How to Use DC Motor: Examples, Pinouts, and Specs

Design with DC Motor in Cirkit Designer

Design with DC Motor in Cirkit DesignerIntroduction

A Direct Current (DC) Motor is an electrical device that converts direct electrical energy into mechanical energy. It operates on the principle that a current-carrying conductor, placed within a magnetic field, experiences a force, which is harnessed to produce rotational motion. DC motors are widely used in various applications ranging from small tools and appliances to electric vehicles and industrial machinery due to their simplicity, reliability, and ease of control.

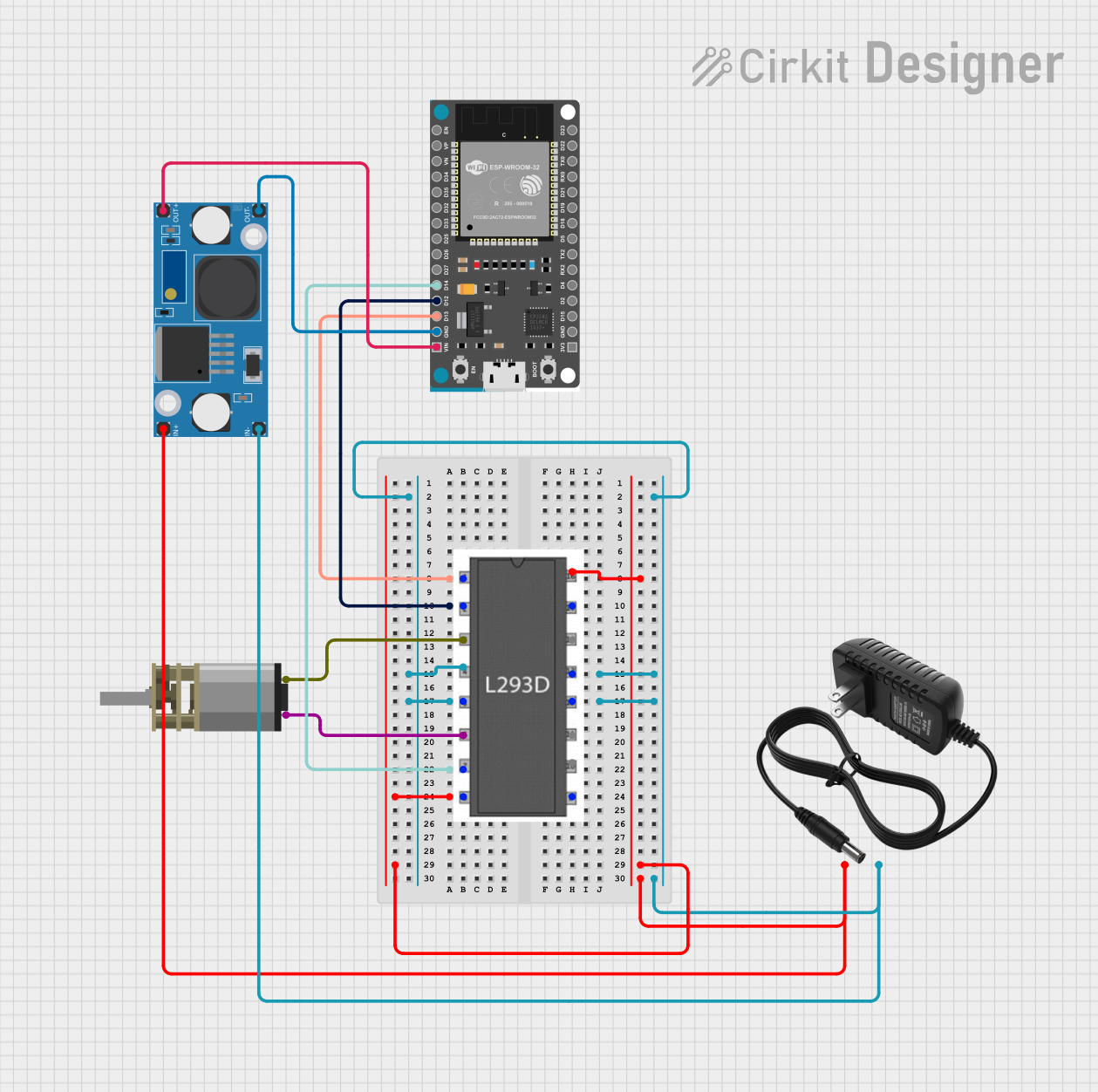

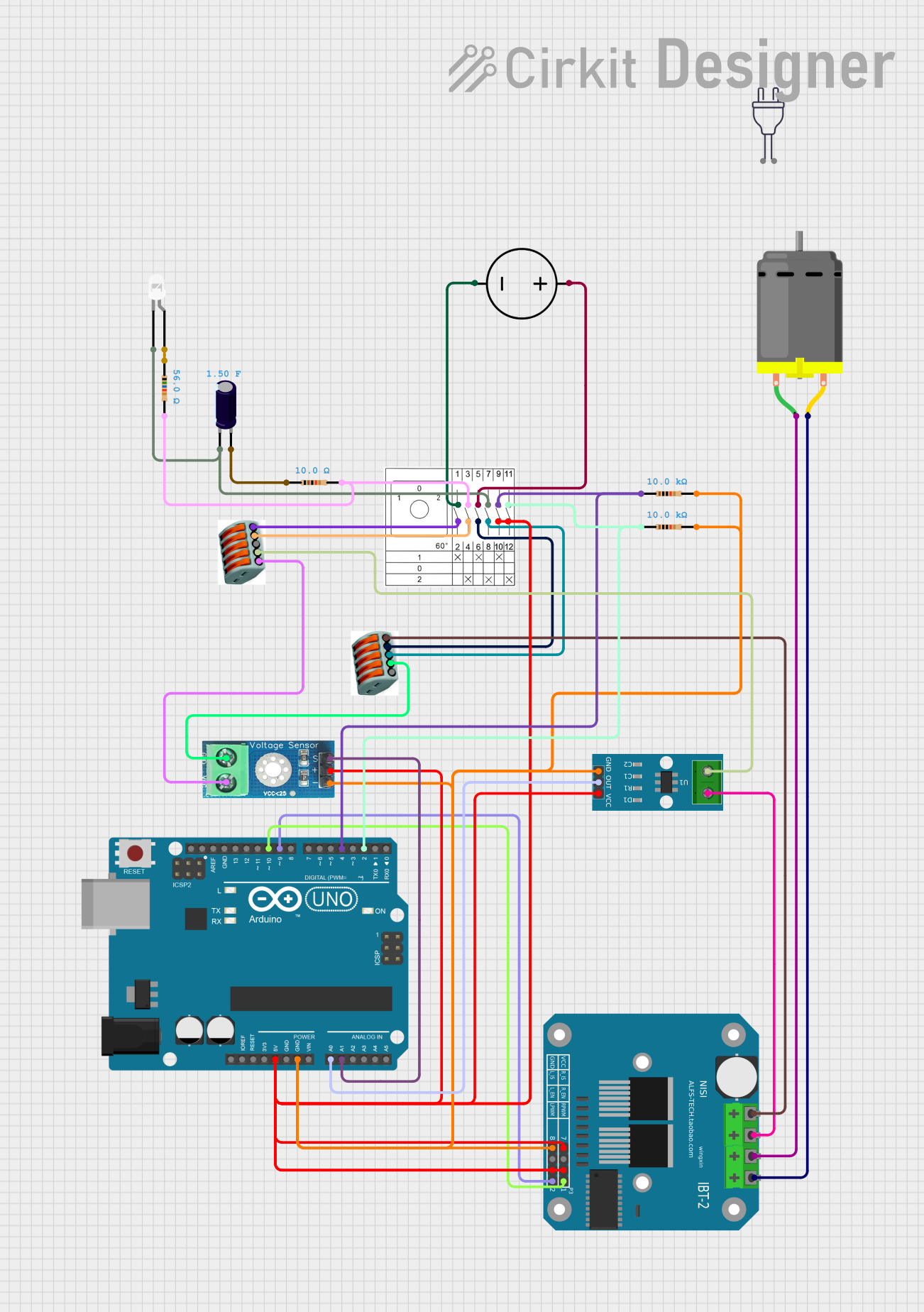

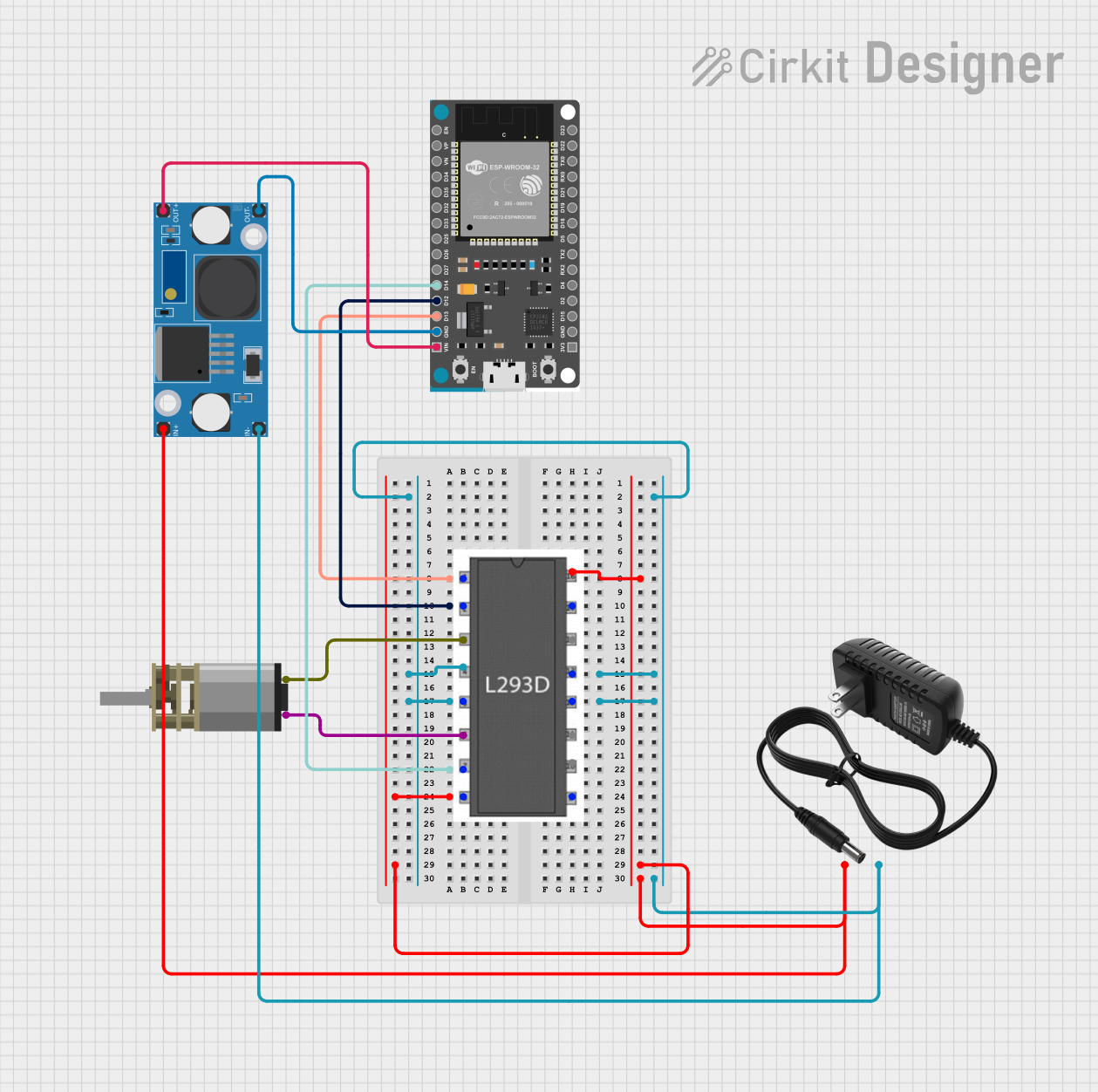

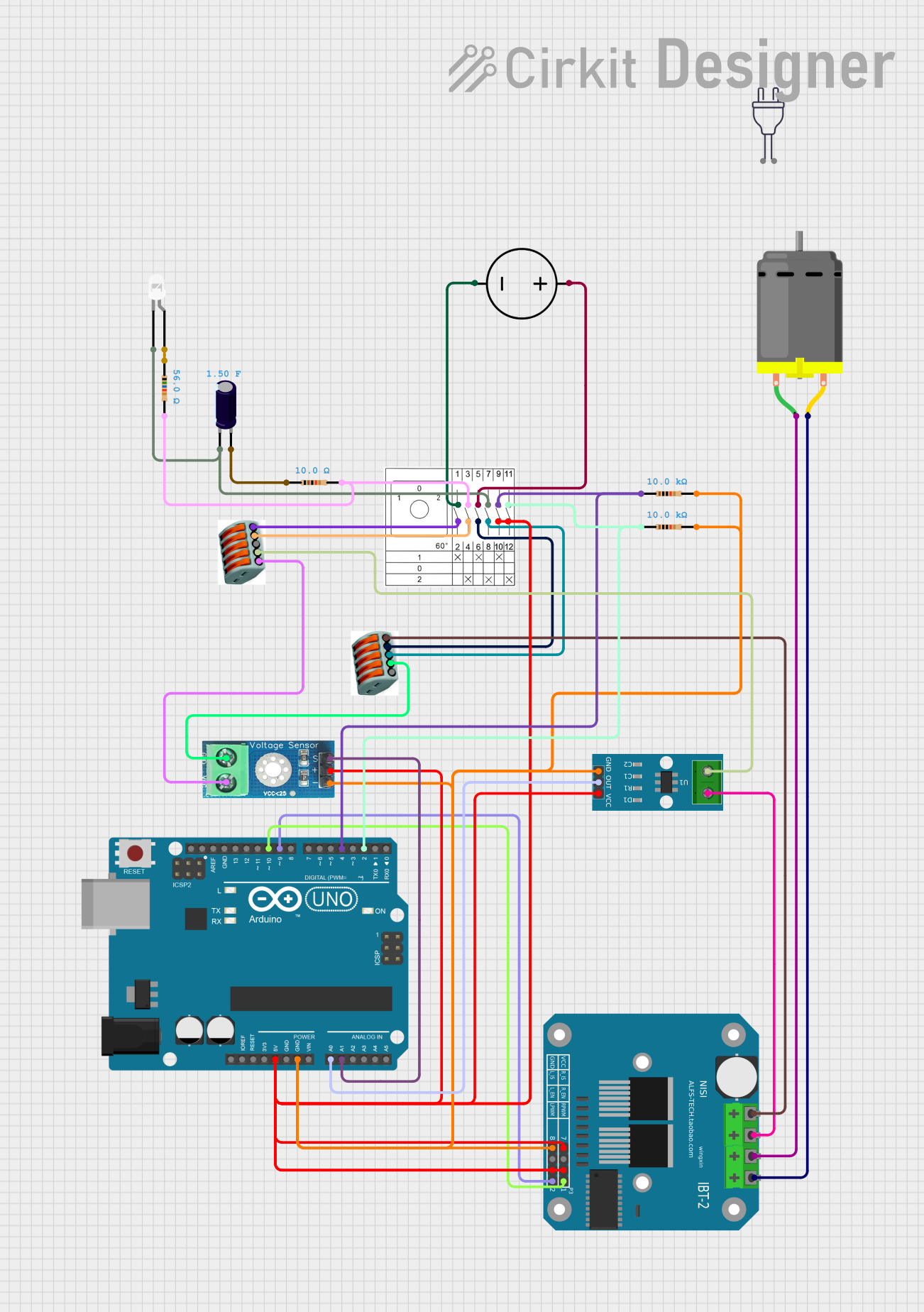

Explore Projects Built with DC Motor

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with DC Motor

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications and Use Cases

- Robotics

- Electric vehicles

- Industrial control systems

- Household appliances

- Toys and hobby projects

Technical Specifications

Key Technical Details

| Specification | Description |

|---|---|

| Voltage Rating | The nominal operating voltage (e.g., 6V, 12V, 24V) |

| Current Rating | Maximum continuous current the motor can handle |

| Power Rating | Output power typically measured in watts (W) |

| Speed | Rotational speed, given in revolutions per minute (RPM) |

| Torque | The rotational force, typically measured in Newton-meters (Nm) |

| Efficiency | Percentage of power input converted to mechanical output |

Pin Configuration and Descriptions

| Pin | Description |

|---|---|

| V+ | Positive voltage supply to the motor |

| V- | Ground or negative voltage supply to the motor |

Usage Instructions

How to Use the DC Motor in a Circuit

- Power Supply: Connect the positive terminal of the power supply to the V+ pin of the DC motor and the negative terminal to the V- pin.

- Motor Driver: To control the motor's direction and speed, use a motor driver circuit or an H-bridge.

- Speed Control: For speed control, a Pulse Width Modulation (PWM) signal can be applied to the motor driver.

- Protection: Always include a diode across the motor terminals to protect against voltage spikes when the motor is turned off.

Important Considerations and Best Practices

- Voltage Rating: Do not exceed the motor's voltage rating as it can cause damage.

- Current Rating: Ensure the power supply and motor driver can handle the motor's current requirements.

- Load: Avoid placing excessive loads on the motor shaft, which can lead to overheating and reduced lifespan.

- Mounting: Securely mount the motor to prevent vibrations and ensure stable operation.

Example Code for Arduino UNO

#include <Arduino.h>

// Define motor control pins

const int motorPin1 = 3; // H-bridge leg 1 (pin 2, 1A)

const int motorPin2 = 4; // H-bridge leg 2 (pin 7, 2A)

void setup() {

// Set motor control pins as outputs

pinMode(motorPin1, OUTPUT);

pinMode(motorPin2, OUTPUT);

}

void loop() {

// Spin motor in one direction

digitalWrite(motorPin1, HIGH);

digitalWrite(motorPin2, LOW);

delay(1000); // Run motor for 1 second

// Stop motor

digitalWrite(motorPin1, LOW);

digitalWrite(motorPin2, LOW);

delay(1000); // Wait for 1 second

// Spin motor in the opposite direction

digitalWrite(motorPin1, LOW);

digitalWrite(motorPin2, HIGH);

delay(1000); // Run motor for 1 second

// Stop motor

digitalWrite(motorPin1, LOW);

digitalWrite(motorPin2, LOW);

delay(1000); // Wait for 1 second

}

Troubleshooting and FAQs

Common Issues

- Motor not spinning: Check power supply connections and ensure the voltage and current ratings are adequate.

- Motor overheating: Reduce load or check for any obstructions that may be causing the motor to work harder than necessary.

- Erratic motor behavior: Ensure that the motor driver is functioning correctly and that the PWM signal is stable.

Solutions and Tips for Troubleshooting

- Check Connections: Loose connections can often cause issues. Ensure all connections are secure.

- Test Power Supply: Verify that the power supply is delivering the correct voltage and current.

- Diode Protection: Always use a flyback diode across the motor terminals to prevent back EMF damage.

- Motor Driver: Use a motor driver compatible with the motor's current and voltage requirements.

FAQs

Q: Can I control the speed of a DC motor directly with an Arduino? A: No, you should not connect a DC motor directly to an Arduino pin. Instead, use a motor driver or an H-bridge with PWM for speed control.

Q: Why is my motor running slowly or with less torque? A: This could be due to an underpowered supply or excessive load. Ensure the power supply can deliver sufficient current at the correct voltage.

Q: How can I reverse the direction of the motor? A: To reverse the direction, reverse the polarity of the voltage applied to the motor, which can be done using an H-bridge circuit.