How to Use Moteur 25GA370 12V: Examples, Pinouts, and Specs

Design with Moteur 25GA370 12V in Cirkit Designer

Design with Moteur 25GA370 12V in Cirkit DesignerIntroduction

The Moteur 25GA370 12V is a compact and efficient 12V DC motor designed for a wide range of applications. Its small size and high torque output make it an ideal choice for robotics, small machinery, and automation systems. This motor is particularly valued for its reliability, low power consumption, and ease of integration into various projects.

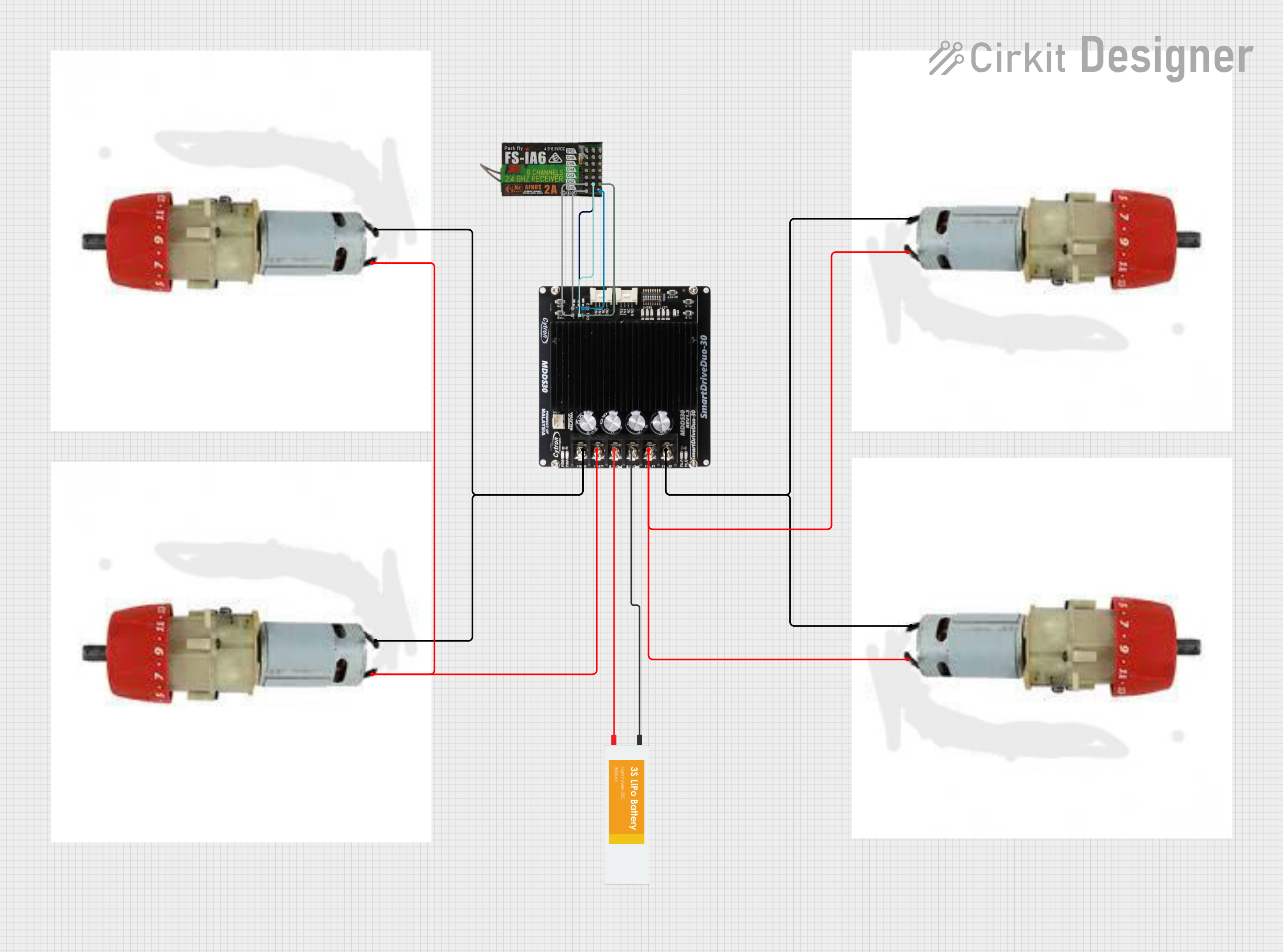

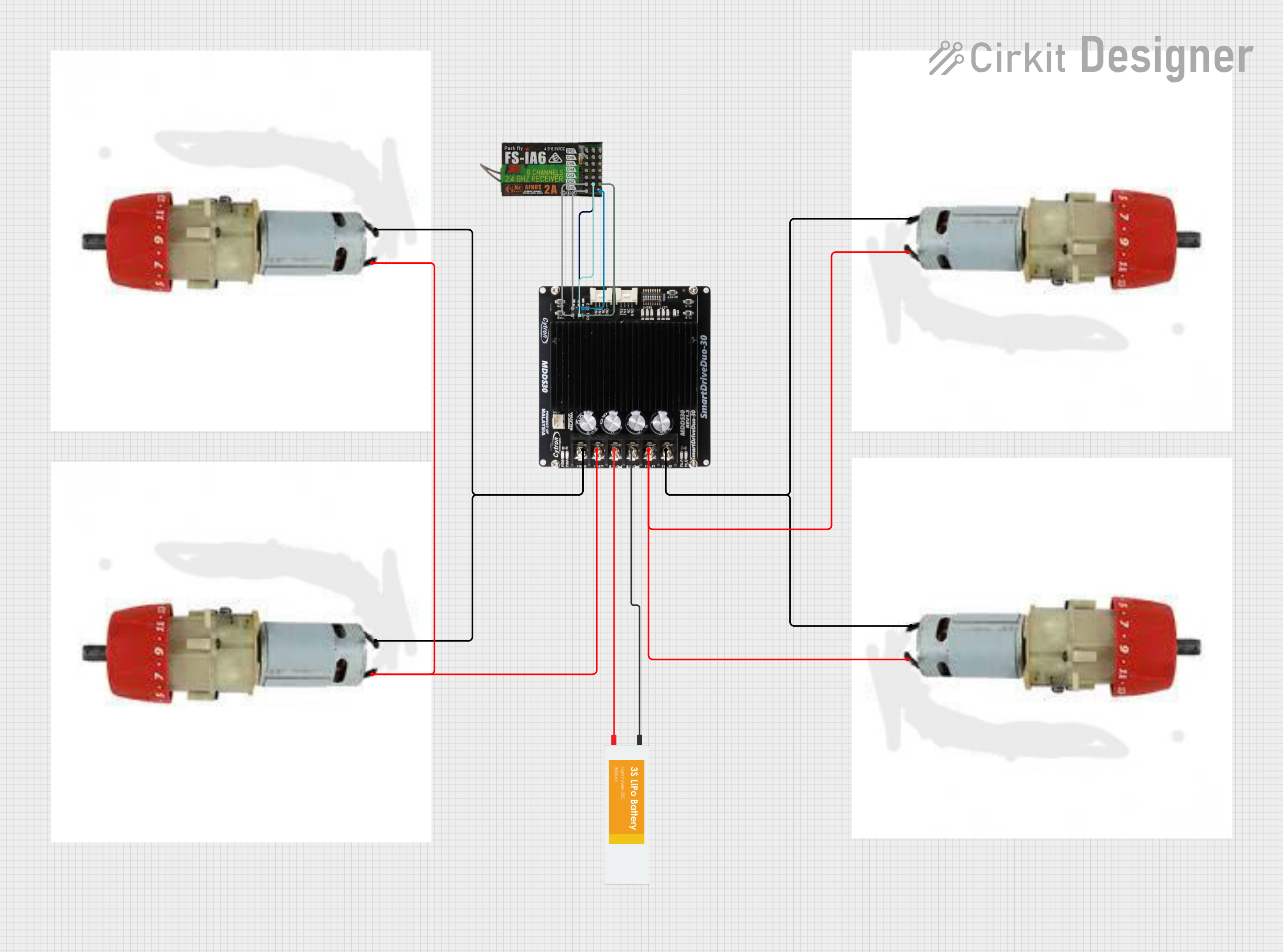

Explore Projects Built with Moteur 25GA370 12V

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with Moteur 25GA370 12V

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications

- Robotics (e.g., mobile robots, robotic arms)

- Small conveyor systems

- Automated mechanisms (e.g., door openers, actuators)

- DIY projects and hobbyist applications

- Educational kits for learning motor control

Technical Specifications

Below are the key technical details of the Moteur 25GA370 12V:

| Parameter | Value |

|---|---|

| Operating Voltage | 12V DC |

| No-Load Speed | ~6000 RPM |

| No-Load Current | ~0.12 A |

| Stall Torque | ~3.5 kg·cm |

| Stall Current | ~1.2 A |

| Gearbox Ratio | 1:30 (varies by model) |

| Shaft Diameter | 4 mm |

| Motor Dimensions | 25 mm (diameter) x 37 mm (length) |

| Weight | ~100 g |

Pin Configuration and Descriptions

The Moteur 25GA370 12V typically has two terminals for electrical connections:

| Pin | Description |

|---|---|

| + | Positive terminal for 12V DC power input |

| - | Negative terminal (ground) for power input |

Note: The motor does not have built-in encoders or feedback mechanisms. If feedback is required, consider pairing it with an external encoder.

Usage Instructions

How to Use the Moteur 25GA370 12V in a Circuit

- Power Supply: Connect the motor to a 12V DC power source. Ensure the power supply can provide sufficient current (at least 1.5A) to handle stall conditions.

- Motor Driver: Use a motor driver (e.g., L298N, L293D, or TB6612FNG) to control the motor. Directly connecting the motor to a microcontroller is not recommended due to high current requirements.

- Polarity Control: Reversing the polarity of the power supply will reverse the motor's rotation direction.

- PWM Control: To control the motor speed, use Pulse Width Modulation (PWM) signals from a microcontroller or motor driver.

Important Considerations and Best Practices

- Current Limiting: Always use a motor driver or controller with current-limiting features to protect the motor and power supply.

- Heat Management: Prolonged operation at high loads may cause the motor to heat up. Ensure proper ventilation or cooling if necessary.

- Mounting: Secure the motor using appropriate brackets to prevent vibration or misalignment.

- Noise Suppression: Add capacitors (e.g., 0.1 µF) across the motor terminals to reduce electrical noise.

Example: Controlling the Motor with Arduino UNO

Below is an example of how to control the Moteur 25GA370 12V using an Arduino UNO and an L298N motor driver:

// Example: Controlling Moteur 25GA370 12V with Arduino UNO

// Motor connected to L298N motor driver

// IN1 and IN2 control motor direction, ENA controls speed

#define IN1 7 // L298N IN1 pin connected to Arduino pin 7

#define IN2 8 // L298N IN2 pin connected to Arduino pin 8

#define ENA 9 // L298N ENA pin connected to Arduino PWM pin 9

void setup() {

pinMode(IN1, OUTPUT); // Set IN1 as output

pinMode(IN2, OUTPUT); // Set IN2 as output

pinMode(ENA, OUTPUT); // Set ENA as output

}

void loop() {

// Rotate motor forward at 50% speed

digitalWrite(IN1, HIGH); // Set IN1 HIGH

digitalWrite(IN2, LOW); // Set IN2 LOW

analogWrite(ENA, 128); // Set ENA to 50% duty cycle (128/255)

delay(3000); // Run motor for 3 seconds

// Rotate motor backward at 75% speed

digitalWrite(IN1, LOW); // Set IN1 LOW

digitalWrite(IN2, HIGH); // Set IN2 HIGH

analogWrite(ENA, 192); // Set ENA to 75% duty cycle (192/255)

delay(3000); // Run motor for 3 seconds

// Stop the motor

digitalWrite(IN1, LOW); // Set IN1 LOW

digitalWrite(IN2, LOW); // Set IN2 LOW

analogWrite(ENA, 0); // Set ENA to 0% duty cycle (motor off)

delay(3000); // Wait for 3 seconds before repeating

}

Troubleshooting and FAQs

Common Issues and Solutions

Motor Does Not Spin

- Cause: Insufficient power supply or loose connections.

- Solution: Verify that the power supply provides 12V and sufficient current. Check all connections.

Motor Spins in the Wrong Direction

- Cause: Incorrect polarity of the power supply or control signals.

- Solution: Reverse the polarity of the motor terminals or adjust the control signals.

Motor Overheats

- Cause: Prolonged operation at high loads or stall conditions.

- Solution: Reduce the load on the motor or add cooling mechanisms.

Electrical Noise Interference

- Cause: Motor generates electrical noise that affects nearby circuits.

- Solution: Add capacitors (e.g., 0.1 µF) across the motor terminals to suppress noise.

FAQs

Q: Can I use the Moteur 25GA370 12V with a 9V battery?

A: While the motor may run at 9V, its performance (speed and torque) will be reduced. A 12V power supply is recommended for optimal performance.

Q: Is the motor waterproof?

A: No, the Moteur 25GA370 12V is not waterproof. Avoid exposing it to water or moisture.

Q: Can I control the motor without a motor driver?

A: Directly connecting the motor to a microcontroller is not recommended due to high current requirements. Always use a motor driver or relay module.

Q: How do I calculate the required power supply?

A: Multiply the operating voltage (12V) by the stall current (1.2A) to determine the maximum power requirement (14.4W). Ensure your power supply can handle this load.