How to Use STEPPER DRIVER: Examples, Pinouts, and Specs

Design with STEPPER DRIVER in Cirkit Designer

Design with STEPPER DRIVER in Cirkit DesignerIntroduction

A stepper driver is a crucial electronic device used to control stepper motors, which are motors that move in discrete steps. They are commonly used in precision positioning systems such as 3D printers, CNC machines, and robotics. Stepper drivers receive input signals from a controller, such as a microcontroller or a computer, and amplify these signals to drive the stepper motor with the required current to move to the desired position.

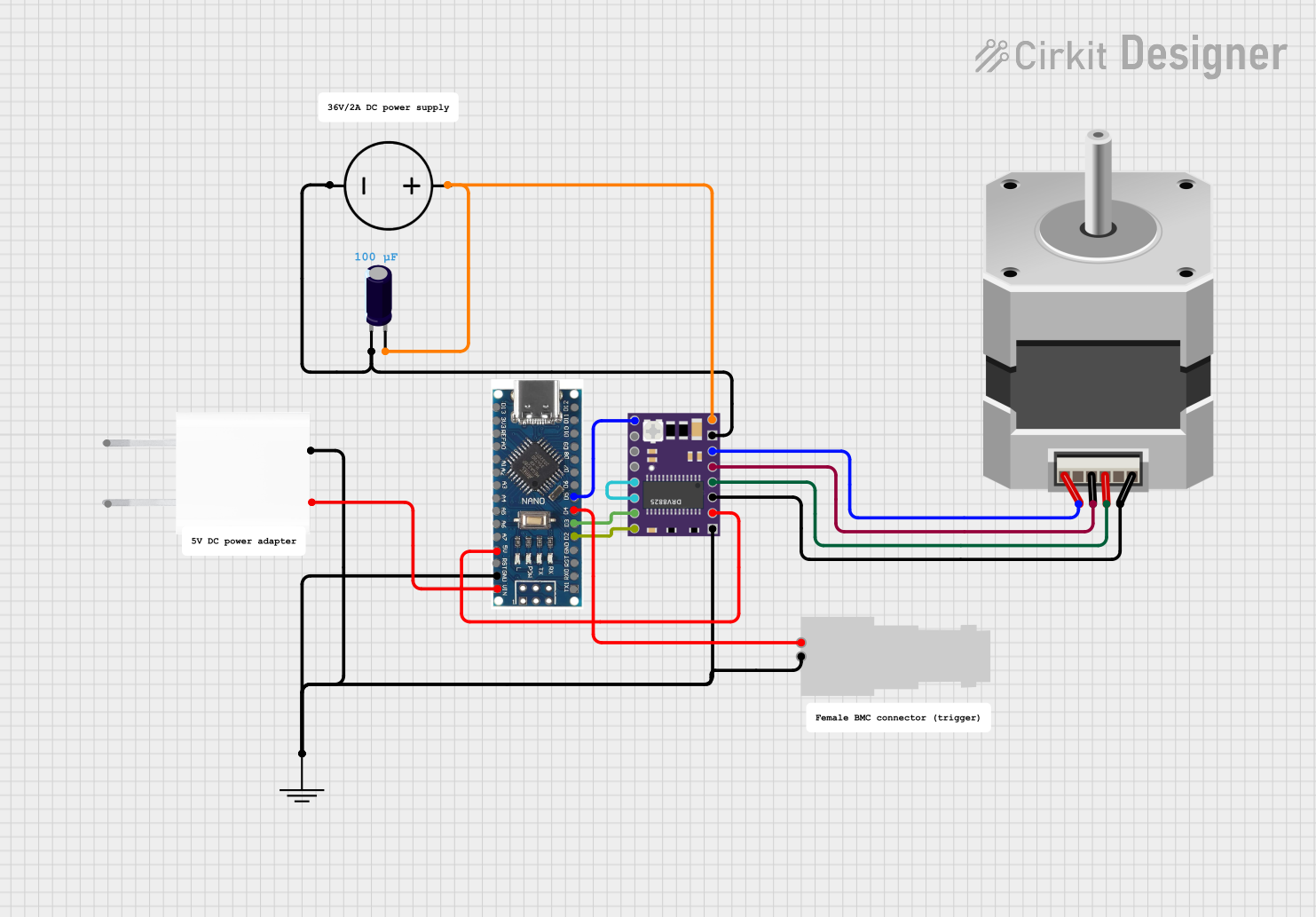

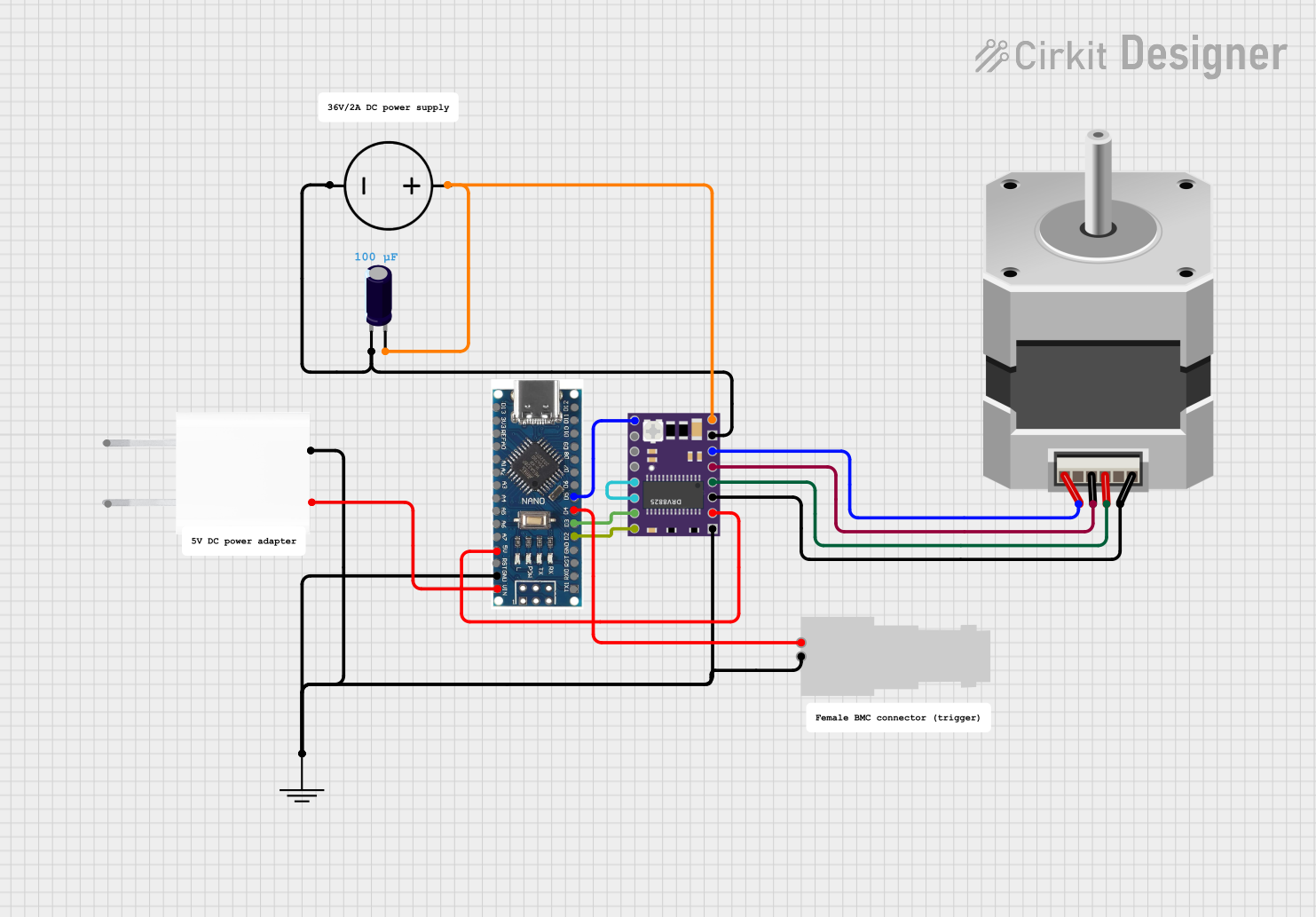

Explore Projects Built with STEPPER DRIVER

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with STEPPER DRIVER

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerTechnical Specifications

Key Technical Details

- Input Voltage Range: Typically from 8V to 45V (varies by model)

- Output Current: Up to several Amps per phase (model-specific)

- Microstepping: Full, 1/2, 1/4, 1/8, 1/16, etc. (model-specific)

- Logic Input Voltage: 3.3V to 5V (compatible with most microcontrollers)

Pin Configuration and Descriptions

| Pin Name | Description |

|---|---|

| VDD | Logic supply voltage (3.3V to 5V) |

| GND | Ground connection |

| VMOT | Motor supply voltage (8V to 45V) |

| 2B, 2A | Connections for one winding of the stepper motor |

| 1A, 1B | Connections for the other winding of the stepper motor |

| EN | Enable input (active low) |

| MS1, MS2, MS3 | Microstepping resolution selection inputs |

| STEP | Step input (triggers one step per pulse) |

| DIR | Direction input (high for one direction, low for the other) |

Usage Instructions

Connecting the Stepper Driver to a Circuit

- Connect the motor windings to the appropriate pins on the driver.

- Apply the logic supply voltage (VDD) and ground (GND) to the driver.

- Connect the motor supply voltage (VMOT) to the driver, ensuring it matches the motor's requirements.

- Set the desired microstepping resolution using the MS1, MS2, and MS3 pins.

- Connect the STEP and DIR pins to the output pins of your microcontroller.

Important Considerations and Best Practices

- Always ensure that the power supply voltage and current ratings match the requirements of both the stepper motor and the driver.

- Use decoupling capacitors close to the driver's power supply pins to minimize voltage spikes.

- Avoid disconnecting the motor while the driver is powered to prevent damage.

- Configure microstepping according to the precision and smoothness required for your application.

- Use heat sinks or cooling systems if the driver operates at high currents for extended periods.

Example Code for Arduino UNO

// Define the stepper motor connections and Arduino digital pins

#define DIR_PIN 2

#define STEP_PIN 3

#define ENABLE_PIN 4

void setup() {

// Set the pin modes for the stepper driver

pinMode(DIR_PIN, OUTPUT);

pinMode(STEP_PIN, OUTPUT);

pinMode(ENABLE_PIN, OUTPUT);

// Enable the stepper driver

digitalWrite(ENABLE_PIN, LOW);

}

void loop() {

// Set the direction of the stepper motor

digitalWrite(DIR_PIN, HIGH); // Set to LOW to change direction

// Move the stepper motor one step

digitalWrite(STEP_PIN, HIGH);

delayMicroseconds(1000); // Delay determines the speed

digitalWrite(STEP_PIN, LOW);

delayMicroseconds(1000);

}

Troubleshooting and FAQs

Common Issues

- Motor does not move: Check power supply, wiring, and ensure the enable pin is set correctly.

- Motor stutters or misses steps: Verify that the current limit is set properly, and the power supply is adequate.

- Motor overheats: Reduce current, check for proper microstepping settings, or improve cooling.

Solutions and Tips

- Ensure all connections are secure and free from shorts.

- Use a multimeter to verify the voltage at the motor and logic supply pins.

- If using microstepping, ensure that the MS pins are set to the correct logic levels.

FAQs

Q: Can I use a stepper driver with any stepper motor? A: While stepper drivers are generally compatible with a wide range of stepper motors, always check the motor's voltage and current requirements to ensure compatibility with the driver's specifications.

Q: How do I set the current limit on my stepper driver? A: The current limit is typically set via a potentiometer on the driver board or through digital configuration, depending on the model. Refer to the specific driver's datasheet for instructions.

Q: What is microstepping and why would I use it? A: Microstepping divides a full step into smaller steps, allowing for smoother and more precise motor movements. It is used when high-resolution positioning is required.