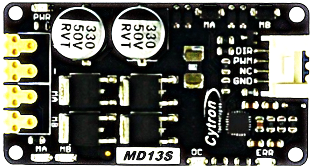

How to Use cytron: Examples, Pinouts, and Specs

Design with cytron in Cirkit Designer

Design with cytron in Cirkit DesignerIntroduction

Cytron is a renowned brand specializing in robotics and electronics components. Their product range includes motor drivers, sensors, and development boards, all designed to simplify the development of robotic and electronic projects. Cytron components are widely used in educational, hobbyist, and professional applications due to their reliability and ease of use.

Common applications of Cytron components include:

- Motor control for robotics and automation systems

- Sensor integration for environmental monitoring

- Development of custom electronic projects using microcontrollers

- Prototyping and educational projects in STEM fields

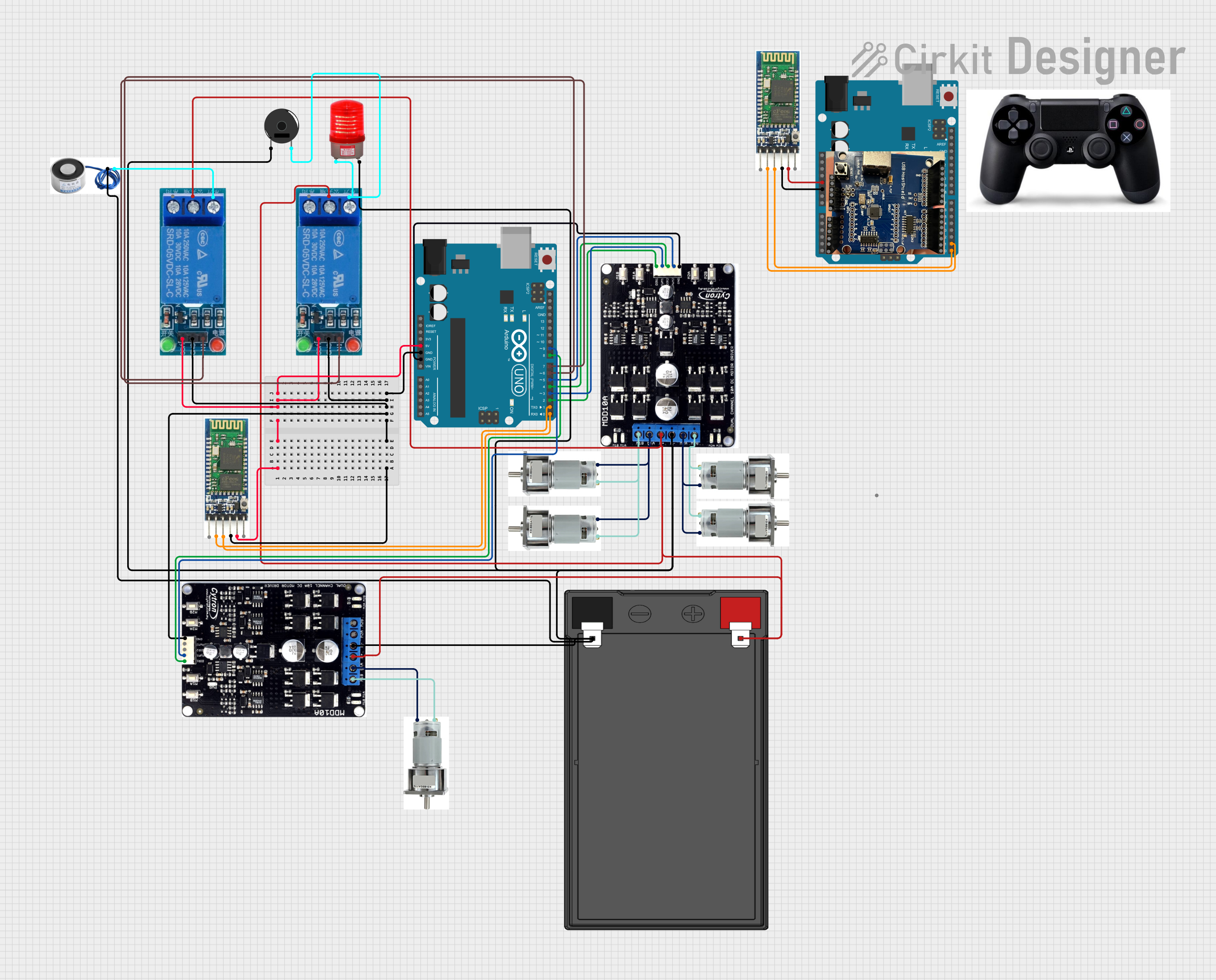

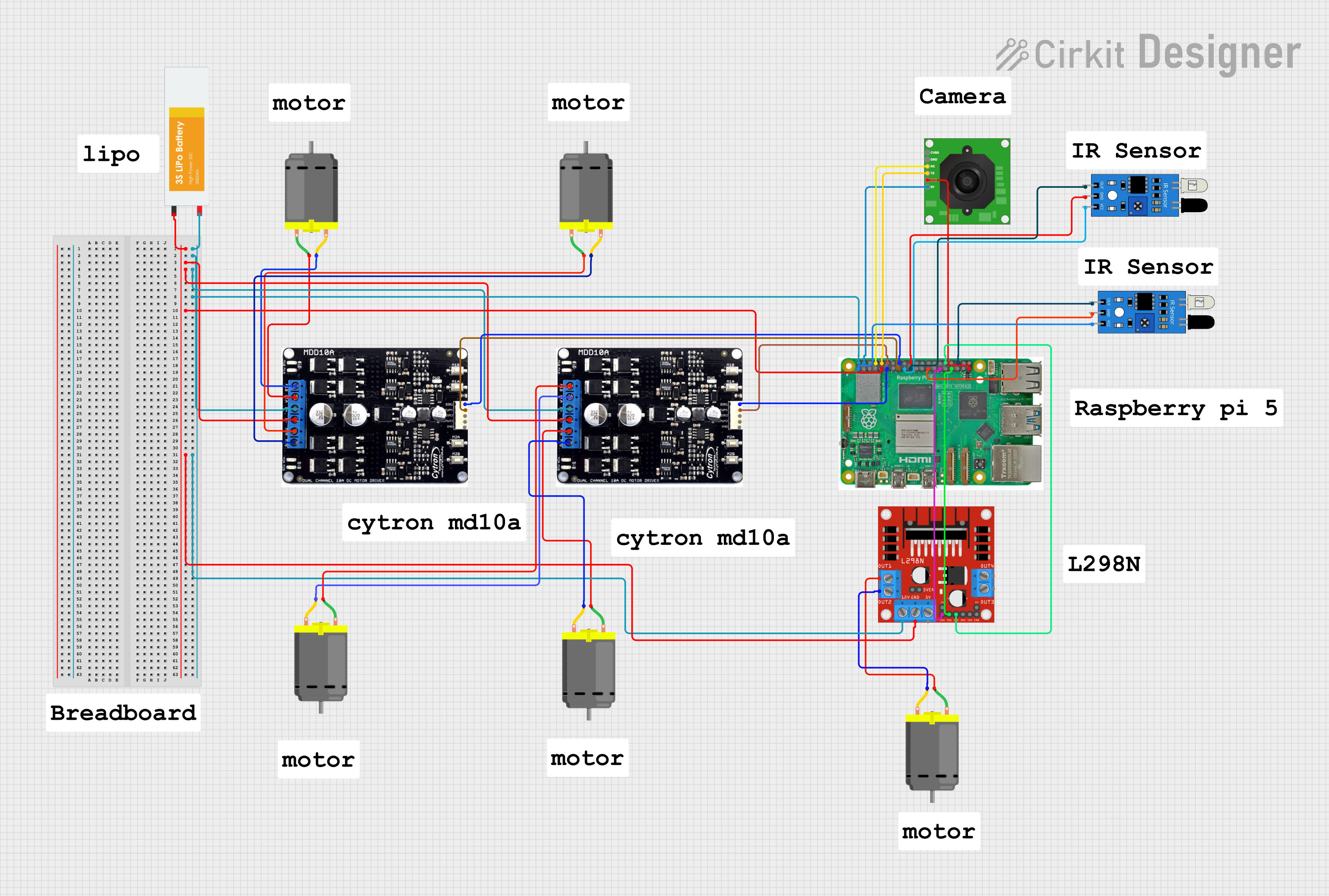

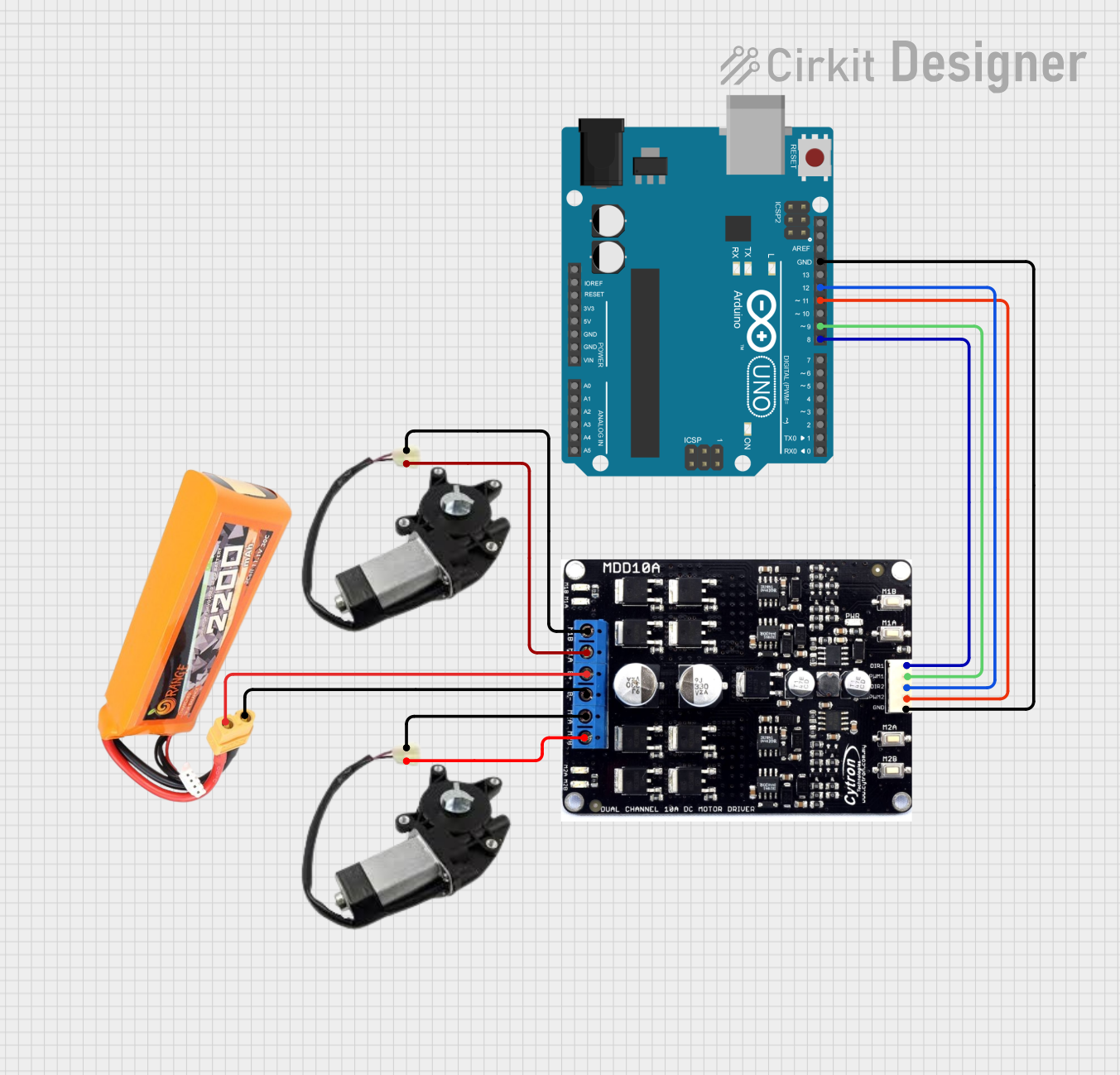

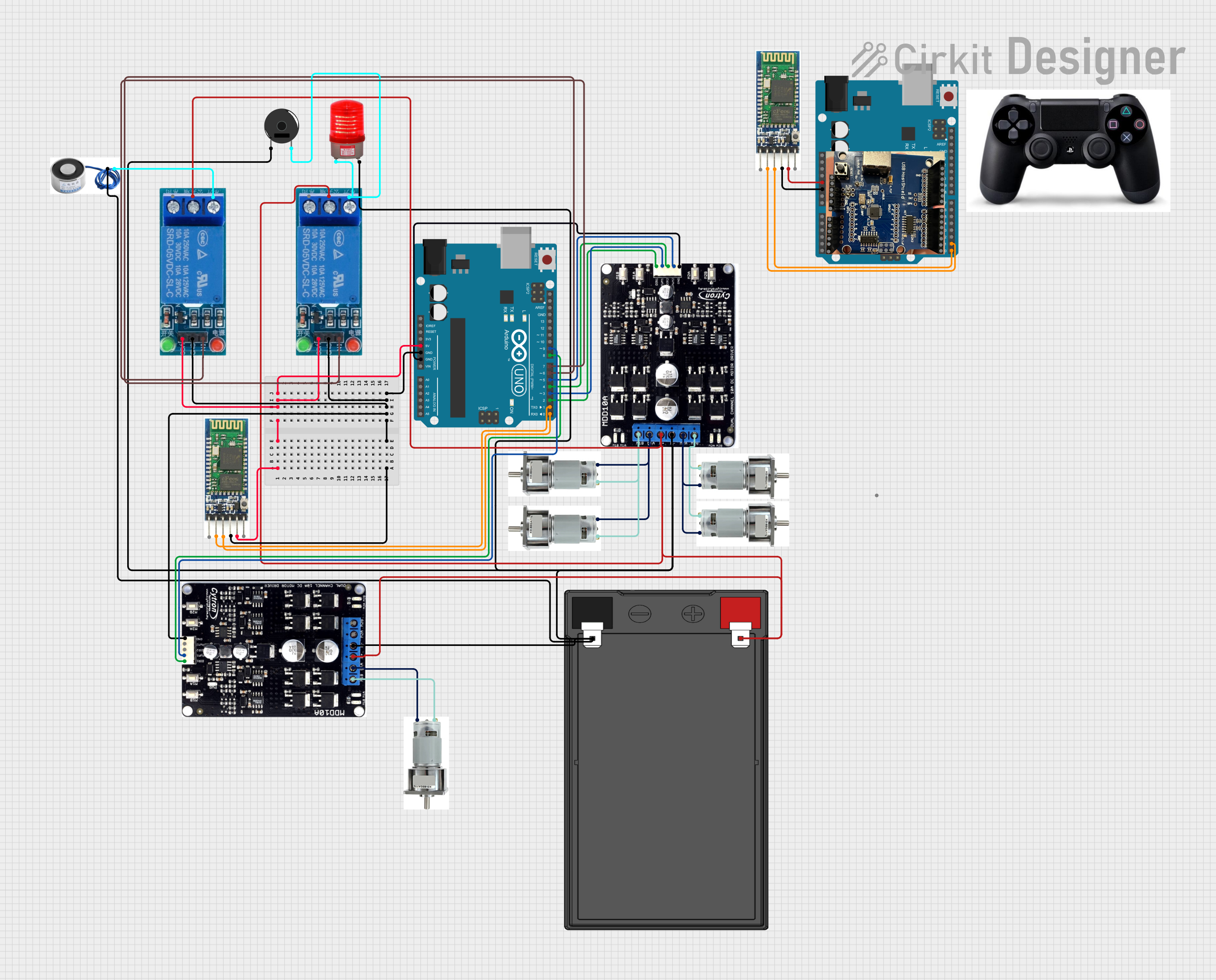

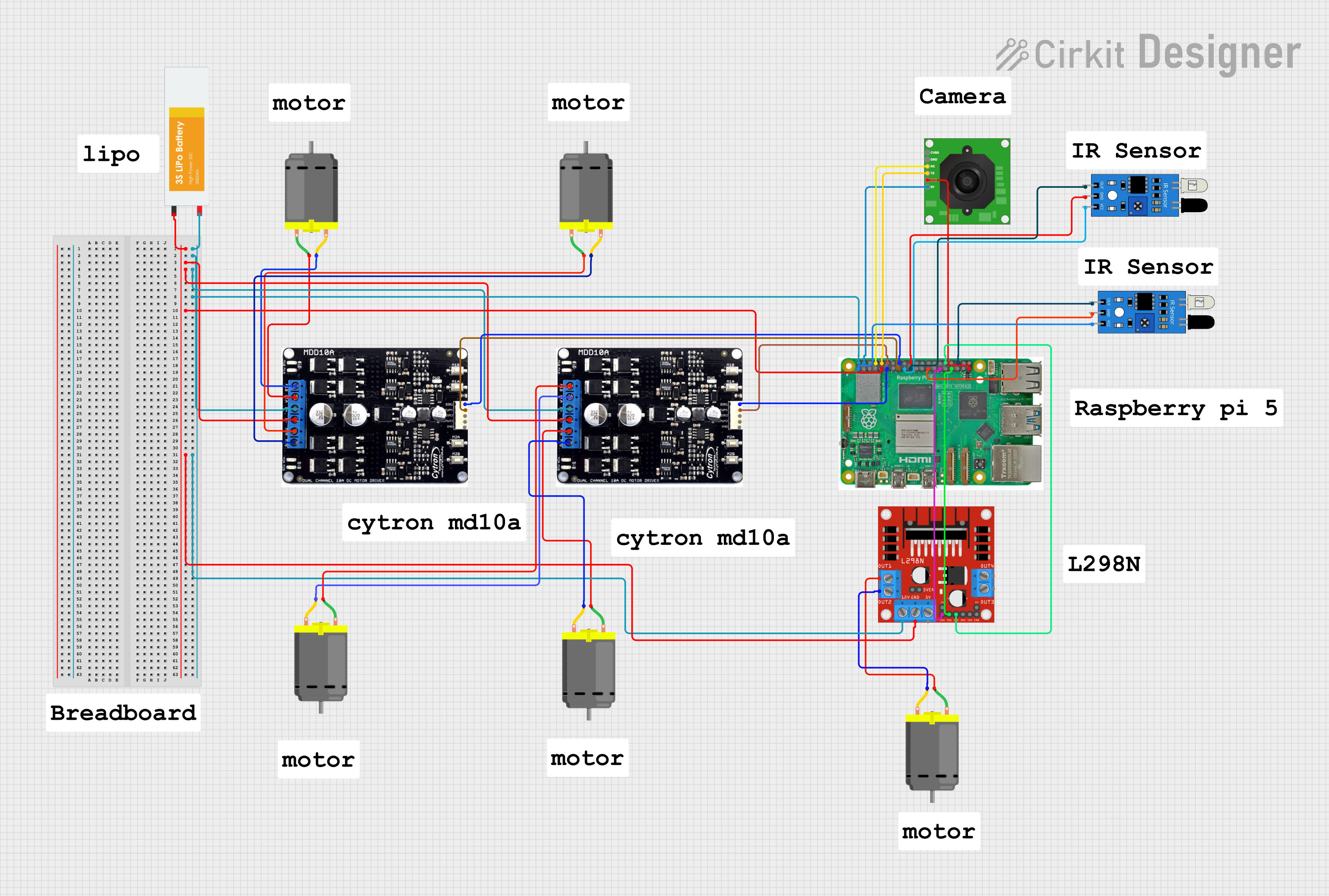

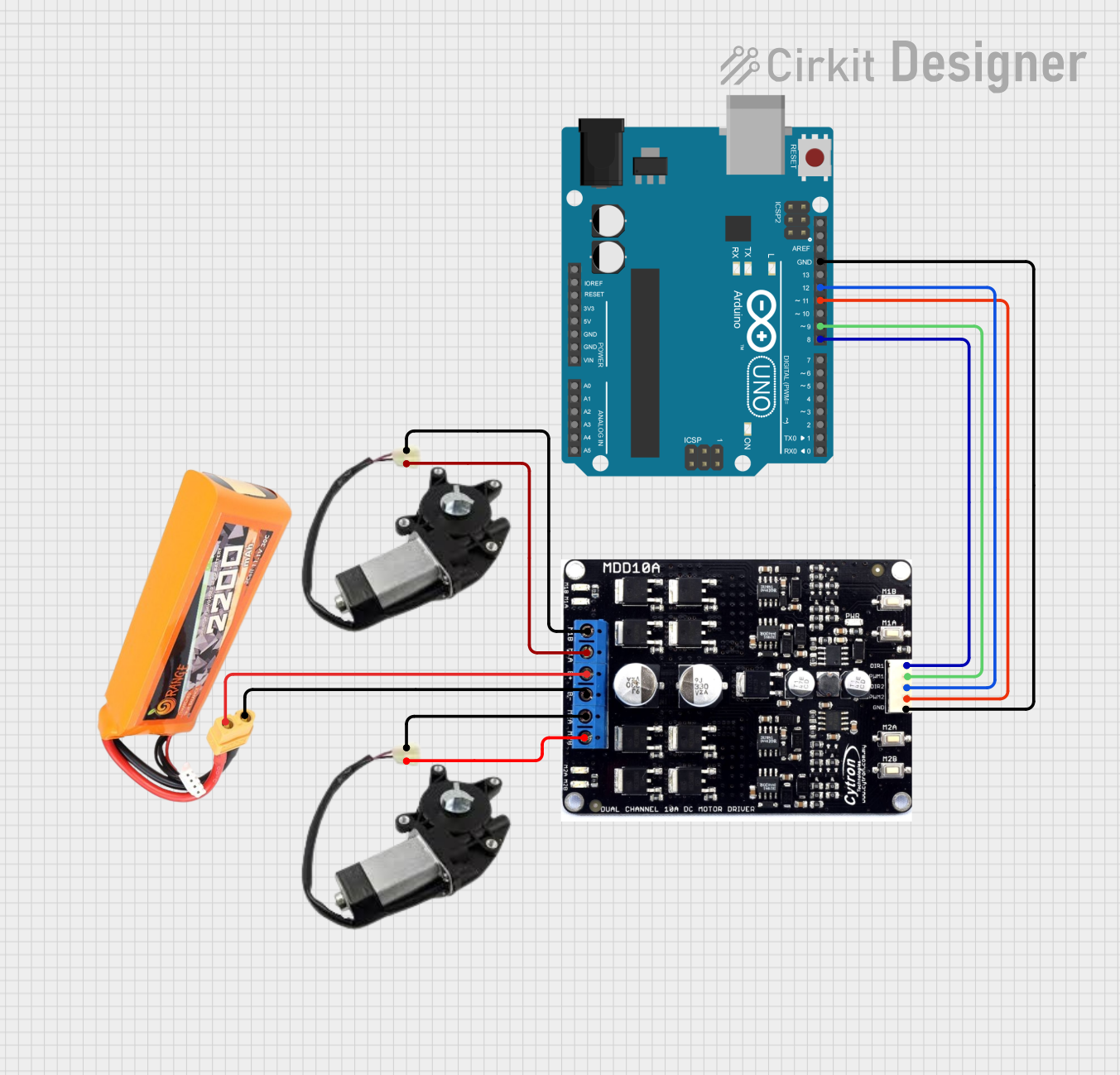

Explore Projects Built with cytron

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with cytron

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerTechnical Specifications

Below are the general technical specifications for Cytron components. Since Cytron offers a variety of products, the specifications may vary depending on the specific component. For this documentation, we will focus on the Cytron MD10C R3 Motor Driver, a popular motor driver from Cytron.

Key Technical Details

- Operating Voltage: 7V to 30V DC

- Continuous Current: 10A (per channel)

- Peak Current: 30A (for 10 seconds)

- Control Signal Voltage: 3.3V or 5V logic compatible

- PWM Frequency: Up to 20 kHz

- Dimensions: 84mm x 62mm x 25mm

- Weight: 70g

Pin Configuration and Descriptions

The Cytron MD10C R3 Motor Driver has the following pin configuration:

| Pin Name | Description |

|---|---|

| VIN | Power input for the motor driver (7V to 30V DC). |

| GND | Ground connection. |

| PWM | Pulse Width Modulation input for speed control (3.3V or 5V logic). |

| DIR | Direction control input (HIGH for forward, LOW for reverse). |

| MOTOR+ | Positive terminal of the motor. |

| MOTOR- | Negative terminal of the motor. |

| VOUT | Regulated output voltage (5V, max 1A) for powering external circuits. |

Usage Instructions

How to Use the Cytron MD10C R3 Motor Driver in a Circuit

- Power Supply: Connect a DC power source (7V to 30V) to the VIN and GND pins. Ensure the power supply can provide sufficient current for your motor.

- Motor Connection: Connect the motor terminals to the MOTOR+ and MOTOR- pins.

- Control Signals:

- Connect the PWM pin to a PWM-capable pin on your microcontroller (e.g., Arduino).

- Connect the DIR pin to a digital output pin on your microcontroller to control the motor's direction.

- Logic Voltage: The MD10C R3 is compatible with both 3.3V and 5V logic levels, making it suitable for a wide range of microcontrollers.

- Optional Output: Use the VOUT pin to power external circuits if needed (e.g., sensors or microcontrollers).

Important Considerations and Best Practices

- Heat Dissipation: The motor driver can handle high currents, but prolonged operation at high currents may cause overheating. Use a heatsink or active cooling if necessary.

- Current Limiting: Ensure the motor's current draw does not exceed the driver's maximum continuous current rating (10A).

- PWM Frequency: Use a PWM frequency of up to 20 kHz for optimal performance.

- Reverse Polarity Protection: The MD10C R3 includes reverse polarity protection, but always double-check your connections to avoid damage.

Example Code for Arduino UNO

Below is an example code snippet to control a motor using the Cytron MD10C R3 Motor Driver with an Arduino UNO:

// Define pin connections

const int pwmPin = 9; // PWM pin connected to MD10C R3's PWM input

const int dirPin = 8; // Direction pin connected to MD10C R3's DIR input

void setup() {

// Set pin modes

pinMode(pwmPin, OUTPUT);

pinMode(dirPin, OUTPUT);

}

void loop() {

// Rotate motor forward at 50% speed

digitalWrite(dirPin, HIGH); // Set direction to forward

analogWrite(pwmPin, 128); // Set PWM duty cycle to 50% (128/255)

delay(2000); // Run for 2 seconds

// Rotate motor backward at 75% speed

digitalWrite(dirPin, LOW); // Set direction to reverse

analogWrite(pwmPin, 192); // Set PWM duty cycle to 75% (192/255)

delay(2000); // Run for 2 seconds

// Stop the motor

analogWrite(pwmPin, 0); // Set PWM duty cycle to 0 (stop)

delay(2000); // Wait for 2 seconds

}

Troubleshooting and FAQs

Common Issues and Solutions

Motor Not Spinning:

- Check the power supply voltage and ensure it is within the 7V to 30V range.

- Verify the motor connections to the MOTOR+ and MOTOR- pins.

- Ensure the PWM and DIR pins are correctly connected to the microcontroller.

Motor Spins in the Wrong Direction:

- Reverse the logic level on the DIR pin (HIGH to LOW or vice versa).

- Alternatively, swap the MOTOR+ and MOTOR- connections.

Overheating:

- Ensure the motor's current draw does not exceed the driver's continuous current rating.

- Add a heatsink or active cooling to the motor driver.

PWM Signal Not Detected:

- Verify that the microcontroller is outputting a PWM signal on the specified pin.

- Check the PWM frequency and ensure it does not exceed 20 kHz.

FAQs

Can I use the MD10C R3 with a 3.3V microcontroller? Yes, the MD10C R3 is compatible with both 3.3V and 5V logic levels.

What type of motors can I control with this driver? The MD10C R3 is designed for brushed DC motors.

Is reverse polarity protection included? Yes, the MD10C R3 includes reverse polarity protection for the power input.

Can I control two motors with this driver? No, the MD10C R3 is a single-channel motor driver and can control only one motor. For dual-motor control, consider Cytron's dual-channel motor drivers.

This documentation provides a comprehensive guide to using the Cytron MD10C R3 Motor Driver. For further assistance, refer to the official Cytron website or contact their support team.