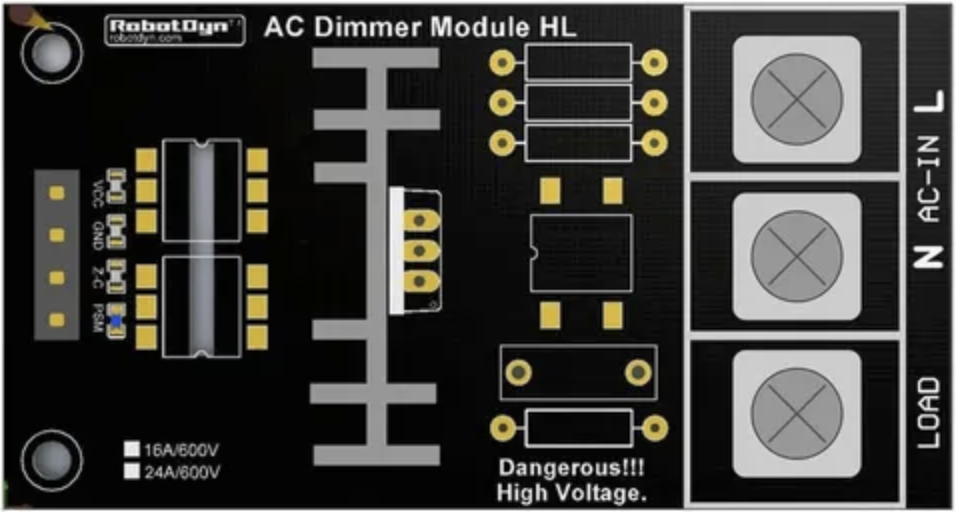

How to Use RobotDyn 16/24A: Examples, Pinouts, and Specs

Design with RobotDyn 16/24A in Cirkit Designer

Design with RobotDyn 16/24A in Cirkit DesignerIntroduction

The RobotDyn 16/24A is a high-performance motor driver designed to control DC motors with a current rating of 16A to 24A. This versatile component is ideal for robotics, automation, and other applications requiring precise motor control. Its robust design ensures reliable operation in demanding environments, making it a popular choice for hobbyists and professionals alike.

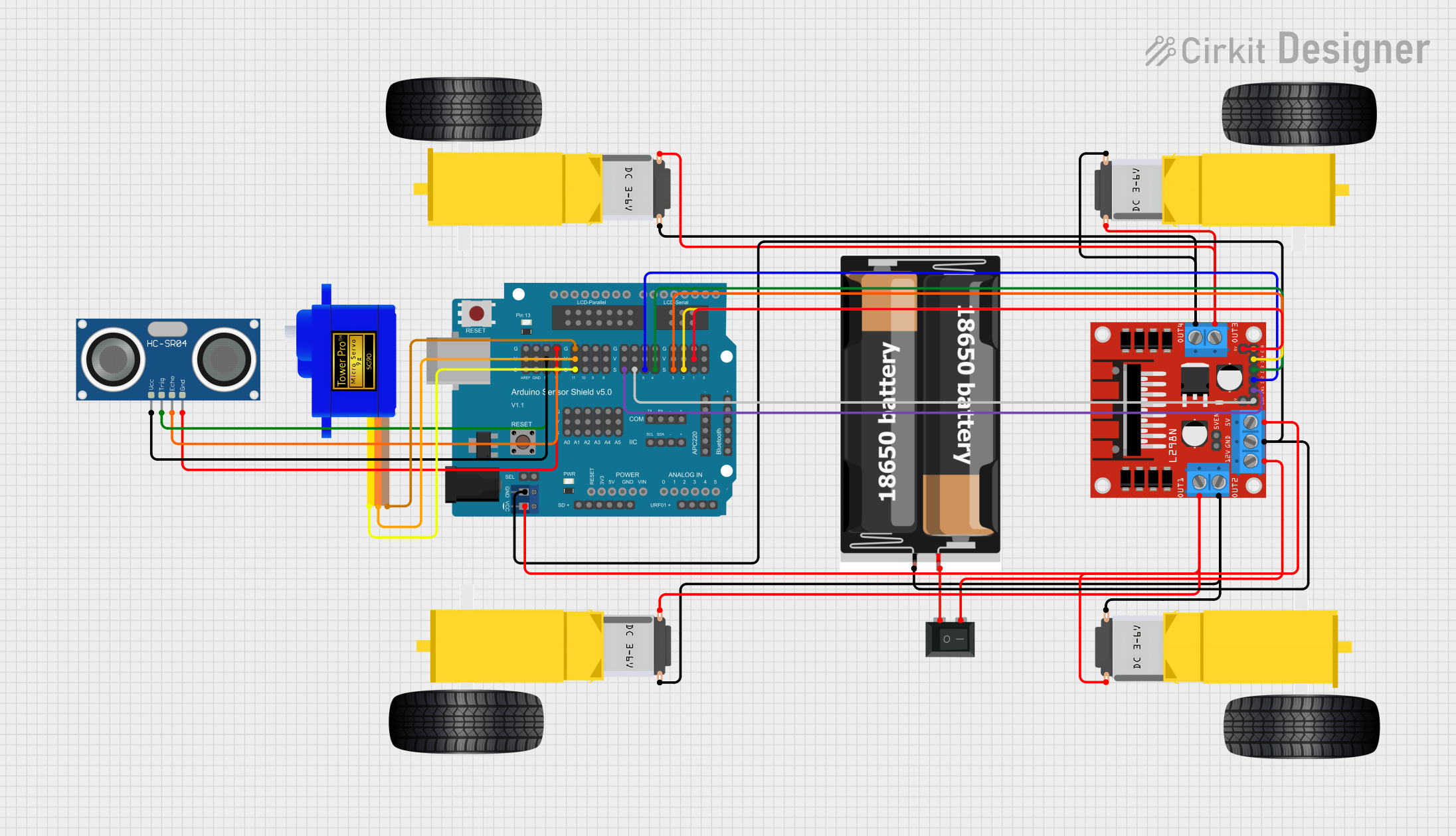

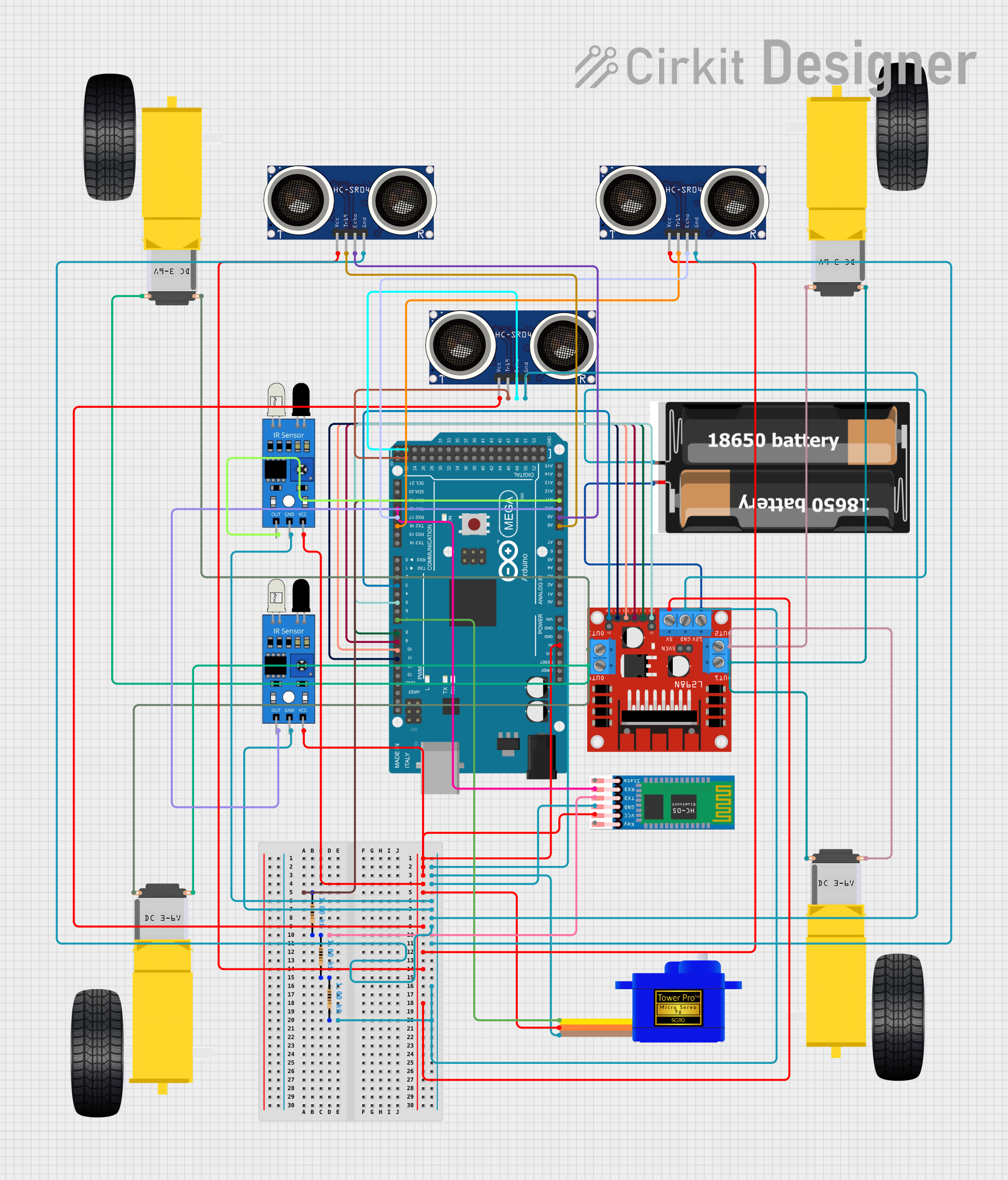

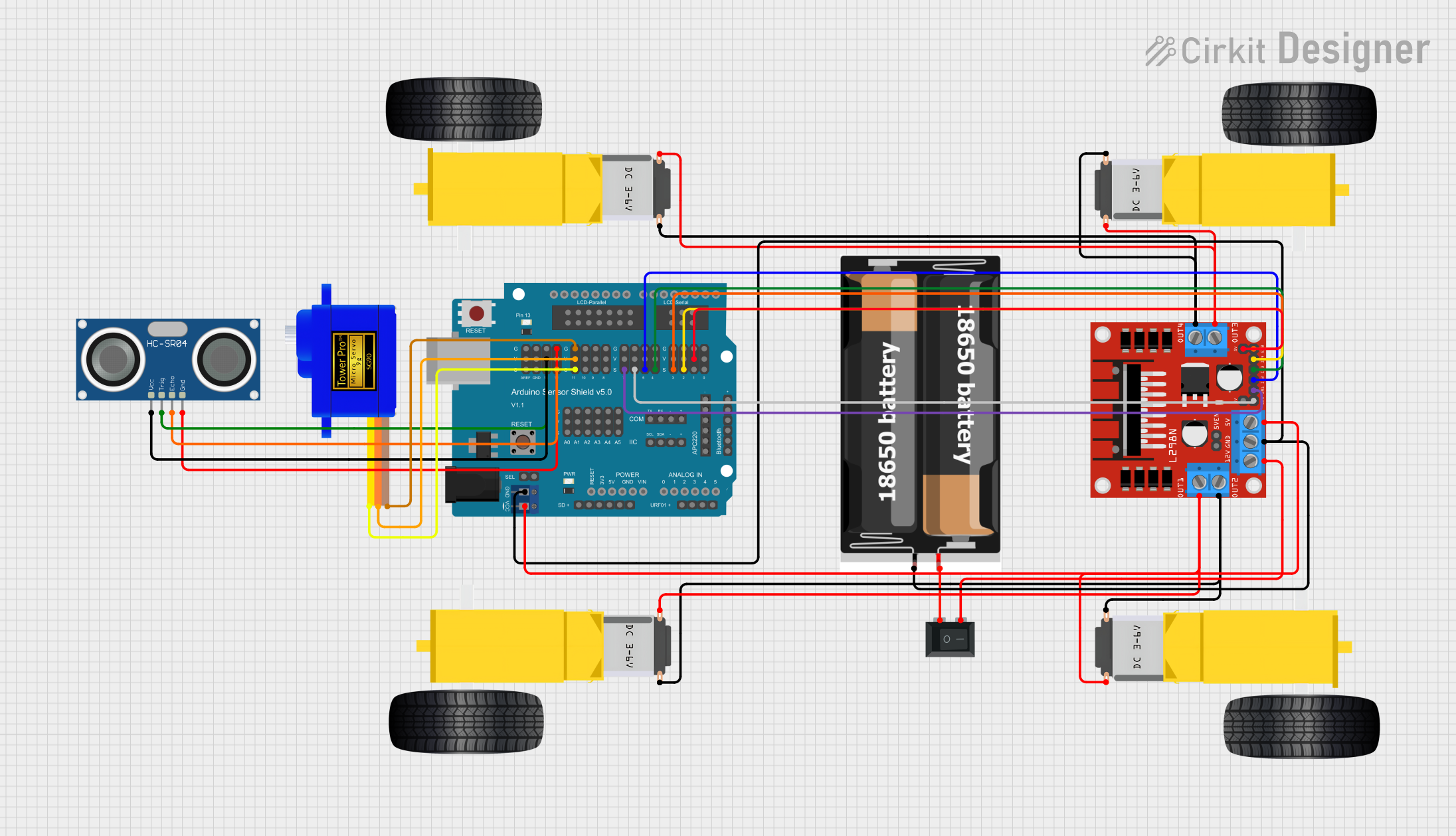

Explore Projects Built with RobotDyn 16/24A

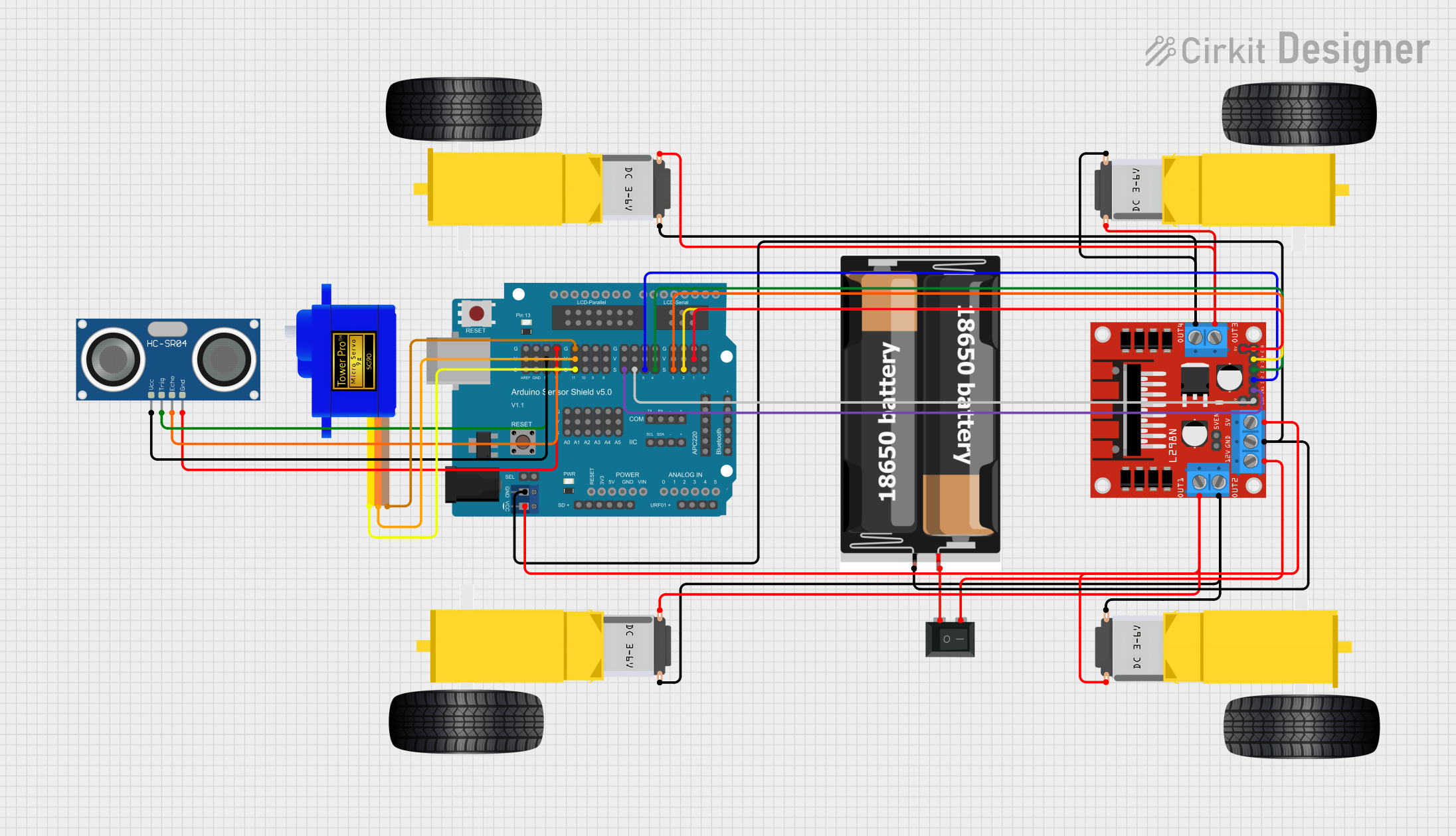

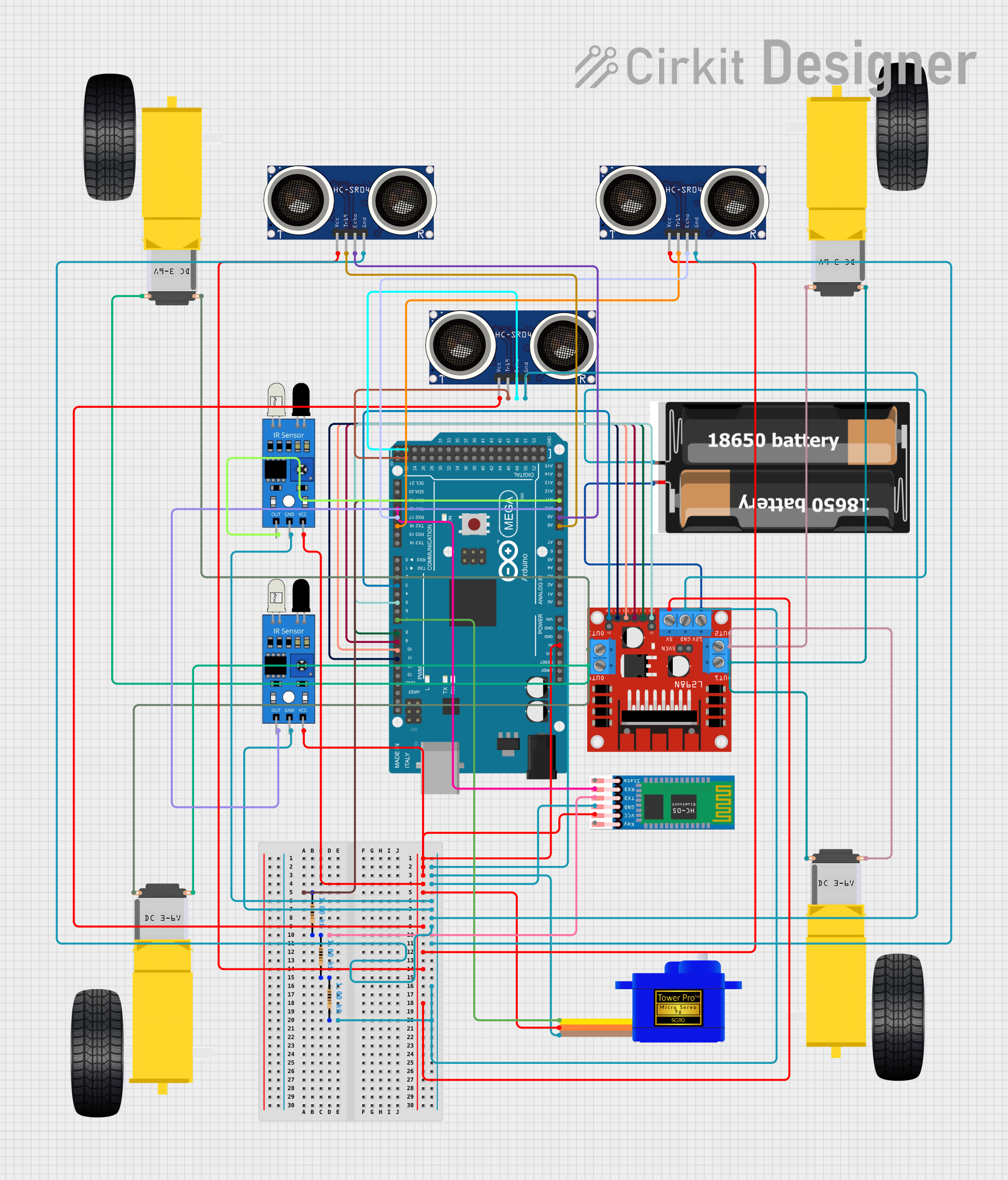

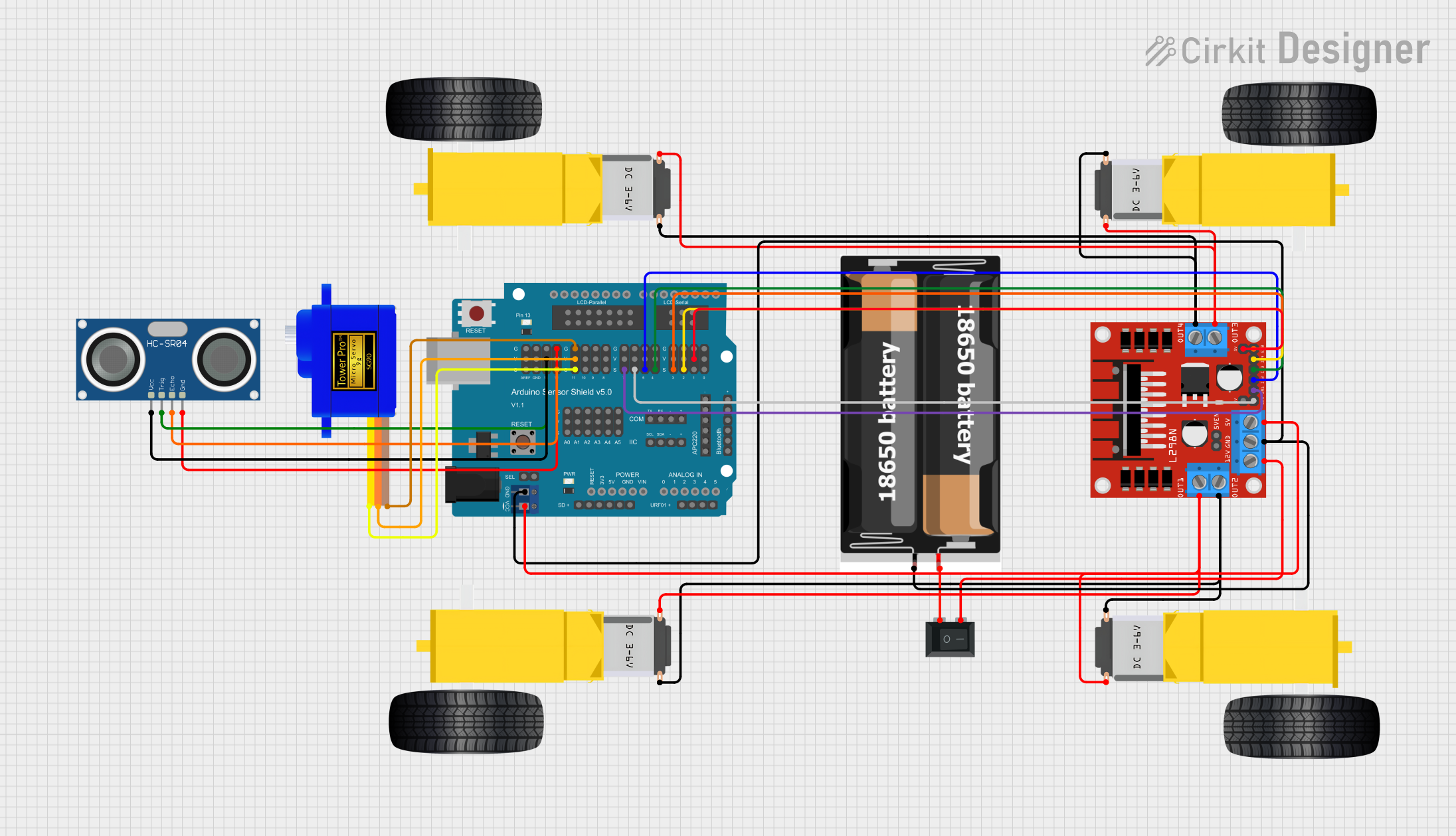

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with RobotDyn 16/24A

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications

- Robotics and automation systems

- Electric vehicles and motorized carts

- Conveyor belts and industrial machinery

- Remote-controlled cars, boats, and drones

- DIY motorized projects

Technical Specifications

The following table outlines the key technical details of the RobotDyn 16/24A motor driver:

| Parameter | Value |

|---|---|

| Operating Voltage | 6V to 36V |

| Continuous Current | 16A |

| Peak Current | 24A |

| Control Logic Voltage | 3.3V to 5V |

| PWM Frequency | Up to 20 kHz |

| Operating Temperature | -40°C to +85°C |

| Dimensions | 60mm x 50mm x 20mm |

Pin Configuration and Descriptions

The RobotDyn 16/24A motor driver has the following pin configuration:

| Pin Name | Type | Description |

|---|---|---|

| VIN | Power Input | Connect to the motor power supply (6V to 36V). |

| GND | Power Ground | Ground connection for the motor power supply. |

| IN1 | Logic Input | Control signal for Motor A direction. |

| IN2 | Logic Input | Control signal for Motor A direction (complementary to IN1). |

| IN3 | Logic Input | Control signal for Motor B direction. |

| IN4 | Logic Input | Control signal for Motor B direction (complementary to IN3). |

| ENA | PWM Input | Speed control for Motor A (Pulse Width Modulation). |

| ENB | PWM Input | Speed control for Motor B (Pulse Width Modulation). |

| OUT1 | Motor Output | Connect to one terminal of Motor A. |

| OUT2 | Motor Output | Connect to the other terminal of Motor A. |

| OUT3 | Motor Output | Connect to one terminal of Motor B. |

| OUT4 | Motor Output | Connect to the other terminal of Motor B. |

Usage Instructions

How to Use the Component in a Circuit

- Power Supply: Connect the VIN and GND pins to a power source that matches the motor's voltage requirements (6V to 36V).

- Motor Connections: Attach the motor terminals to the OUT1/OUT2 pins (for Motor A) and OUT3/OUT4 pins (for Motor B).

- Control Signals: Use IN1/IN2 and IN3/IN4 to control the direction of Motor A and Motor B, respectively.

- Speed Control: Provide PWM signals to the ENA and ENB pins to adjust the speed of Motor A and Motor B.

Important Considerations and Best Practices

- Ensure the power supply can handle the peak current (24A) to avoid voltage drops or damage.

- Use appropriate heat sinks or cooling mechanisms if operating at high currents for extended periods.

- Avoid reversing the polarity of the power supply to prevent damage to the motor driver.

- Use decoupling capacitors near the VIN and GND pins to reduce noise and improve stability.

Example: Connecting to an Arduino UNO

Below is an example of how to control two DC motors using the RobotDyn 16/24A motor driver and an Arduino UNO:

// Define motor control pins

const int IN1 = 7; // Motor A direction control

const int IN2 = 8; // Motor A direction control

const int ENA = 9; // Motor A speed control (PWM)

const int IN3 = 10; // Motor B direction control

const int IN4 = 11; // Motor B direction control

const int ENB = 6; // Motor B speed control (PWM)

void setup() {

// Set motor control pins as outputs

pinMode(IN1, OUTPUT);

pinMode(IN2, OUTPUT);

pinMode(ENA, OUTPUT);

pinMode(IN3, OUTPUT);

pinMode(IN4, OUTPUT);

pinMode(ENB, OUTPUT);

}

void loop() {

// Motor A: Forward at 50% speed

digitalWrite(IN1, HIGH);

digitalWrite(IN2, LOW);

analogWrite(ENA, 128); // 50% duty cycle (0-255)

// Motor B: Reverse at 75% speed

digitalWrite(IN3, LOW);

digitalWrite(IN4, HIGH);

analogWrite(ENB, 192); // 75% duty cycle (0-255)

delay(5000); // Run motors for 5 seconds

// Stop both motors

analogWrite(ENA, 0);

analogWrite(ENB, 0);

delay(2000); // Wait for 2 seconds before repeating

}

Troubleshooting and FAQs

Common Issues and Solutions

Motors Not Running:

- Verify that the power supply is connected and providing the correct voltage.

- Check the control signals (IN1, IN2, IN3, IN4) and ensure they are set correctly.

- Ensure the ENA and ENB pins are receiving valid PWM signals.

Overheating:

- Ensure the motor driver is not exceeding its continuous current rating (16A).

- Add a heat sink or active cooling if operating near the peak current (24A).

Erratic Motor Behavior:

- Check for loose connections or damaged wires.

- Add decoupling capacitors to the power supply to reduce noise.

Arduino Not Controlling the Driver:

- Ensure the Arduino's logic voltage (3.3V or 5V) matches the motor driver's control logic voltage.

- Verify that the Arduino pins are correctly configured as outputs.

FAQs

Q: Can I use this motor driver with stepper motors?

A: No, the RobotDyn 16/24A is designed for DC motors and is not suitable for stepper motors.

Q: What is the maximum PWM frequency supported?

A: The motor driver supports PWM frequencies up to 20 kHz.

Q: Can I control only one motor with this driver?

A: Yes, you can use the driver to control a single motor by connecting it to either Motor A or Motor B outputs.

Q: Is reverse polarity protection included?

A: No, the driver does not have built-in reverse polarity protection. Ensure correct polarity to avoid damage.