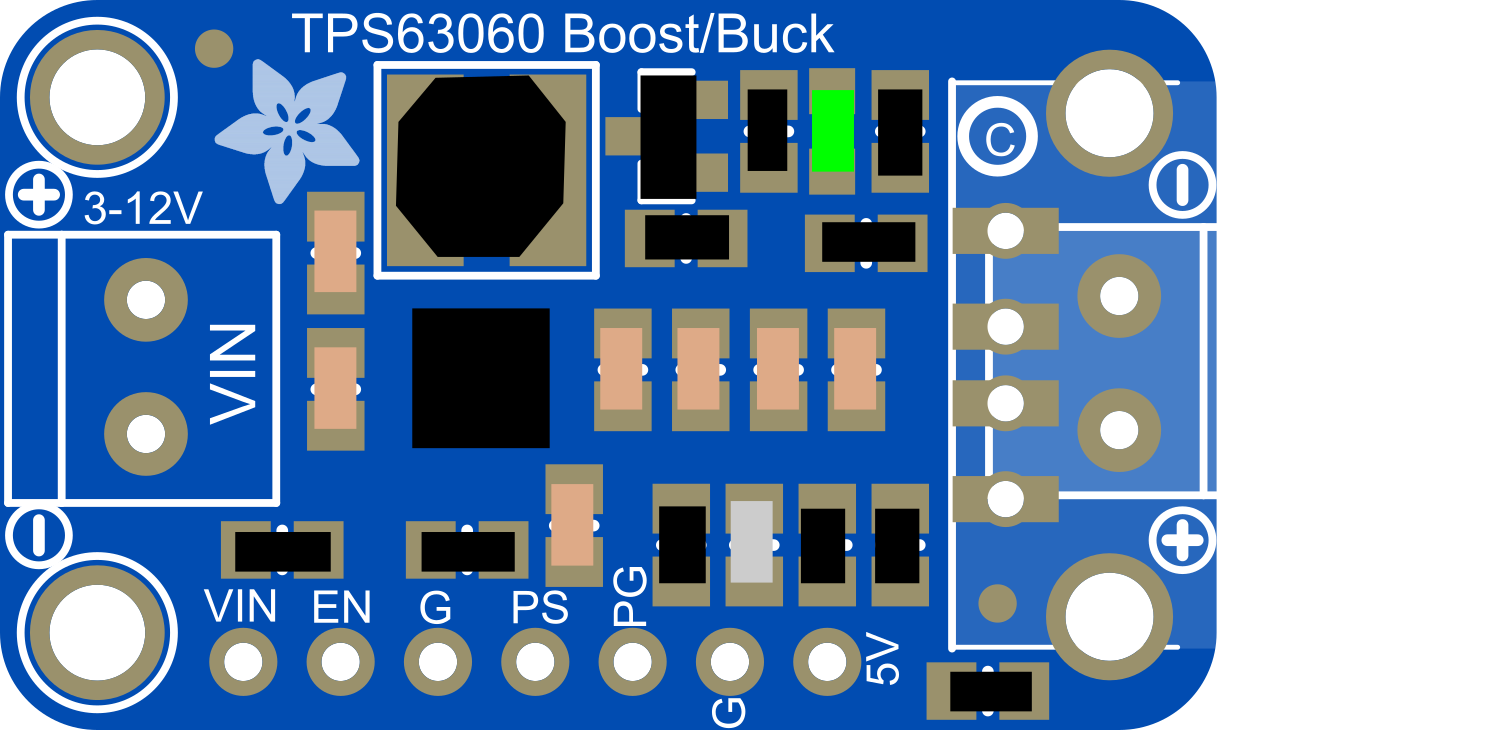

How to Use verter_pad: Examples, Pinouts, and Specs

Design with verter_pad in Cirkit Designer

Design with verter_pad in Cirkit DesignerIntroduction

The Verter_Pad is an innovative electronic component designed to convert DC power from a power source into a regulated and adjustable voltage output. This versatile device is essential for providing a stable power supply to electronic circuits, especially when the input voltage is not aligned with the voltage requirements of the components in the circuit. Common applications include battery-powered projects, portable devices, and any system that requires a specific voltage level for operation.

Explore Projects Built with verter_pad

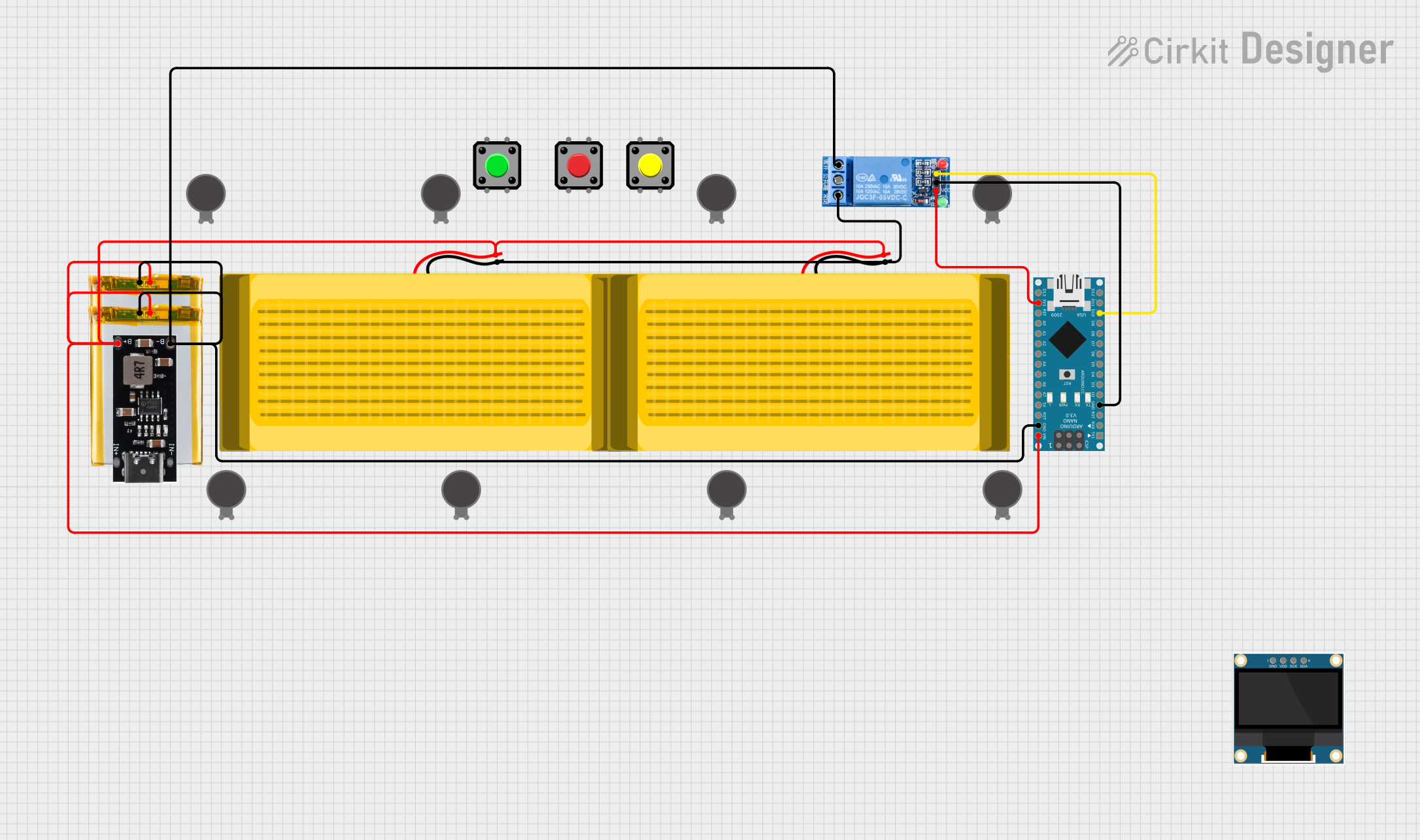

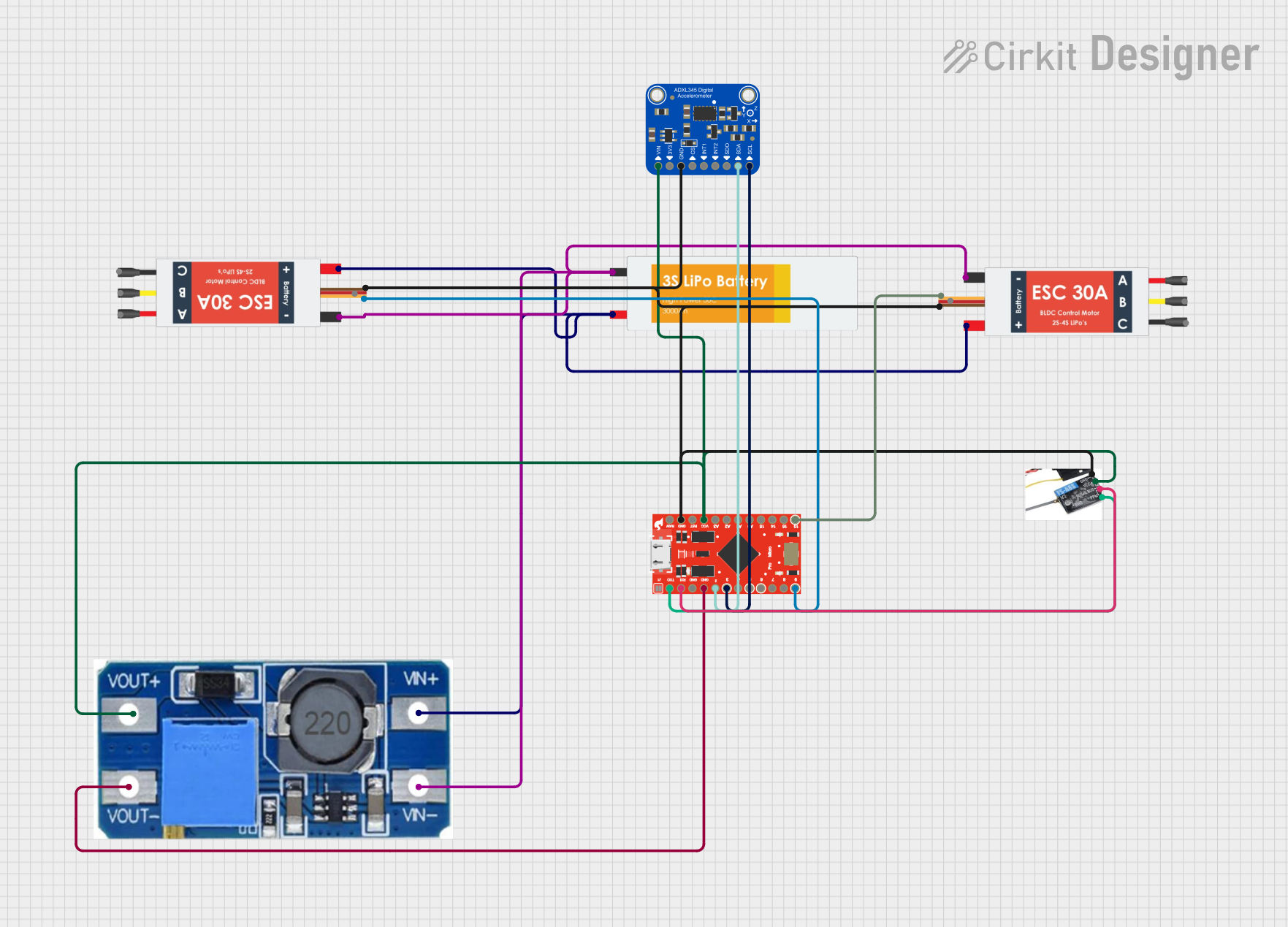

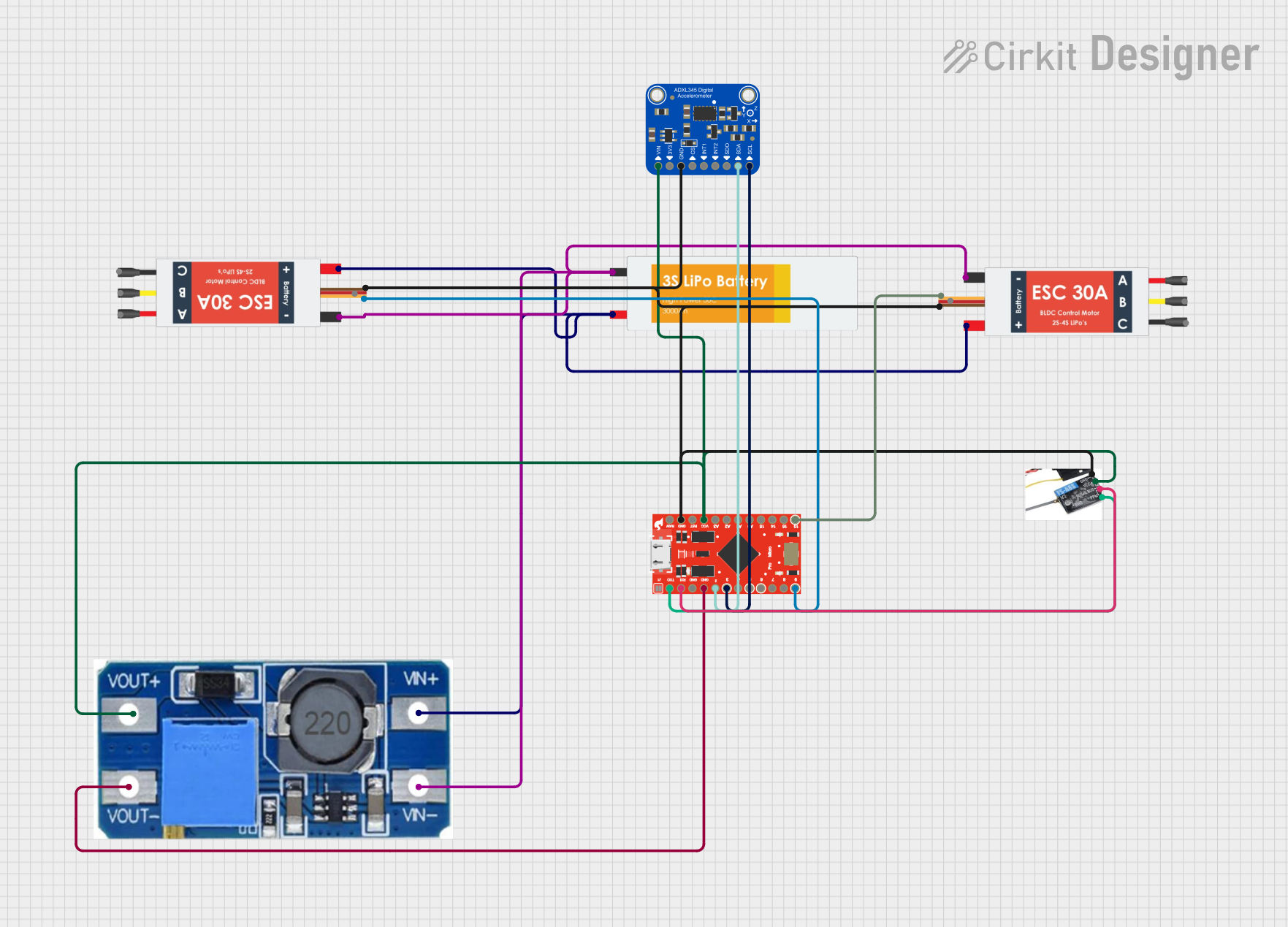

Open Project in Cirkit Designer

Open Project in Cirkit Designer

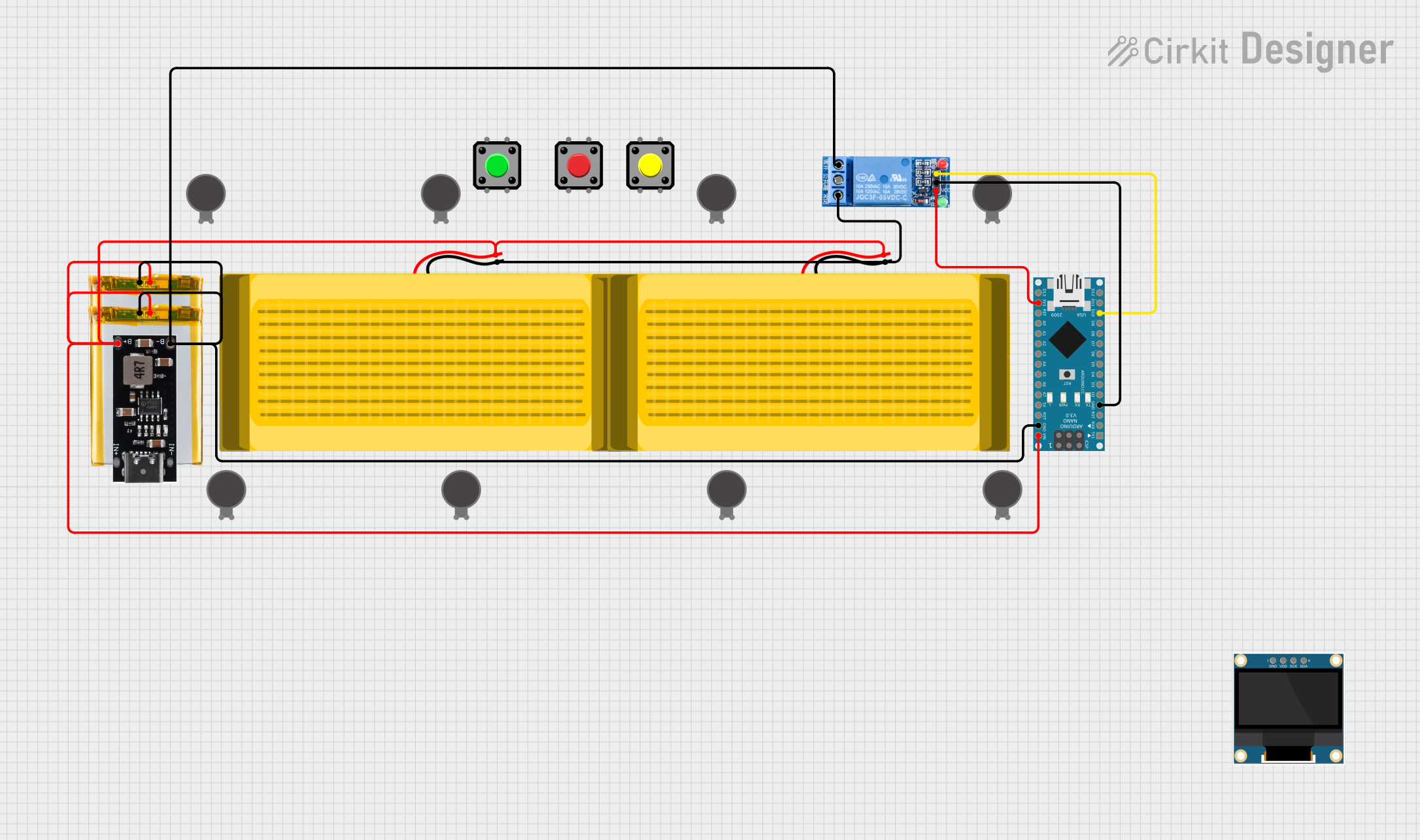

Open Project in Cirkit Designer

Open Project in Cirkit Designer

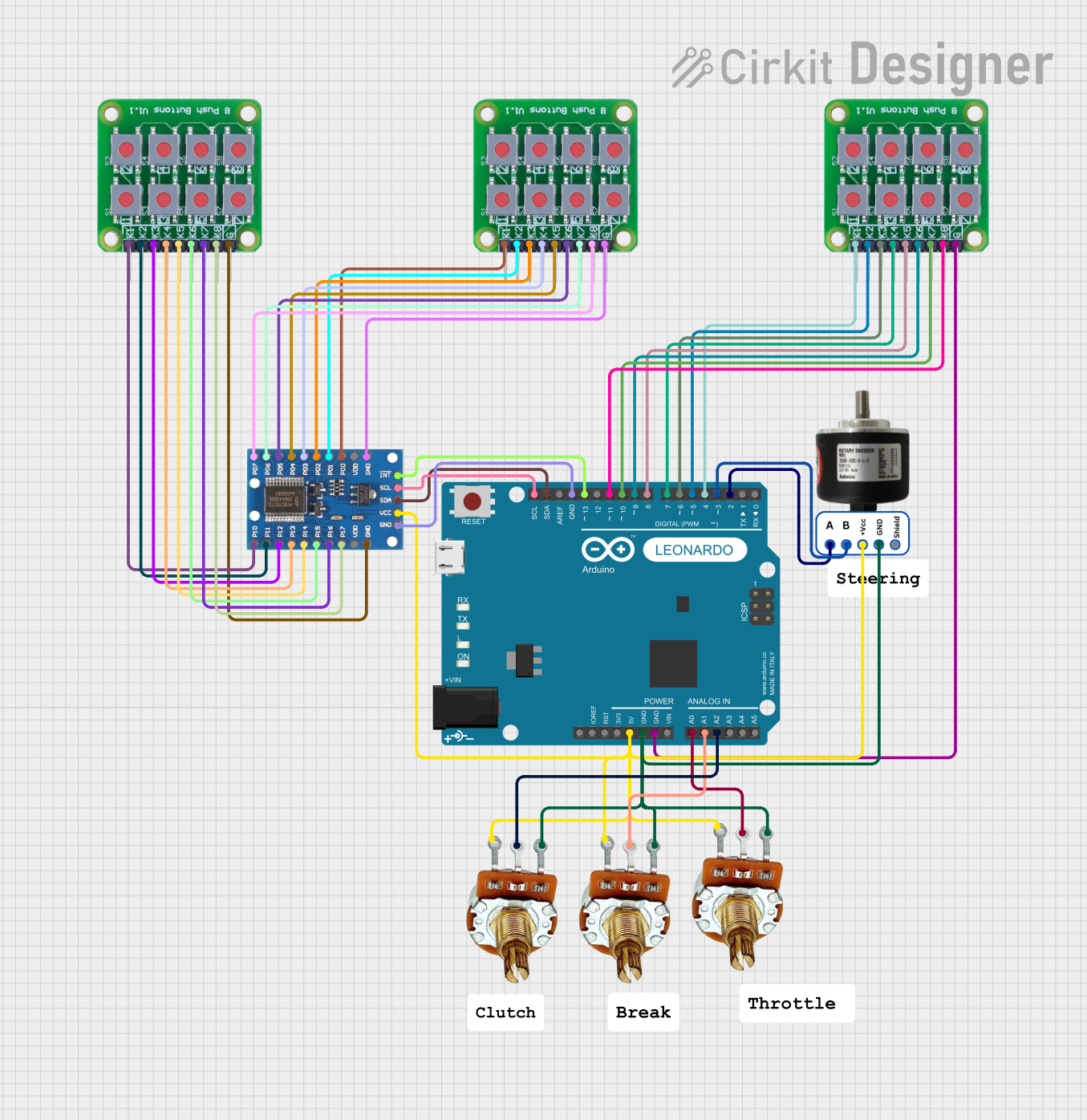

Open Project in Cirkit Designer

Open Project in Cirkit Designer

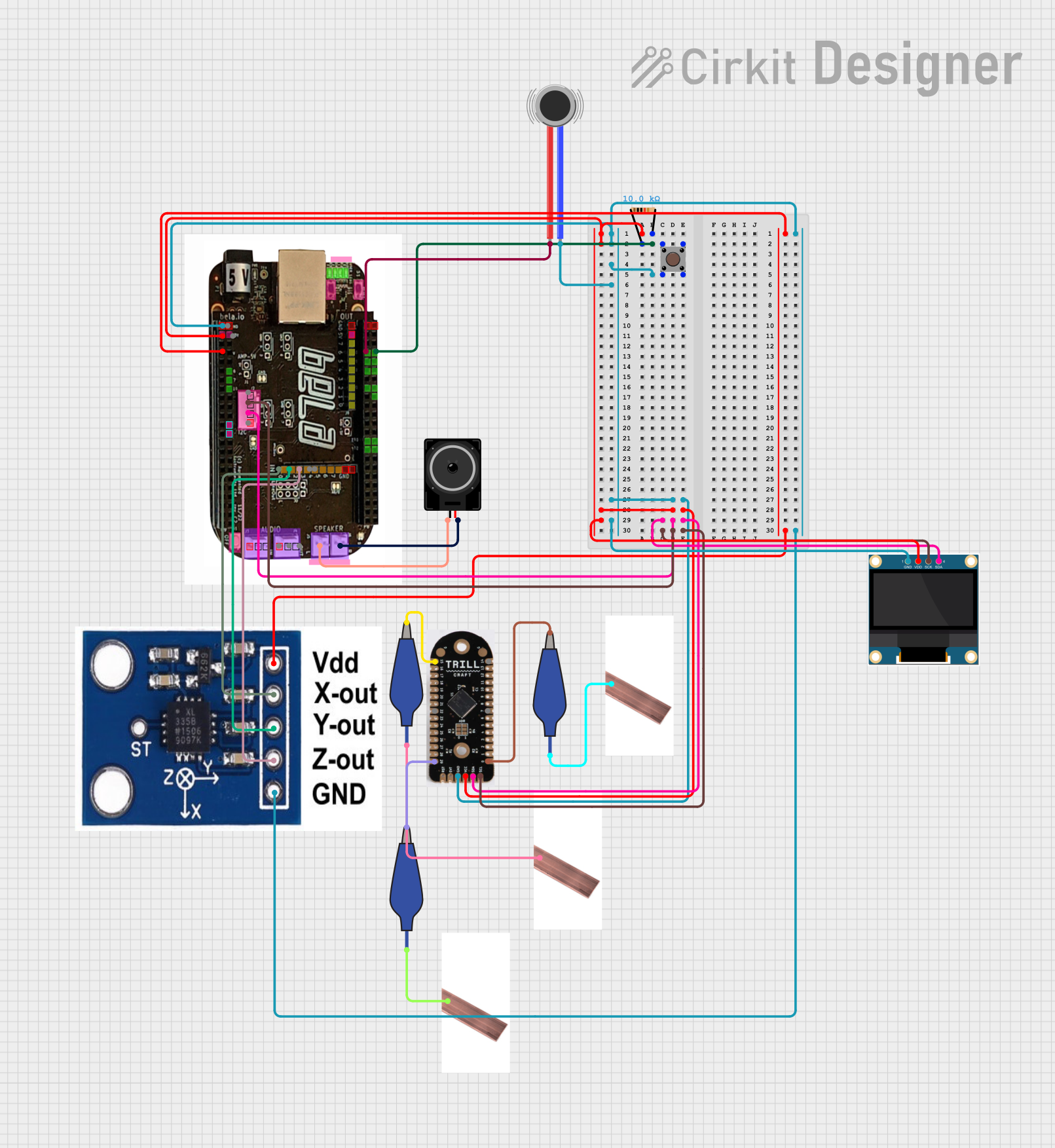

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with verter_pad

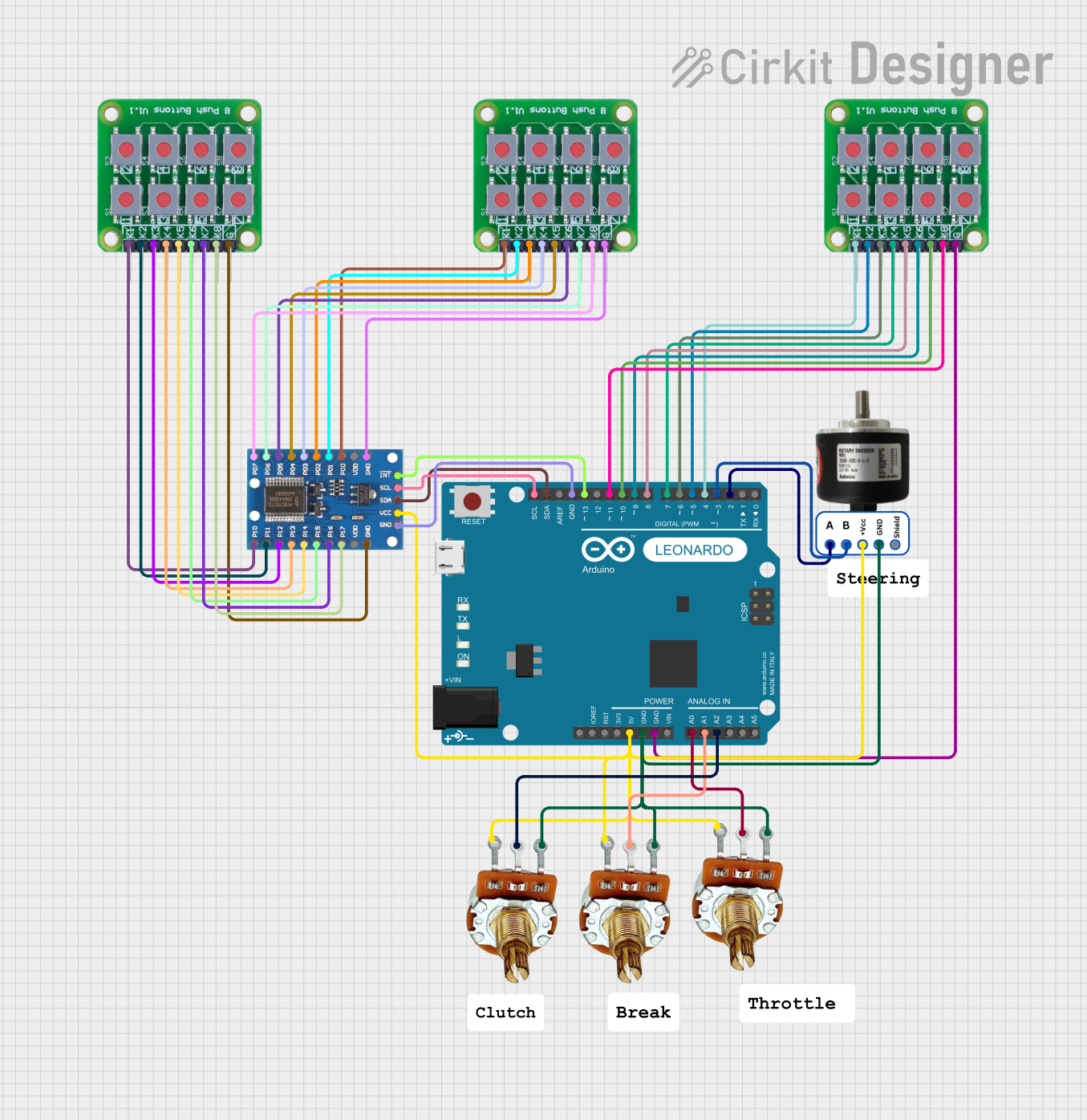

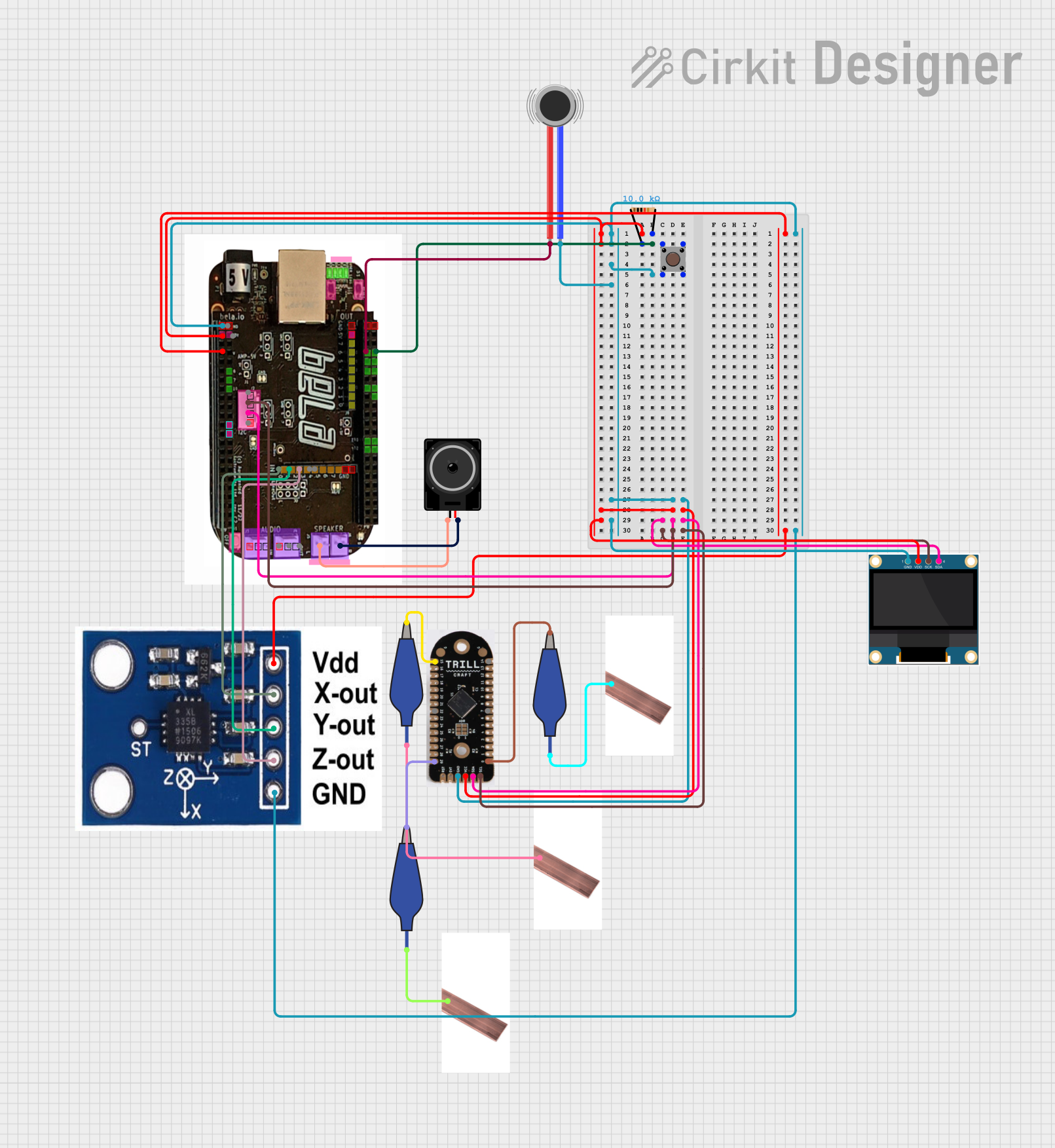

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerTechnical Specifications

Key Technical Details

- Input Voltage Range: 2V to 5.5V

- Output Voltage Range: 1.8V to 5V (adjustable)

- Maximum Output Current: 500mA

- Conversion Efficiency: Up to 95%

- Operating Temperature: -40°C to +85°C

- Quiescent Current: 0.1mA

Pin Configuration and Descriptions

| Pin Number | Name | Description |

|---|---|---|

| 1 | VIN | Input voltage to the Verter_Pad. Connect to your DC power source. |

| 2 | GND | Ground pin. Connect to the ground of your power source and circuit. |

| 3 | VOUT | Regulated output voltage. Connect to the power input of your circuit. |

| 4 | ADJ | Adjustment pin. Connect to a resistor or potentiometer to set VOUT. |

Usage Instructions

How to Use the Verter_Pad in a Circuit

Connecting Power Source:

- Connect the positive terminal of your DC power source to the VIN pin.

- Connect the negative terminal to the GND pin.

Adjusting Output Voltage:

- Connect a resistor or potentiometer between the ADJ and GND pins.

- Adjust the resistance to change the output voltage according to the desired level.

Connecting to Load:

- Connect the VOUT pin to the power input of your electronic circuit.

- Ensure that the adjusted output voltage matches the voltage requirements of your circuit.

Important Considerations and Best Practices

- Always verify the input voltage range before connecting the Verter_Pad to avoid damage.

- Do not exceed the maximum output current rating.

- Use a multimeter to confirm the output voltage before connecting to sensitive components.

- If using a potentiometer for voltage adjustment, choose one with a high resolution for precise control.

- Ensure proper heat dissipation if the Verter_Pad is expected to handle high power levels.

Troubleshooting and FAQs

Common Issues and Solutions

- Output Voltage is Too Low or Too High:

- Check the resistance between the ADJ and GND pins. Adjust the resistor or potentiometer to correct the voltage.

- Verter_Pad is Overheating:

- Ensure that the current draw is within the specified limits.

- Improve ventilation or add a heatsink to the Verter_Pad.

FAQs

- Q: Can I use the Verter_Pad with a 9V battery?

- A: No, the input voltage range is 2V to 5.5V. Exceeding this range can damage the component.

- Q: How do I set a specific output voltage?

- A: Use the formula provided in the datasheet to calculate the resistance needed for your desired output voltage, and adjust the resistor or potentiometer accordingly.

Example Code for Arduino UNO

// Example code to read the output voltage of the Verter_Pad using an Arduino UNO

const int analogPin = A0; // Connect VOUT of Verter_Pad to A0 of Arduino

void setup() {

Serial.begin(9600);

}

void loop() {

int sensorValue = analogRead(analogPin); // Read the analog value from Verter_Pad

float voltage = sensorValue * (5.0 / 1023.0); // Convert to voltage

Serial.print("Output Voltage: ");

Serial.println(voltage);

delay(1000); // Wait for a second before reading again

}

Remember to adjust the Verter_Pad to output a voltage within the range that the Arduino can handle on its analog inputs (0-5V). The code above assumes that the Verter_Pad's output voltage is within this range.