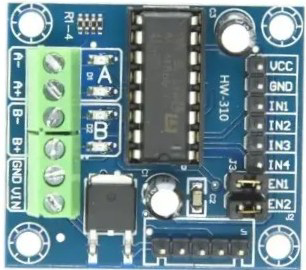

How to Use Mini L293D Motor Driver: Examples, Pinouts, and Specs

Design with Mini L293D Motor Driver in Cirkit Designer

Design with Mini L293D Motor Driver in Cirkit DesignerIntroduction

The Mini L293D Motor Driver is a compact dual H-bridge motor driver designed to control the direction and speed of DC motors and stepper motors. It is widely used in robotics, automation, and other motor control applications due to its small size, ease of use, and versatility. This component is ideal for projects requiring precise motor control, such as robotic arms, wheeled robots, and conveyor systems.

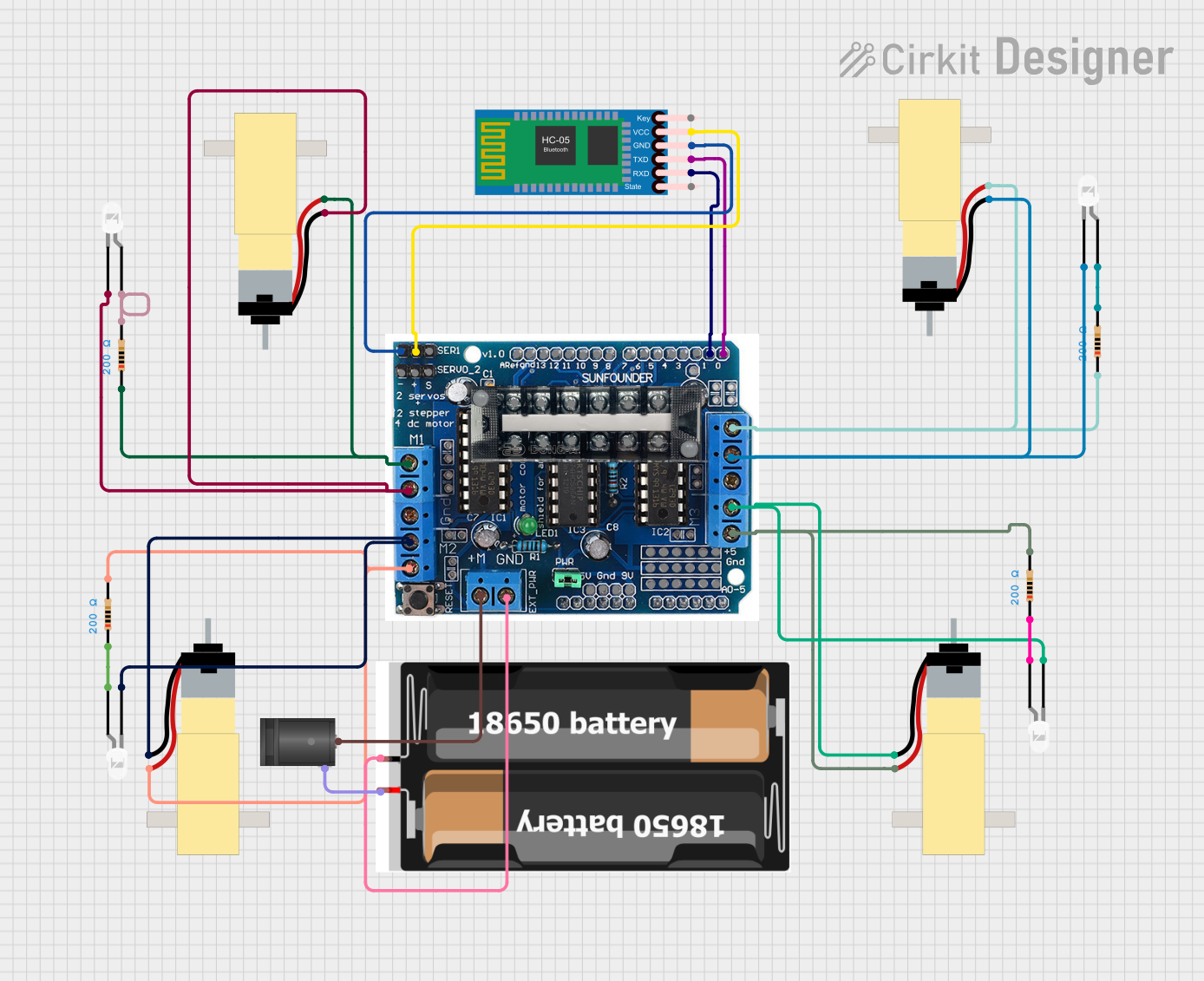

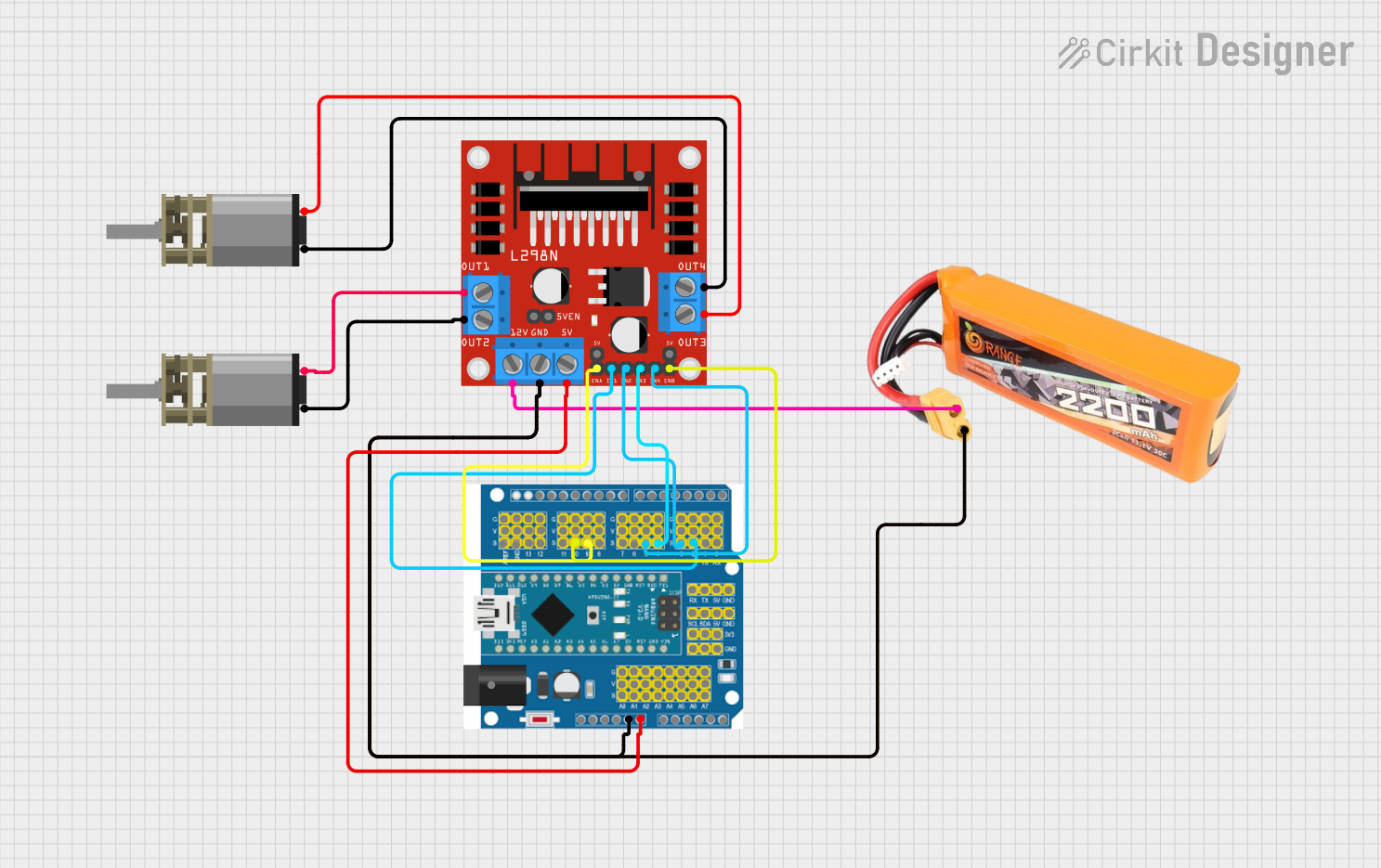

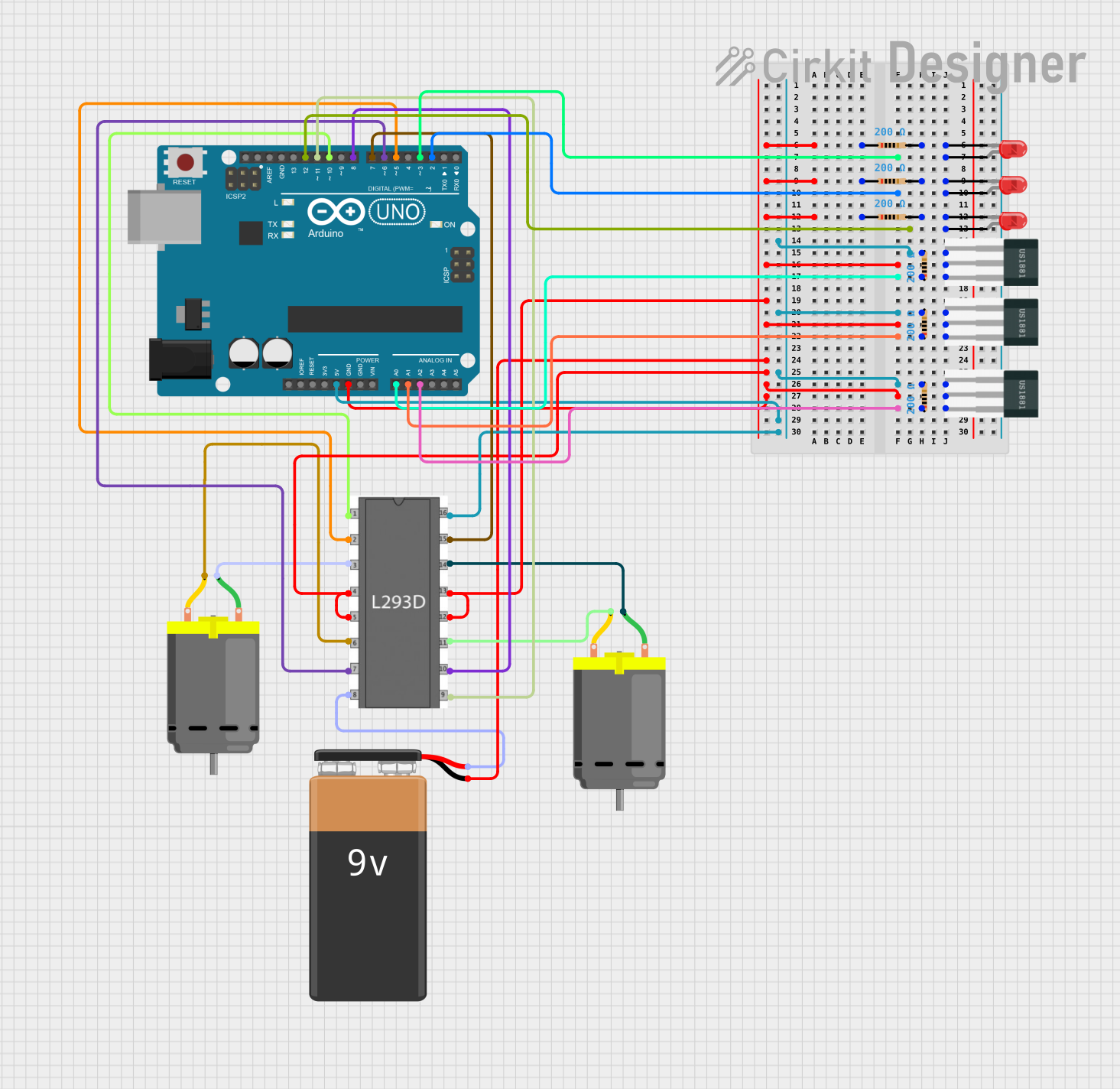

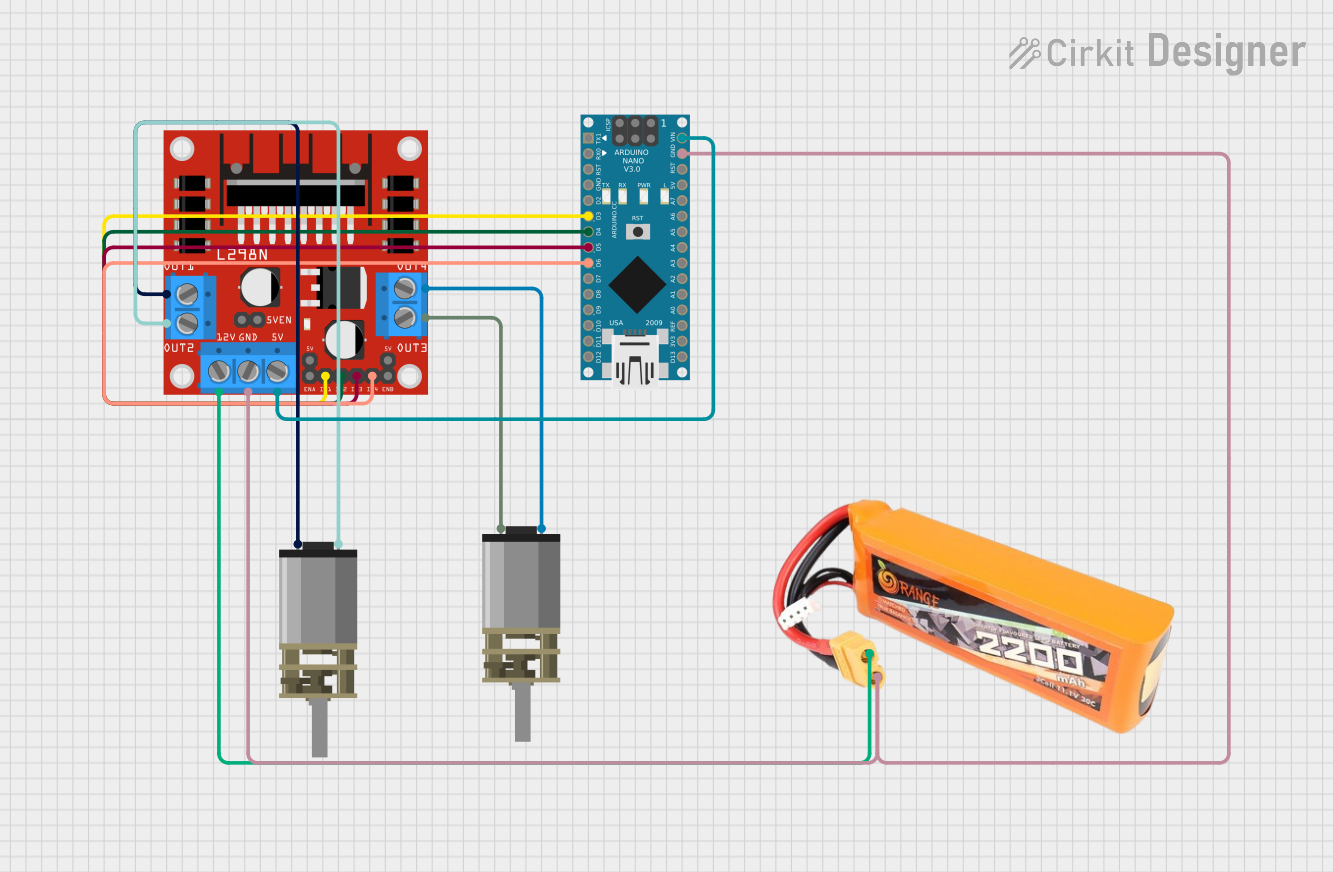

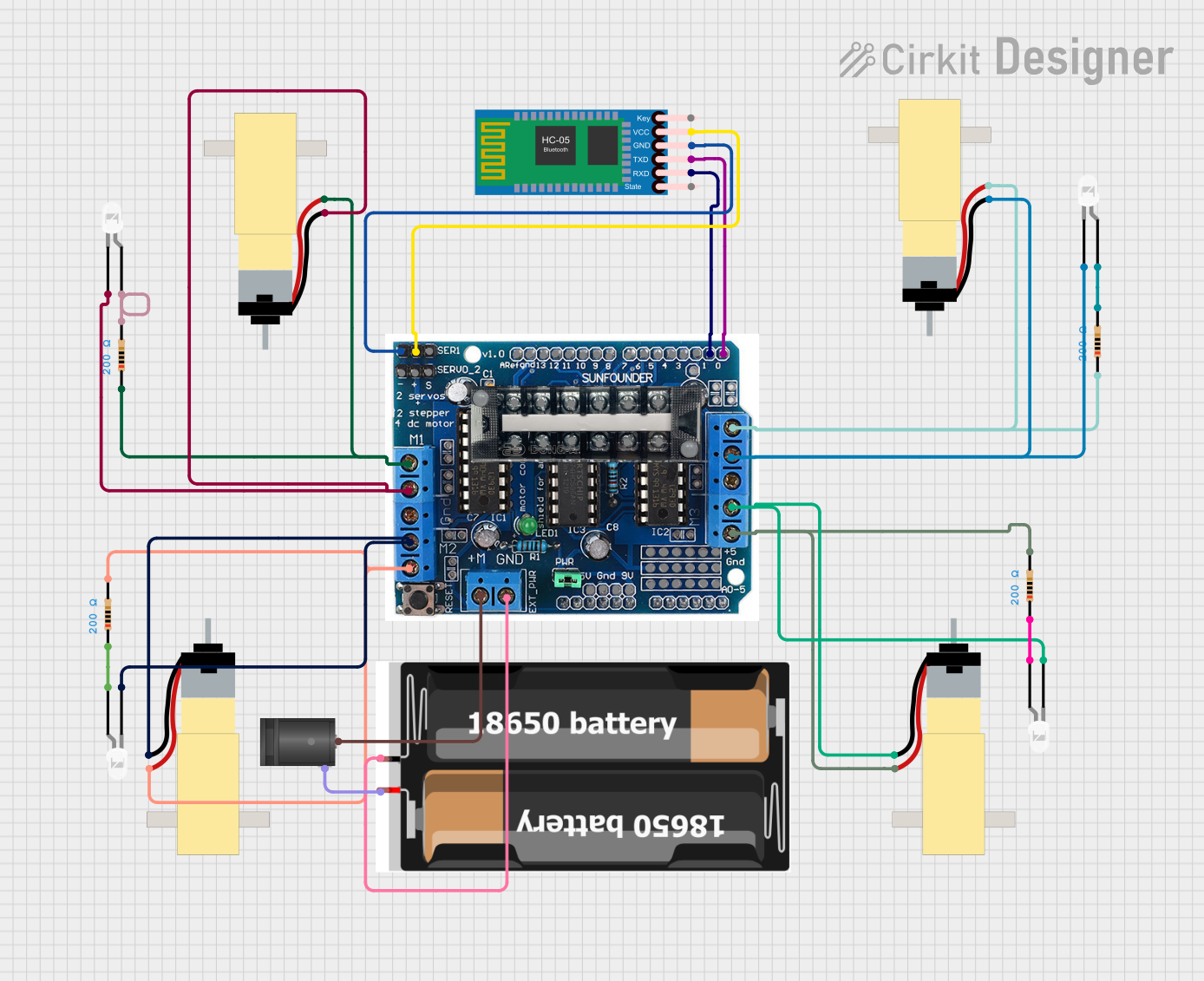

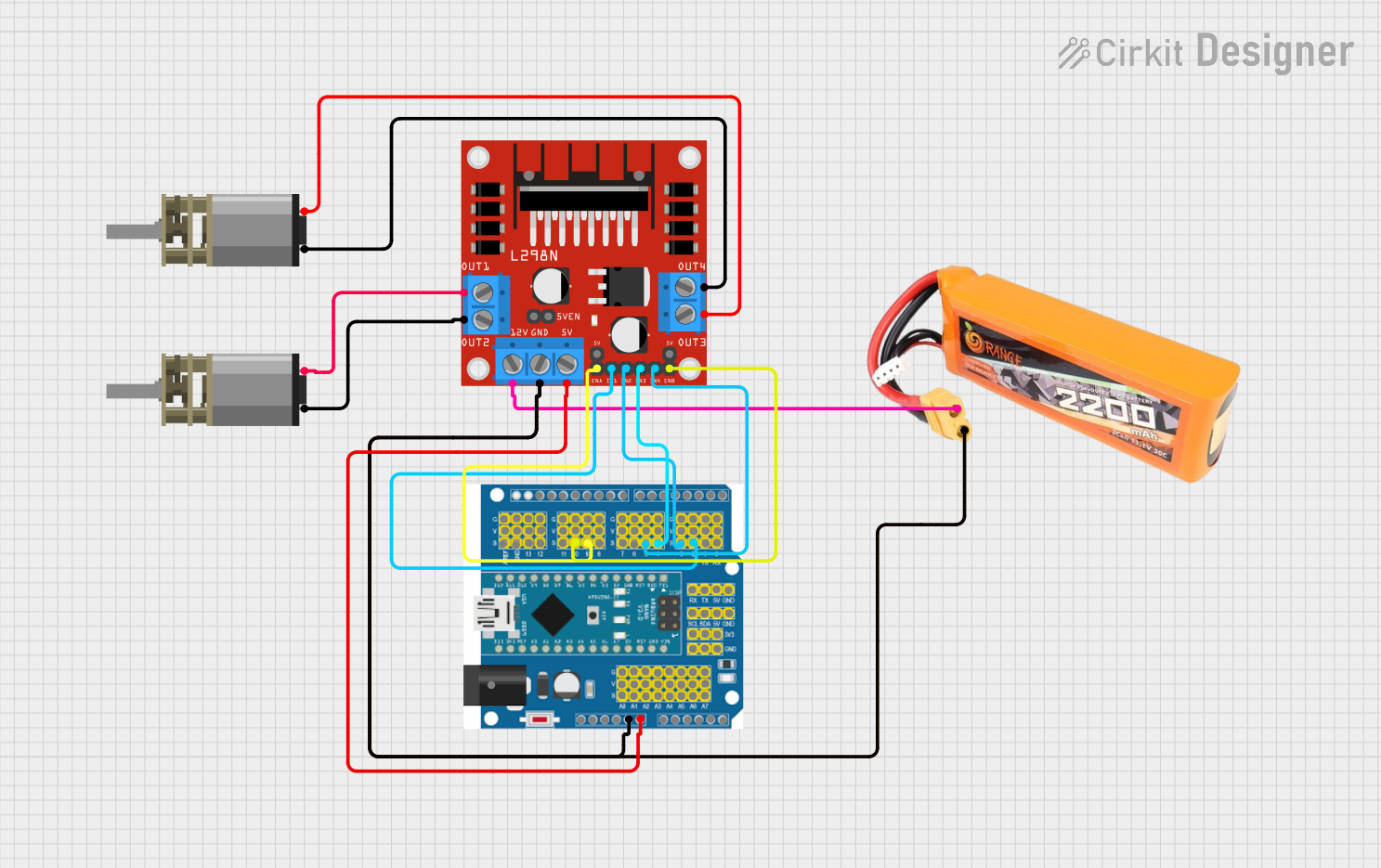

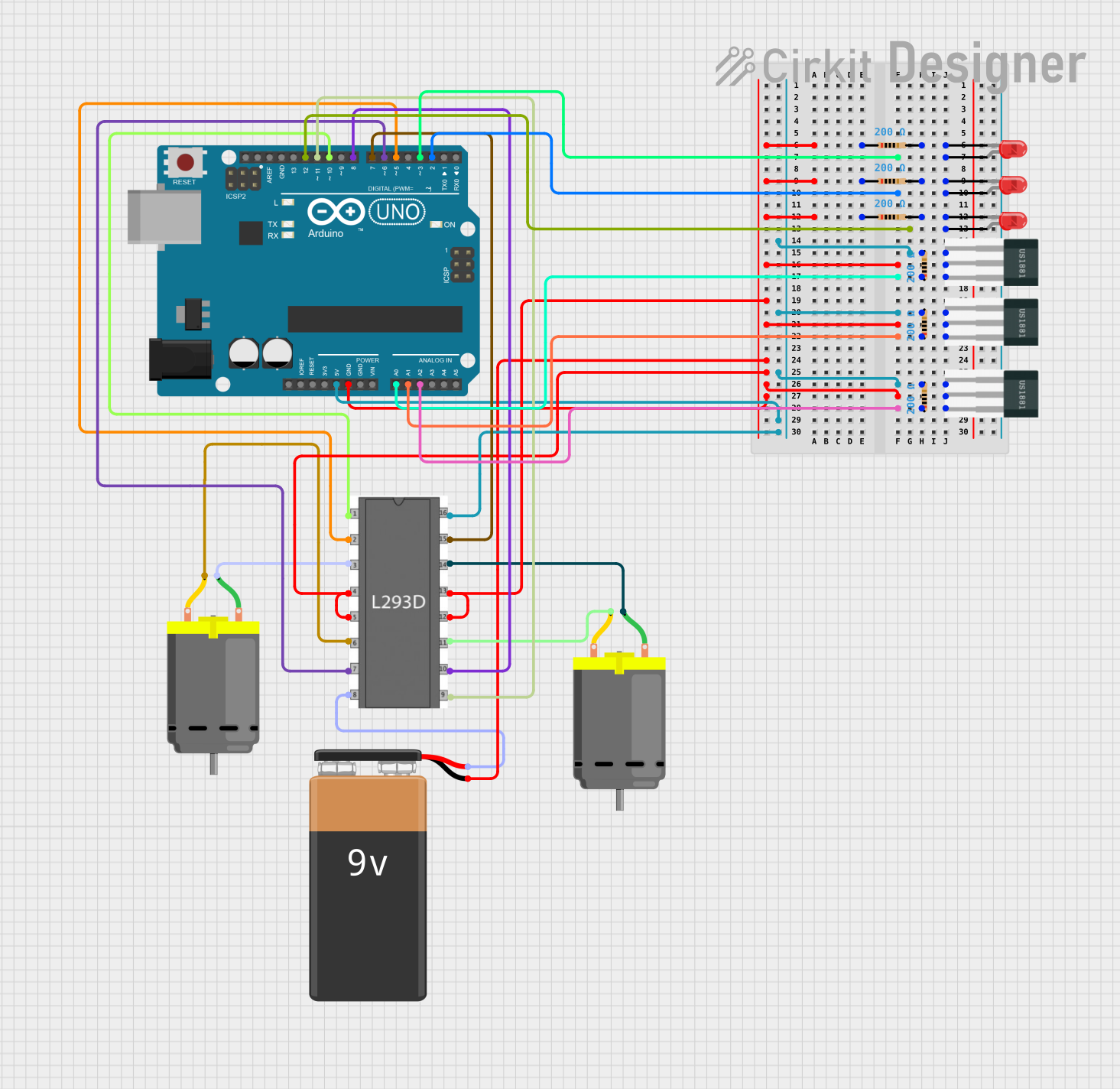

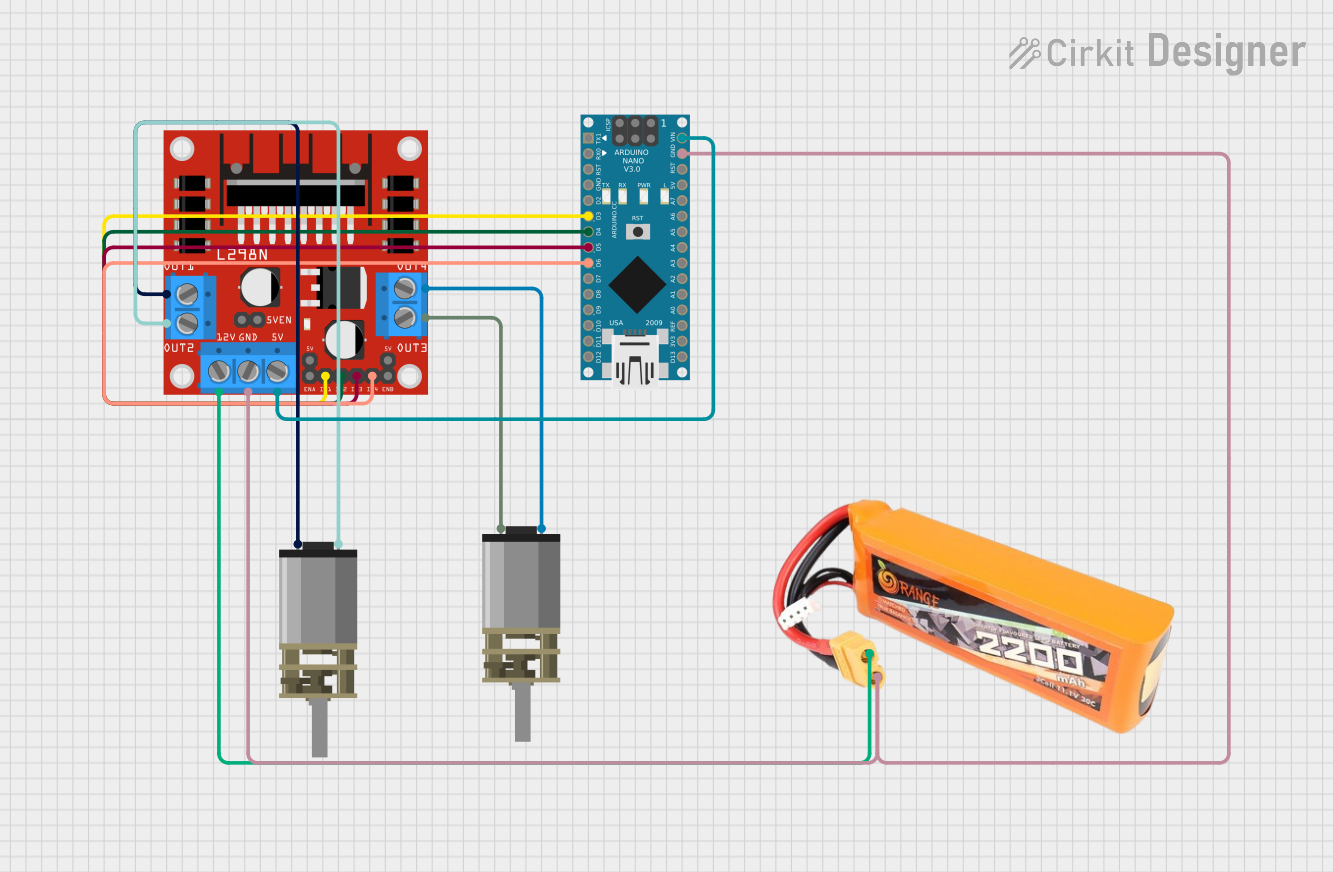

Explore Projects Built with Mini L293D Motor Driver

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with Mini L293D Motor Driver

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications:

- Robotics (e.g., motorized vehicles, robotic arms)

- Automation systems

- DIY electronics projects

- Stepper motor control for CNC machines or 3D printers

Technical Specifications

The Mini L293D Motor Driver is based on the L293D IC, which is capable of driving two DC motors or one stepper motor. Below are the key technical details:

Key Specifications:

- Operating Voltage: 4.5V to 36V

- Logic Voltage: 5V

- Maximum Output Current (per channel): 600mA (peak: 1.2A)

- Number of Channels: 2 (dual H-bridge)

- Motor Types Supported: DC motors, stepper motors

- Control Logic: TTL-compatible

- Thermal Shutdown Protection: Yes

- Dimensions: Compact form factor (varies by manufacturer)

Pin Configuration and Descriptions:

The Mini L293D Motor Driver typically has the following pin layout:

Input/Control Pins:

| Pin Name | Pin Number | Description |

|---|---|---|

| IN1 | 1 | Input 1 for Motor A (controls direction) |

| IN2 | 2 | Input 2 for Motor A (controls direction) |

| IN3 | 7 | Input 1 for Motor B (controls direction) |

| IN4 | 8 | Input 2 for Motor B (controls direction) |

| ENA | 9 | Enable pin for Motor A (PWM for speed control) |

| ENB | 10 | Enable pin for Motor B (PWM for speed control) |

Power and Output Pins:

| Pin Name | Pin Number | Description |

|---|---|---|

| VCC | 16 | Motor power supply (4.5V to 36V) |

| GND | 4, 5, 12, 13 | Ground |

| VS | 8 | Logic voltage supply (typically 5V) |

| OUT1 | 3 | Output 1 for Motor A |

| OUT2 | 6 | Output 2 for Motor A |

| OUT3 | 11 | Output 1 for Motor B |

| OUT4 | 14 | Output 2 for Motor B |

Usage Instructions

How to Use the Mini L293D Motor Driver in a Circuit:

Power Connections:

- Connect the motor power supply to the

VCCpin (4.5V to 36V). - Connect the logic voltage (5V) to the

VSpin. - Connect all

GNDpins to the ground of your circuit.

- Connect the motor power supply to the

Motor Connections:

- Connect the terminals of Motor A to

OUT1andOUT2. - Connect the terminals of Motor B to

OUT3andOUT4.

- Connect the terminals of Motor A to

Control Connections:

- Use the

IN1andIN2pins to control the direction of Motor A. - Use the

IN3andIN4pins to control the direction of Motor B. - Use the

ENAandENBpins to enable/disable the motors and control their speed using PWM signals.

- Use the

Logic Control:

- Use a microcontroller (e.g., Arduino UNO) to send control signals to the input pins (

IN1,IN2,IN3,IN4) and PWM signals to the enable pins (ENA,ENB).

- Use a microcontroller (e.g., Arduino UNO) to send control signals to the input pins (

Example Arduino Code:

Below is an example of how to control two DC motors using the Mini L293D Motor Driver and an Arduino UNO:

// Define motor control pins

#define IN1 2 // Motor A direction control pin 1

#define IN2 3 // Motor A direction control pin 2

#define ENA 9 // Motor A speed control (PWM pin)

#define IN3 4 // Motor B direction control pin 1

#define IN4 5 // Motor B direction control pin 2

#define ENB 10 // Motor B speed control (PWM pin)

void setup() {

// Set motor control pins as outputs

pinMode(IN1, OUTPUT);

pinMode(IN2, OUTPUT);

pinMode(ENA, OUTPUT);

pinMode(IN3, OUTPUT);

pinMode(IN4, OUTPUT);

pinMode(ENB, OUTPUT);

}

void loop() {

// Motor A: Forward at 50% speed

digitalWrite(IN1, HIGH); // Set IN1 high

digitalWrite(IN2, LOW); // Set IN2 low

analogWrite(ENA, 128); // Set ENA to 50% duty cycle (128/255)

// Motor B: Reverse at 75% speed

digitalWrite(IN3, LOW); // Set IN3 low

digitalWrite(IN4, HIGH); // Set IN4 high

analogWrite(ENB, 192); // Set ENB to 75% duty cycle (192/255)

delay(2000); // Run motors for 2 seconds

// Stop both motors

analogWrite(ENA, 0); // Set ENA to 0% duty cycle (stop motor A)

analogWrite(ENB, 0); // Set ENB to 0% duty cycle (stop motor B)

delay(2000); // Wait for 2 seconds

}

Important Considerations:

- Ensure the motor power supply voltage matches the motor's rated voltage.

- Do not exceed the maximum current rating of 600mA per channel.

- Use proper heat dissipation if operating at high currents for extended periods.

- Always connect all ground pins to a common ground to avoid erratic behavior.

Troubleshooting and FAQs

Common Issues and Solutions:

Motors Not Running:

- Check all power connections (

VCC,VS, andGND). - Ensure the enable pins (

ENA,ENB) are receiving a valid PWM signal or are set high.

- Check all power connections (

Motors Running in the Wrong Direction:

- Reverse the connections to the input pins (

IN1,IN2,IN3,IN4) or swap the motor terminals.

- Reverse the connections to the input pins (

Overheating:

- Ensure the current draw of the motors does not exceed the driver’s maximum rating.

- Add a heat sink or cooling fan if necessary.

Erratic Motor Behavior:

- Verify that all ground connections are properly connected.

- Check for noise or interference in the control signals.

FAQs:

Can I control stepper motors with this driver? Yes, the Mini L293D can control stepper motors by driving the coils in sequence. Refer to your stepper motor's datasheet for the correct sequence.

What happens if I exceed the current rating? The driver may overheat and shut down due to thermal protection. Prolonged overcurrent may damage the IC.

Can I use this driver with a 3.3V microcontroller? The L293D requires 5V logic levels. Use a level shifter if your microcontroller operates at 3.3V.

This concludes the documentation for the Mini L293D Motor Driver.