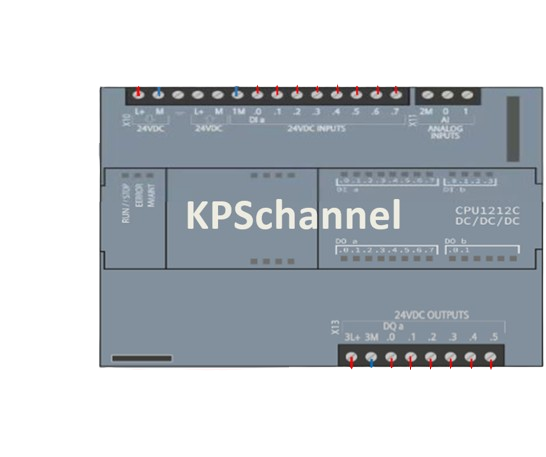

How to Use PLC siemens s7-1200: Examples, Pinouts, and Specs

Design with PLC siemens s7-1200 in Cirkit Designer

Design with PLC siemens s7-1200 in Cirkit DesignerIntroduction

The Siemens S7-1200 is a modular programmable logic controller (PLC) designed for automation tasks in industrial environments. It is part of Siemens' SIMATIC series and is known for its compact design, integrated I/O options, and robust performance. The S7-1200 supports various communication protocols, including PROFINET, making it ideal for small to medium-sized automation applications. Its flexibility and scalability allow it to be used in a wide range of industries, including manufacturing, process control, and building automation.

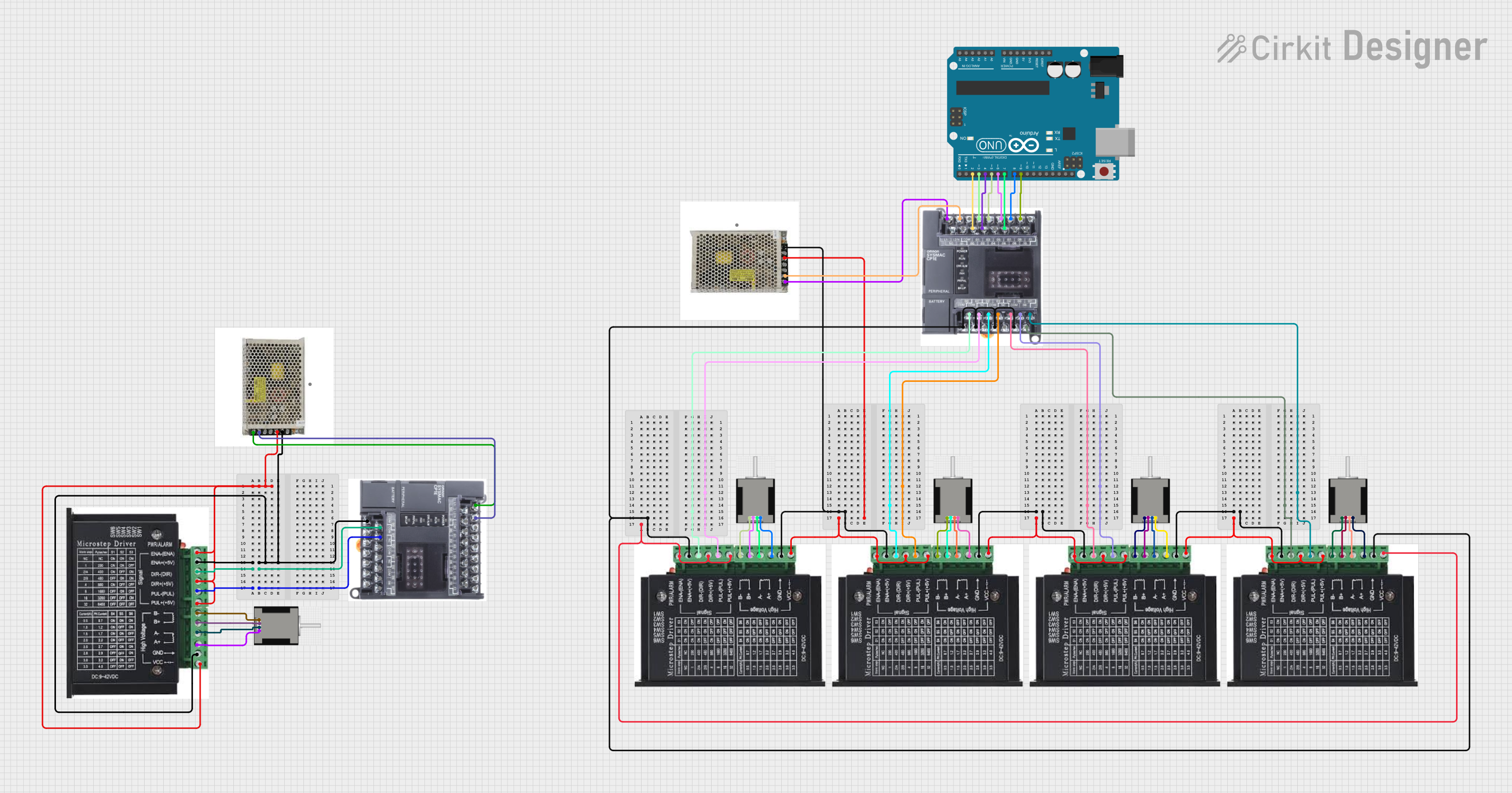

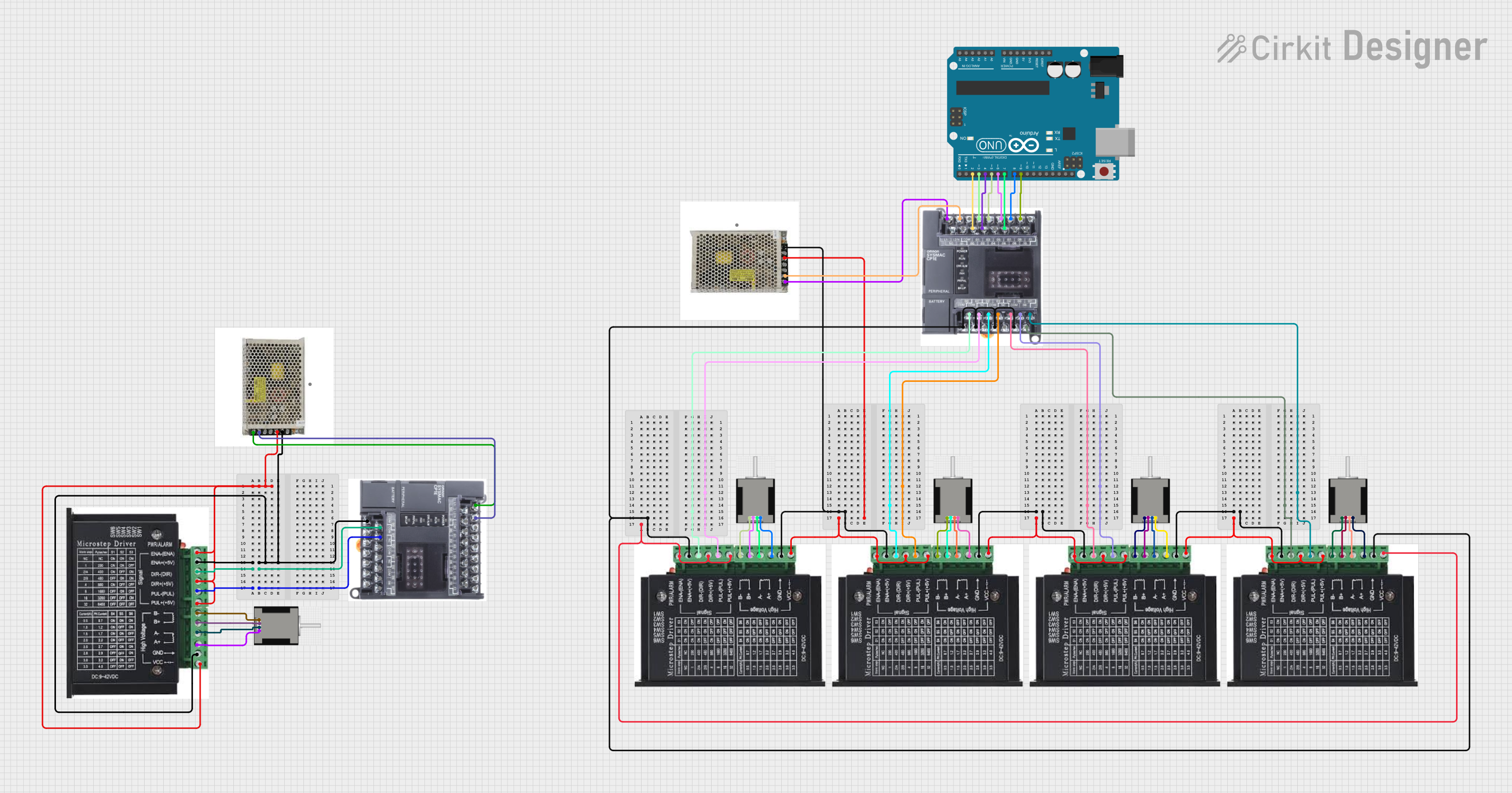

Explore Projects Built with PLC siemens s7-1200

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with PLC siemens s7-1200

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications and Use Cases

- Industrial automation and process control

- Machine control and monitoring

- Building automation systems

- Data acquisition and remote monitoring

- Integration with SCADA and HMI systems

Technical Specifications

The Siemens S7-1200 PLC is available in various models, each with different specifications. Below are the general technical details for the S7-1200 series:

Key Technical Details

- Power Supply Voltage: 24 V DC

- CPU Variants: Multiple options (e.g., CPU 1211C, CPU 1212C, CPU 1214C)

- Integrated I/O: Digital and analog inputs/outputs (varies by model)

- Communication Protocols: PROFINET, Modbus TCP, and optional communication modules

- Programming Software: TIA Portal (Totally Integrated Automation Portal)

- Memory: Up to 125 KB for program and 2 MB for data

- Operating Temperature: -20°C to +60°C

- Dimensions: Compact design, typically 90 mm x 100 mm x 75 mm (varies by model)

Pin Configuration and Descriptions

The S7-1200 PLC has a modular design, and the pin configuration depends on the specific CPU and I/O modules used. Below is an example of the pin configuration for the CPU 1212C:

| Pin Number | Pin Name | Description |

|---|---|---|

| 1-4 | Digital Inputs | Accepts 24 V DC signals for input |

| 5-8 | Digital Outputs | Provides 24 V DC signals for output |

| 9-12 | Analog Inputs | Accepts 0-10 V or 4-20 mA signals |

| 13-16 | Analog Outputs | Provides 0-10 V or 4-20 mA signals |

| 17-18 | Power Supply (+/-) | Connects to 24 V DC power supply |

| 19-20 | PROFINET Ports | Ethernet communication for networking |

Note: The exact pin configuration may vary depending on the specific CPU and I/O modules used. Refer to the Siemens S7-1200 datasheet for detailed information.

Usage Instructions

How to Use the S7-1200 in a Circuit

- Power Connection: Connect a 24 V DC power supply to the power input terminals of the PLC.

- I/O Wiring: Wire the digital and analog inputs/outputs to the respective devices (e.g., sensors, actuators).

- Communication Setup: Use the PROFINET port to connect the PLC to a network or other devices.

- Programming: Use Siemens' TIA Portal software to create and upload the control logic to the PLC.

- Testing: Verify the connections and test the program to ensure proper operation.

Important Considerations and Best Practices

- Power Supply: Ensure the power supply voltage is stable and within the specified range (24 V DC).

- Grounding: Properly ground the PLC to avoid electrical noise and interference.

- I/O Protection: Use appropriate protection devices (e.g., fuses, diodes) to safeguard the I/O terminals.

- Communication: Configure the network settings (e.g., IP address) correctly for seamless communication.

- Firmware Updates: Keep the PLC firmware updated to the latest version for improved performance and security.

Example Code for Arduino UNO Integration

Although the S7-1200 is not typically used with Arduino, it can communicate with an Arduino UNO via Modbus TCP. Below is an example of Arduino code to read data from the S7-1200:

#include <Ethernet.h>

#include <ModbusTCP.h>

// Define Modbus TCP client

ModbusTCP modbus;

// Ethernet settings

byte mac[] = { 0xDE, 0xAD, 0xBE, 0xEF, 0xFE, 0xED }; // MAC address

IPAddress plcIP(192, 168, 0, 1); // IP address of the S7-1200

int plcPort = 502; // Modbus TCP port

void setup() {

// Initialize Ethernet connection

Ethernet.begin(mac);

Serial.begin(9600);

while (!Serial) {

; // Wait for serial port to connect

}

Serial.println("Connecting to PLC...");

// Connect to the PLC

if (modbus.connect(plcIP, plcPort)) {

Serial.println("Connected to PLC!");

} else {

Serial.println("Failed to connect to PLC.");

}

}

void loop() {

// Read a holding register (e.g., address 40001)

int value = modbus.readHoldingRegisters(0, 1);

if (modbus.isConnected()) {

Serial.print("Register Value: ");

Serial.println(value);

} else {

Serial.println("Connection lost. Reconnecting...");

modbus.connect(plcIP, plcPort);

}

delay(1000); // Wait 1 second before next read

}

Note: Replace the plcIP and mac values with the actual IP address and MAC address of your setup. Ensure the S7-1200 is configured to communicate via Modbus TCP.

Troubleshooting and FAQs

Common Issues and Solutions

PLC Not Powering On

- Cause: Incorrect power supply voltage or loose connections.

- Solution: Verify the power supply voltage (24 V DC) and check the wiring.

Communication Failure

- Cause: Incorrect network settings or faulty cables.

- Solution: Check the IP address, subnet mask, and cable connections. Use a network diagnostic tool if needed.

I/O Not Responding

- Cause: Incorrect wiring or configuration.

- Solution: Verify the I/O wiring and ensure the program logic is correct.

Program Upload Fails

- Cause: Incompatible firmware or software version.

- Solution: Update the PLC firmware and ensure the TIA Portal version matches the PLC model.

FAQs

Q: Can the S7-1200 be expanded with additional modules?

- A: Yes, the S7-1200 supports expansion modules for additional I/O, communication, and functionality.

Q: What programming languages are supported?

- A: The S7-1200 supports Ladder Logic (LAD), Function Block Diagram (FBD), and Structured Text (ST).

Q: Is the S7-1200 compatible with SCADA systems?

- A: Yes, the S7-1200 can be integrated with SCADA systems using communication protocols like PROFINET or Modbus TCP.

Q: How do I reset the PLC to factory settings?

- A: Use the TIA Portal software or the hardware reset button (if available) to reset the PLC.

This documentation provides a comprehensive overview of the Siemens S7-1200 PLC, including its specifications, usage, and troubleshooting tips. For more detailed information, refer to the official Siemens user manual.