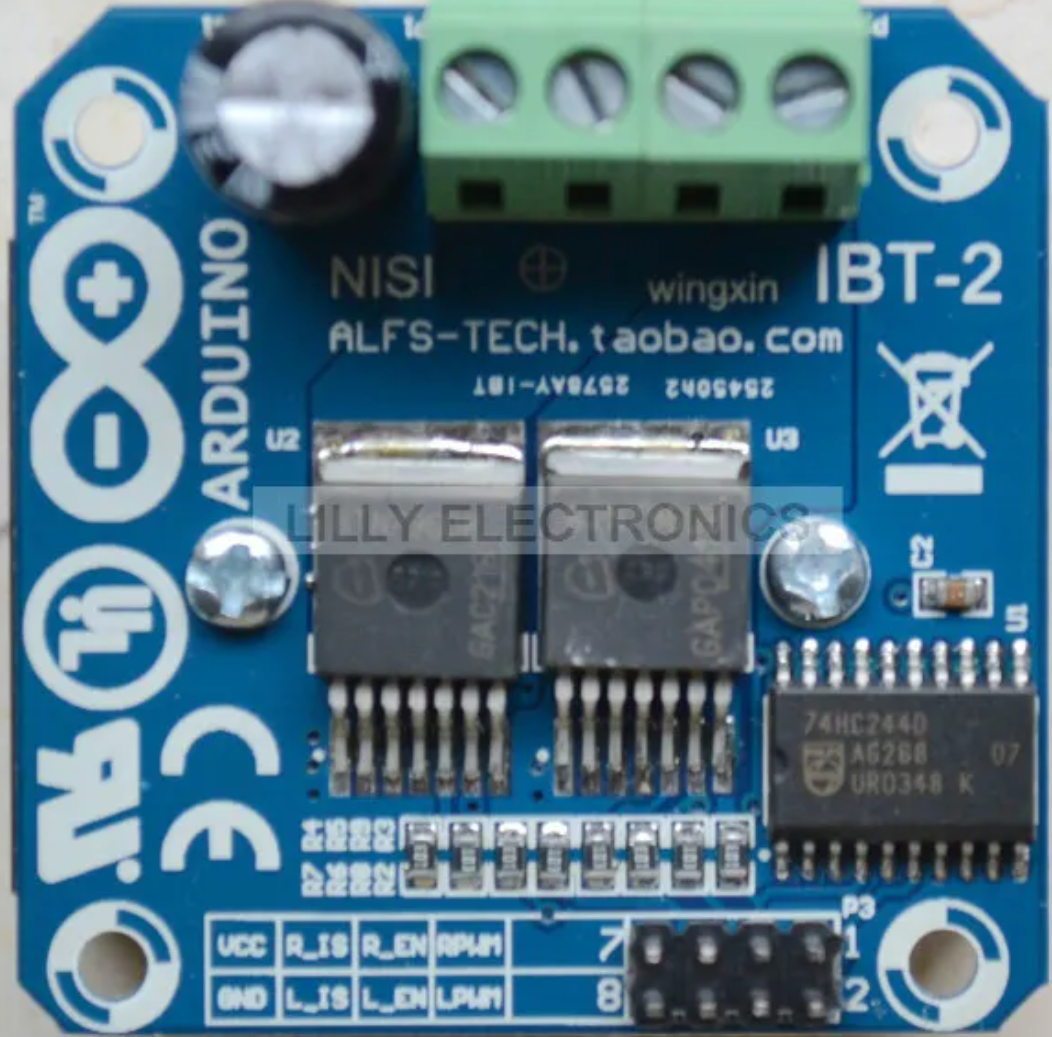

How to Use IBT-2 H-Bridge Motor Driver: Examples, Pinouts, and Specs

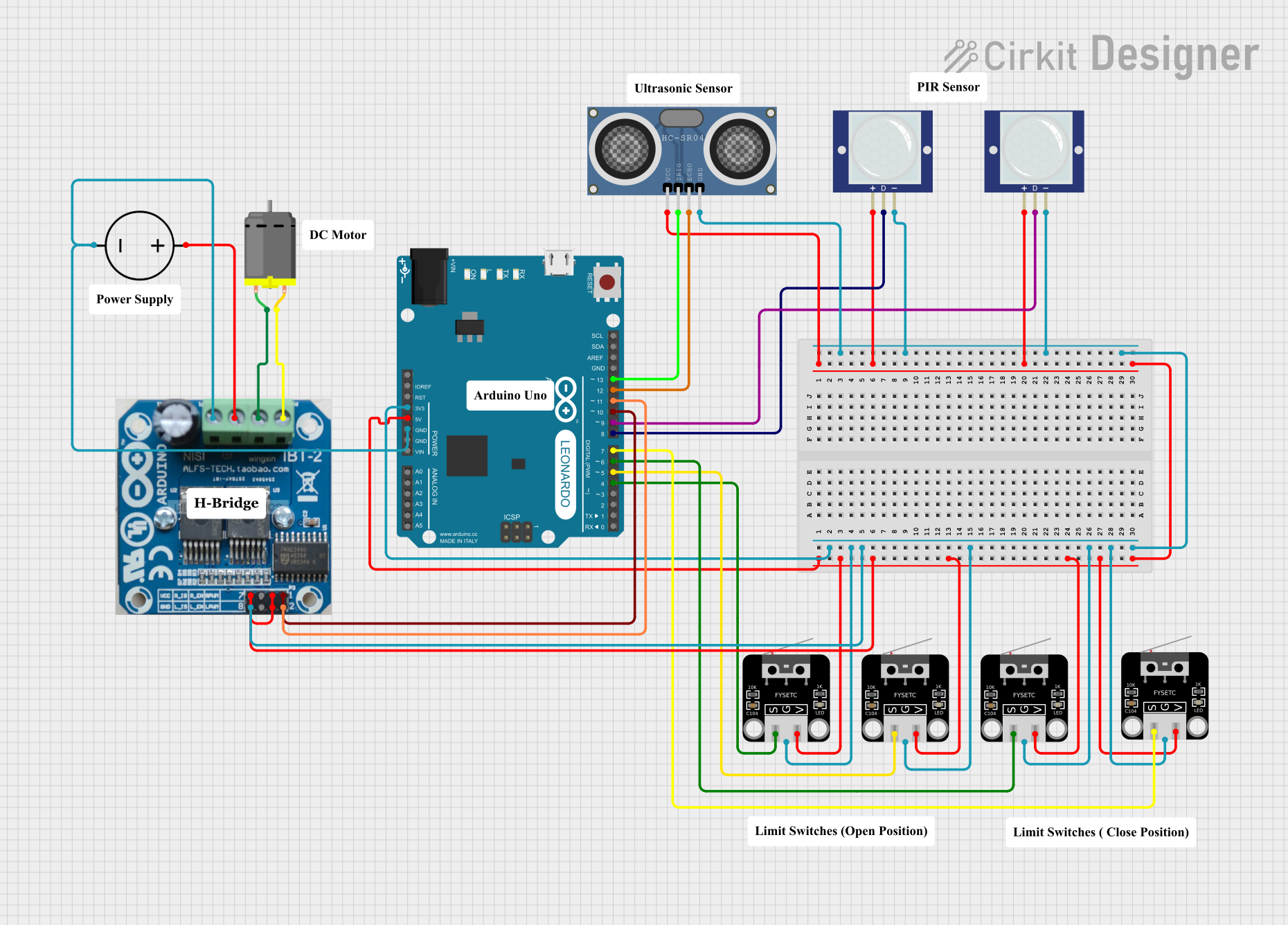

Design with IBT-2 H-Bridge Motor Driver in Cirkit Designer

Design with IBT-2 H-Bridge Motor Driver in Cirkit DesignerIntroduction

The IBT-2 H-Bridge Motor Driver is a robust electronic component designed for controlling DC motors' direction and speed. It is capable of driving high-power motors in both forward and reverse directions. This makes it an ideal choice for robotics, automation projects, and any application requiring bidirectional motor control.

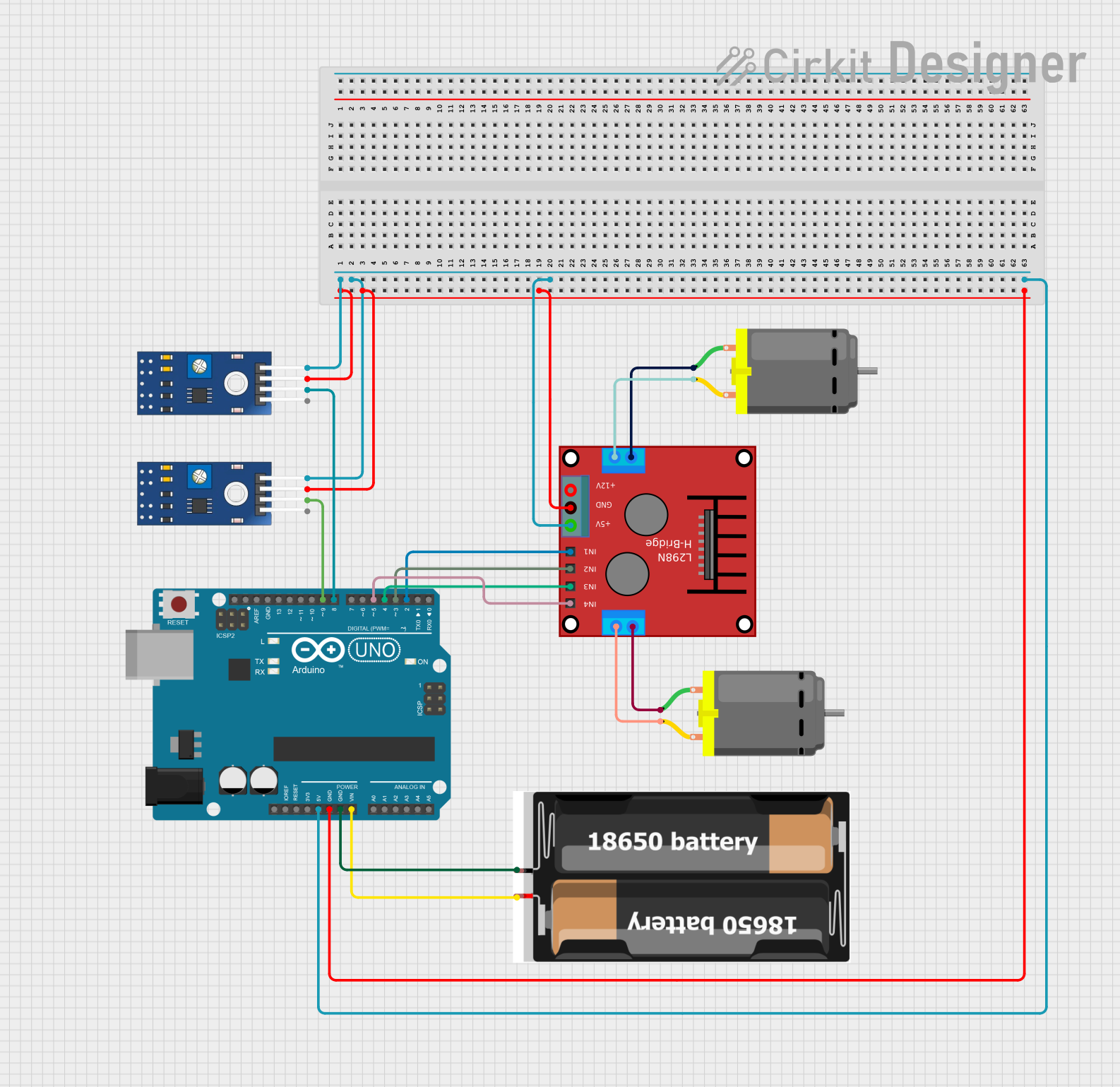

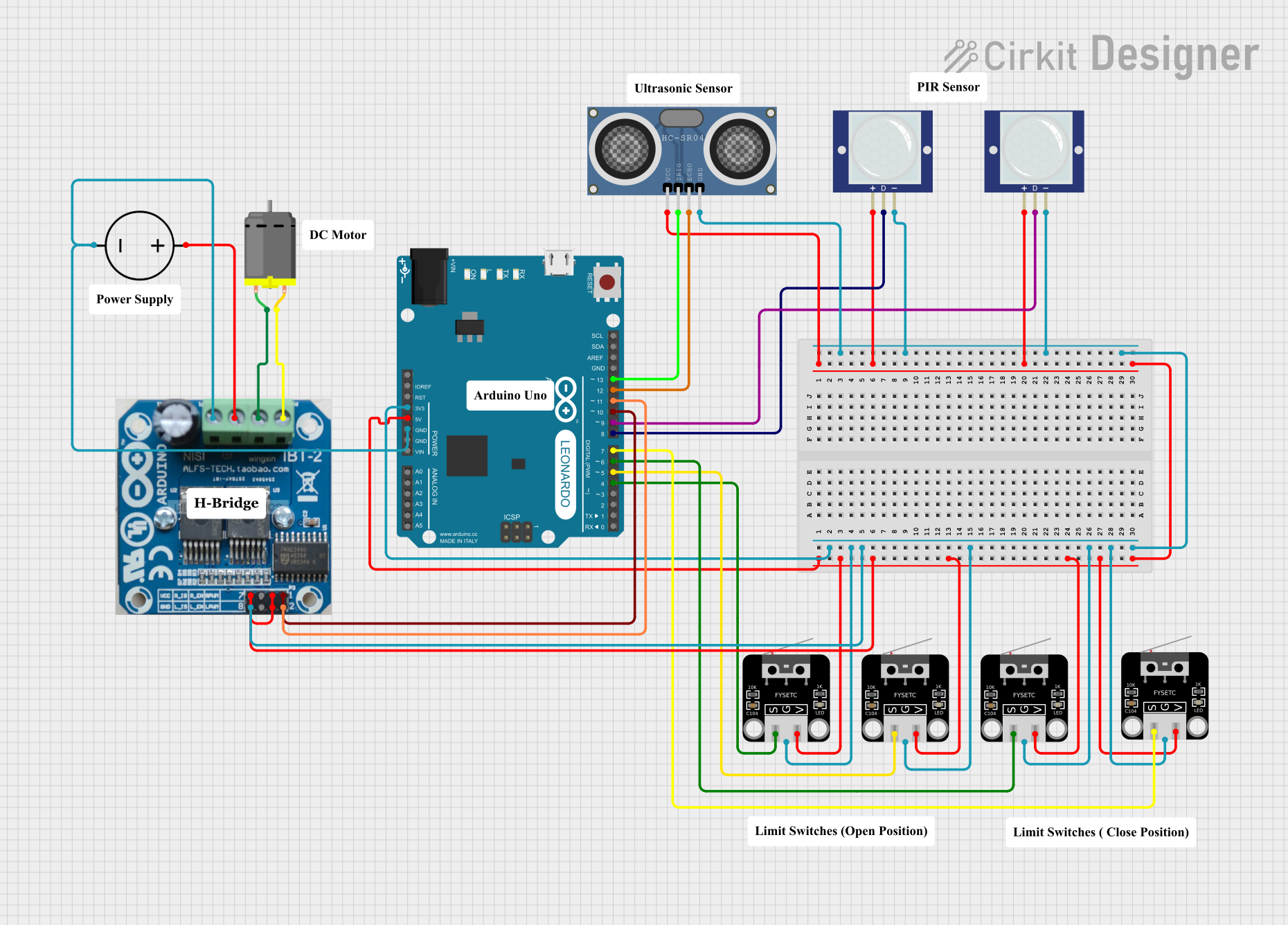

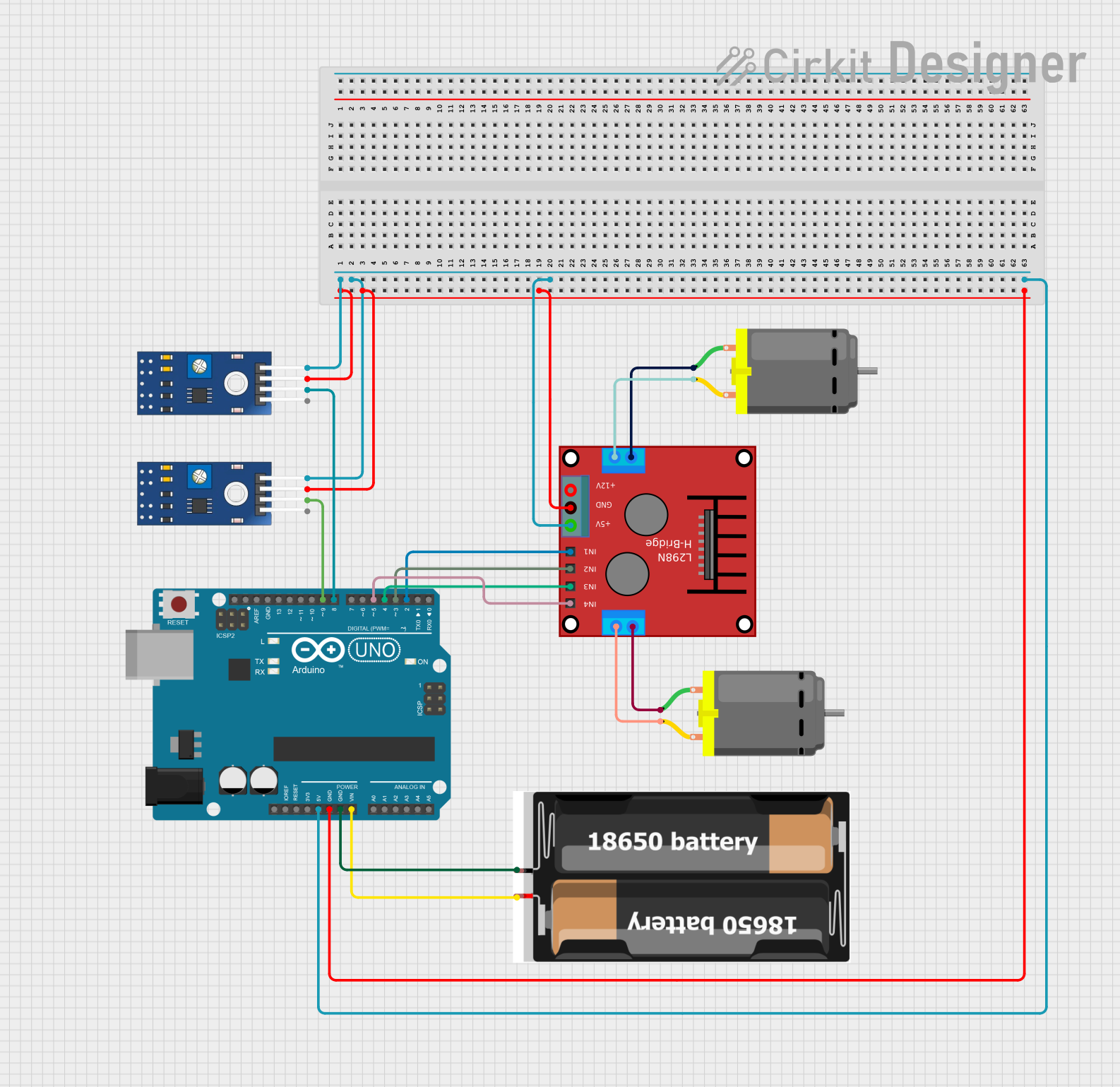

Explore Projects Built with IBT-2 H-Bridge Motor Driver

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with IBT-2 H-Bridge Motor Driver

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications and Use Cases

- Robotics

- Automated machinery

- Electric vehicles

- Conveyor systems

- Actuators for mechanical systems

Technical Specifications

Key Technical Details

- Supply Voltage (Vcc): 6V to 27V

- Logic Voltage (Vlogic): 5V (compatible with Arduino)

- Continuous Current: Up to 43A

- Peak Current: 100A (for a few seconds)

- Operating Temperature: -25°C to +135°C

Pin Configuration and Descriptions

| Pin Number | Pin Name | Description |

|---|---|---|

| 1 | RPWM | Right PWM input for motor speed and direction |

| 2 | LPWM | Left PWM input for motor speed and direction |

| 3 | R_EN | Right Enable input |

| 4 | L_EN | Left Enable input |

| 5 | Vcc | Power supply for motor (6V to 27V) |

| 6 | GND | Ground |

| 7 | B+ | Motor power supply positive |

| 8 | B- | Motor power supply negative |

Usage Instructions

How to Use the Component in a Circuit

Power Connections:

- Connect the motor's positive lead to the B+ pin and the negative lead to the B- pin.

- Apply a DC voltage between 6V and 27V to the Vcc pin for the motor power supply.

- Connect the ground of the power supply to the GND pin.

Control Connections:

- Connect the R_EN and L_EN pins to a digital output on your control board (e.g., Arduino) to enable or disable the motor driver.

- Apply PWM signals to the RPWM and LPWM pins to control the motor's speed and direction.

Important Considerations and Best Practices

- Ensure that the power supply can handle the motor's current requirements.

- Use a flyback diode across the motor terminals to protect the driver from voltage spikes.

- Avoid running the motor driver at its peak current for extended periods to prevent overheating.

- Implement proper heat dissipation techniques if operating near the maximum current rating.

Example Code for Arduino UNO

// Define the control pins for the IBT-2

const int RPWM = 3; // Right PWM pin connected to Arduino pin 3

const int LPWM = 5; // Left PWM pin connected to Arduino pin 5

const int R_EN = 4; // Right Enable pin connected to Arduino pin 4

const int L_EN = 6; // Left Enable pin connected to Arduino pin 6

void setup() {

// Set all the control pins as outputs

pinMode(RPWM, OUTPUT);

pinMode(LPWM, OUTPUT);

pinMode(R_EN, OUTPUT);

pinMode(L_EN, OUTPUT);

// Enable the motor driver

digitalWrite(R_EN, HIGH);

digitalWrite(L_EN, HIGH);

}

void loop() {

// Spin motor forward at full speed

analogWrite(RPWM, 255); // Full speed forward

analogWrite(LPWM, 0); // Ensure LPWM is low

delay(2000); // Run for 2 seconds

// Spin motor in reverse at half speed

analogWrite(RPWM, 0); // Ensure RPWM is low

analogWrite(LPWM, 127); // Half speed reverse

delay(2000); // Run for 2 seconds

// Stop the motor

analogWrite(RPWM, 0);

analogWrite(LPWM, 0);

delay(2000); // Stop for 2 seconds

}

Troubleshooting and FAQs

Common Issues

- Motor not responding: Check power supply connections and ensure that the enable pins are set high.

- Overheating: Ensure proper heat dissipation and that the current does not exceed the continuous rating.

- Erratic motor behavior: Verify that the PWM signals are correctly applied and that there is no interference.

Solutions and Tips for Troubleshooting

- Double-check wiring and solder joints for any loose connections or shorts.

- Use a multimeter to verify the voltage at the motor driver's power pins.

- Implement a gradual start/stop in your code to reduce mechanical stress and electrical spikes.

FAQs

Q: Can I control two motors with one IBT-2? A: No, the IBT-2 is designed to control one motor. For two motors, you would need two IBT-2 modules.

Q: What is the maximum PWM frequency for the IBT-2? A: The IBT-2 can handle PWM frequencies up to 25kHz.

Q: How do I reverse the motor direction? A: To reverse the motor direction, invert the PWM signals: apply the PWM signal to LPWM for forward and RPWM for reverse.

Q: Can I use the IBT-2 with a microcontroller running at 3.3V logic? A: While the IBT-2 is designed for 5V logic, it may work at 3.3V. However, it is recommended to use a logic level converter for reliable operation.