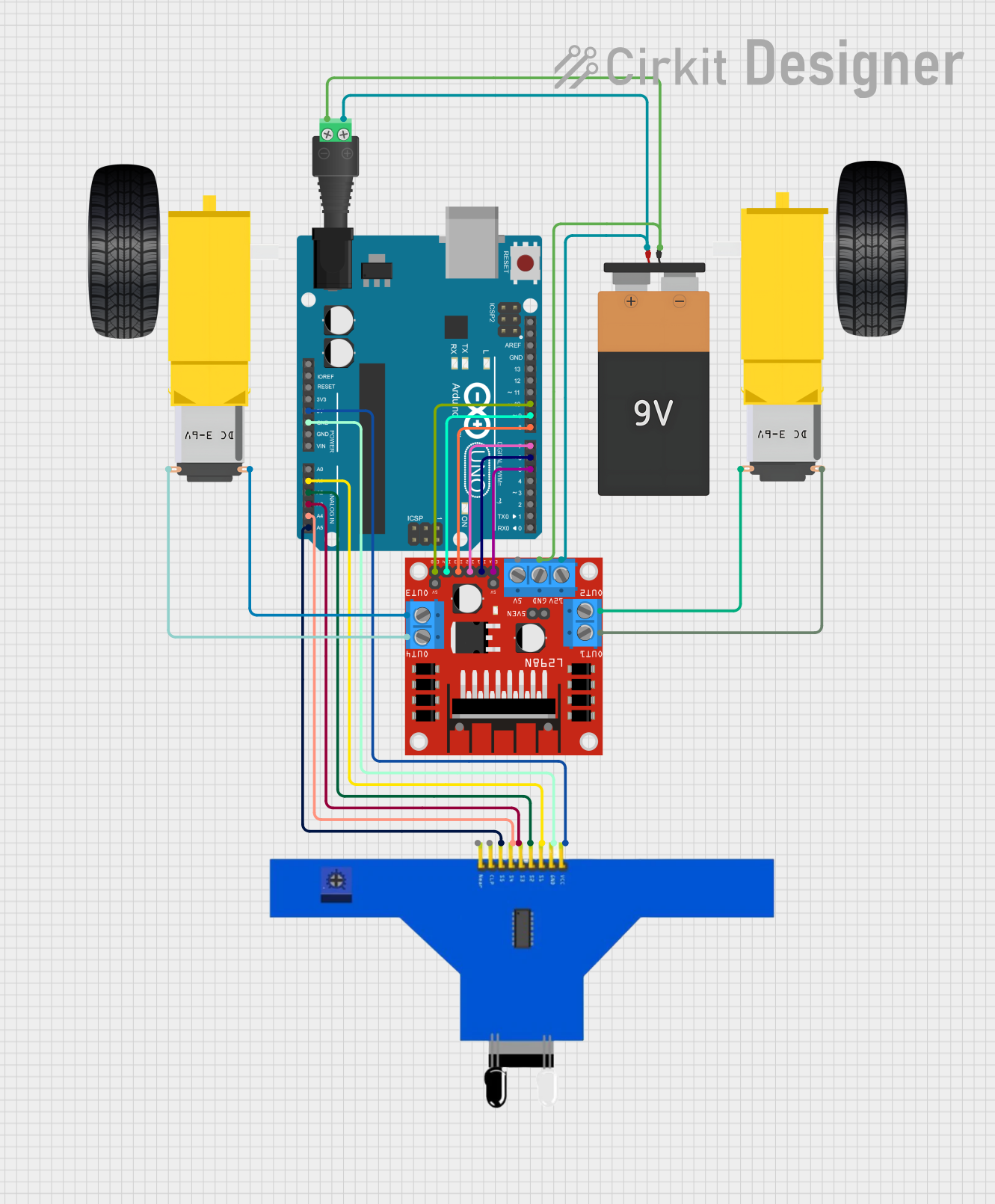

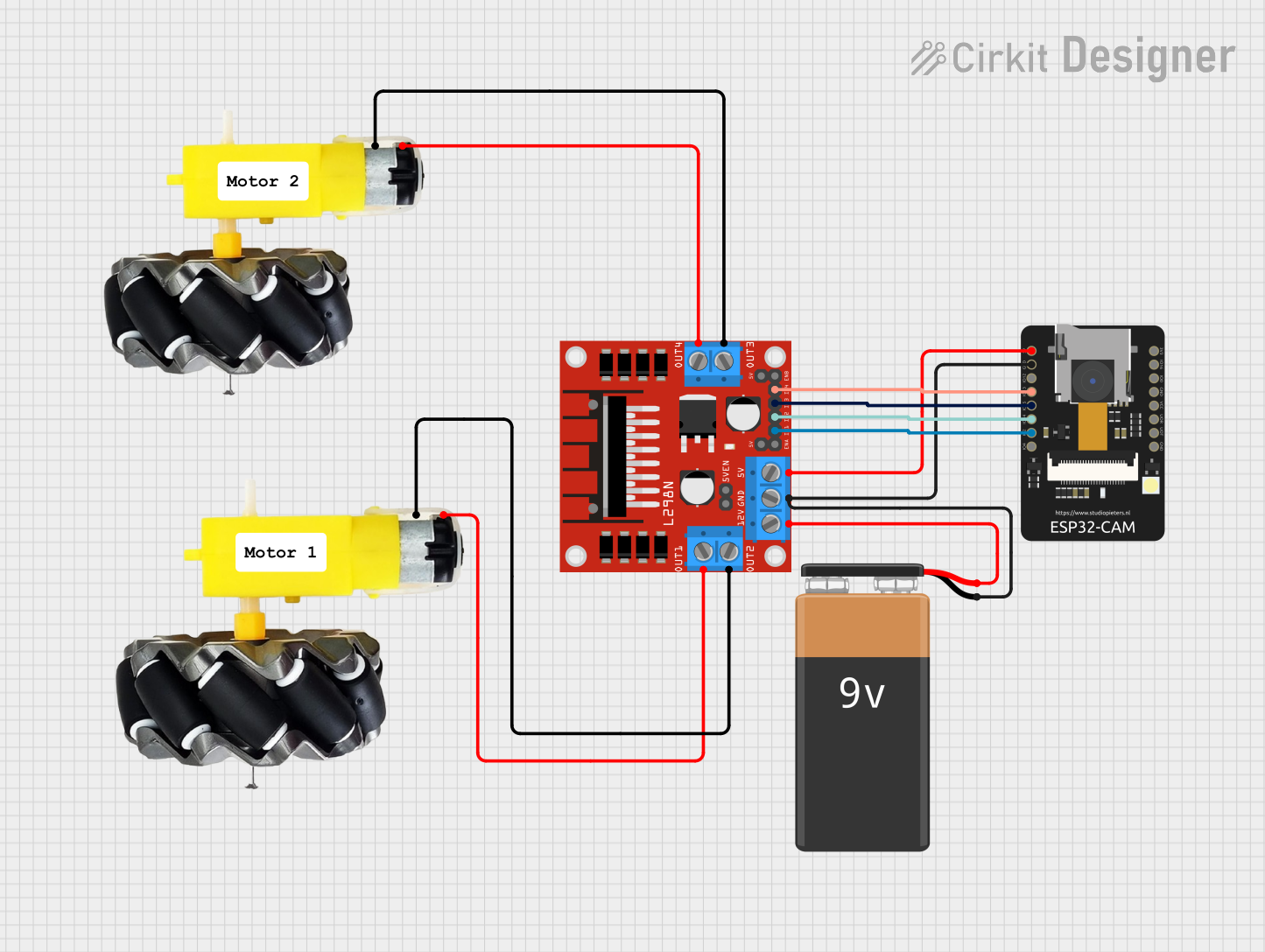

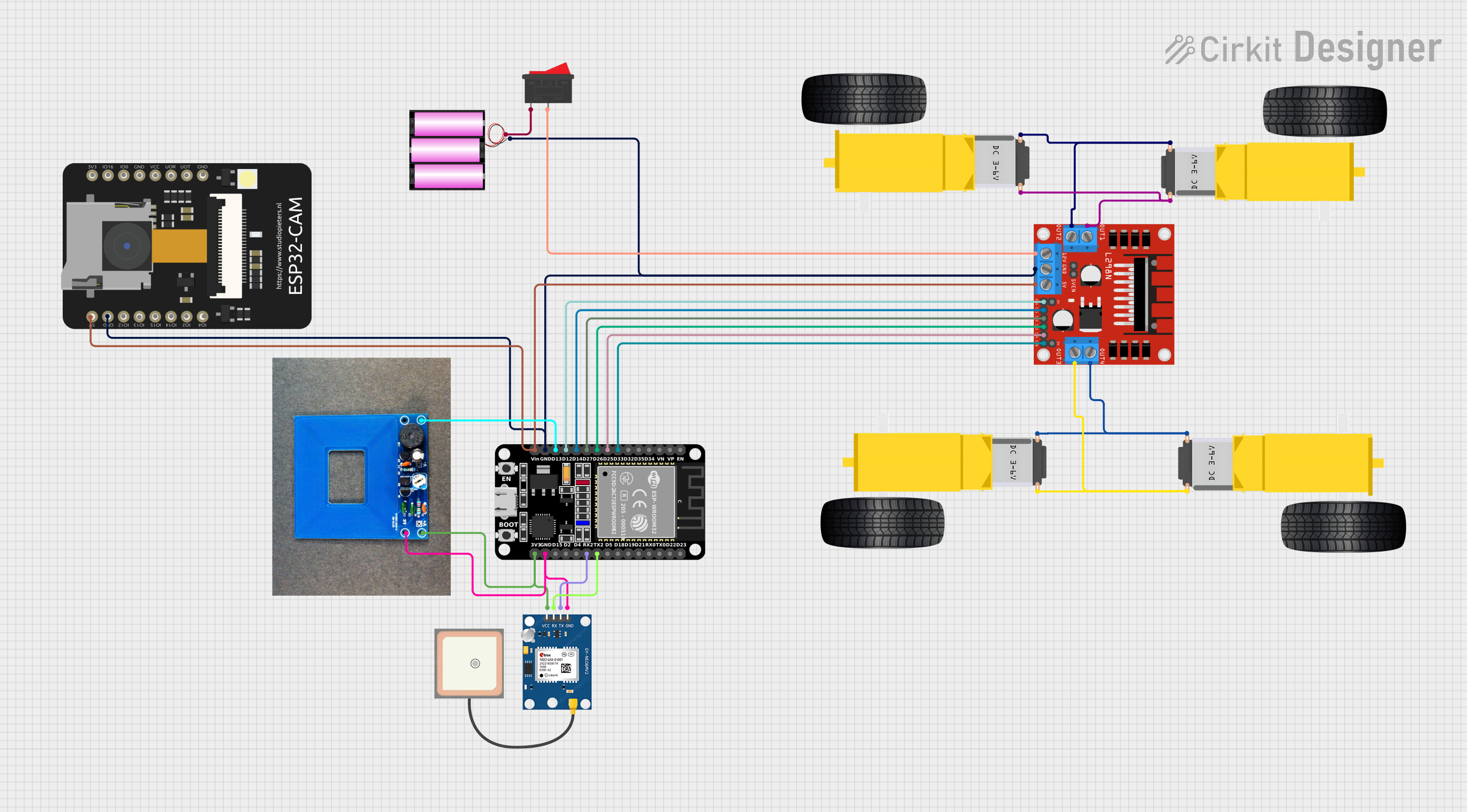

Explore Projects Built with motor and wheels

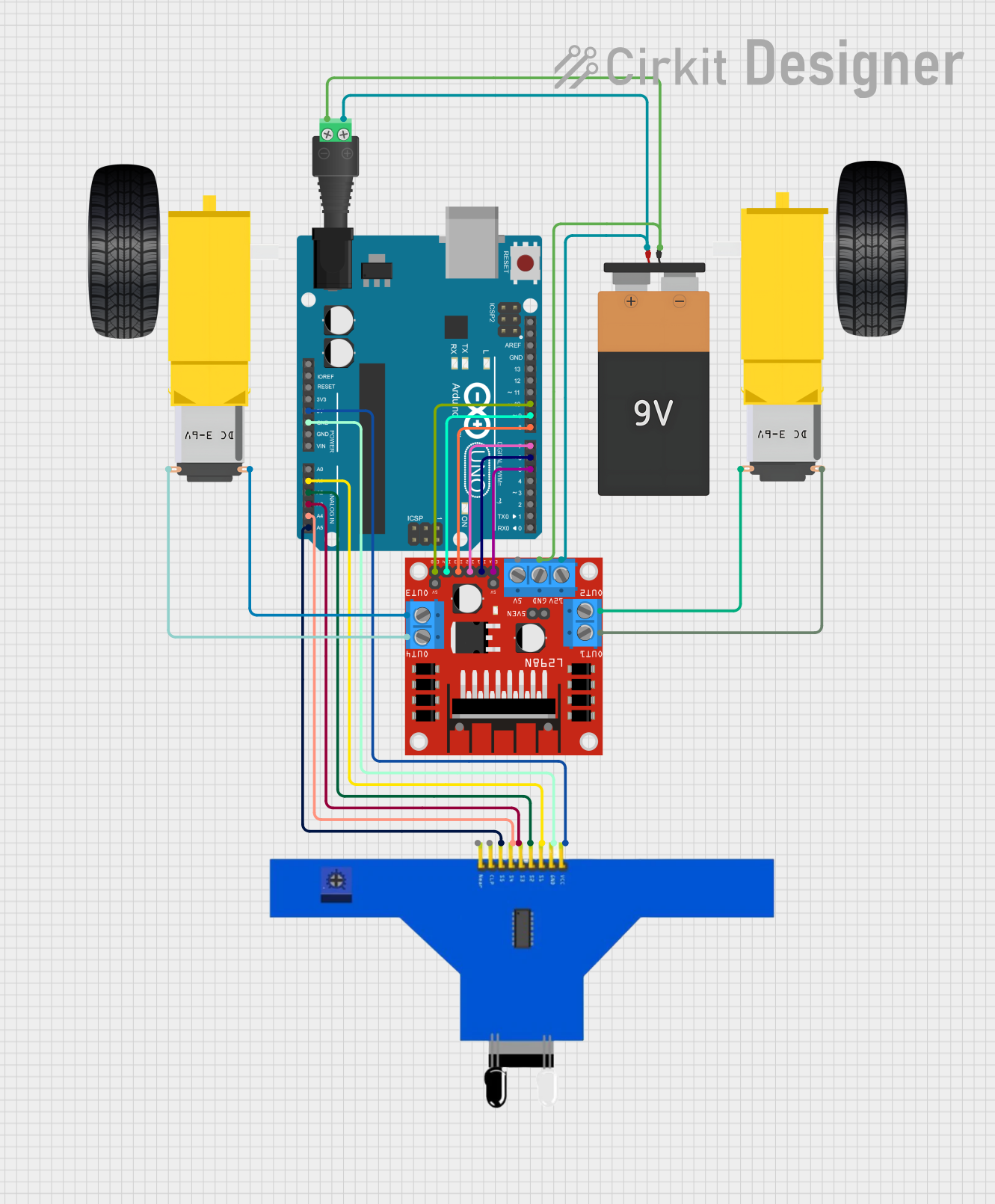

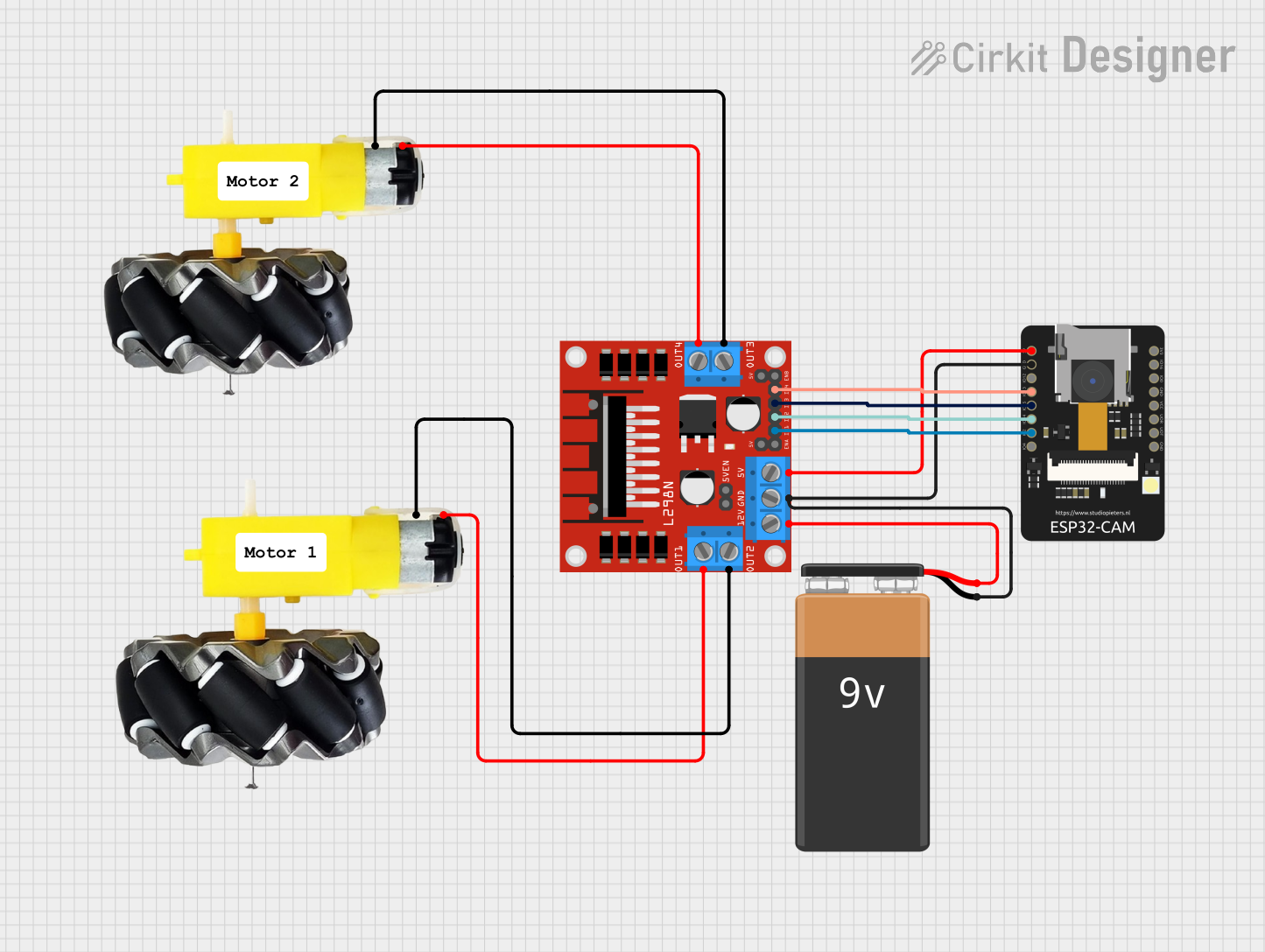

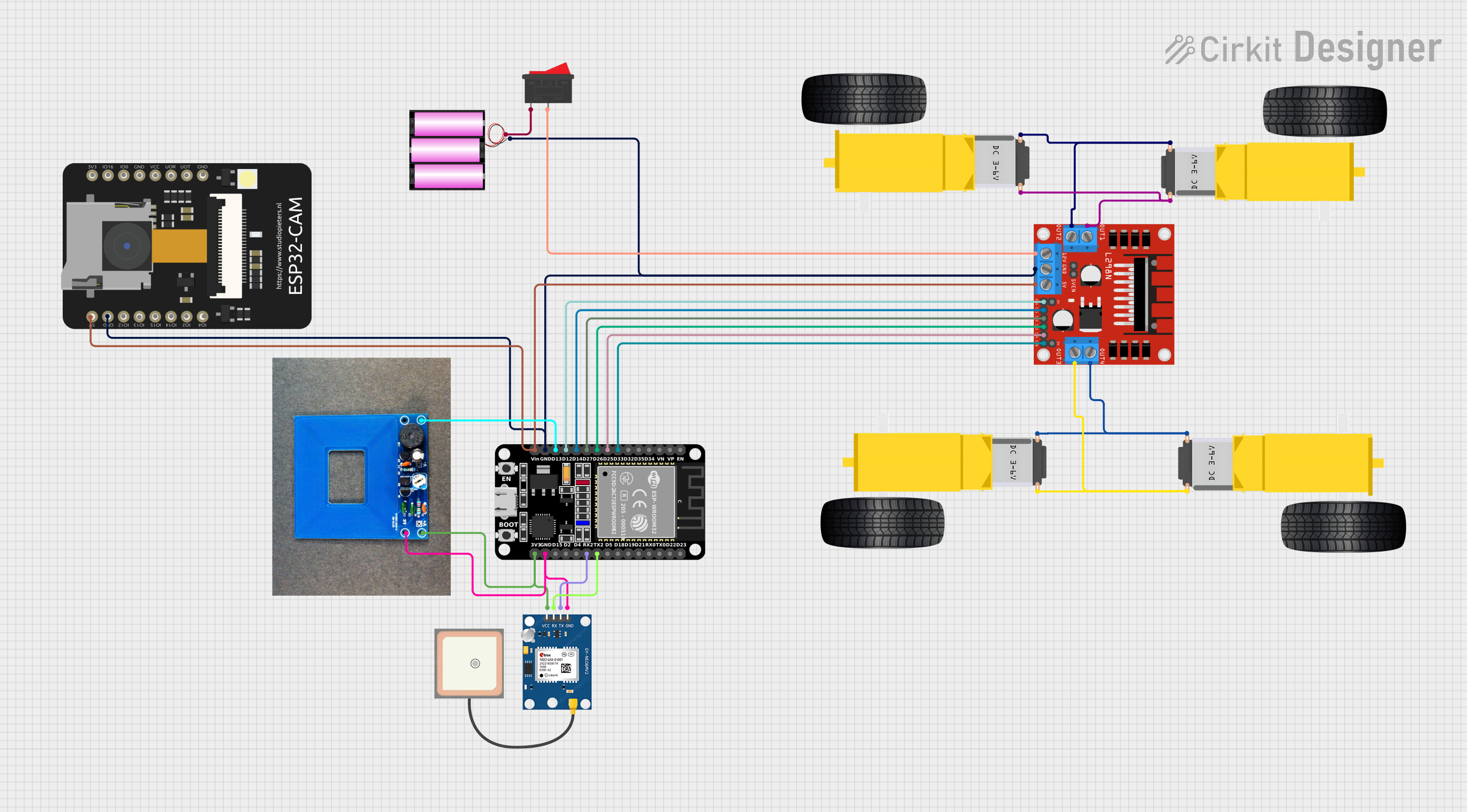

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with motor and wheels

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerTechnical Specifications

- Motor Type: DC motor or stepper motor (varies by model)

- Operating Voltage: 3V to 12V (typical for DC motors)

- Current Rating: 100mA to 2A (depending on motor size and load)

- Wheel Diameter: 65mm (common size, may vary)

- Torque: 0.2 Nm to 1 Nm (varies by motor)

- Speed: 100 RPM to 300 RPM (depending on voltage and load)

Pin Configuration and Descriptions

For a DC motor with a motor driver (e.g., L298N), the pin configuration is as follows:

| Pin Name | Description |

|---|---|

| IN1 | Input pin 1 for controlling motor direction (connect to microcontroller GPIO). |

| IN2 | Input pin 2 for controlling motor direction (connect to microcontroller GPIO). |

| ENA | Enable pin for motor (can be connected to PWM for speed control). |

| VCC | Power supply for the motor (typically 5V or 12V). |

| GND | Ground connection. |

| OUT1 | Output pin connected to one terminal of the motor. |

| OUT2 | Output pin connected to the other terminal of the motor. |

Usage Instructions

Connecting the Motor and Wheels:

- Attach the wheels securely to the motor shaft using screws or press-fit mechanisms.

- Ensure the motor is mounted on a stable chassis or frame to prevent misalignment during operation.

Wiring the Motor to a Driver:

- Connect the motor terminals to the output pins (OUT1 and OUT2) of the motor driver.

- Connect the input pins (IN1, IN2) of the motor driver to the GPIO pins of a microcontroller (e.g., Arduino UNO).

- Provide appropriate power to the motor driver (VCC and GND).

Controlling the Motor with Arduino:

- Use the following sample code to control the motor's direction and speed:

// Define motor driver pins

const int IN1 = 9; // Motor direction control pin 1

const int IN2 = 10; // Motor direction control pin 2

const int ENA = 5; // PWM pin for speed control

void setup() {

// Set motor driver pins as outputs

pinMode(IN1, OUTPUT);

pinMode(IN2, OUTPUT);

pinMode(ENA, OUTPUT);

}

void loop() {

// Rotate motor forward at 50% speed

digitalWrite(IN1, HIGH); // Set IN1 high

digitalWrite(IN2, LOW); // Set IN2 low

analogWrite(ENA, 128); // Set speed (0-255, 128 = 50%)

delay(2000); // Run for 2 seconds

// Rotate motor backward at 75% speed

digitalWrite(IN1, LOW); // Set IN1 low

digitalWrite(IN2, HIGH); // Set IN2 high

analogWrite(ENA, 192); // Set speed (0-255, 192 = 75%)

delay(2000); // Run for 2 seconds

// Stop the motor

digitalWrite(IN1, LOW); // Set IN1 low

digitalWrite(IN2, LOW); // Set IN2 low

analogWrite(ENA, 0); // Set speed to 0

delay(2000); // Wait for 2 seconds

}

- Important Considerations:

- Always check the motor's voltage and current ratings to avoid damage.

- Use a motor driver or H-bridge circuit to safely control the motor with a microcontroller.

- Ensure the power supply can handle the motor's startup current, which is typically higher than its running current.

Troubleshooting and FAQs

Common Issues

Motor not spinning:

- Check the wiring connections between the motor, driver, and microcontroller.

- Ensure the power supply voltage matches the motor's requirements.

- Verify that the enable pin (ENA) is receiving a PWM signal or is set to HIGH.

Motor spins in the wrong direction:

- Swap the connections of IN1 and IN2 on the motor driver.

- Adjust the logic in your microcontroller code to reverse the direction.

Motor speed is inconsistent:

- Check for loose connections or insufficient power supply.

- Ensure the PWM signal is stable and within the correct range.

Motor overheats:

- Reduce the load on the motor or use a motor with a higher torque rating.

- Ensure the motor is not running at its maximum voltage for extended periods.

FAQs

Can I use this motor and wheels with a Raspberry Pi? Yes, but you will need a motor driver or H-bridge circuit to interface the motor with the Raspberry Pi's GPIO pins.

What type of power supply should I use? Use a power supply that matches the motor's voltage rating and provides sufficient current (e.g., 12V, 2A for a typical DC motor).

How do I calculate the required torque for my application? Torque depends on the load and wheel size. Use the formula:

Torque (Nm) = Force (N) × Radius (m)

where Force is the weight or resistance the motor needs to overcome.Can I control multiple motors with one Arduino? Yes, you can control multiple motors using a multi-channel motor driver (e.g., L298N or L293D). Ensure the Arduino has enough GPIO pins for all motor control signals.