How to Use DFRobot GP8501: Examples, Pinouts, and Specs

Design with DFRobot GP8501 in Cirkit Designer

Design with DFRobot GP8501 in Cirkit DesignerIntroduction

The DFRobot GP8501 is a high-precision gas sensor designed to detect various gases, including carbon dioxide (CO2) and methane (CH4). Its compact design and high sensitivity make it ideal for applications such as air quality monitoring, environmental sensing, and industrial gas detection. The GP8501 is easy to integrate into a variety of systems, offering reliable performance in detecting gas concentrations.

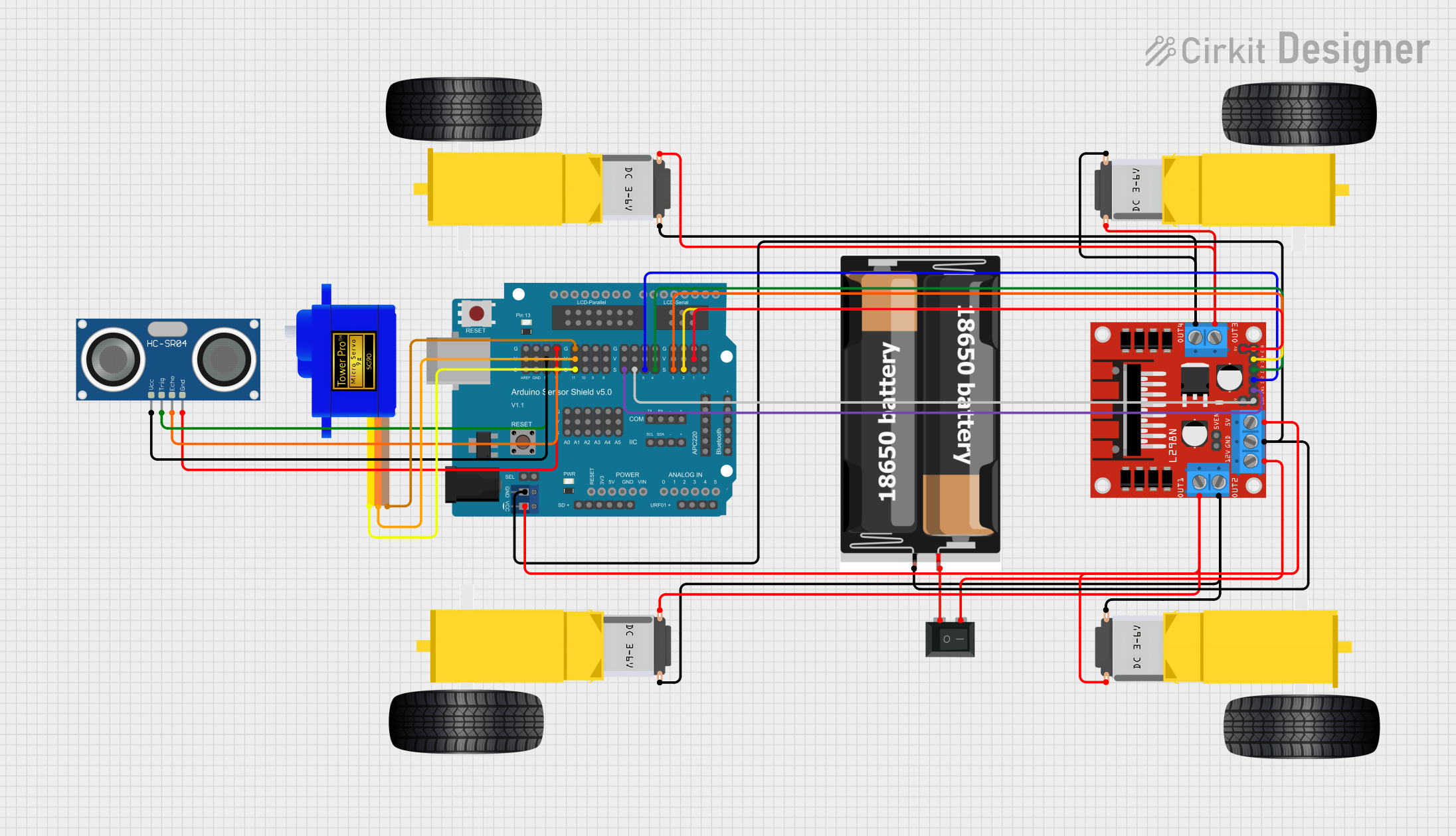

Explore Projects Built with DFRobot GP8501

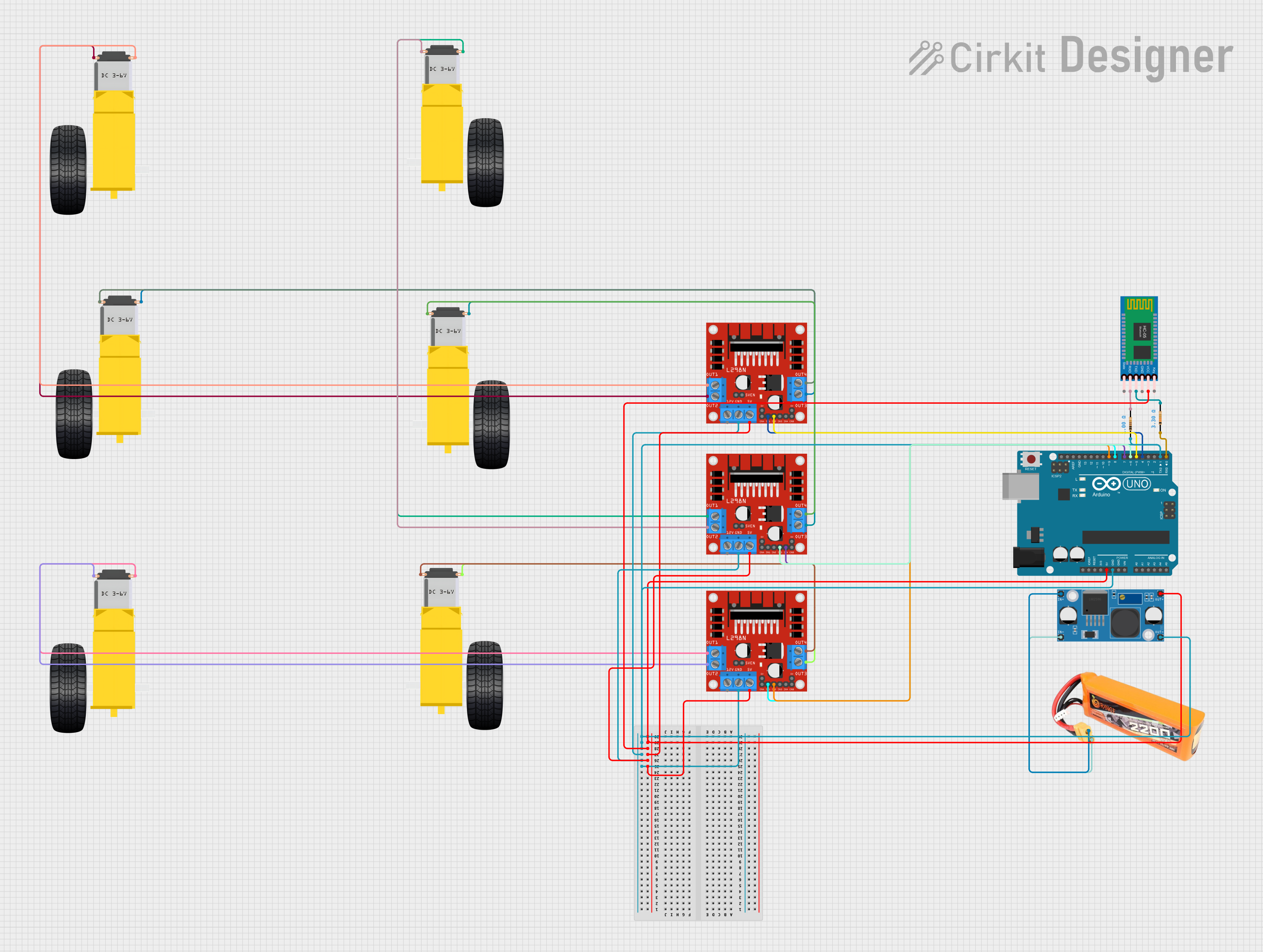

Open Project in Cirkit Designer

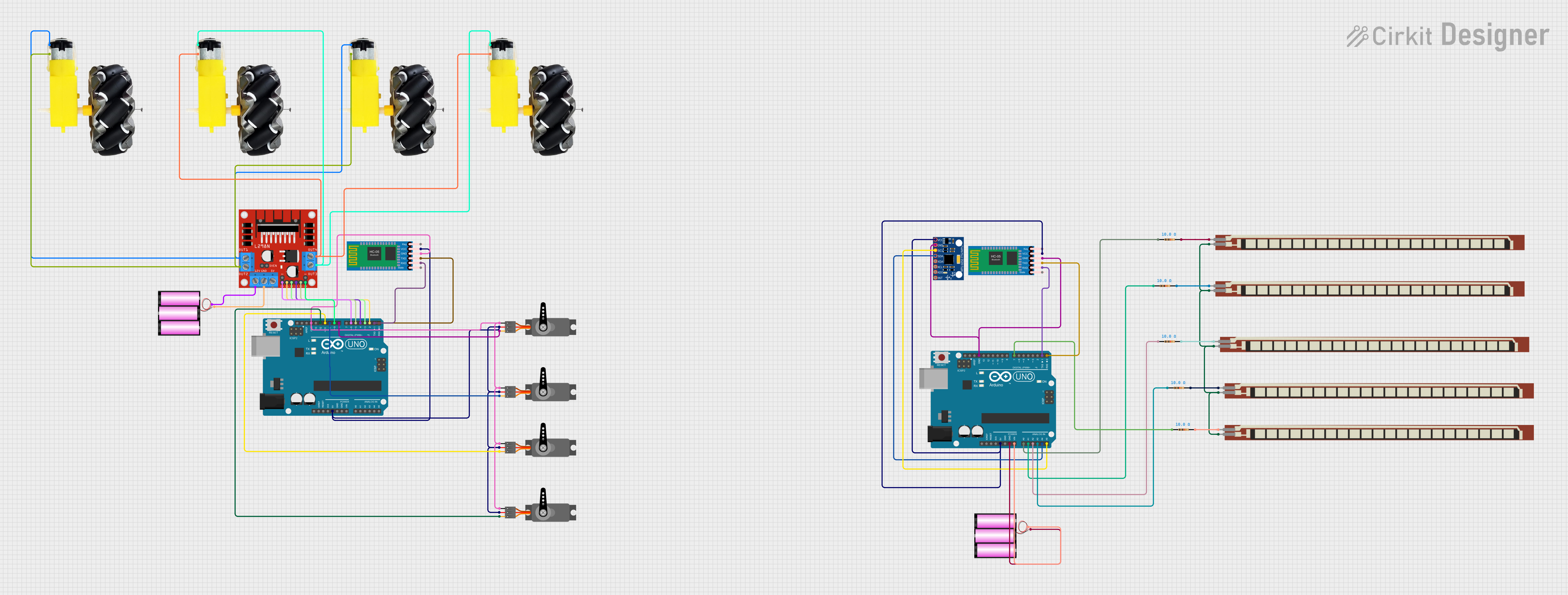

Open Project in Cirkit Designer

Open Project in Cirkit Designer

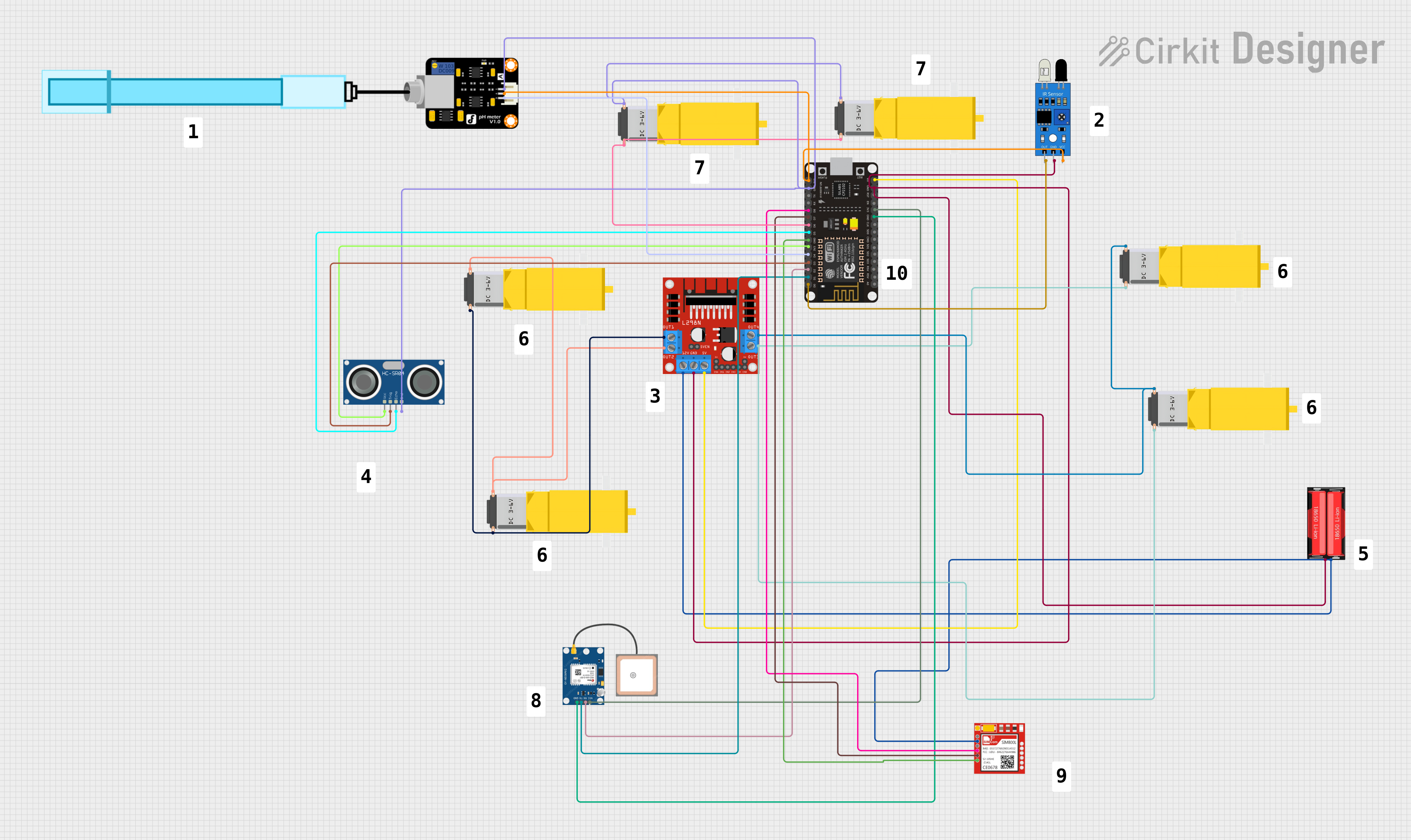

Open Project in Cirkit Designer

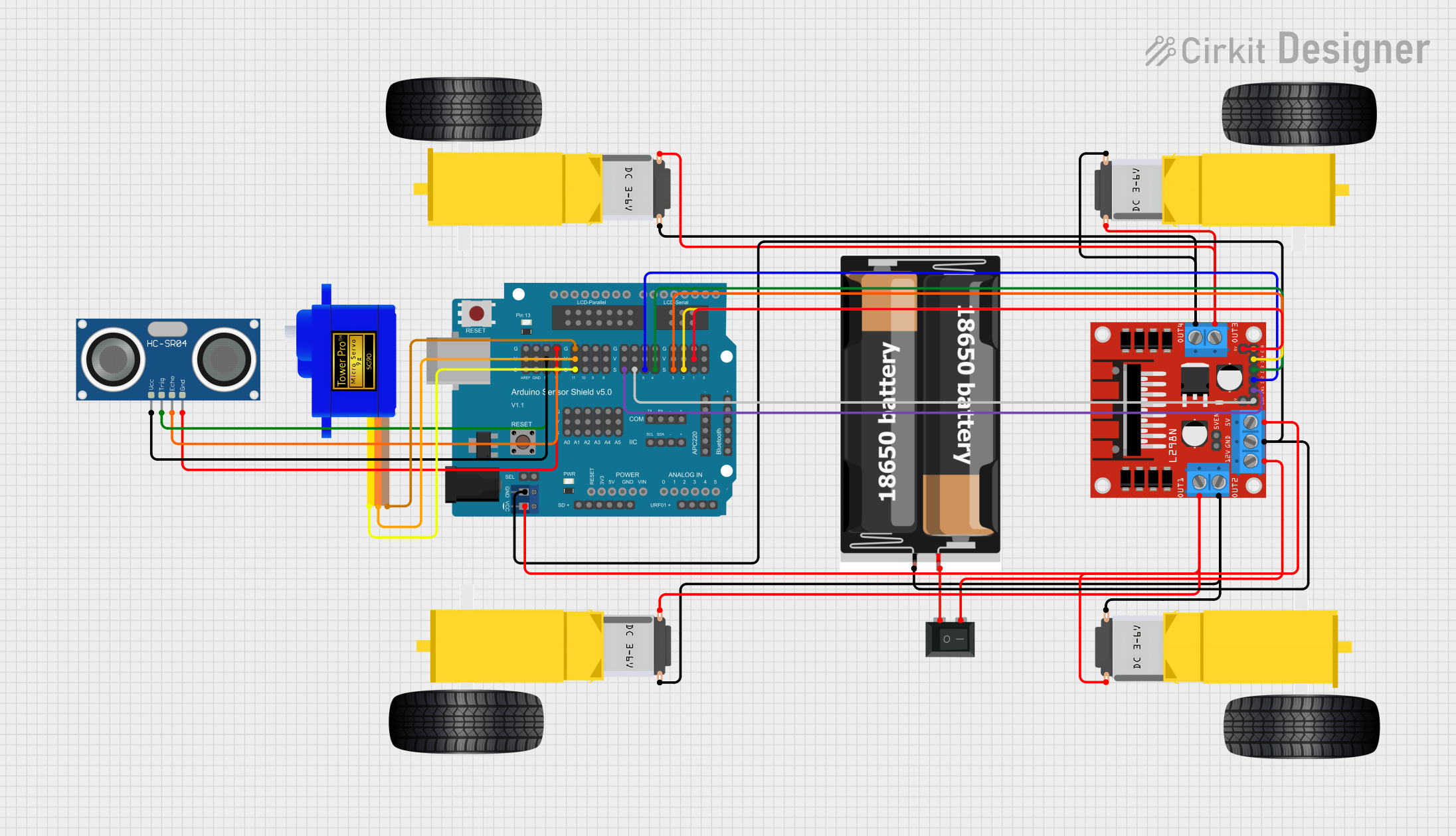

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with DFRobot GP8501

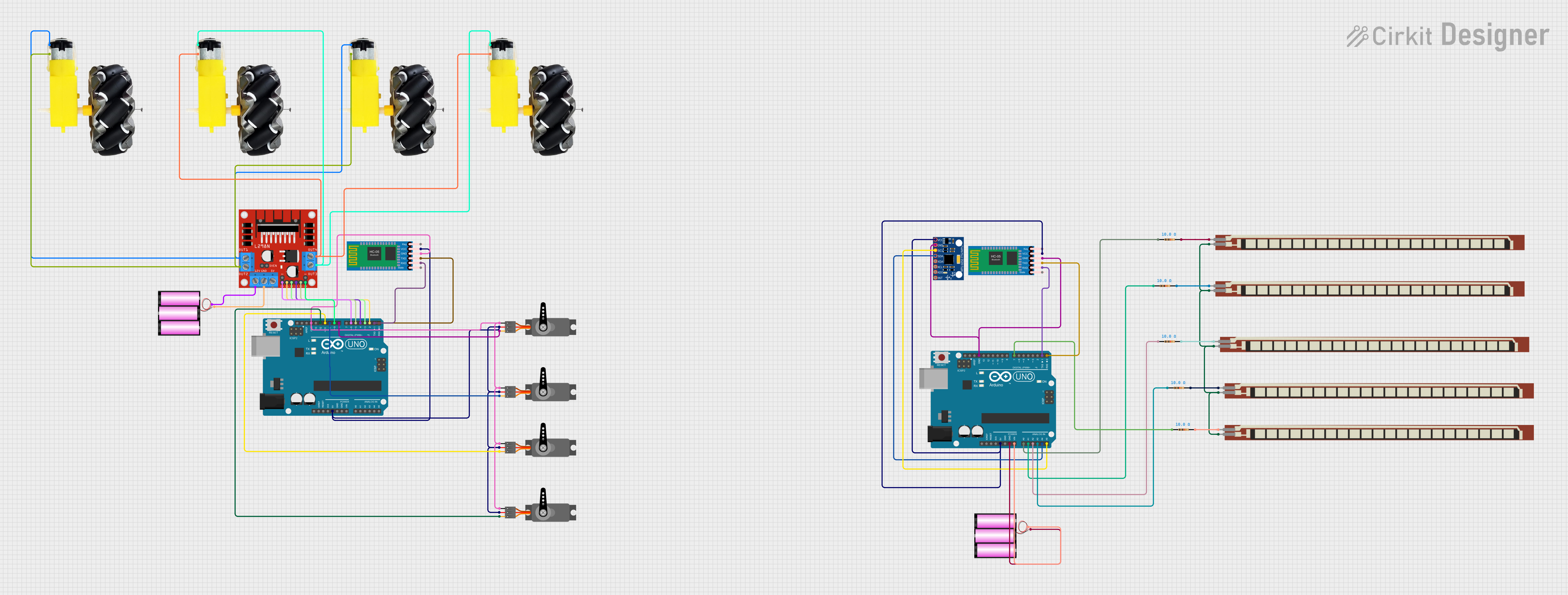

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

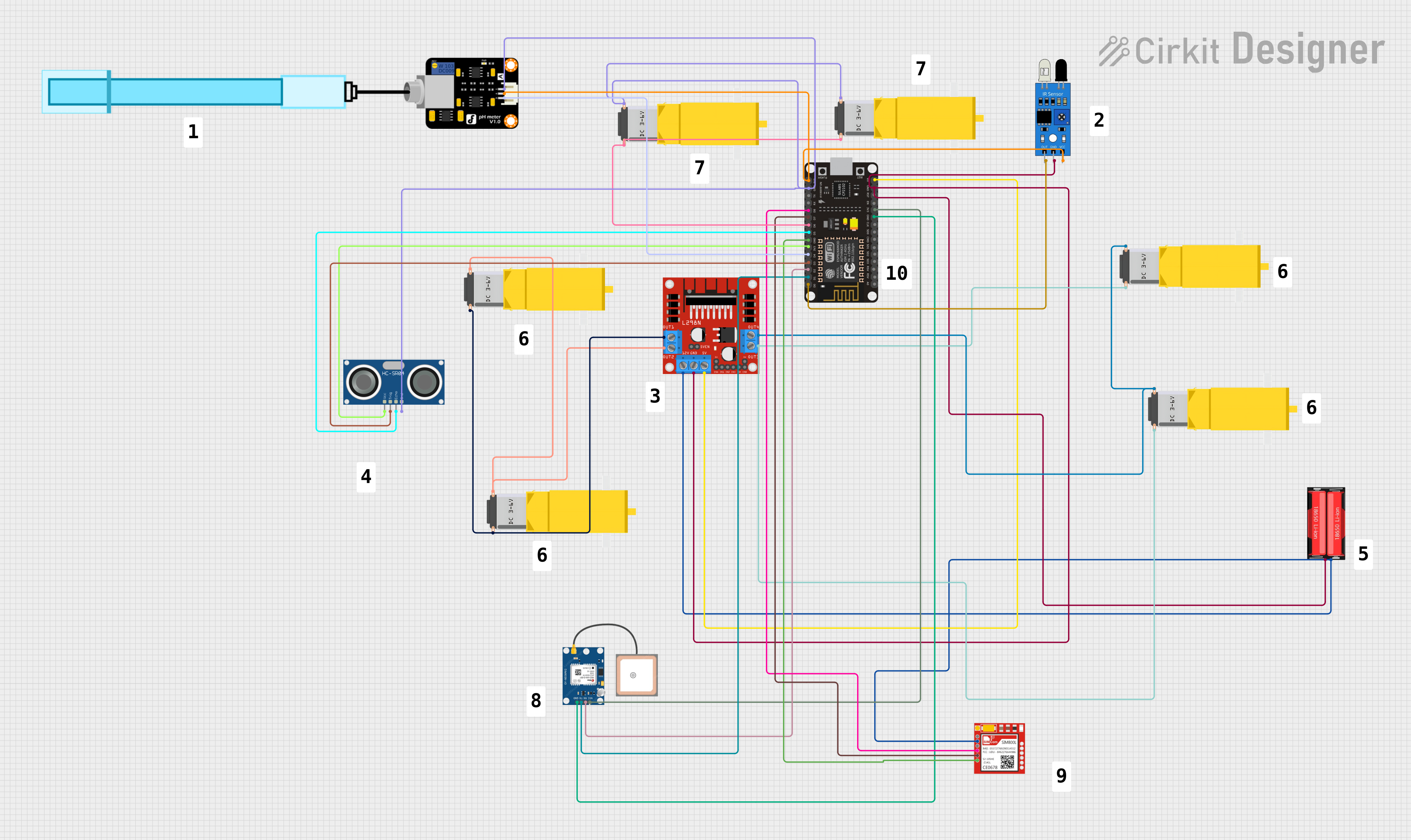

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications and Use Cases

- Air quality monitoring in homes, offices, and public spaces

- Environmental sensing for research and development

- Industrial gas detection and safety systems

- Smart home and IoT applications

- Agricultural monitoring (e.g., greenhouse gas levels)

Technical Specifications

The GP8501 is designed to provide accurate gas concentration readings with minimal power consumption. Below are the key technical details:

Key Technical Details

| Parameter | Value |

|---|---|

| Manufacturer | DFRobot |

| Part ID | GP8501 |

| Gas Detection Targets | CO2, CH4 |

| Operating Voltage | 3.3V to 5V |

| Operating Current | ≤ 20mA |

| Output Signal | Analog Voltage (0-3.3V) |

| Measurement Range | 0 to 10,000 ppm (CO2) |

| Response Time | ≤ 30 seconds |

| Operating Temperature | -10°C to 50°C |

| Humidity Range | 0% to 95% RH (non-condensing) |

| Dimensions | 32mm x 20mm x 10mm |

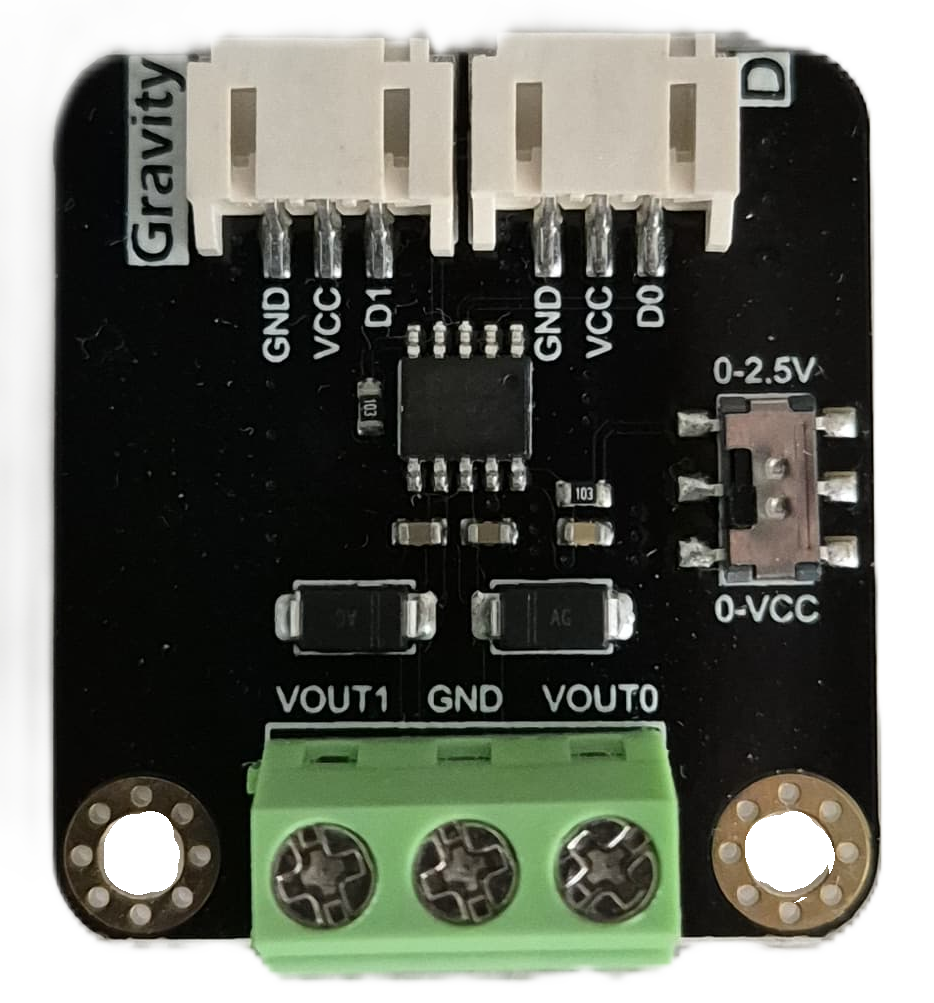

Pin Configuration and Descriptions

The GP8501 sensor has a simple pinout for easy integration into circuits. Below is the pin configuration:

| Pin Number | Pin Name | Description |

|---|---|---|

| 1 | VCC | Power supply input (3.3V to 5V) |

| 2 | GND | Ground connection |

| 3 | AOUT | Analog output signal proportional to gas levels |

Usage Instructions

The GP8501 is straightforward to use in a circuit. Follow the steps below to integrate and operate the sensor:

How to Use the GP8501 in a Circuit

- Power the Sensor: Connect the

VCCpin to a 3.3V or 5V power source and theGNDpin to the ground of your circuit. - Read the Analog Output: Connect the

AOUTpin to an analog input pin of your microcontroller or ADC (Analog-to-Digital Converter). The voltage on this pin corresponds to the gas concentration. - Calibrate the Sensor: Allow the sensor to warm up for at least 2 minutes after powering it on to ensure accurate readings.

- Interpret the Output: Use the analog voltage output to calculate the gas concentration. Refer to the sensor's datasheet for the specific voltage-to-ppm conversion formula.

Important Considerations and Best Practices

- Power Supply: Ensure a stable power supply to avoid fluctuations in the sensor's output.

- Ventilation: Place the sensor in a well-ventilated area for accurate gas detection.

- Avoid Condensation: Operate the sensor in environments with non-condensing humidity levels.

- Warm-Up Time: Always allow the sensor to warm up for at least 2 minutes before taking measurements.

- Analog Signal Filtering: Use a capacitor or software filtering to smooth out noise in the analog output signal.

Example: Connecting the GP8501 to an Arduino UNO

Below is an example of how to connect and read data from the GP8501 using an Arduino UNO:

Circuit Connections

- Connect the

VCCpin of the GP8501 to the 5V pin of the Arduino. - Connect the

GNDpin of the GP8501 to the GND pin of the Arduino. - Connect the

AOUTpin of the GP8501 to the A0 analog input pin of the Arduino.

Arduino Code

// DFRobot GP8501 Gas Sensor Example Code

// This code reads the analog output from the GP8501 and prints the gas level

// to the Serial Monitor. Ensure the sensor is connected to the A0 pin.

const int sensorPin = A0; // Analog pin connected to GP8501 AOUT

float sensorVoltage = 0; // Variable to store the sensor voltage

float gasConcentration = 0; // Variable to store gas concentration (ppm)

void setup() {

Serial.begin(9600); // Initialize serial communication at 9600 baud

pinMode(sensorPin, INPUT); // Set the sensor pin as input

}

void loop() {

// Read the analog value from the sensor

int analogValue = analogRead(sensorPin);

// Convert the analog value to voltage (assuming 5V reference)

sensorVoltage = analogValue * (5.0 / 1023.0);

// Convert the voltage to gas concentration (ppm)

// Note: Replace the formula below with the actual conversion formula

// from the GP8501 datasheet for accurate results.

gasConcentration = sensorVoltage * 1000; // Example conversion

// Print the results to the Serial Monitor

Serial.print("Sensor Voltage: ");

Serial.print(sensorVoltage);

Serial.print(" V, Gas Concentration: ");

Serial.print(gasConcentration);

Serial.println(" ppm");

delay(1000); // Wait for 1 second before the next reading

}

Troubleshooting and FAQs

Common Issues and Solutions

No Output Signal

- Cause: Incorrect wiring or power supply.

- Solution: Double-check the connections and ensure the sensor is powered with 3.3V to 5V.

Fluctuating Readings

- Cause: Electrical noise or unstable power supply.

- Solution: Add a decoupling capacitor (e.g., 0.1µF) between

VCCandGNDto stabilize the power supply.

Slow Response Time

- Cause: Insufficient warm-up time.

- Solution: Allow the sensor to warm up for at least 2 minutes before taking measurements.

Inaccurate Readings

- Cause: Calibration issues or environmental factors (e.g., high humidity).

- Solution: Ensure proper calibration and operate the sensor within the specified temperature and humidity range.

FAQs

Q: Can the GP8501 detect gases other than CO2 and CH4?

A: The GP8501 is optimized for CO2 and CH4 detection. While it may respond to other gases, the accuracy and sensitivity are not guaranteed.

Q: How do I convert the analog output to gas concentration?

A: Refer to the sensor's datasheet for the specific voltage-to-ppm conversion formula. The example code above provides a basic framework.

Q: Can I use the GP8501 with a 3.3V microcontroller?

A: Yes, the GP8501 operates with a supply voltage of 3.3V to 5V, making it compatible with 3.3V microcontrollers.

Q: Is the sensor suitable for outdoor use?

A: The GP8501 can be used outdoors, but it should be protected from direct exposure to water and extreme environmental conditions.

Q: How often should I calibrate the sensor?

A: Calibration frequency depends on the application. For critical applications, periodic calibration is recommended to maintain accuracy.