How to Use Pressure Sensor Module: Examples, Pinouts, and Specs

Design with Pressure Sensor Module in Cirkit Designer

Design with Pressure Sensor Module in Cirkit DesignerIntroduction

The CFSensor XGZP6857 Pressure Sensor Module is a high-precision device designed to measure the pressure of gases or liquids and convert it into an electrical signal. This module is widely used in industrial, automotive, and medical applications where accurate pressure monitoring and control are essential. Its compact design and reliable performance make it suitable for integration into a variety of systems.

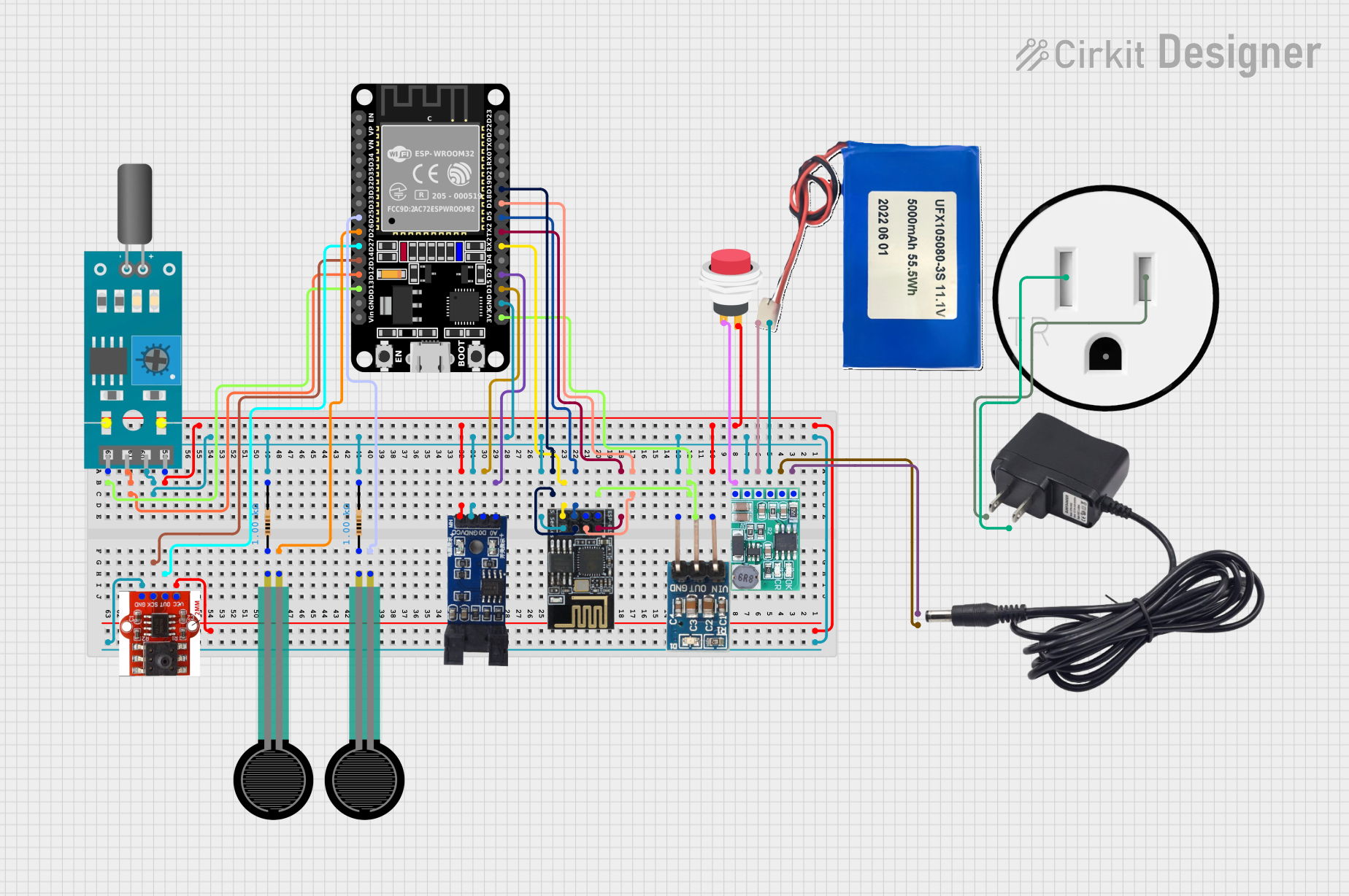

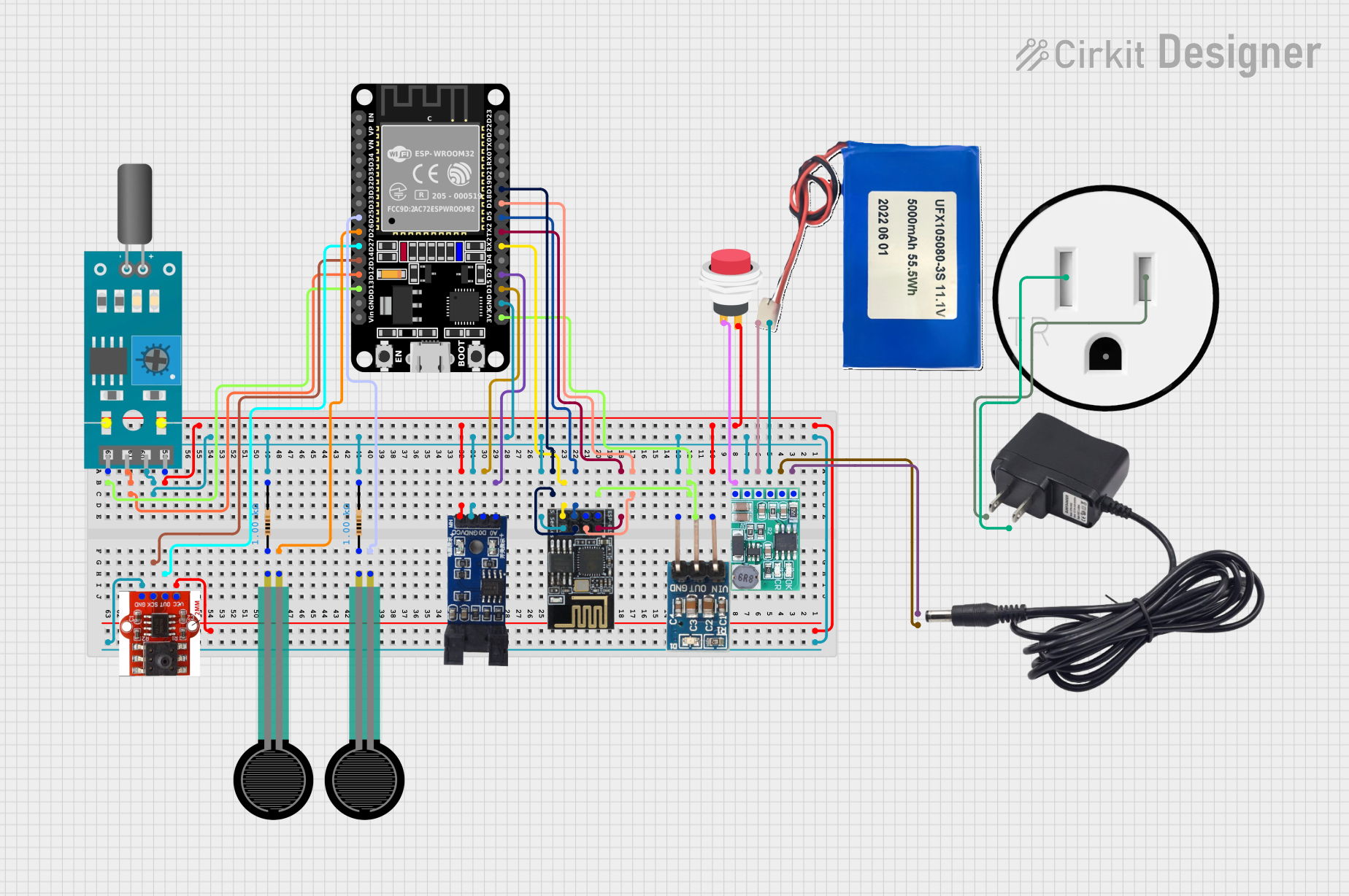

Explore Projects Built with Pressure Sensor Module

Open Project in Cirkit Designer

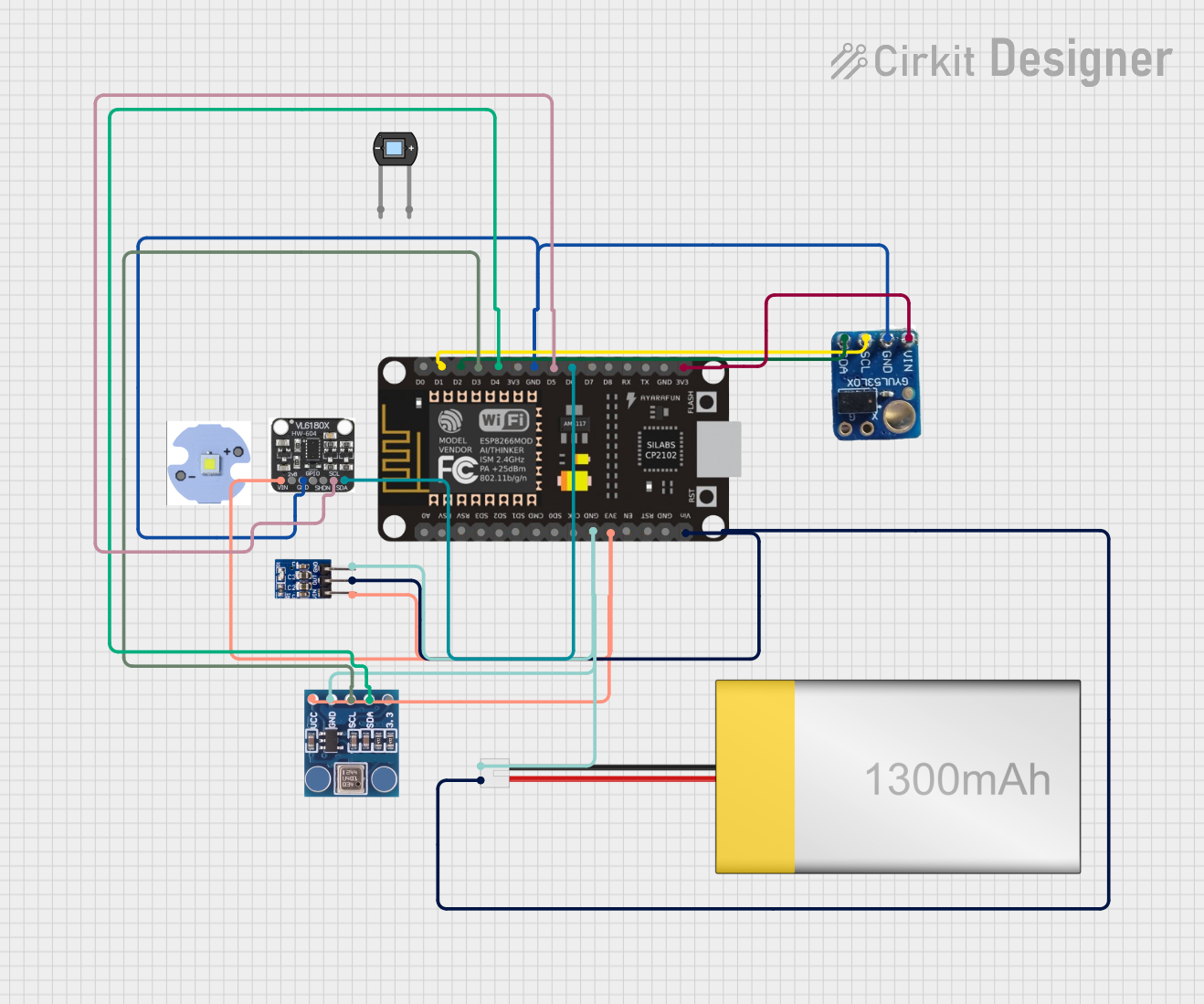

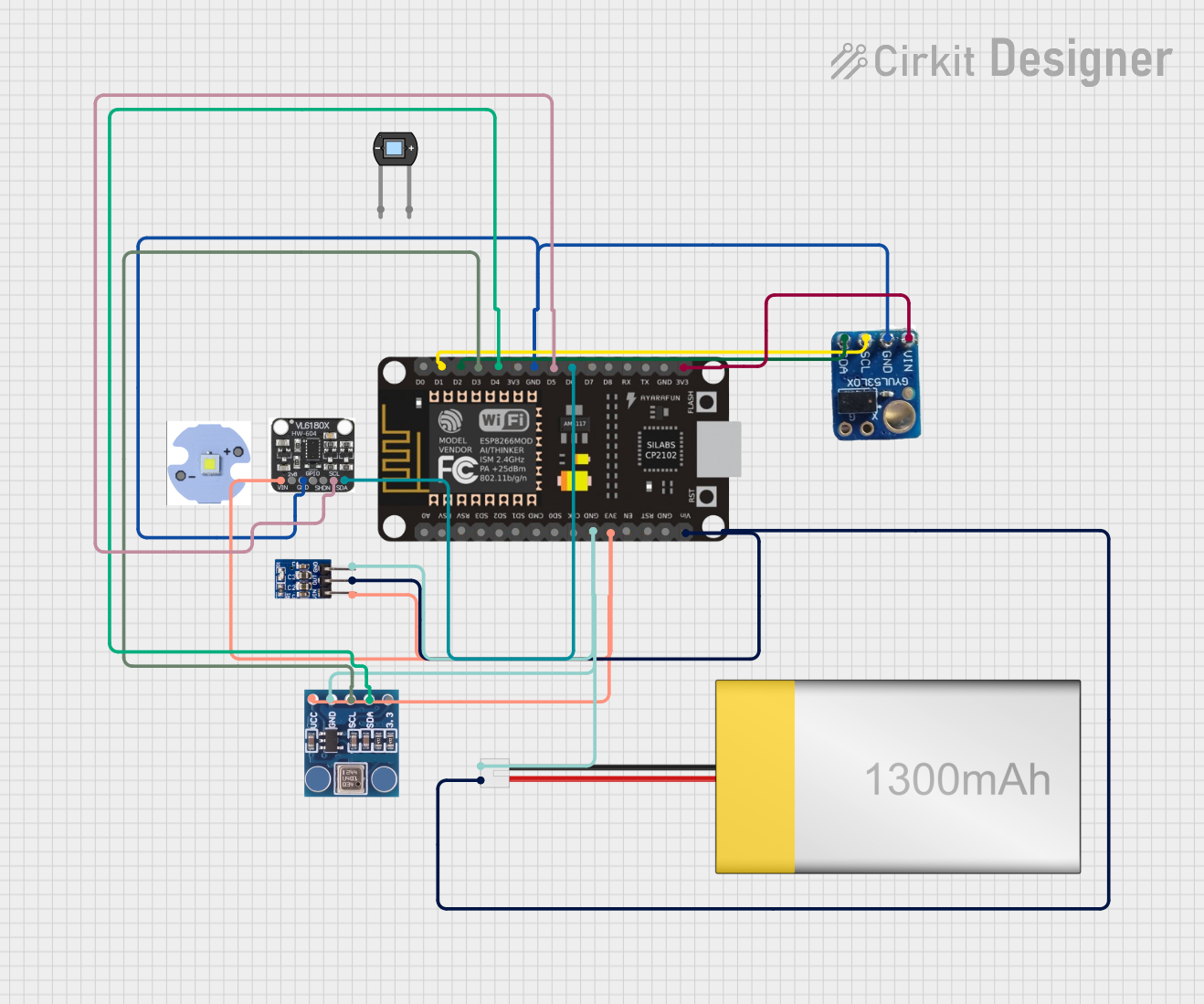

Open Project in Cirkit Designer

Open Project in Cirkit Designer

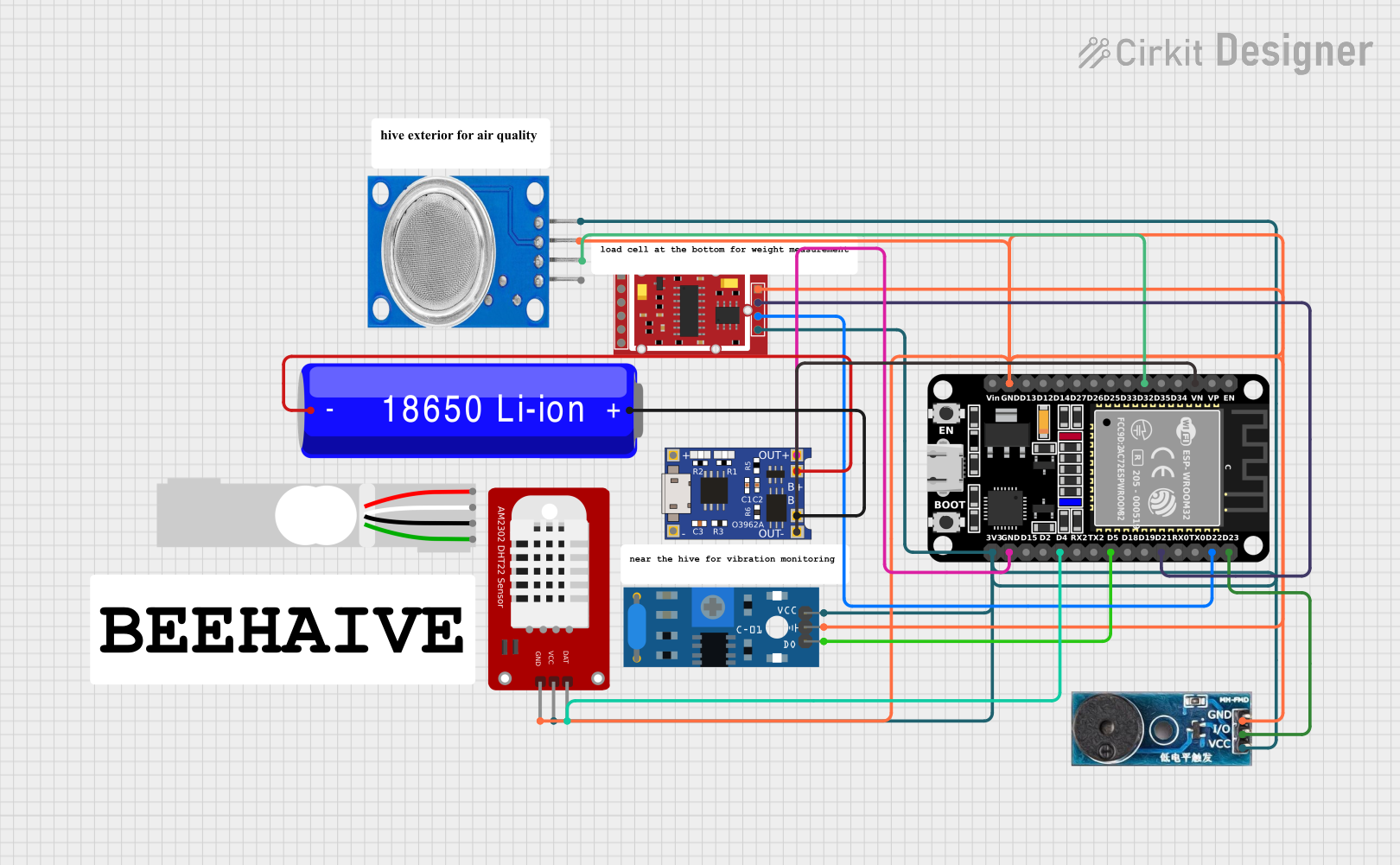

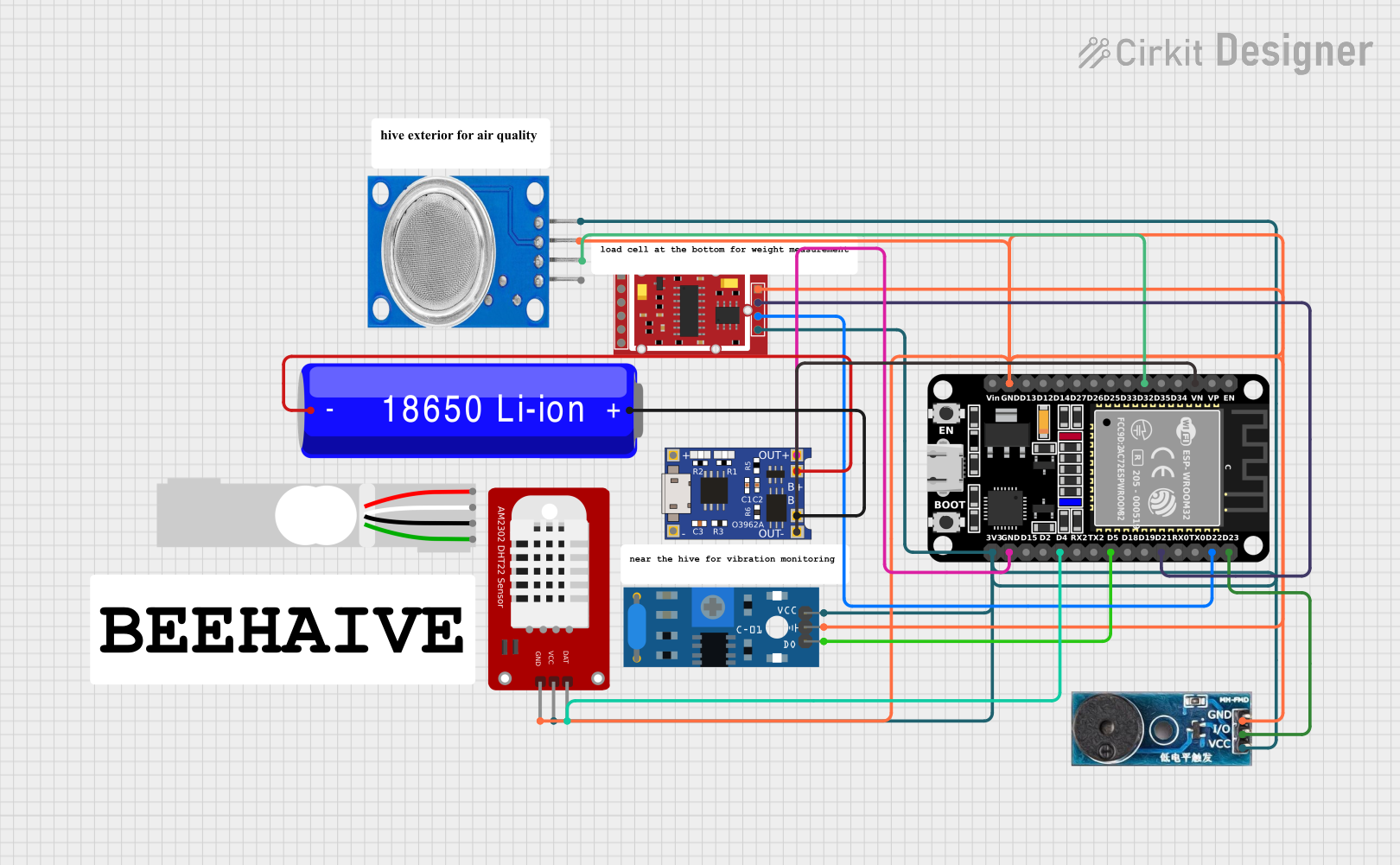

Open Project in Cirkit Designer

Open Project in Cirkit Designer

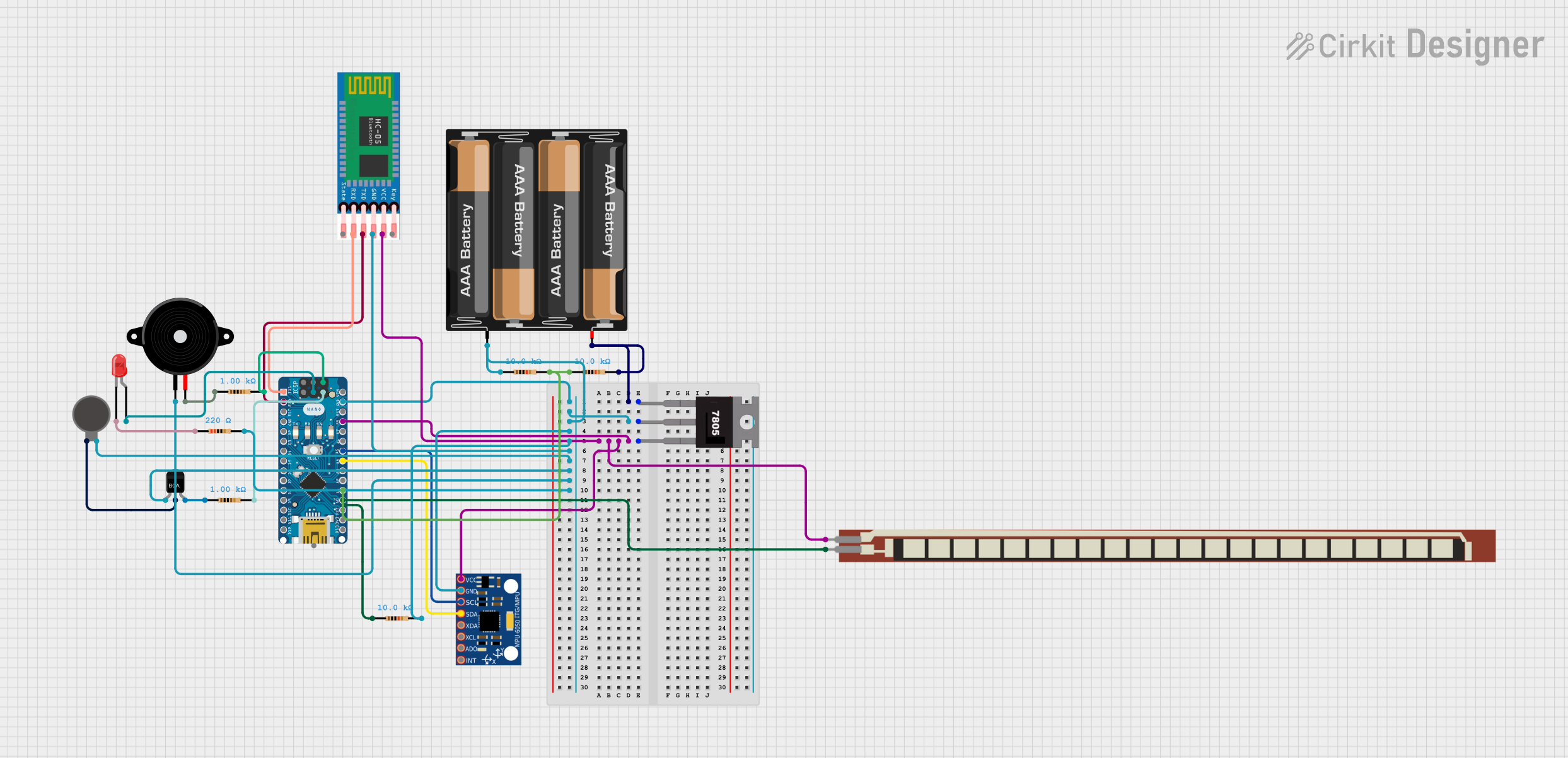

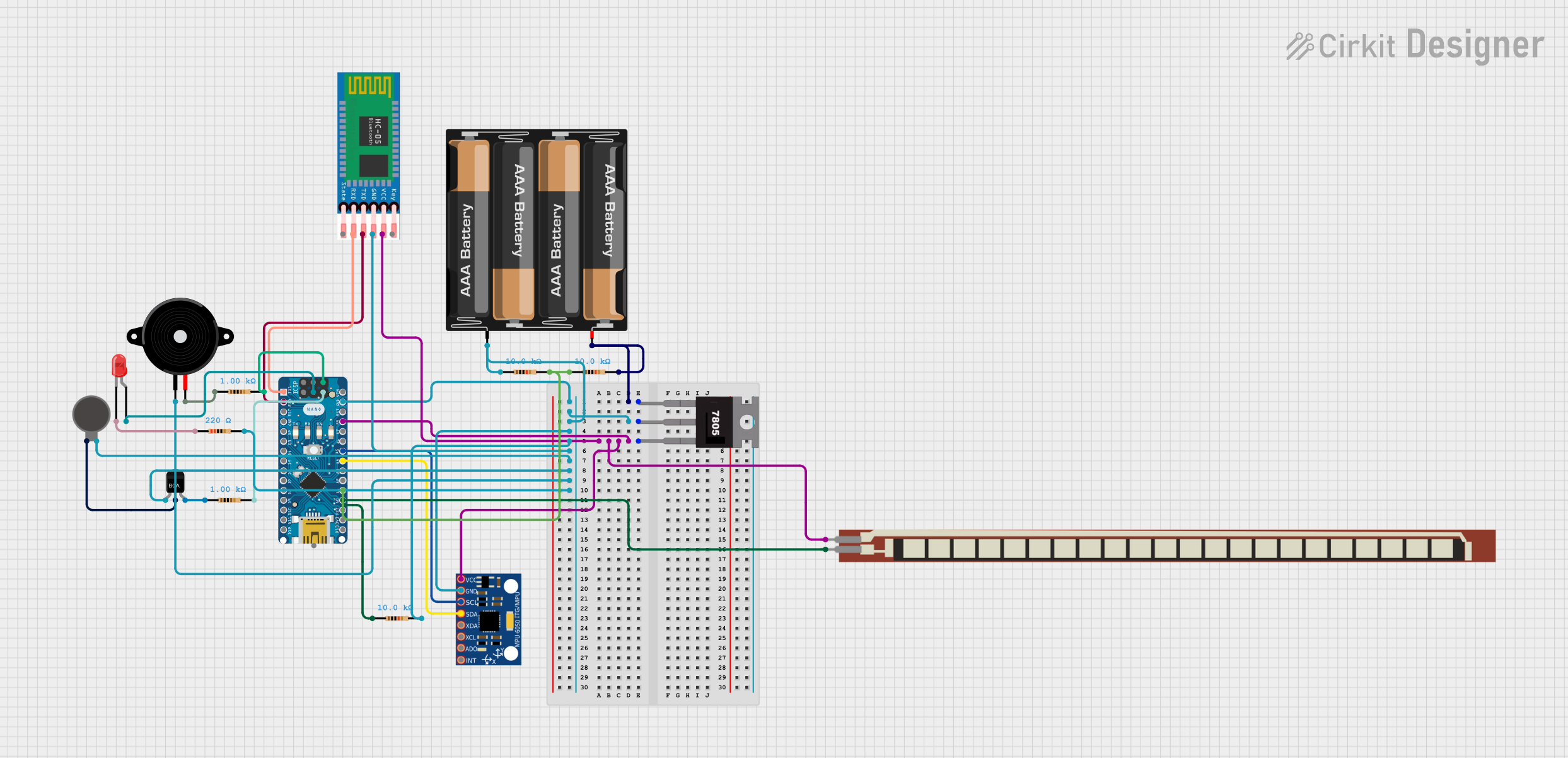

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with Pressure Sensor Module

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications and Use Cases

- Industrial Automation: Monitoring and controlling pressure in pipelines and tanks.

- Automotive Systems: Measuring tire pressure, engine oil pressure, or fuel pressure.

- Medical Devices: Blood pressure monitoring and respiratory equipment.

- HVAC Systems: Ensuring optimal air pressure in heating, ventilation, and air conditioning systems.

- Weather Stations: Measuring atmospheric pressure for forecasting.

Technical Specifications

The following table outlines the key technical details of the XGZP6857 Pressure Sensor Module:

| Parameter | Value |

|---|---|

| Manufacturer | CFSensor |

| Part ID | XGZP6857 |

| Pressure Range | 0 to 100 kPa |

| Supply Voltage | 3.3V to 5V |

| Output Signal | Analog Voltage (0.5V to 4.5V) |

| Accuracy | ±1% Full Scale |

| Operating Temperature | -40°C to +85°C |

| Response Time | < 1 ms |

| Interface Type | Analog |

| Dimensions | 18mm x 12mm x 8mm |

Pin Configuration and Descriptions

The XGZP6857 module has a 3-pin interface. The pinout is as follows:

| Pin | Name | Description |

|---|---|---|

| 1 | VCC | Power supply input (3.3V to 5V) |

| 2 | GND | Ground connection |

| 3 | OUT | Analog output signal proportional to pressure input |

Usage Instructions

How to Use the Component in a Circuit

- Power the Module: Connect the

VCCpin to a 3.3V or 5V power supply and theGNDpin to the ground of your circuit. - Read the Output Signal: The

OUTpin provides an analog voltage signal that corresponds to the measured pressure. This signal can be read using an analog-to-digital converter (ADC) on a microcontroller, such as an Arduino UNO. - Calibrate the Sensor: For accurate measurements, calibrate the sensor by mapping the output voltage range (0.5V to 4.5V) to the pressure range (0 to 100 kPa).

Important Considerations and Best Practices

- Power Supply: Ensure a stable power supply to avoid fluctuations in the output signal.

- Environmental Conditions: Avoid exposing the sensor to conditions beyond its operating temperature or pressure range.

- Signal Noise: Use proper grounding and shielding to minimize noise in the output signal.

- Mounting: Secure the sensor in a stable position to prevent mechanical vibrations from affecting readings.

Example Code for Arduino UNO

The following code demonstrates how to interface the XGZP6857 Pressure Sensor Module with an Arduino UNO to read and display pressure values:

// Define the analog pin connected to the sensor's OUT pin

const int sensorPin = A0;

// Define the pressure range and output voltage range of the sensor

const float pressureMin = 0.0; // Minimum pressure in kPa

const float pressureMax = 100.0; // Maximum pressure in kPa

const float voltageMin = 0.5; // Minimum output voltage in volts

const float voltageMax = 4.5; // Maximum output voltage in volts

void setup() {

Serial.begin(9600); // Initialize serial communication at 9600 baud

}

void loop() {

// Read the analog value from the sensor

int sensorValue = analogRead(sensorPin);

// Convert the analog value to a voltage (assuming 5V reference)

float voltage = sensorValue * (5.0 / 1023.0);

// Map the voltage to the pressure range

float pressure = (voltage - voltageMin) * (pressureMax - pressureMin) /

(voltageMax - voltageMin) + pressureMin;

// Print the pressure value to the Serial Monitor

Serial.print("Pressure: ");

Serial.print(pressure);

Serial.println(" kPa");

delay(1000); // Wait for 1 second before the next reading

}

Troubleshooting and FAQs

Common Issues and Solutions

No Output Signal:

- Cause: Incorrect wiring or insufficient power supply.

- Solution: Verify the connections and ensure the power supply voltage is within the specified range (3.3V to 5V).

Inaccurate Readings:

- Cause: Sensor not calibrated or exposed to electrical noise.

- Solution: Calibrate the sensor and ensure proper grounding and shielding.

Fluctuating Output:

- Cause: Unstable power supply or mechanical vibrations.

- Solution: Use a regulated power supply and secure the sensor in a stable position.

FAQs

Q: Can the XGZP6857 measure negative pressure?

A: No, the sensor is designed to measure pressures in the range of 0 to 100 kPa only.Q: Is the sensor waterproof?

A: The sensor is not waterproof. Avoid exposing it to liquids unless it is properly enclosed in a protective housing.Q: Can I use this sensor with a 3.3V microcontroller?

A: Yes, the sensor operates with a supply voltage of 3.3V to 5V, making it compatible with 3.3V microcontrollers.Q: How do I improve the accuracy of the sensor?

A: Perform a calibration procedure and ensure the sensor is used within its specified operating conditions.