How to Use SparkFun PicoBuck LED Driver: Examples, Pinouts, and Specs

Design with SparkFun PicoBuck LED Driver in Cirkit Designer

Design with SparkFun PicoBuck LED Driver in Cirkit DesignerIntroduction

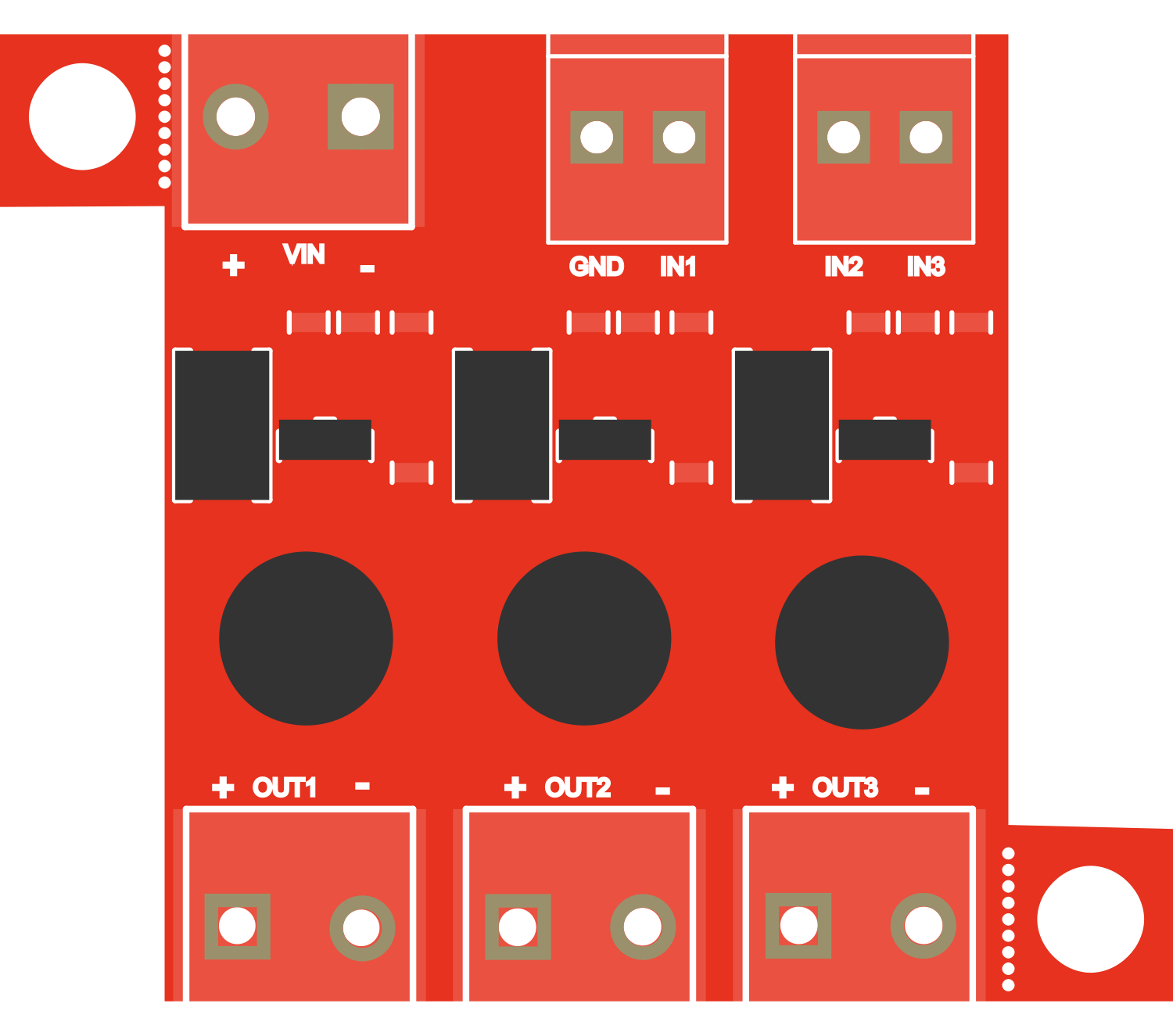

The SparkFun PicoBuck LED Driver is an exceptionally versatile board designed to drive high-power LEDs with ease. It is capable of controlling up to three separate channels of LEDs and is suitable for a variety of lighting projects, from DIY home decor to industrial applications. The PicoBuck is popular for its simplicity and efficiency, accepting a wide range of input voltages and providing built-in PWM control for adjustable brightness.

Explore Projects Built with SparkFun PicoBuck LED Driver

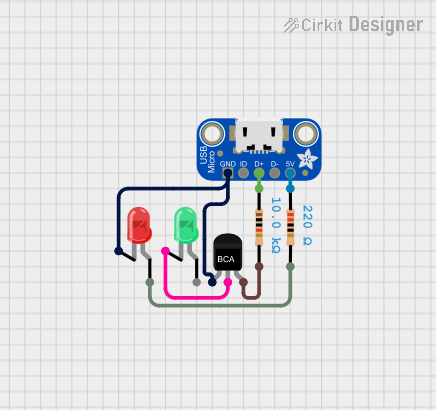

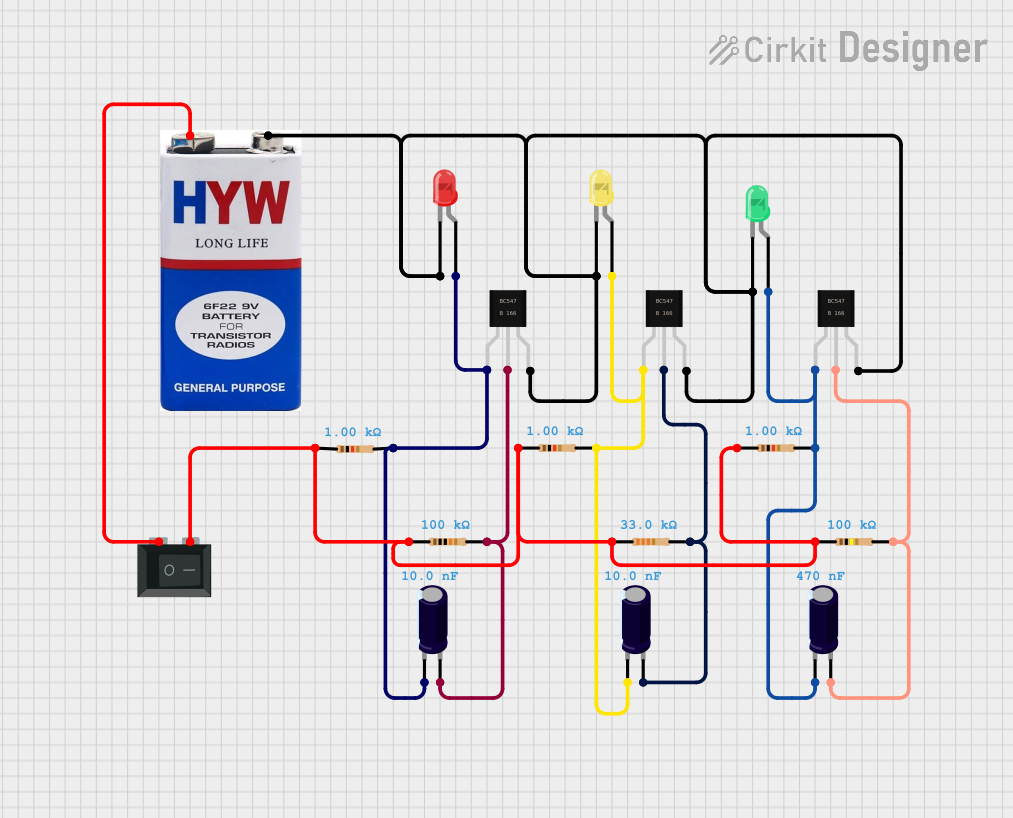

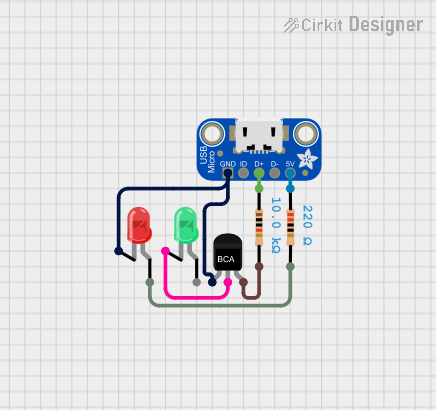

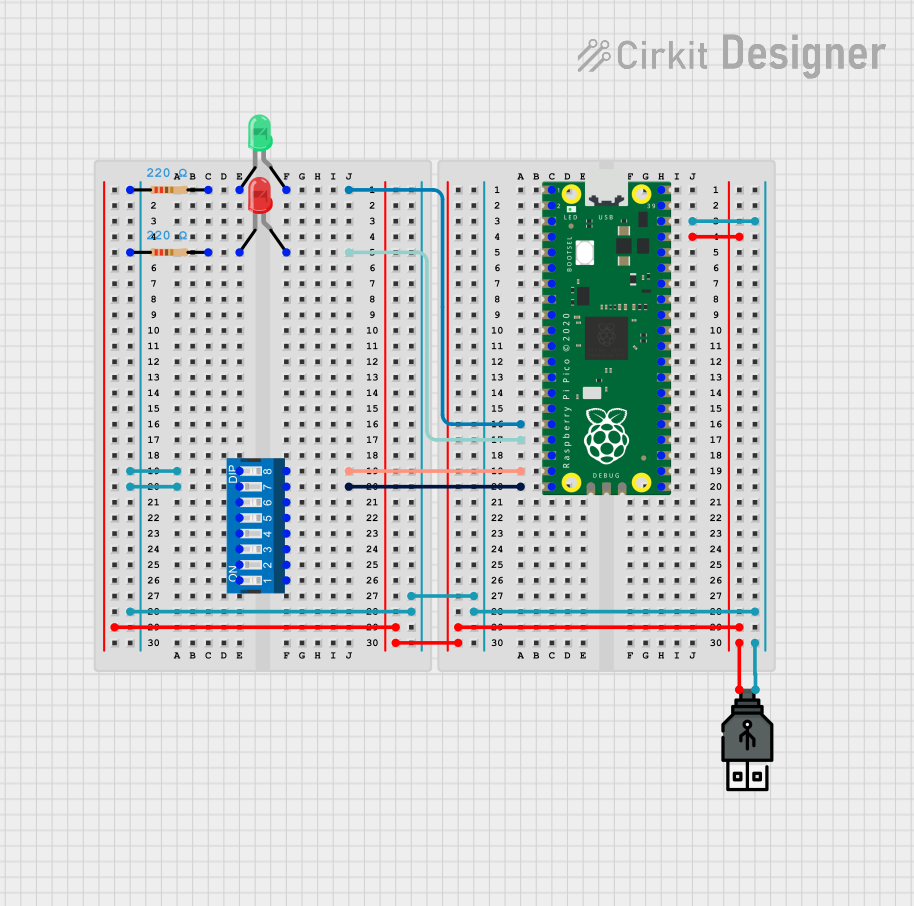

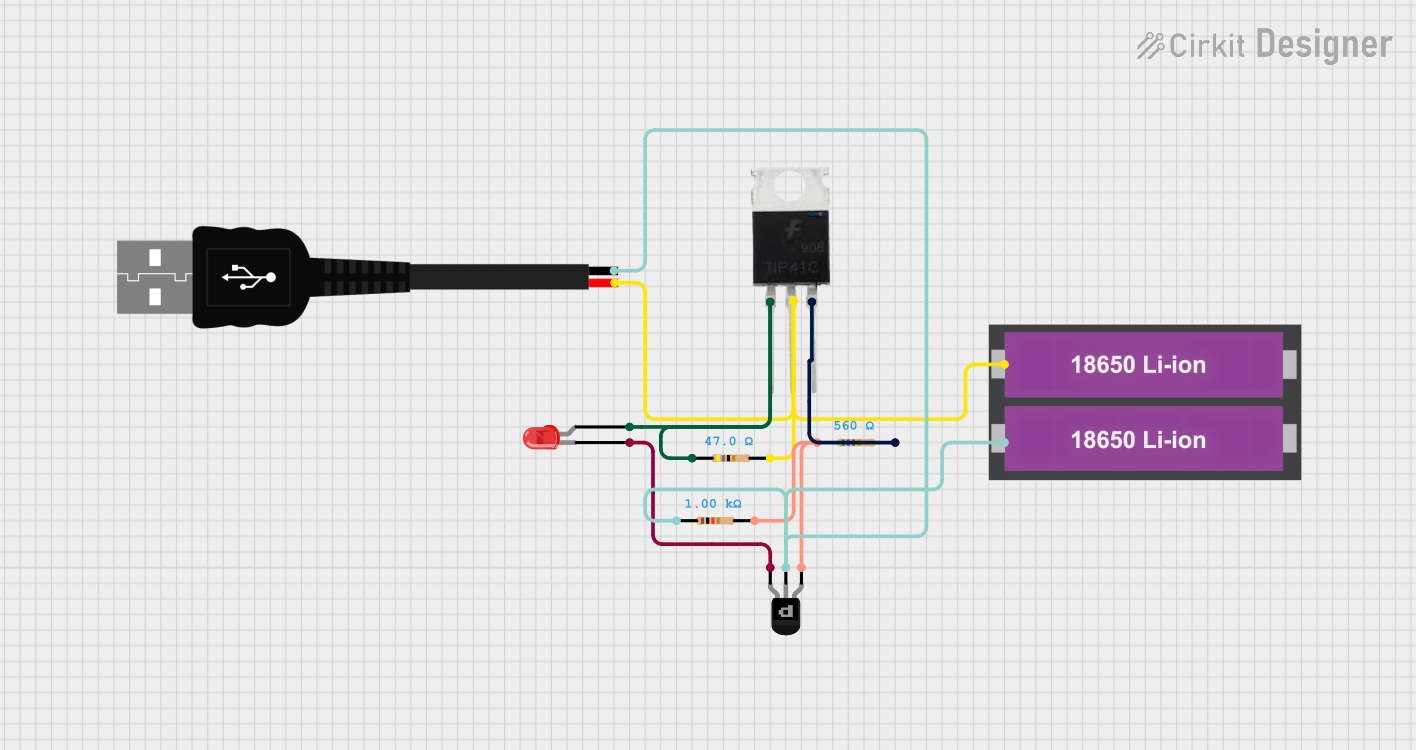

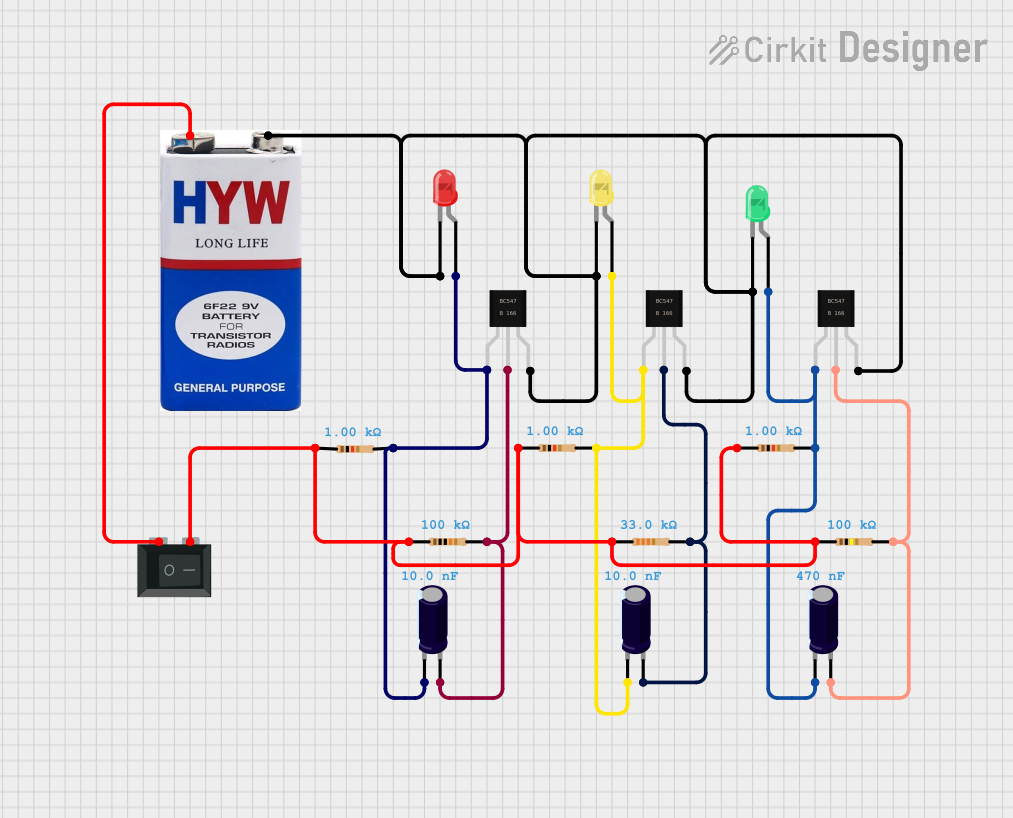

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

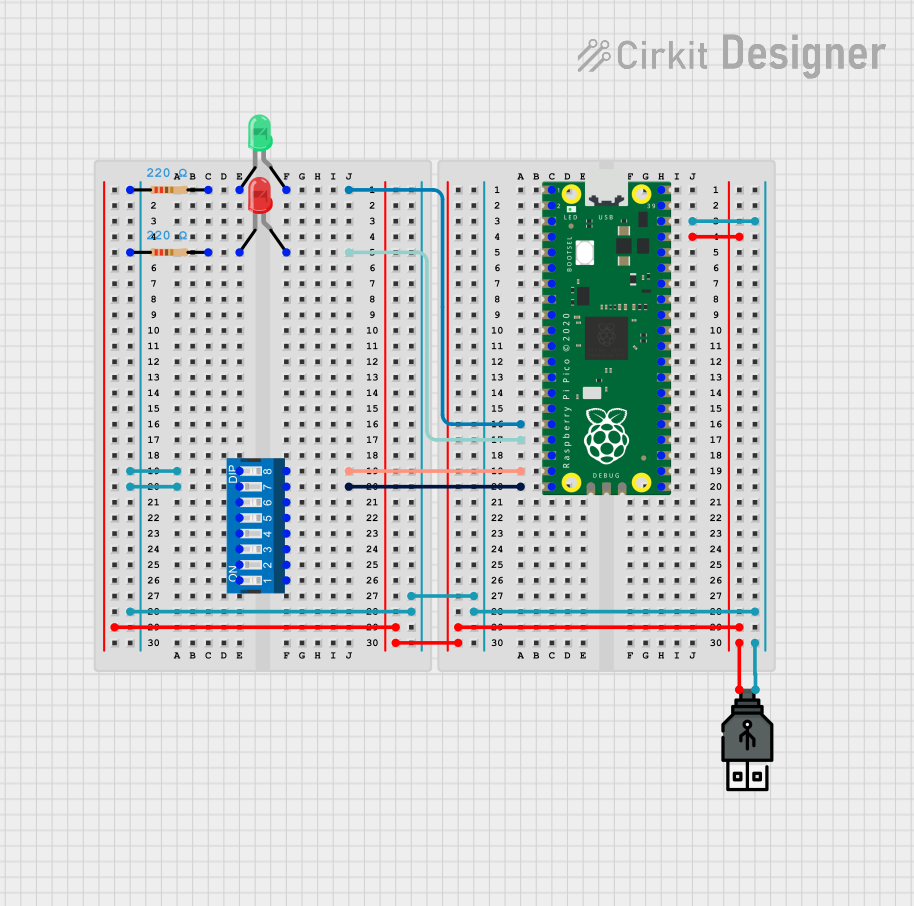

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with SparkFun PicoBuck LED Driver

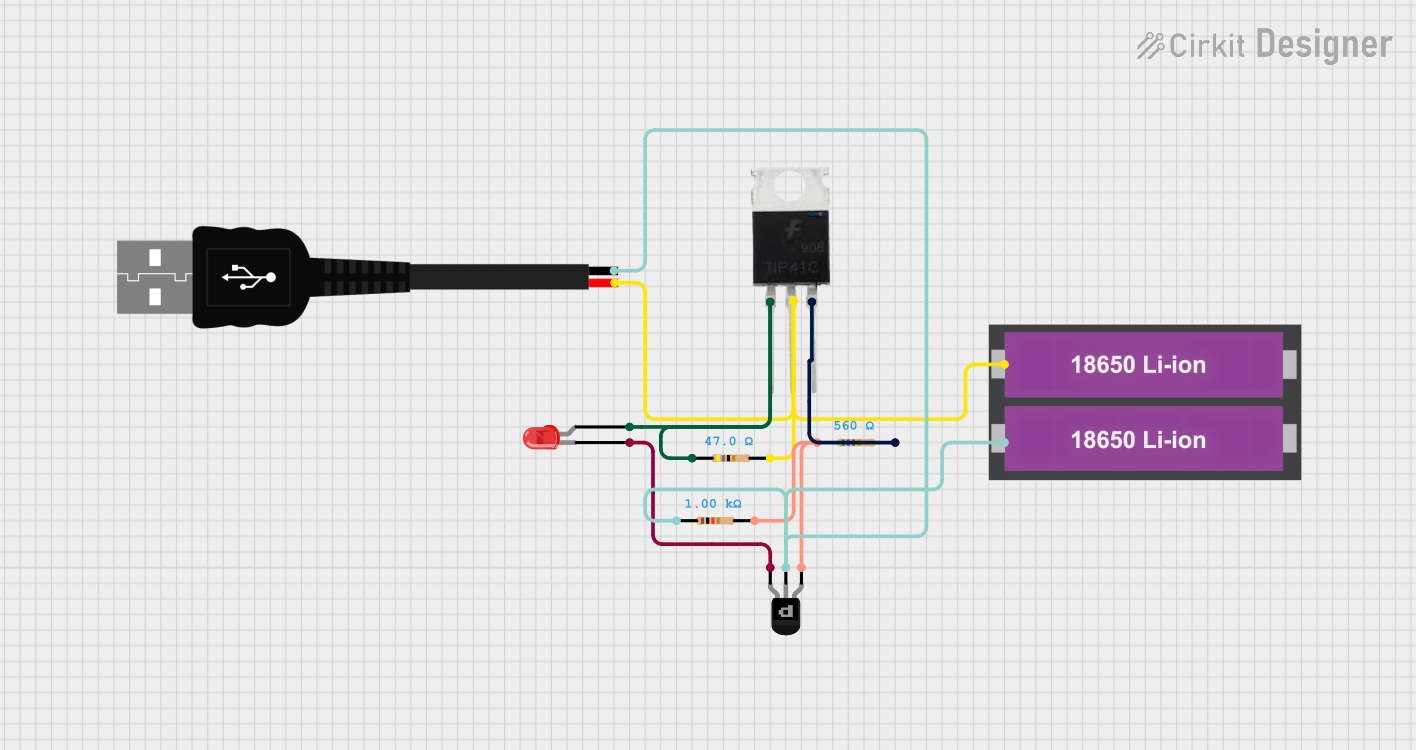

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications and Use Cases

- Architectural lighting

- Automotive and bicycle lights

- DIY home lighting projects

- Signage and display lighting

- Horticulture and grow lights

- Prototyping for industrial lighting solutions

Technical Specifications

Key Technical Details

- Input Voltage: 6V to 20V

- Output Current: Up to 350mA per channel (adjustable)

- Maximum Power Rating: 1W per channel

- PWM Control: Up to 20kHz

- Efficiency: Up to 95%

- Operating Temperature: -40°C to 85°C

Pin Configuration and Descriptions

| Pin Number | Name | Description |

|---|---|---|

| 1 | VIN | Input voltage (6V to 20V) |

| 2 | GND | Ground connection |

| 3 | EN | Enable pin (active high) |

| 4 | PWM | PWM brightness control input |

| 5-7 | OUT1-OUT3 | LED output channels |

Usage Instructions

How to Use the Component in a Circuit

- Connecting Power: Connect a power supply to the VIN and GND pins, ensuring that the voltage is within the specified range (6V to 20V).

- Attaching LEDs: Connect your high-power LEDs to the OUT1, OUT2, and OUT3 channels, with the anode to the output pin and the cathode to the common ground.

- Enabling the Driver: Apply a high signal to the EN pin to enable the driver. A low signal will turn off all outputs.

- Controlling Brightness: Connect a PWM signal to the PWM pin to adjust the brightness of the LEDs. The frequency can be up to 20kHz.

Important Considerations and Best Practices

- Ensure that the total power does not exceed the maximum power rating of the board.

- Use proper heat sinking for the LEDs to prevent overheating.

- If dimming is not required, the PWM pin can be tied to VIN for full brightness.

- Avoid applying a voltage to the PWM pin that is higher than VIN to prevent damage.

Example Code for Arduino UNO

// Define the PWM pin connected to the PicoBuck

const int pwmPin = 9; // Must be a PWM-capable pin

void setup() {

// Set the PWM pin as an output

pinMode(pwmPin, OUTPUT);

}

void loop() {

// Increase brightness gradually

for (int dutyCycle = 0; dutyCycle <= 255; dutyCycle++) {

analogWrite(pwmPin, dutyCycle);

delay(10);

}

// Decrease brightness gradually

for (int dutyCycle = 255; dutyCycle >= 0; dutyCycle--) {

analogWrite(pwmPin, dutyCycle);

delay(10);

}

}

Troubleshooting and FAQs

Common Issues Users Might Face

- LEDs Not Lighting Up: Ensure that the power supply is connected correctly and that the EN pin is set high.

- Flickering LEDs: Check the PWM signal for proper frequency and ensure it is not exceeding the input voltage.

- Overheating: Make sure that the LEDs are properly heat-sinked and that the current settings do not exceed the LEDs' ratings.

Solutions and Tips for Troubleshooting

- Double-check all connections for any loose wires or solder joints.

- Verify that the input voltage is stable and within the specified range.

- Use a multimeter to check the current through each LED channel.

- If using PWM control, ensure that the signal is clean and within the correct voltage range.

FAQs

Q: Can I drive LEDs that require more than 350mA? A: No, the PicoBuck is designed to drive LEDs up to 350mA per channel. Exceeding this limit may damage the board or the LEDs.

Q: Is it possible to chain multiple PicoBuck boards together? A: Yes, you can chain multiple boards for additional channels, but ensure that each board has its own power connection and that the PWM signals are synchronized.

Q: How do I adjust the current limit for each channel? A: The current limit is set by onboard resistors. To adjust the current, you would need to change these resistors to the appropriate values based on the desired current limit.

Q: Can I use the PicoBuck without a PWM signal? A: Yes, if you do not require dimming, you can tie the PWM pin to VIN for constant full brightness.