Cirkit Designer

Your all-in-one circuit design IDE

Home /

Component Documentation

How to Use PTC Heater Plate: Examples, Pinouts, and Specs

Design with PTC Heater Plate in Cirkit Designer

Design with PTC Heater Plate in Cirkit DesignerIntroduction

The PTC (Positive Temperature Coefficient) heater plate, part ID: PTC, is a ceramic-based heating element designed to provide efficient and safe heating. Unlike traditional heating elements, the PTC heater plate is self-regulating, meaning it automatically adjusts its resistance to maintain a constant temperature. This feature makes it energy-efficient and reduces the risk of overheating, making it suitable for a wide range of applications.

Explore Projects Built with PTC Heater Plate

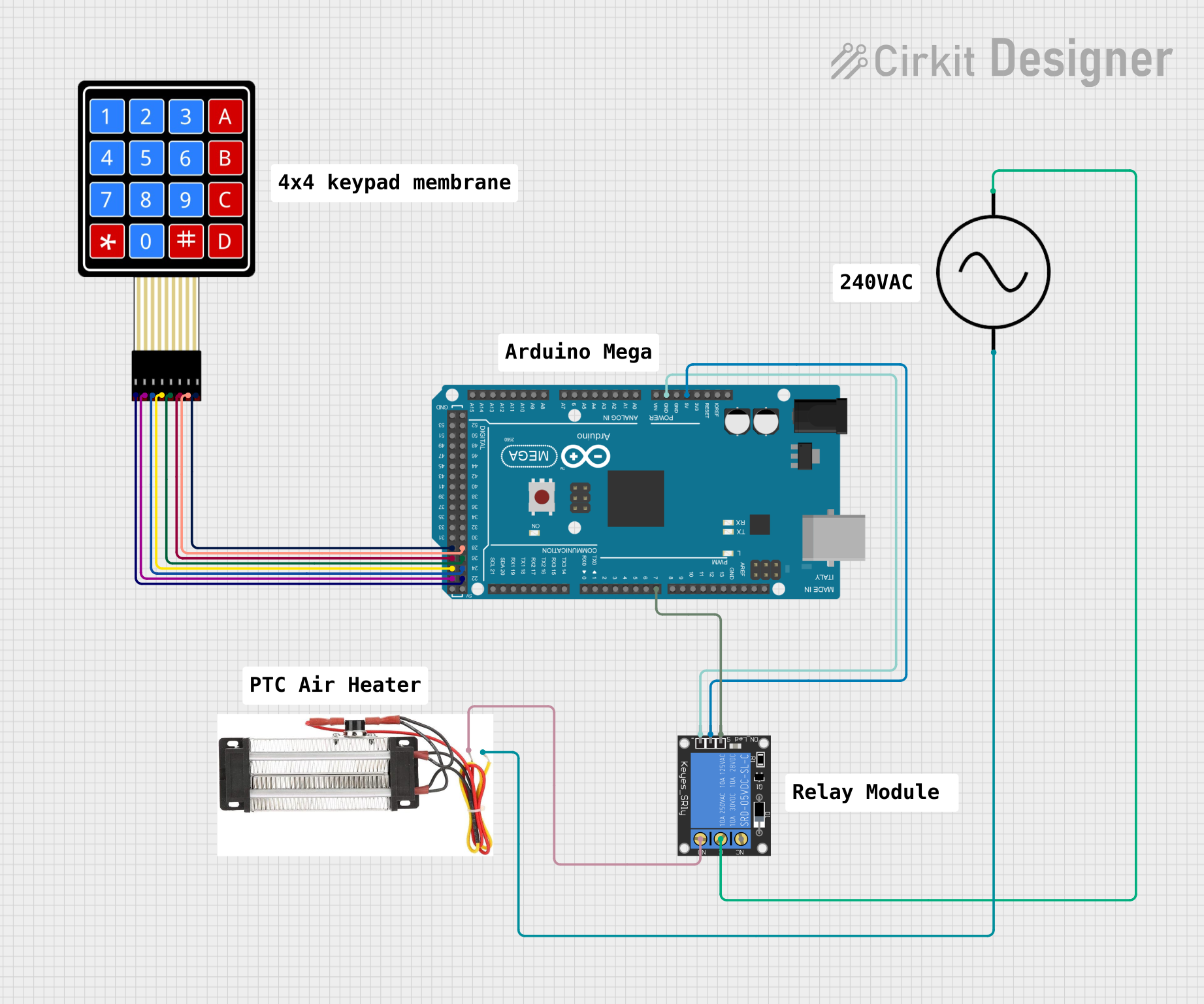

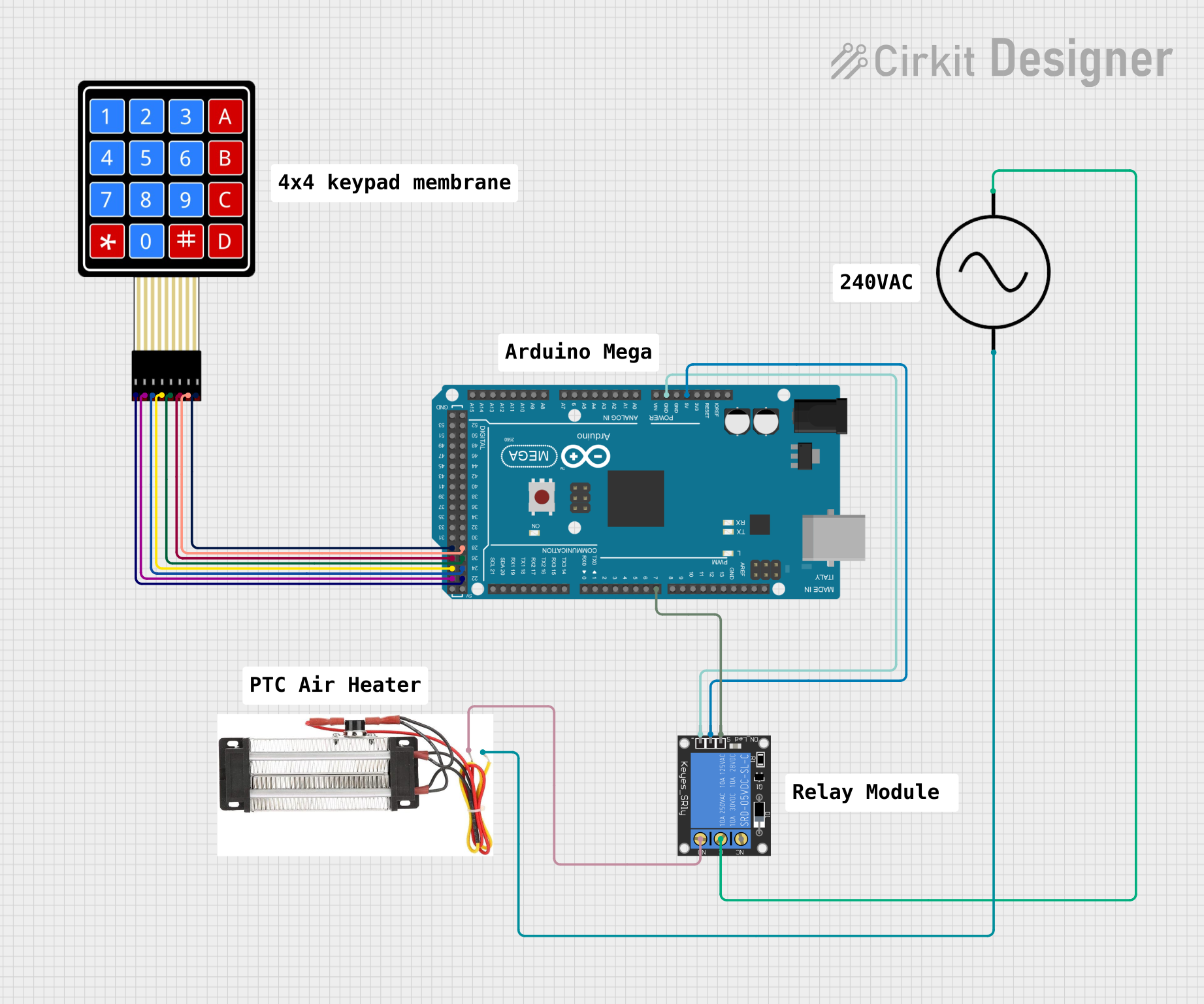

Arduino Mega 2560 Controlled Relay Switch for PTC Air Heater

This circuit features an Arduino Mega 2560 microcontroller connected to a 4x4 membrane matrix keypad and a 1-channel relay module. The Arduino is programmed to interact with the keypad inputs and control the relay, which switches an AC supply connected to a PTC air heater. The purpose of the circuit is likely to allow user input via the keypad to control the heating element, potentially for a temperature regulation system.

Open Project in Cirkit Designer

Open Project in Cirkit DesignerPID Temperature Control System with Thermocouple and SSR

This circuit is a temperature control system that uses a thermocouple to measure temperature and a PID controller to regulate it. The PID controller drives a solid-state relay (SSR) to control an external load, with power supplied through an AC inlet socket.

Open Project in Cirkit Designer

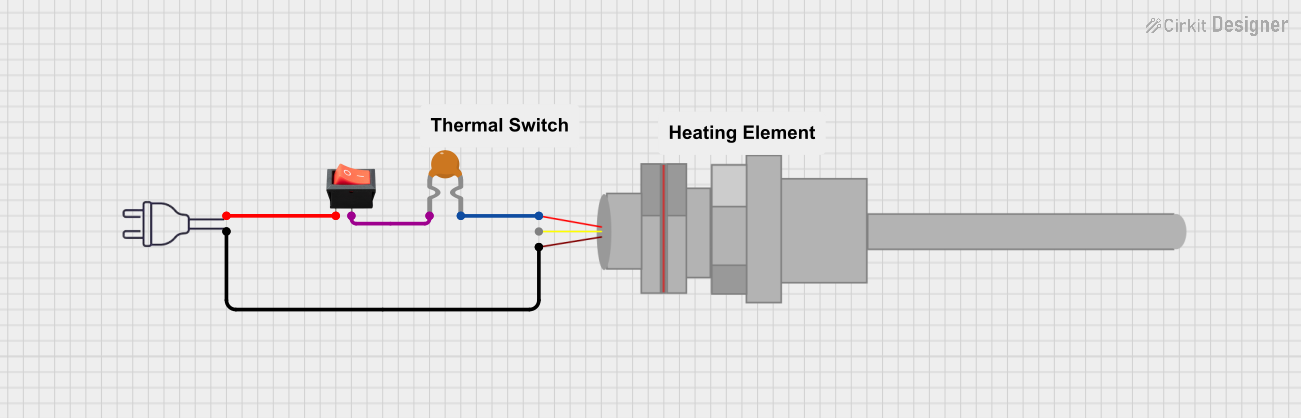

Open Project in Cirkit DesignerPT100 Temperature Sensor with Rocker Switch and Resettable Fuse

This circuit is a basic power control system that uses a rocker switch to control the flow of 220V power through a resettable fuse and a PT100 temperature sensor. The switch allows the user to turn the power on or off, while the fuse provides overcurrent protection and the PT100 sensor can be used for temperature monitoring.

Open Project in Cirkit Designer

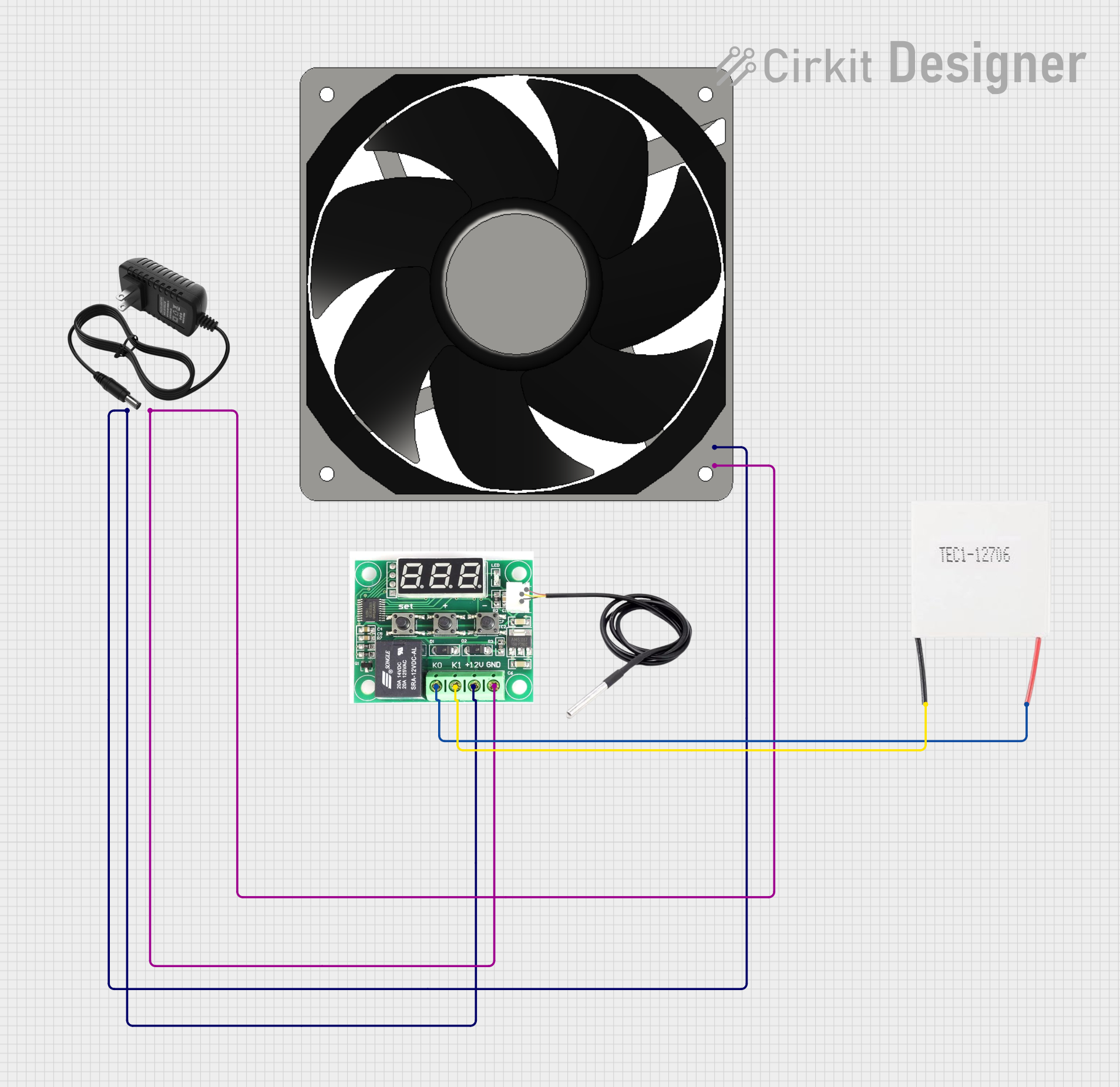

Open Project in Cirkit DesignerW1209 Thermostat-Controlled Peltier Cooler with 12V Fan

This circuit is a temperature control system that uses a W1209 thermostat module to regulate a Peltier module and a 12V fan. The 12V power supply provides power to the W1209 module and the fan, while the W1209 controls the Peltier module based on temperature readings.

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with PTC Heater Plate

Arduino Mega 2560 Controlled Relay Switch for PTC Air Heater

This circuit features an Arduino Mega 2560 microcontroller connected to a 4x4 membrane matrix keypad and a 1-channel relay module. The Arduino is programmed to interact with the keypad inputs and control the relay, which switches an AC supply connected to a PTC air heater. The purpose of the circuit is likely to allow user input via the keypad to control the heating element, potentially for a temperature regulation system.

Open Project in Cirkit Designer

Open Project in Cirkit Designer

PID Temperature Control System with Thermocouple and SSR

This circuit is a temperature control system that uses a thermocouple to measure temperature and a PID controller to regulate it. The PID controller drives a solid-state relay (SSR) to control an external load, with power supplied through an AC inlet socket.

Open Project in Cirkit Designer

Open Project in Cirkit Designer

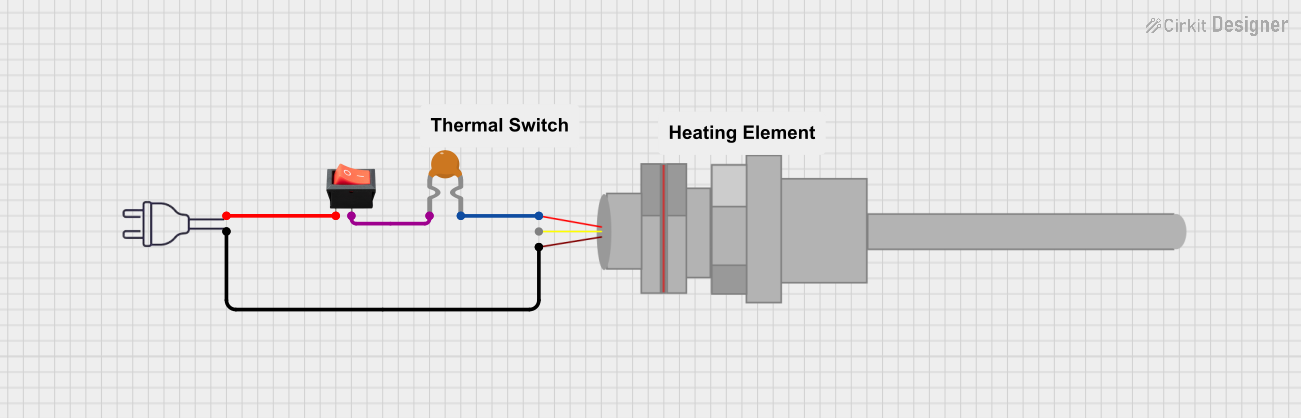

PT100 Temperature Sensor with Rocker Switch and Resettable Fuse

This circuit is a basic power control system that uses a rocker switch to control the flow of 220V power through a resettable fuse and a PT100 temperature sensor. The switch allows the user to turn the power on or off, while the fuse provides overcurrent protection and the PT100 sensor can be used for temperature monitoring.

Open Project in Cirkit Designer

Open Project in Cirkit Designer

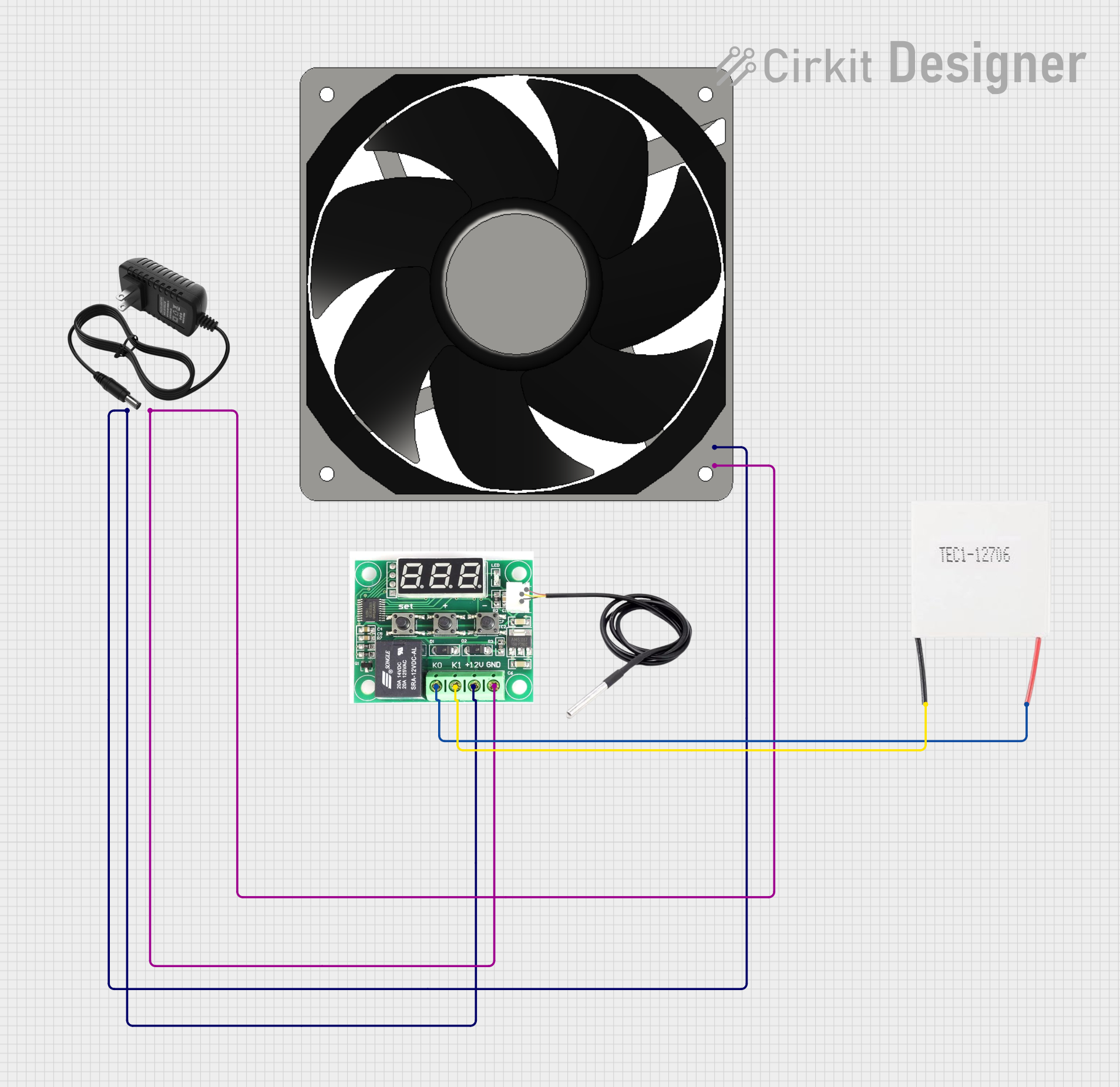

W1209 Thermostat-Controlled Peltier Cooler with 12V Fan

This circuit is a temperature control system that uses a W1209 thermostat module to regulate a Peltier module and a 12V fan. The 12V power supply provides power to the W1209 module and the fan, while the W1209 controls the Peltier module based on temperature readings.

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications and Use Cases

- Space Heaters: Used in portable and fixed space heaters for residential and commercial use.

- Automotive: Employed in car seat warmers, defoggers, and other automotive heating applications.

- Household Appliances: Found in hair dryers, electric kettles, and other small appliances.

- Industrial Equipment: Used in machinery that requires consistent and reliable heating.

- Medical Devices: Utilized in devices that need precise temperature control.

Technical Specifications

Key Technical Details

| Parameter | Value |

|---|---|

| Voltage Rating | 12V - 240V |

| Current Rating | 0.5A - 10A |

| Power Rating | 5W - 500W |

| Operating Temperature Range | 0°C to 250°C |

| Resistance Range | 10Ω - 1000Ω |

| Material | Ceramic |

| Self-Regulating Temperature | 60°C - 300°C |

Pin Configuration and Descriptions

| Pin Number | Description |

|---|---|

| 1 | Positive Voltage Input (V+) |

| 2 | Ground (GND) |

| 3 | Temperature Control Signal (Optional) |

Usage Instructions

How to Use the Component in a Circuit

- Power Supply: Connect the positive voltage input (Pin 1) to the power supply's positive terminal. Ensure the voltage matches the heater plate's rating.

- Ground Connection: Connect the ground (Pin 2) to the power supply's ground terminal.

- Temperature Control (Optional): If your application requires precise temperature control, connect the temperature control signal (Pin 3) to a suitable control circuit or microcontroller.

Important Considerations and Best Practices

- Voltage Matching: Ensure the power supply voltage matches the heater plate's rated voltage to avoid damage.

- Heat Dissipation: Provide adequate ventilation or heat sinks to dissipate heat effectively.

- Safety Precautions: Avoid direct contact with the heater plate during operation to prevent burns.

- Temperature Control: Use a thermostat or microcontroller for applications requiring precise temperature regulation.

Example Circuit with Arduino UNO

/*

* Example code to control a PTC heater plate using Arduino UNO.

* This code assumes the use of a relay module to switch the heater plate.

*/

const int relayPin = 7; // Pin connected to the relay module

void setup() {

pinMode(relayPin, OUTPUT); // Set relay pin as output

digitalWrite(relayPin, LOW); // Ensure relay is off at startup

}

void loop() {

// Turn on the heater plate

digitalWrite(relayPin, HIGH);

delay(10000); // Keep heater on for 10 seconds

// Turn off the heater plate

digitalWrite(relayPin, LOW);

delay(10000); // Keep heater off for 10 seconds

}

Troubleshooting and FAQs

Common Issues Users Might Face

Heater Plate Not Heating:

- Solution: Check the power supply connections and ensure the voltage matches the heater plate's rating. Verify that the relay or control circuit is functioning correctly.

Overheating:

- Solution: Ensure proper ventilation and heat dissipation. Use a thermostat or temperature control circuit to regulate the temperature.

Inconsistent Heating:

- Solution: Verify the power supply's stability. Check for loose connections and ensure the heater plate is not damaged.

Solutions and Tips for Troubleshooting

- Check Connections: Ensure all connections are secure and correctly oriented.

- Verify Power Supply: Use a multimeter to check the voltage and current supplied to the heater plate.

- Inspect for Damage: Examine the heater plate for any visible signs of damage or wear.

- Use Proper Control Circuits: For applications requiring precise temperature control, use appropriate control circuits or microcontrollers.

By following this documentation, users can effectively utilize the PTC heater plate in various applications, ensuring safe and efficient operation.