How to Use stepper motor driver : Examples, Pinouts, and Specs

Design with stepper motor driver in Cirkit Designer

Design with stepper motor driver in Cirkit DesignerIntroduction

A stepper motor driver is an electronic device that controls the operation of a stepper motor by sending precise electrical pulses to its coils. This enables accurate positioning, speed control, and direction of rotation. Stepper motor drivers are essential for applications requiring precise motion control, such as 3D printers, CNC machines, robotics, and automated systems.

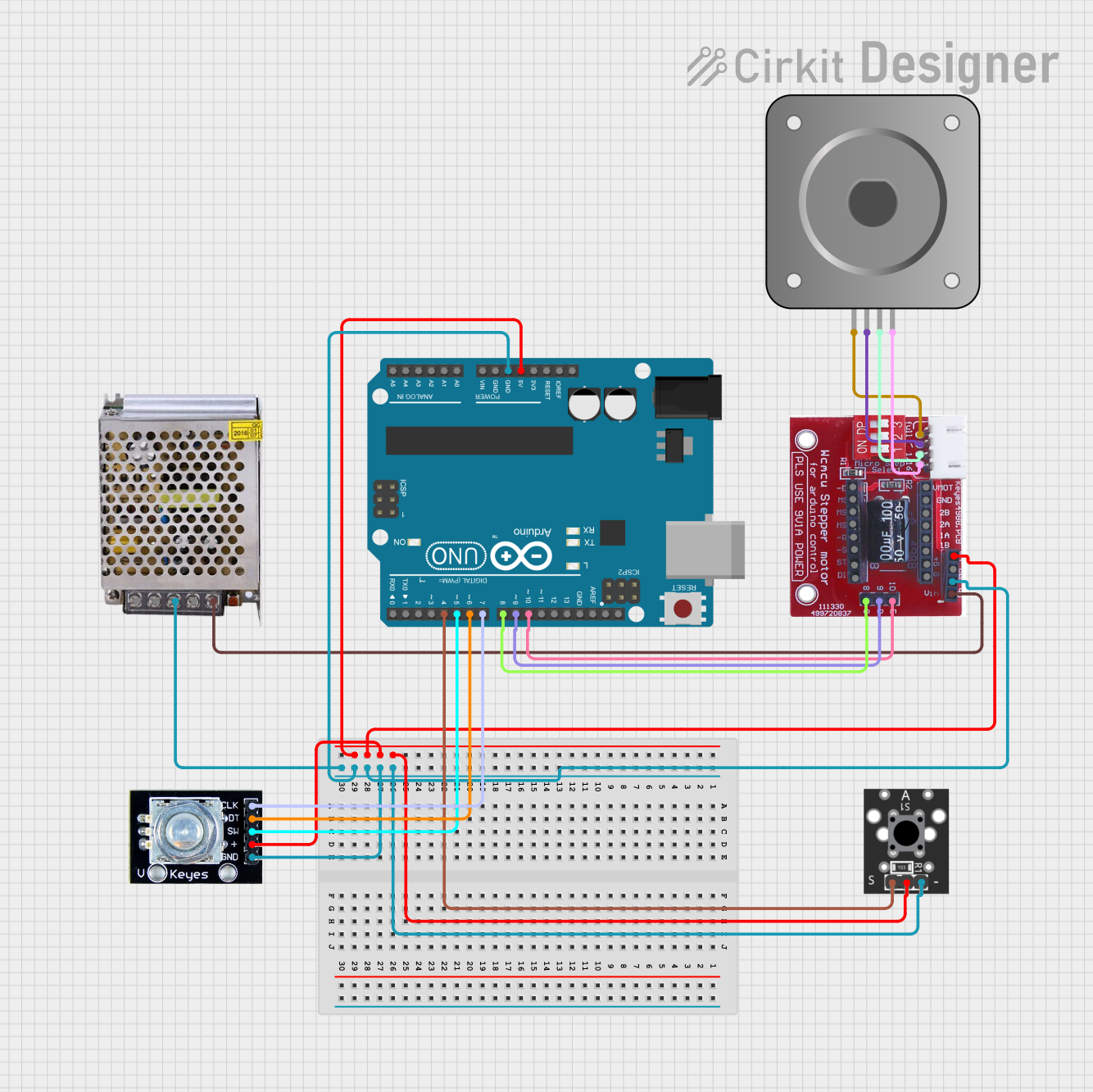

Explore Projects Built with stepper motor driver

Open Project in Cirkit Designer

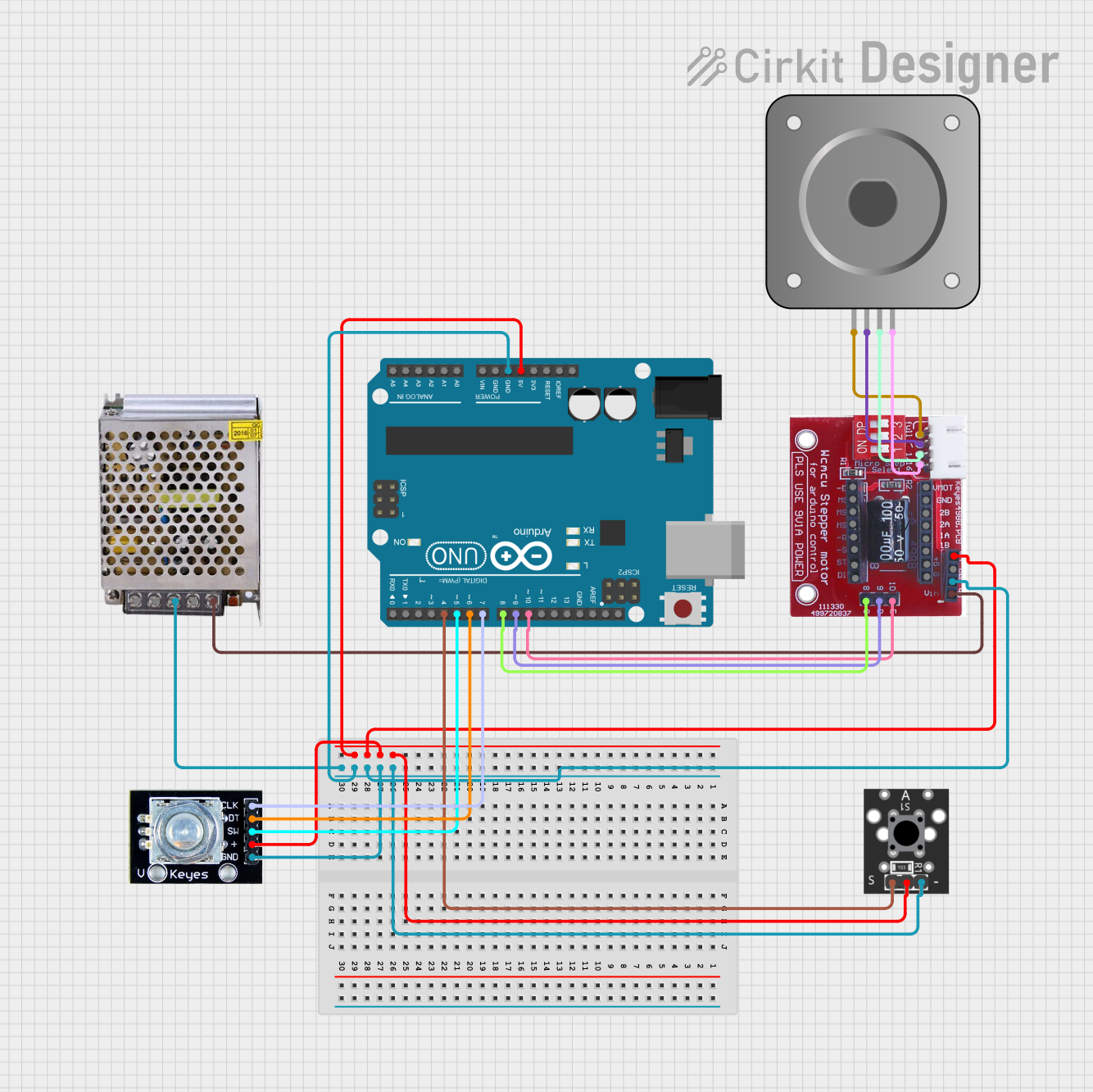

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with stepper motor driver

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications and Use Cases

- 3D printers for precise layer positioning

- CNC machines for accurate cutting and engraving

- Robotics for controlled movement and positioning

- Camera sliders and gimbals for smooth motion

- Automated conveyor systems in industrial settings

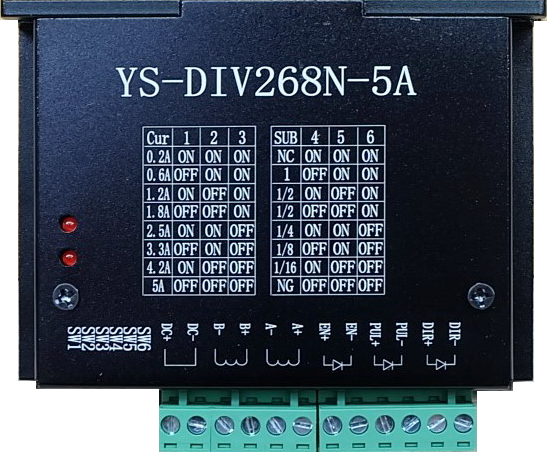

Technical Specifications

Below are the general technical specifications for a typical stepper motor driver. Specific models may vary, so always refer to the datasheet of the driver you are using.

Key Technical Details

- Input Voltage Range: 8V to 45V (varies by model)

- Output Current: Up to 2A per phase (adjustable via potentiometer)

- Microstepping Support: Full step, half step, 1/4 step, 1/8 step, 1/16 step

- Control Interface: Step and direction pins

- Protection Features: Overcurrent, overtemperature, and undervoltage lockout

- Operating Temperature: -20°C to 85°C

Pin Configuration and Descriptions

The following table describes the pinout for a common stepper motor driver, such as the A4988 or DRV8825.

| Pin Name | Description |

|---|---|

| VCC | Power supply input for the logic circuit (typically 3.3V or 5V). |

| GND | Ground connection for the logic and motor power supply. |

| VMOT | Power supply input for the motor (e.g., 8V to 45V). |

| STEP | Input pin to control the step signal. Each pulse moves the motor one step. |

| DIR | Input pin to control the direction of motor rotation. |

| ENABLE | Optional input to enable or disable the driver (active low). |

| MS1, MS2, MS3 | Microstepping mode selection pins. Configure the step resolution. |

| RESET | Resets the driver to its initial state (active low). |

| SLEEP | Puts the driver into low-power sleep mode (active low). |

| OUT1, OUT2 | Outputs connected to one coil of the stepper motor. |

| OUT3, OUT4 | Outputs connected to the other coil of the stepper motor. |

Usage Instructions

How to Use the Component in a Circuit

Power Connections:

- Connect the motor power supply to the

VMOTpin and ground to theGNDpin. - Connect the logic power supply (3.3V or 5V) to the

VCCpin and ground to theGNDpin.

- Connect the motor power supply to the

Motor Connections:

- Connect the stepper motor coils to the

OUT1,OUT2,OUT3, andOUT4pins. Refer to the motor datasheet to identify the coil pairs.

- Connect the stepper motor coils to the

Control Pins:

- Connect the

STEPandDIRpins to a microcontroller or other control circuit. - Optionally, connect the

ENABLE,RESET, andSLEEPpins as needed.

- Connect the

Microstepping Configuration:

- Use the

MS1,MS2, andMS3pins to set the desired microstepping mode. Refer to the driver datasheet for the configuration table.

- Use the

Adjust Current Limit:

- Use the onboard potentiometer to set the current limit for the motor. This prevents overheating and ensures safe operation.

Important Considerations and Best Practices

- Always use a capacitor (e.g., 100µF) across the

VMOTandGNDpins to prevent voltage spikes. - Ensure the motor power supply voltage matches the requirements of your stepper motor.

- Avoid disconnecting the motor while the driver is powered, as this can damage the driver.

- Use heatsinks or active cooling if the driver operates at high currents for extended periods.

Example Code for Arduino UNO

Below is an example of how to control a stepper motor driver using an Arduino UNO.

// Define the control pins for the stepper motor driver

#define STEP_PIN 3 // Pin connected to the STEP input of the driver

#define DIR_PIN 4 // Pin connected to the DIR input of the driver

void setup() {

// Set the STEP and DIR pins as outputs

pinMode(STEP_PIN, OUTPUT);

pinMode(DIR_PIN, OUTPUT);

// Set the initial direction of the motor

digitalWrite(DIR_PIN, HIGH); // HIGH for one direction, LOW for the other

}

void loop() {

// Generate a pulse on the STEP pin to move the motor one step

digitalWrite(STEP_PIN, HIGH); // Set STEP pin HIGH

delayMicroseconds(500); // Wait for 500 microseconds

digitalWrite(STEP_PIN, LOW); // Set STEP pin LOW

delayMicroseconds(500); // Wait for 500 microseconds

}

Troubleshooting and FAQs

Common Issues and Solutions

Motor Not Moving:

- Cause: Incorrect wiring or insufficient power supply.

- Solution: Double-check all connections and ensure the power supply meets the voltage and current requirements.

Driver Overheating:

- Cause: Current limit set too high or inadequate cooling.

- Solution: Adjust the current limit using the potentiometer and add a heatsink or fan.

Motor Vibrates but Does Not Rotate:

- Cause: Incorrect stepper motor wiring.

- Solution: Verify the coil pairs and ensure they are connected to the correct driver outputs.

Inconsistent or Jerky Movement:

- Cause: Noise or insufficient delay between steps.

- Solution: Add decoupling capacitors and increase the delay in the control code.

FAQs

Q: Can I use a stepper motor driver with a DC motor?

A: No, stepper motor drivers are specifically designed for stepper motors and are not compatible with DC motors.Q: How do I determine the correct current limit for my motor?

A: Refer to the motor datasheet for the rated current per phase and adjust the driver’s potentiometer accordingly.Q: Can I control multiple stepper motors with one Arduino?

A: Yes, but each motor will require its own driver, and you must assign separate control pins for each driver.Q: What happens if I exceed the driver’s voltage or current ratings?

A: Exceeding the ratings can damage the driver and potentially the motor. Always operate within the specified limits.

This concludes the documentation for the stepper motor driver. Always refer to the specific driver’s datasheet for additional details and recommendations.