Cirkit Designer

Your all-in-one circuit design IDE

Home /

Component Documentation

How to Use valve: Examples, Pinouts, and Specs

Design with valve in Cirkit Designer

Design with valve in Cirkit DesignerIntroduction

A valve is a device that regulates, directs, or controls the flow of a fluid by opening, closing, or partially obstructing various passageways. Valves are essential components in various systems, including plumbing, industrial processes, and automotive applications. They are used to control the flow of liquids, gases, and slurries, ensuring that these substances move efficiently and safely through pipelines and other conduits.

Explore Projects Built with valve

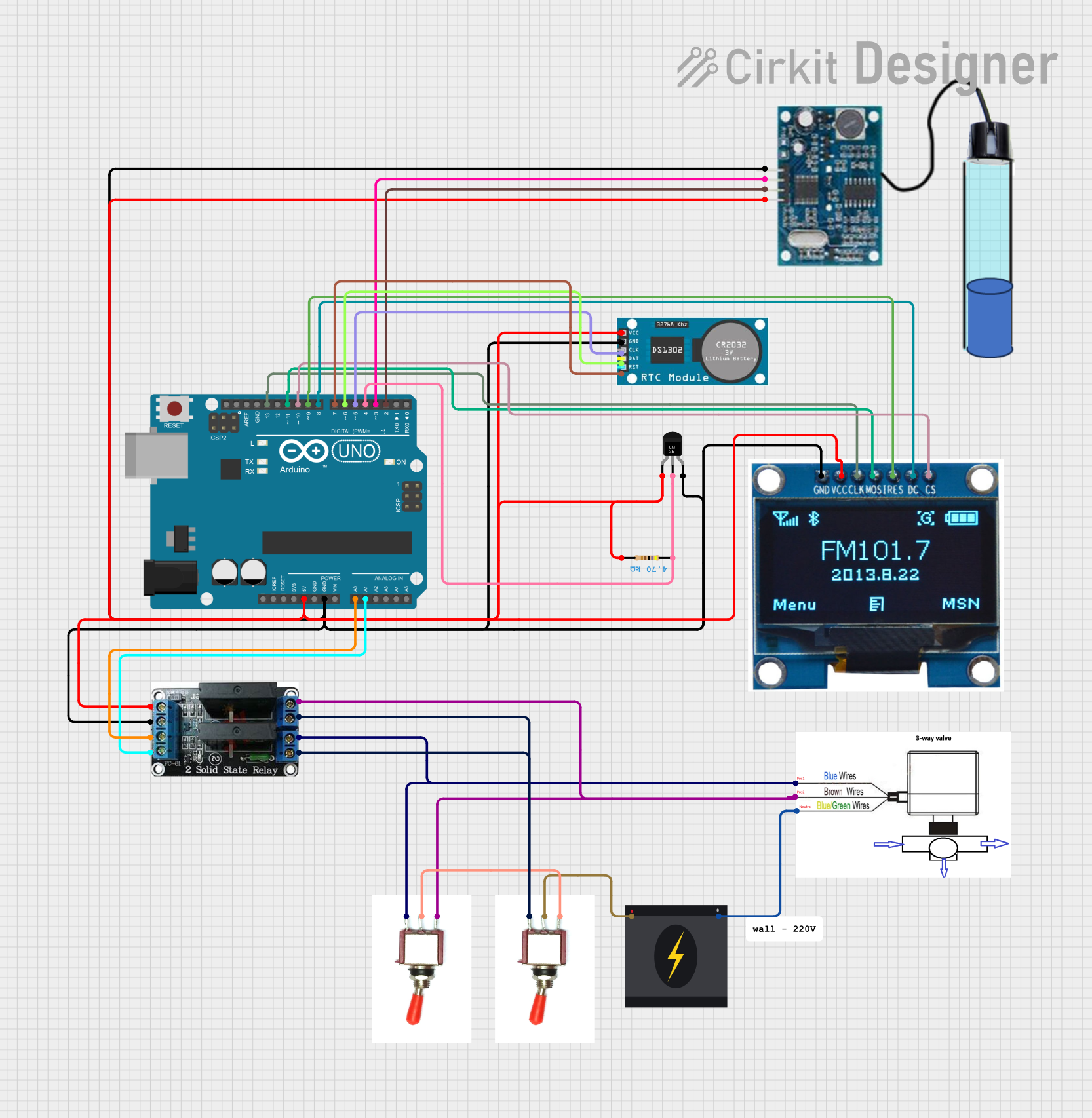

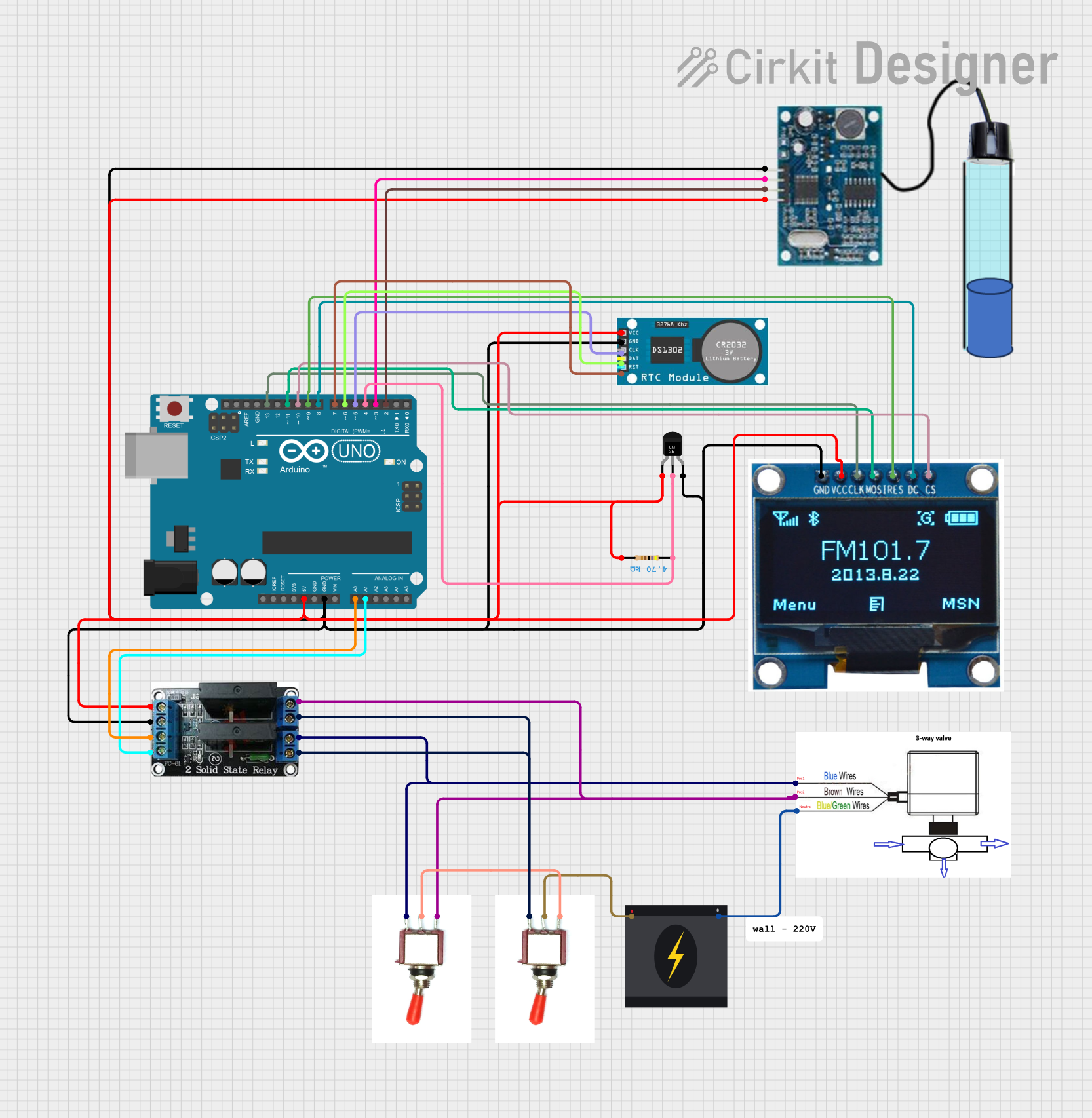

Arduino-Controlled Environmental Monitoring System with OLED Display and Sonar Level Sensing

This circuit is a microcontroller-based control system designed to monitor environmental parameters and control a 3-way ball valve. It uses an Arduino UNO to process inputs from a temperature sensor, a real-time clock, and a sonar sensor, and outputs control signals to solid-state relays for valve actuation. The system is capable of interfacing with high-voltage components and provides user interaction through toggle switches and an OLED display.

Open Project in Cirkit Designer

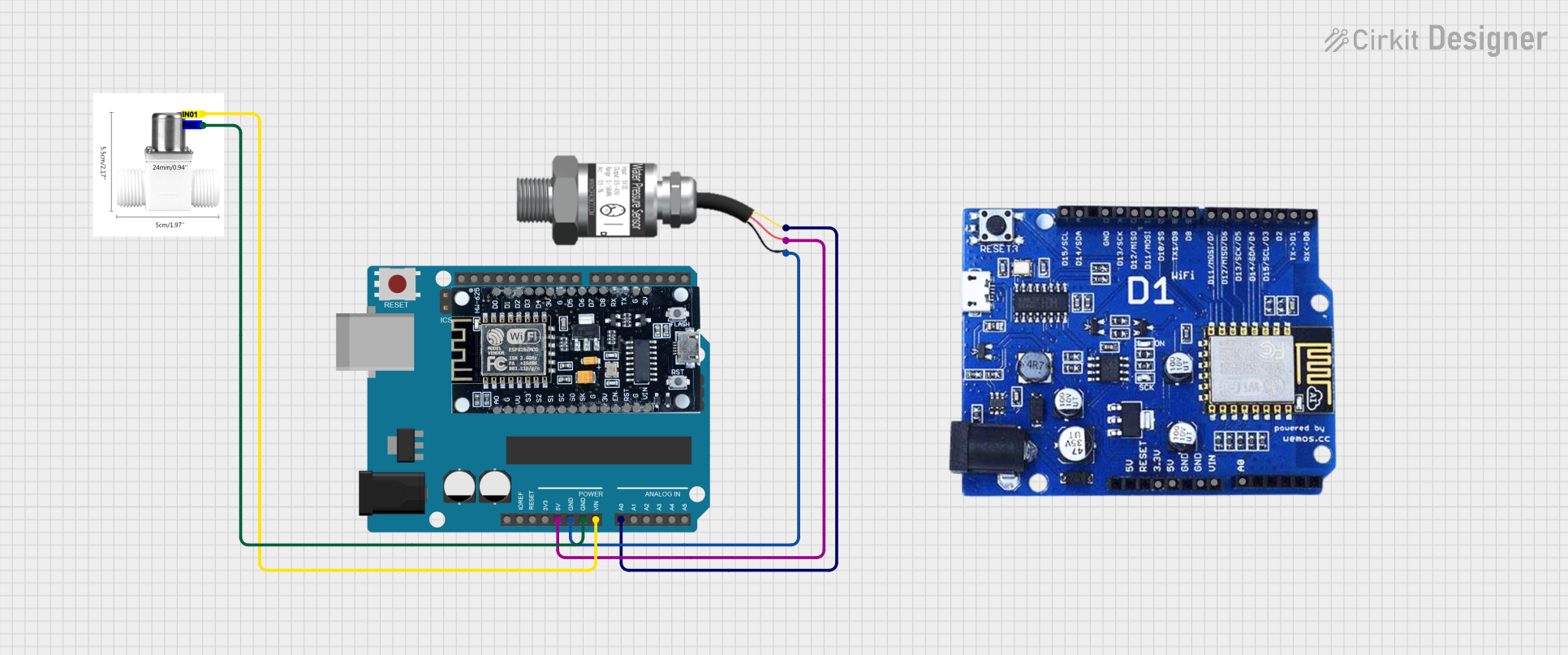

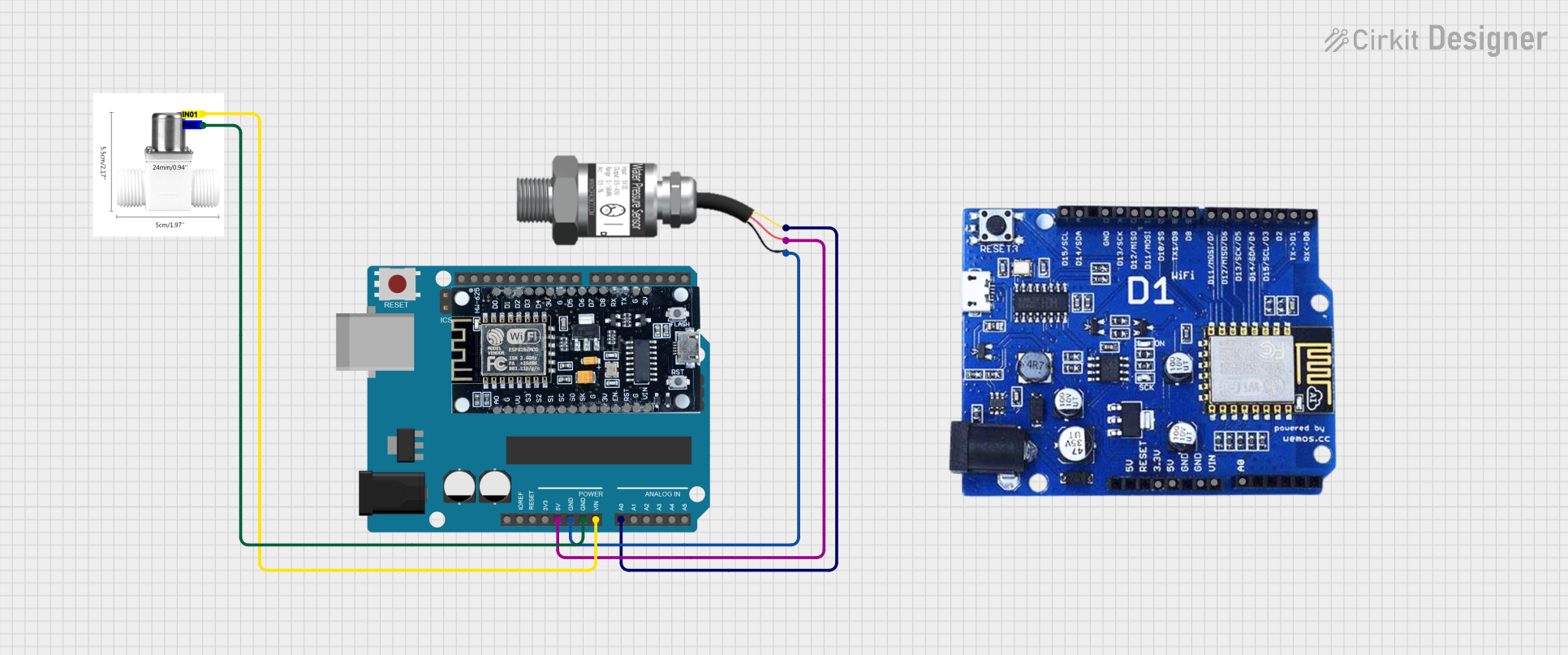

Open Project in Cirkit DesignerArduino-Controlled Water Pressure Monitoring and Solenoid Valve System

This circuit features an Arduino UNO connected to a Gravity: Analog Water Pressure Sensor and a valve solenoid. The water pressure sensor's signal pin is connected to the Arduino's A0 analog input for pressure measurement, while the solenoid valve is controlled by the Arduino's Vin pin, likely for on/off operation based on the sensor input. The provided code for the Arduino UNO is a template with empty setup and loop functions, indicating that the specific control logic has not been implemented yet.

Open Project in Cirkit Designer

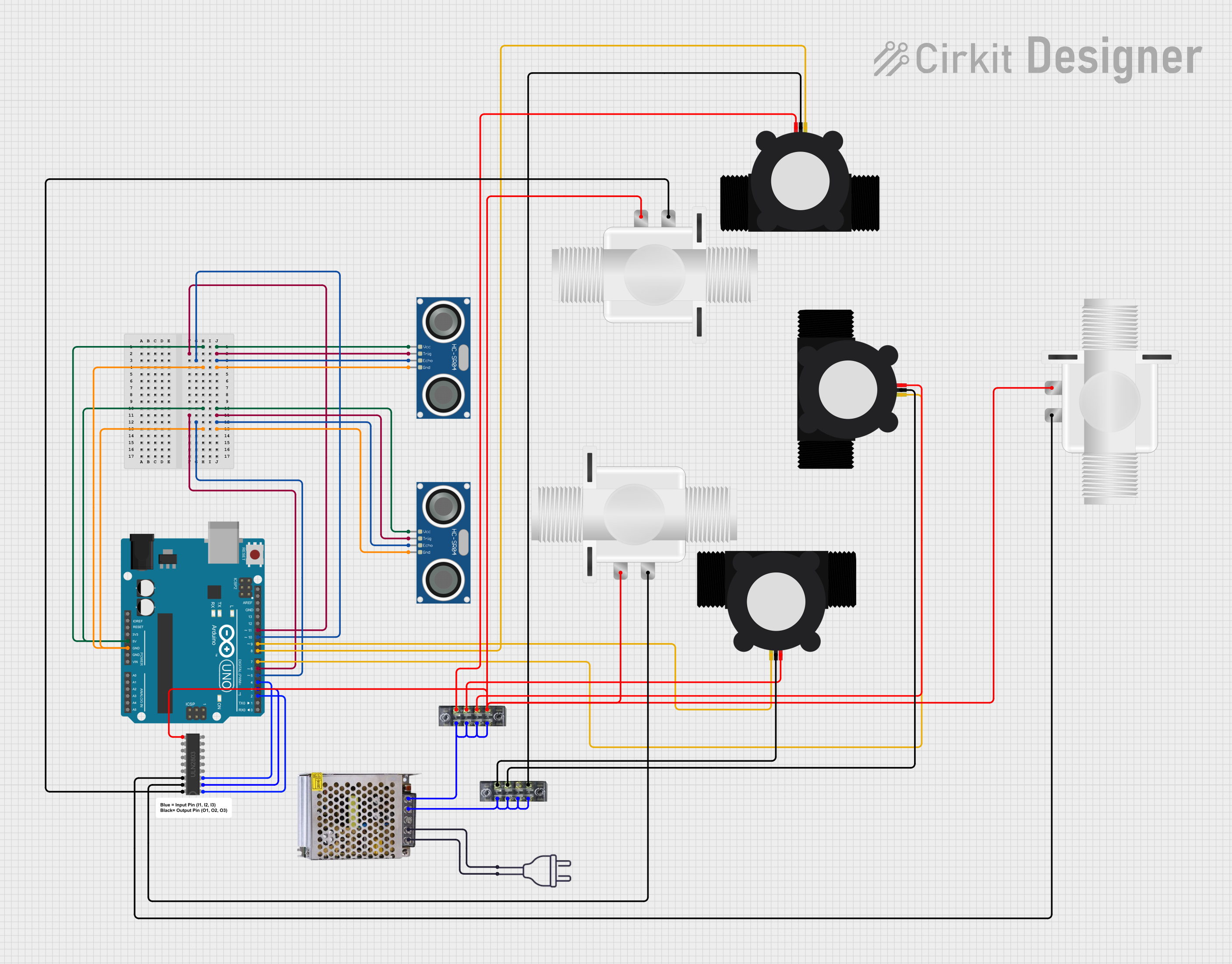

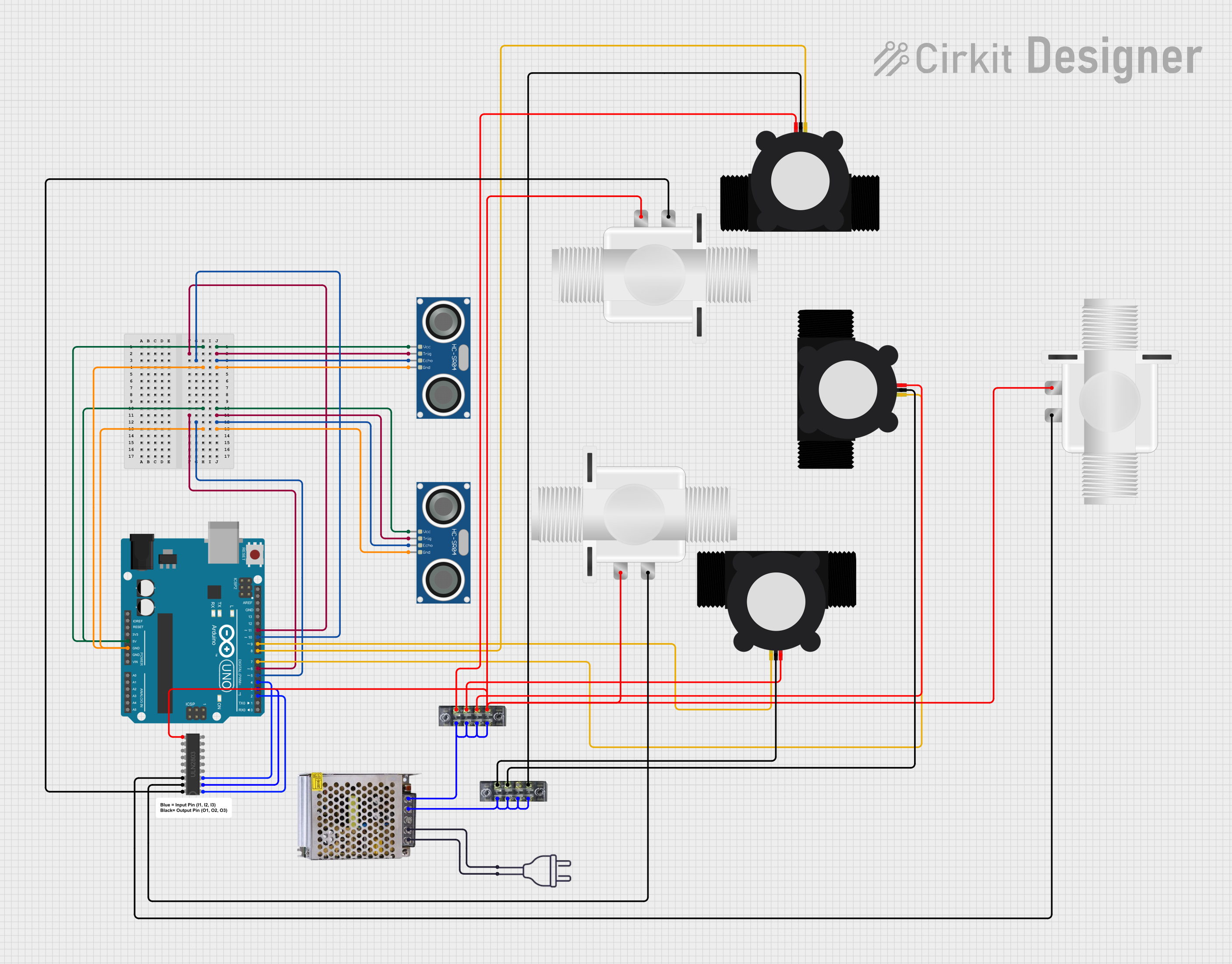

Open Project in Cirkit DesignerArduino UNO-Based Water Management System with Ultrasonic Sensors and Solenoid Valves

This circuit is an Arduino-controlled water management system that uses ultrasonic sensors to detect objects, water flow sensors to monitor flow rates, and solenoid valves to control water flow. The system ensures water flow is managed based on object detection and flow rate, operating three sets of sensors and valves for efficient water usage.

Open Project in Cirkit Designer

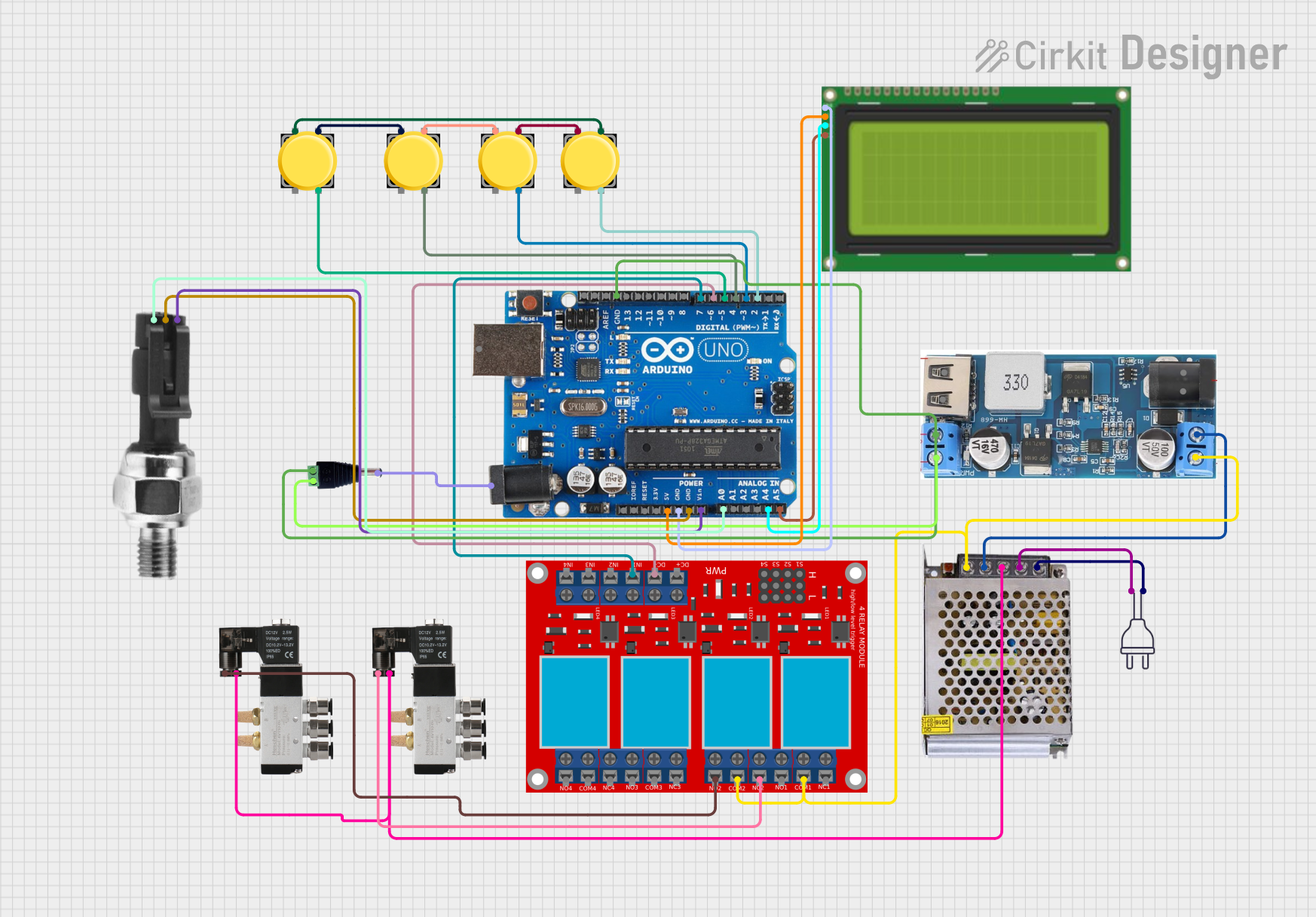

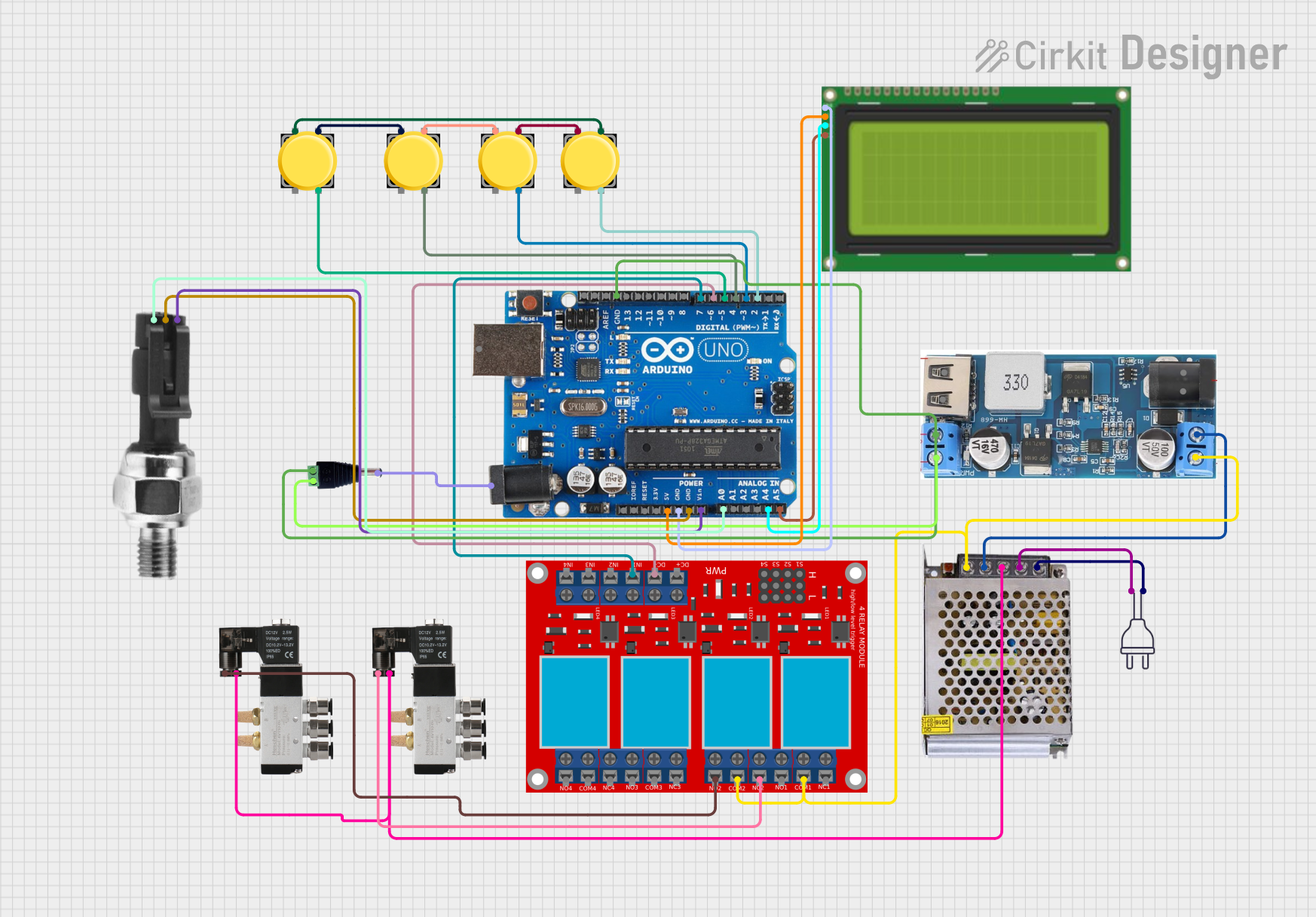

Open Project in Cirkit DesignerArduino-Based Automatic Tyre Inflator with LCD Display and Pressure Sensor

This circuit is an automated tire inflator system controlled by an Arduino Uno. It uses multiple pushbuttons for user input, an industrial pressure sensor to monitor tire pressure, and a 4-channel relay module to control solenoid valves for inflating and purging air. The system also includes an LCD display for user interface and feedback.

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with valve

Arduino-Controlled Environmental Monitoring System with OLED Display and Sonar Level Sensing

This circuit is a microcontroller-based control system designed to monitor environmental parameters and control a 3-way ball valve. It uses an Arduino UNO to process inputs from a temperature sensor, a real-time clock, and a sonar sensor, and outputs control signals to solid-state relays for valve actuation. The system is capable of interfacing with high-voltage components and provides user interaction through toggle switches and an OLED display.

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Arduino-Controlled Water Pressure Monitoring and Solenoid Valve System

This circuit features an Arduino UNO connected to a Gravity: Analog Water Pressure Sensor and a valve solenoid. The water pressure sensor's signal pin is connected to the Arduino's A0 analog input for pressure measurement, while the solenoid valve is controlled by the Arduino's Vin pin, likely for on/off operation based on the sensor input. The provided code for the Arduino UNO is a template with empty setup and loop functions, indicating that the specific control logic has not been implemented yet.

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Arduino UNO-Based Water Management System with Ultrasonic Sensors and Solenoid Valves

This circuit is an Arduino-controlled water management system that uses ultrasonic sensors to detect objects, water flow sensors to monitor flow rates, and solenoid valves to control water flow. The system ensures water flow is managed based on object detection and flow rate, operating three sets of sensors and valves for efficient water usage.

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Arduino-Based Automatic Tyre Inflator with LCD Display and Pressure Sensor

This circuit is an automated tire inflator system controlled by an Arduino Uno. It uses multiple pushbuttons for user input, an industrial pressure sensor to monitor tire pressure, and a 4-channel relay module to control solenoid valves for inflating and purging air. The system also includes an LCD display for user interface and feedback.

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications and Use Cases

- Plumbing Systems: Valves are used to control water flow in residential and commercial plumbing systems.

- Industrial Processes: Valves regulate the flow of chemicals, gases, and other fluids in manufacturing and processing plants.

- Automotive Systems: Valves control the flow of fuel, air, and exhaust gases in internal combustion engines.

- HVAC Systems: Valves manage the flow of refrigerants and air in heating, ventilation, and air conditioning systems.

- Irrigation Systems: Valves control the distribution of water in agricultural and landscaping applications.

Technical Specifications

Key Technical Details

| Parameter | Value |

|---|---|

| Operating Voltage | 12V DC |

| Current Rating | 500mA |

| Power Rating | 6W |

| Pressure Rating | 0-10 bar |

| Flow Rate | 0-10 liters per minute (LPM) |

| Material | Brass |

| Connection Type | 1/2 inch NPT |

Pin Configuration and Descriptions

| Pin Number | Pin Name | Description |

|---|---|---|

| 1 | VCC | Power supply (12V DC) |

| 2 | GND | Ground |

| 3 | IN | Control signal input (0-5V DC) |

Usage Instructions

How to Use the Valve in a Circuit

- Power Supply: Connect the VCC pin to a 12V DC power supply and the GND pin to the ground.

- Control Signal: Connect the IN pin to a microcontroller or control circuit that provides a 0-5V DC signal to open or close the valve.

- Fluid Connections: Attach the fluid inlet and outlet to the appropriate pipes or hoses using the 1/2 inch NPT connections.

Important Considerations and Best Practices

- Power Supply: Ensure that the power supply provides a stable 12V DC output to avoid damaging the valve.

- Control Signal: Use a microcontroller or control circuit that can provide a precise 0-5V DC signal to control the valve accurately.

- Pressure Rating: Do not exceed the maximum pressure rating of 10 bar to prevent damage to the valve and ensure safe operation.

- Flow Rate: Ensure that the flow rate does not exceed the specified range to maintain optimal performance.

- Material Compatibility: Verify that the fluid being controlled is compatible with brass to prevent corrosion and damage to the valve.

Example: Connecting the Valve to an Arduino UNO

// Define the pin connected to the valve control signal

const int valvePin = 9;

void setup() {

// Initialize the valve control pin as an output

pinMode(valvePin, OUTPUT);

}

void loop() {

// Open the valve by setting the control signal to HIGH

digitalWrite(valvePin, HIGH);

delay(5000); // Keep the valve open for 5 seconds

// Close the valve by setting the control signal to LOW

digitalWrite(valvePin, LOW);

delay(5000); // Keep the valve closed for 5 seconds

}

Troubleshooting and FAQs

Common Issues Users Might Face

Valve Not Opening or Closing:

- Cause: Insufficient power supply or incorrect control signal.

- Solution: Verify that the power supply provides a stable 12V DC output and that the control signal is within the 0-5V DC range.

Fluid Leakage:

- Cause: Improper connections or damaged seals.

- Solution: Ensure that all connections are secure and check for any damaged seals that may need replacement.

Erratic Operation:

- Cause: Electrical noise or interference.

- Solution: Use proper shielding and grounding techniques to minimize electrical noise and interference.

Solutions and Tips for Troubleshooting

- Check Connections: Ensure that all electrical and fluid connections are secure and correctly made.

- Verify Power Supply: Confirm that the power supply provides a stable 12V DC output.

- Inspect Control Signal: Use an oscilloscope or multimeter to verify that the control signal is within the specified range.

- Monitor Pressure and Flow: Use appropriate sensors to monitor the pressure and flow rate to ensure they are within the specified limits.

- Regular Maintenance: Perform regular maintenance checks to ensure the valve and associated components are in good working condition.

By following these guidelines and best practices, users can ensure reliable and efficient operation of the valve in various applications.