How to Use Stepper Motor: Examples, Pinouts, and Specs

Design with Stepper Motor in Cirkit Designer

Design with Stepper Motor in Cirkit DesignerIntroduction

The STP-MTRD-17038E is a high-performance stepper motor manufactured by Automation Direct. This motor is designed to divide a full rotation into a large number of discrete steps, enabling precise control of position, speed, and acceleration. Stepper motors are widely used in applications requiring accurate positioning, such as robotics, CNC machines, 3D printers, and automated manufacturing systems.

This stepper motor is particularly well-suited for applications where open-loop control is sufficient, eliminating the need for complex feedback systems. Its robust design ensures reliable operation in demanding environments.

Explore Projects Built with Stepper Motor

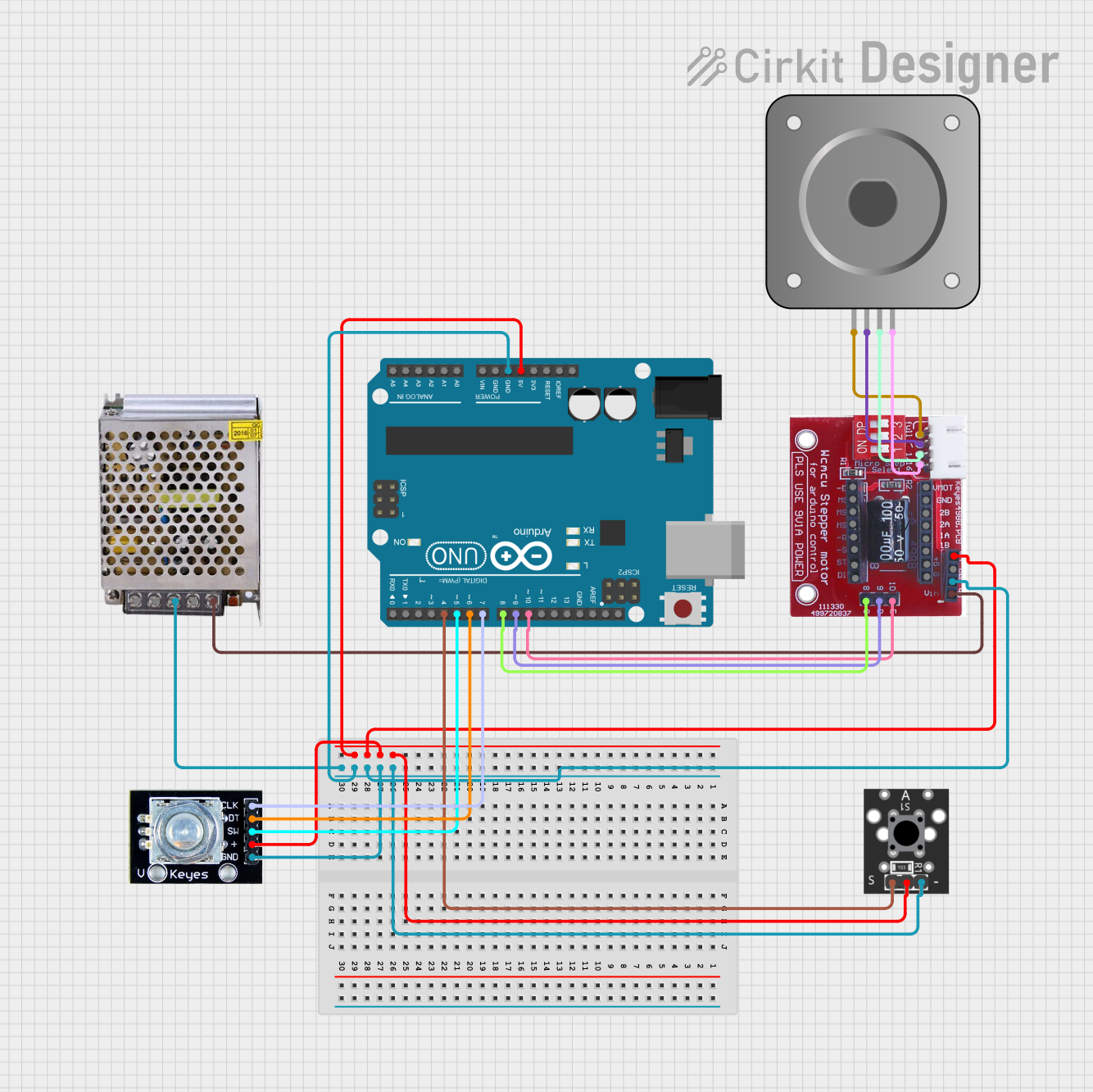

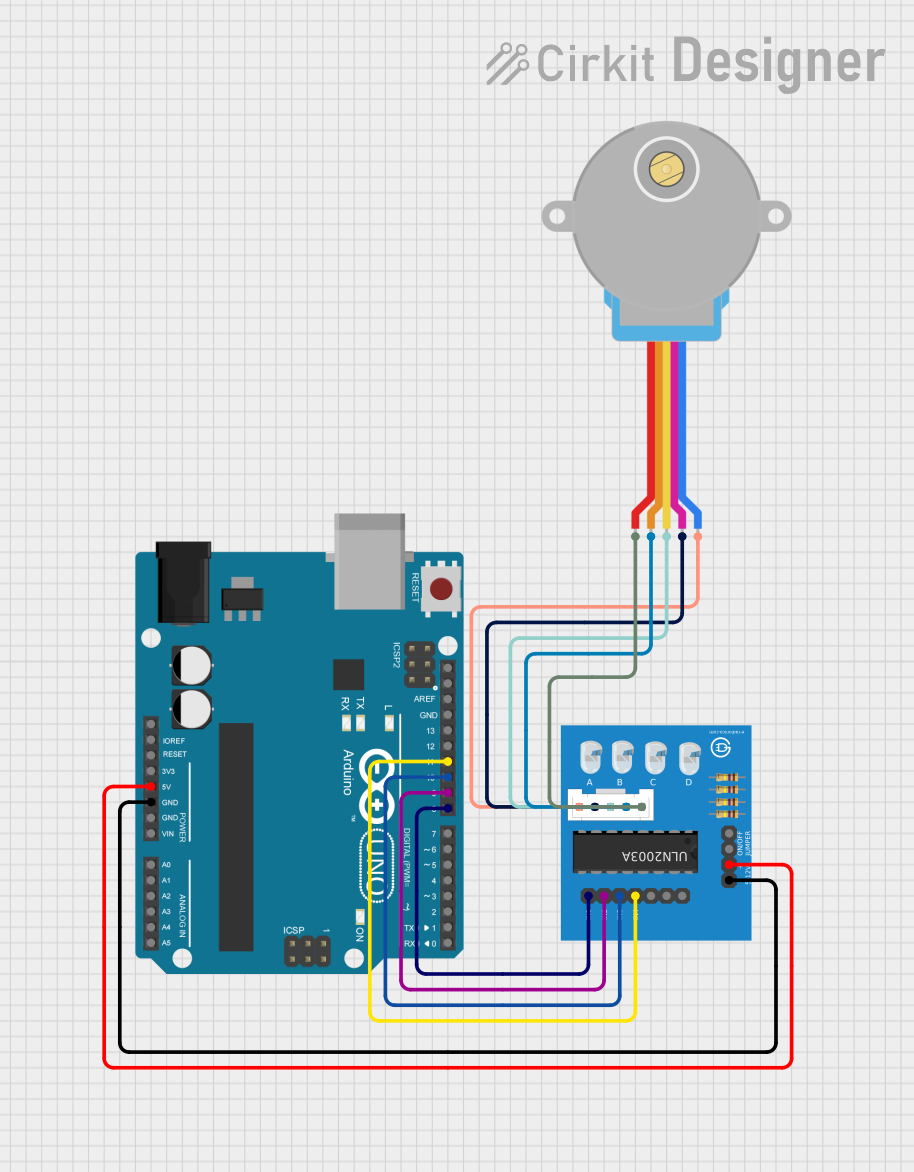

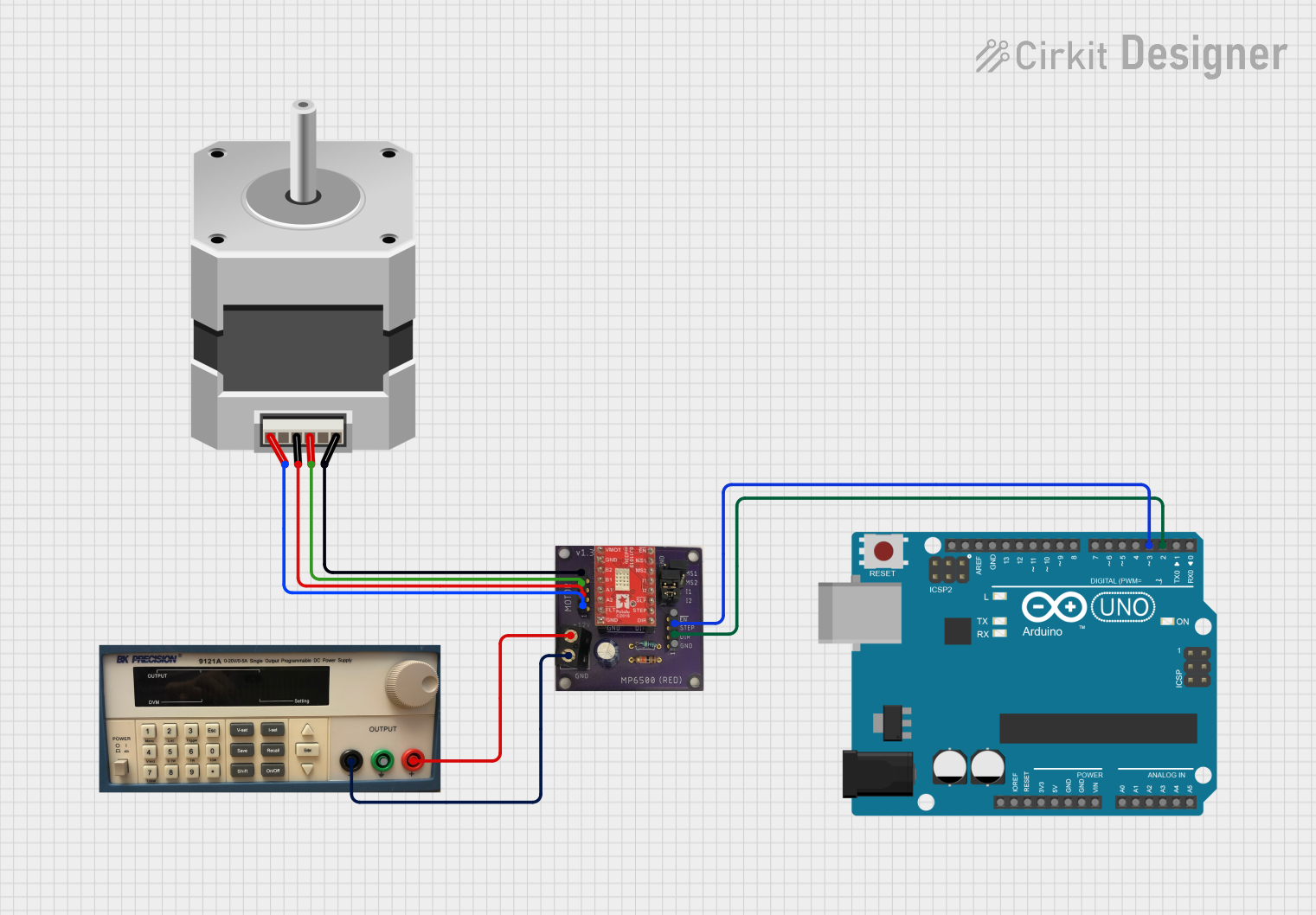

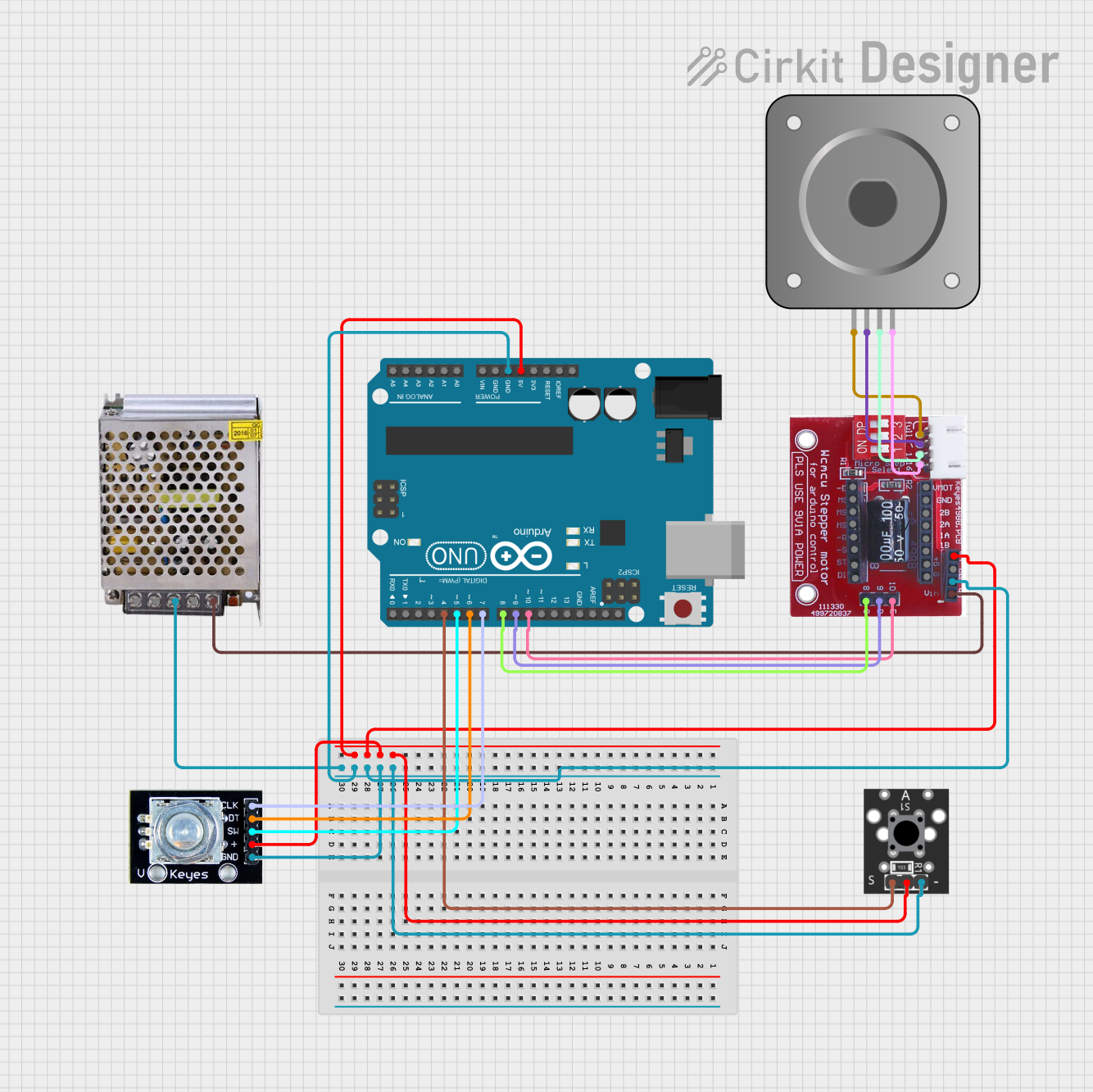

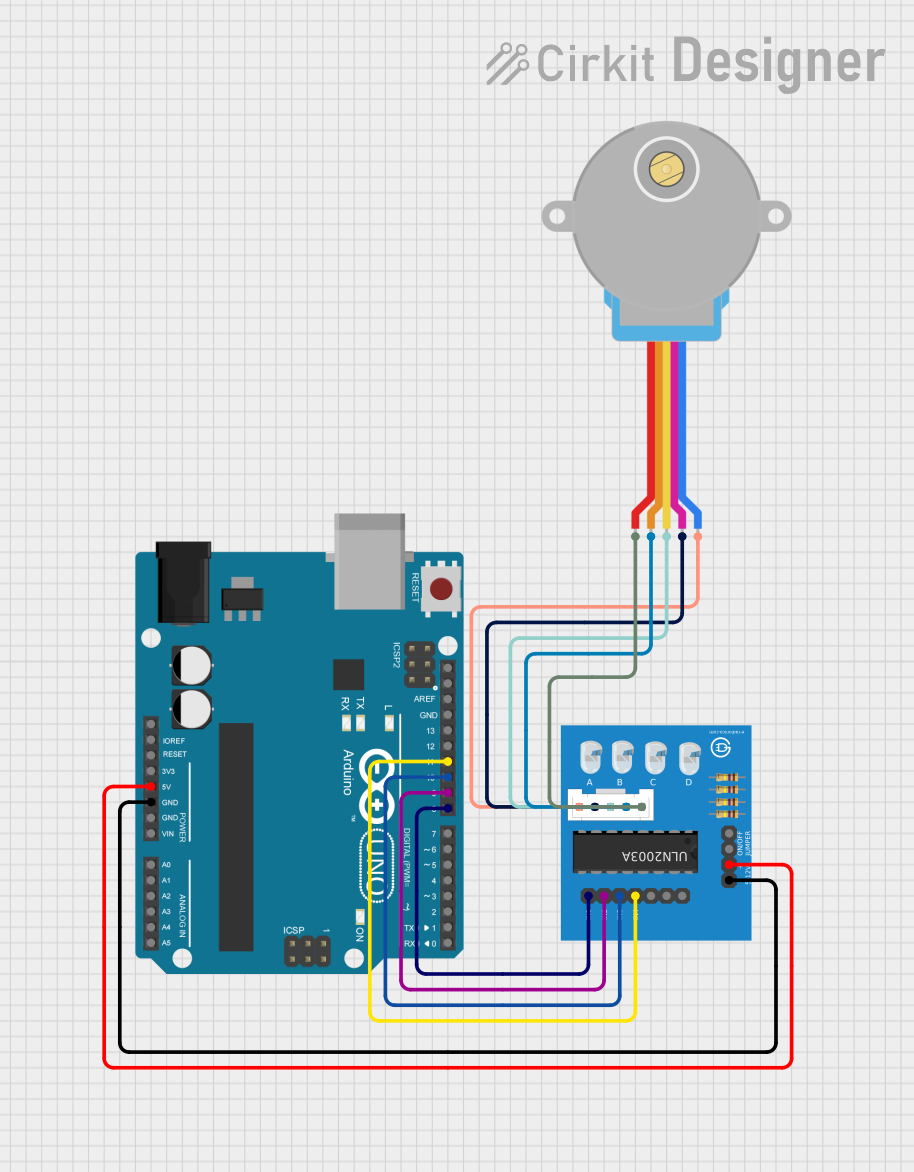

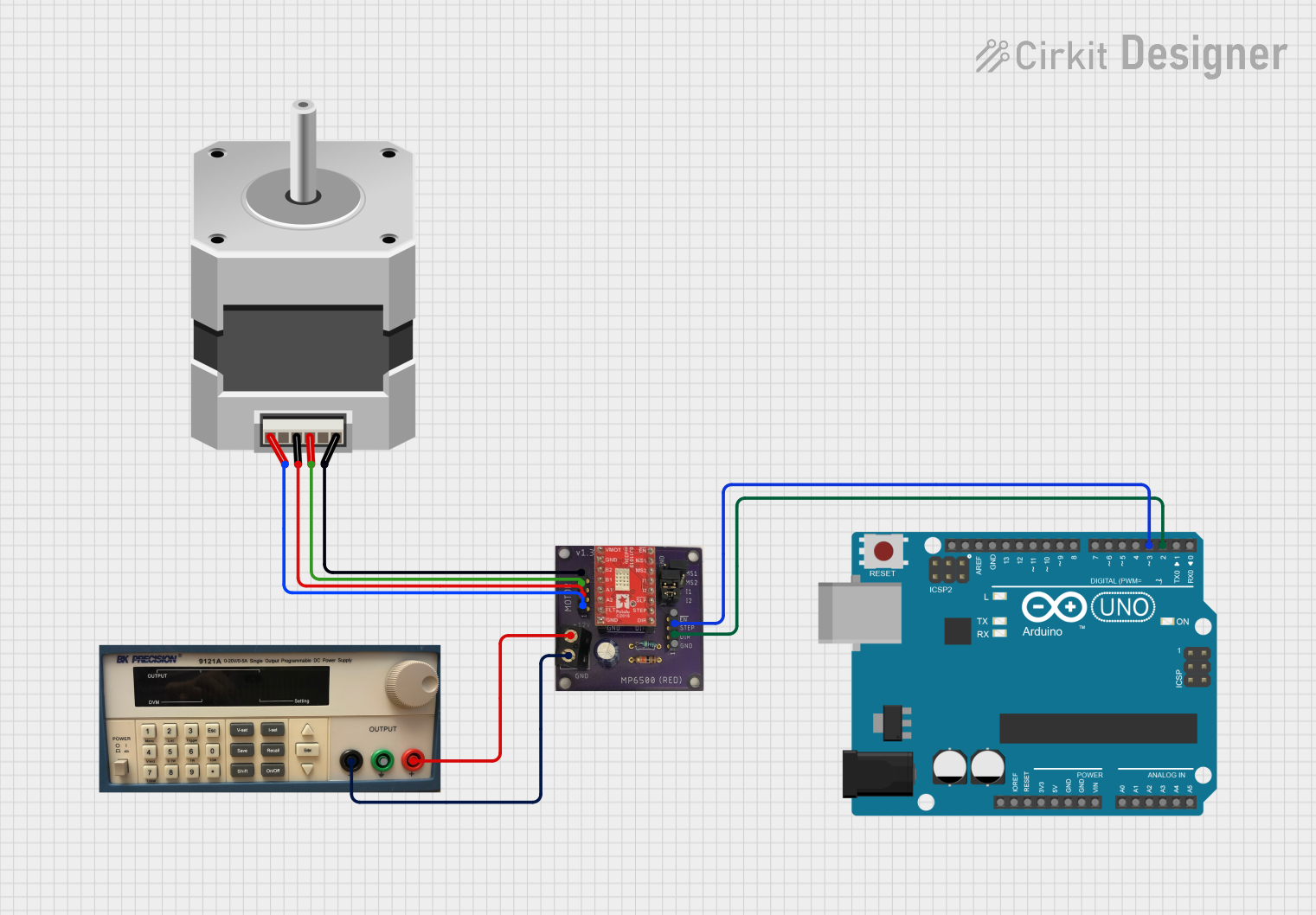

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with Stepper Motor

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerTechnical Specifications

Below are the key technical details for the STP-MTRD-17038E stepper motor:

General Specifications

| Parameter | Value |

|---|---|

| Manufacturer | Automation Direct |

| Part Number | STP-MTRD-17038E |

| Motor Type | Bipolar Stepper Motor |

| Step Angle | 1.8° per step (200 steps/rev) |

| Holding Torque | 1.26 Nm (178 oz-in) |

| Rated Current per Phase | 2.8 A |

| Voltage | 2.55 V |

| Resistance per Phase | 0.91 Ω |

| Inductance per Phase | 3.6 mH |

| Rotor Inertia | 275 g·cm² |

| Weight | 1.1 kg |

Pin Configuration

The STP-MTRD-17038E has four leads for its bipolar winding configuration. The table below describes the pinout:

| Lead Color | Function | Description |

|---|---|---|

| Black | Coil A+ | Positive terminal of Coil A |

| Green | Coil A- | Negative terminal of Coil A |

| Red | Coil B+ | Positive terminal of Coil B |

| Blue | Coil B- | Negative terminal of Coil B |

Mechanical Dimensions

| Parameter | Value |

|---|---|

| Frame Size | NEMA 17 |

| Shaft Diameter | 5 mm |

| Shaft Length | 24 mm |

| Mounting Hole Spacing | 31 mm |

Usage Instructions

How to Use the Stepper Motor in a Circuit

- Power Supply: Ensure the power supply matches the motor's rated voltage and current. Use a stepper motor driver capable of handling the motor's current rating (e.g., 2.8 A per phase).

- Driver Connection: Connect the motor leads to the stepper motor driver as follows:

- Black and Green wires to Coil A terminals.

- Red and Blue wires to Coil B terminals.

- Microcontroller Interface: Use a microcontroller (e.g., Arduino UNO) to send step and direction signals to the driver. Ensure proper grounding between the microcontroller and the driver.

- Step Resolution: Configure the driver for the desired step resolution (e.g., full-step, half-step, microstepping) based on your application's precision requirements.

Important Considerations and Best Practices

- Current Limiting: Set the current limit on the driver to 2.8 A to prevent overheating and ensure optimal performance.

- Cooling: Provide adequate ventilation or a heatsink for the motor and driver to avoid thermal issues during prolonged operation.

- Wiring: Use high-quality wires and ensure secure connections to prevent signal loss or interference.

- Back EMF Protection: Use a driver with built-in protection against back electromotive force (EMF) to safeguard your circuit.

Example Code for Arduino UNO

Below is an example of how to control the STP-MTRD-17038E stepper motor using an Arduino UNO and a compatible stepper motor driver:

// Include the Stepper library

#include <Stepper.h>

// Define the number of steps per revolution for the motor

#define STEPS_PER_REV 200

// Initialize the Stepper library with the motor's step count and pin connections

// Pins 8 and 9 control Coil A, Pins 10 and 11 control Coil B

Stepper stepperMotor(STEPS_PER_REV, 8, 9, 10, 11);

void setup() {

// Set the motor speed (in RPM)

stepperMotor.setSpeed(60); // 60 RPM

Serial.begin(9600);

Serial.println("Stepper Motor Test Initialized");

}

void loop() {

// Rotate the motor one full revolution clockwise

Serial.println("Rotating clockwise...");

stepperMotor.step(STEPS_PER_REV);

delay(1000); // Wait for 1 second

// Rotate the motor one full revolution counterclockwise

Serial.println("Rotating counterclockwise...");

stepperMotor.step(-STEPS_PER_REV);

delay(1000); // Wait for 1 second

}

Notes:

- Replace the pin numbers in the code with the actual pins connected to your driver.

- Adjust the speed and step count as needed for your application.

Troubleshooting and FAQs

Common Issues and Solutions

Motor Not Moving:

- Cause: Incorrect wiring or loose connections.

- Solution: Double-check the wiring and ensure all connections are secure.

Motor Vibrates but Does Not Rotate:

- Cause: Incorrect step sequence or insufficient current.

- Solution: Verify the step sequence in your code and ensure the driver is set to the correct current limit.

Overheating:

- Cause: Excessive current or poor ventilation.

- Solution: Reduce the current limit on the driver and improve cooling.

Skipping Steps:

- Cause: Excessive load or incorrect step resolution.

- Solution: Reduce the load on the motor or increase the step resolution.

Noise During Operation:

- Cause: Resonance or improper microstepping configuration.

- Solution: Use microstepping and adjust the speed to avoid resonance frequencies.

FAQs

Q: Can I use this motor with a unipolar driver?

A: No, the STP-MTRD-17038E is a bipolar stepper motor and requires a bipolar driver.Q: What is the maximum speed of this motor?

A: The maximum speed depends on the driver, power supply, and load. Typically, stepper motors operate efficiently at speeds up to 1000 RPM.Q: Can I run this motor without a driver?

A: No, a stepper motor driver is required to control the current and step sequence.Q: Is this motor compatible with Arduino?

A: Yes, it can be controlled using an Arduino and a compatible stepper motor driver.

By following this documentation, you can effectively integrate the STP-MTRD-17038E stepper motor into your projects for precise and reliable motion control.