How to Use MRB Planetary gearbox motor: Examples, Pinouts, and Specs

Design with MRB Planetary gearbox motor in Cirkit Designer

Design with MRB Planetary gearbox motor in Cirkit DesignerIntroduction

The MRB Planetary Gearbox Motor is a motor integrated with a planetary gearbox, designed to deliver high torque and precise speed control. This component is widely used in applications requiring compact design, high efficiency, and reliable performance. Its robust construction and ability to handle high torque loads make it ideal for robotics, automation systems, conveyor belts, and industrial machinery.

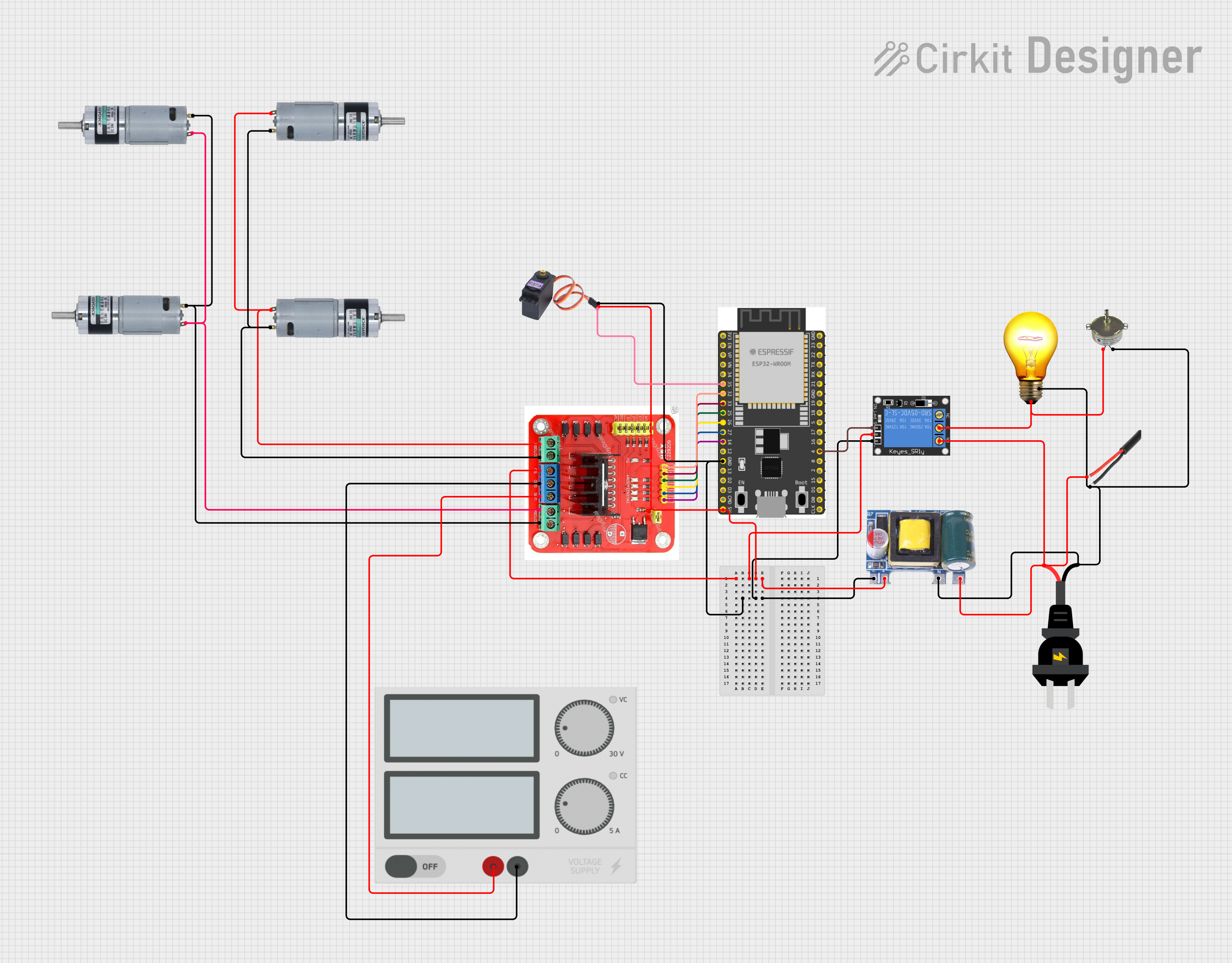

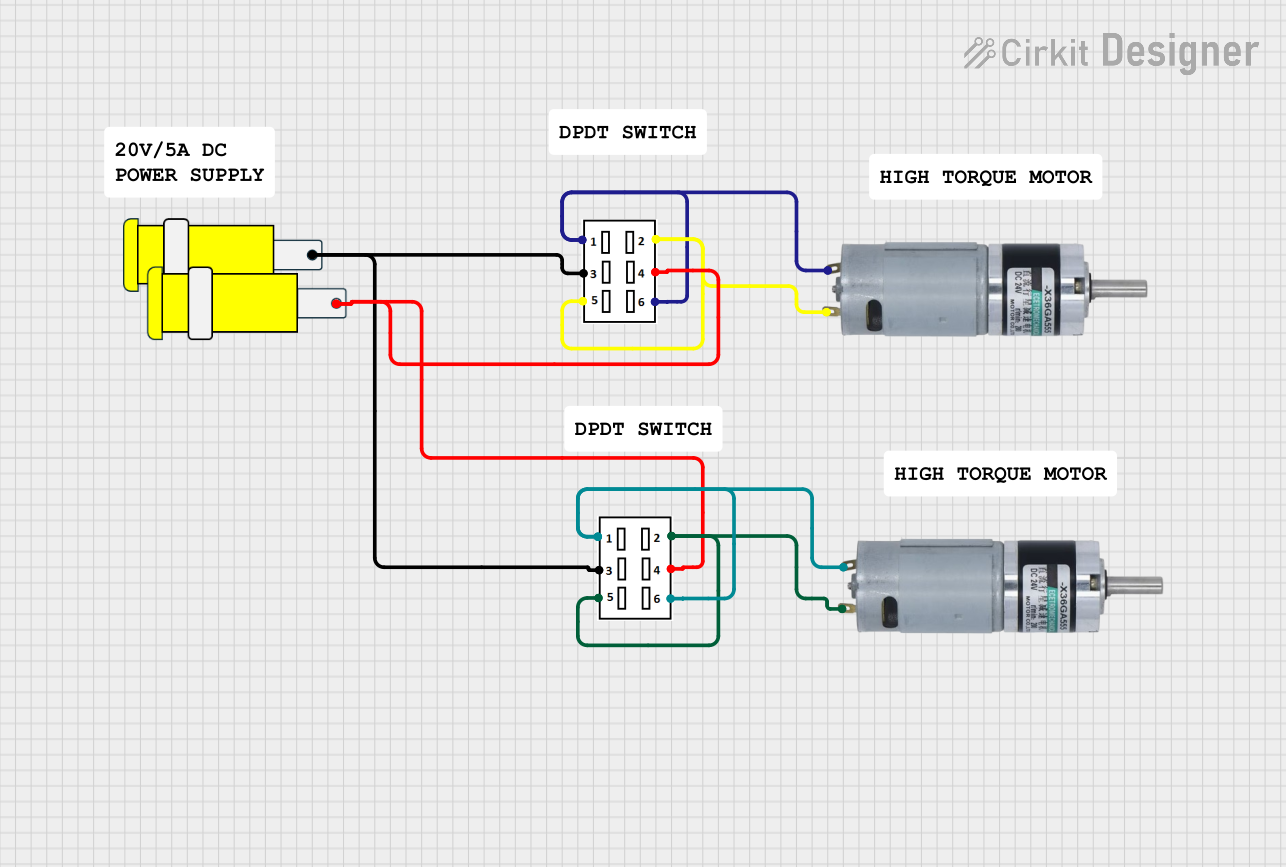

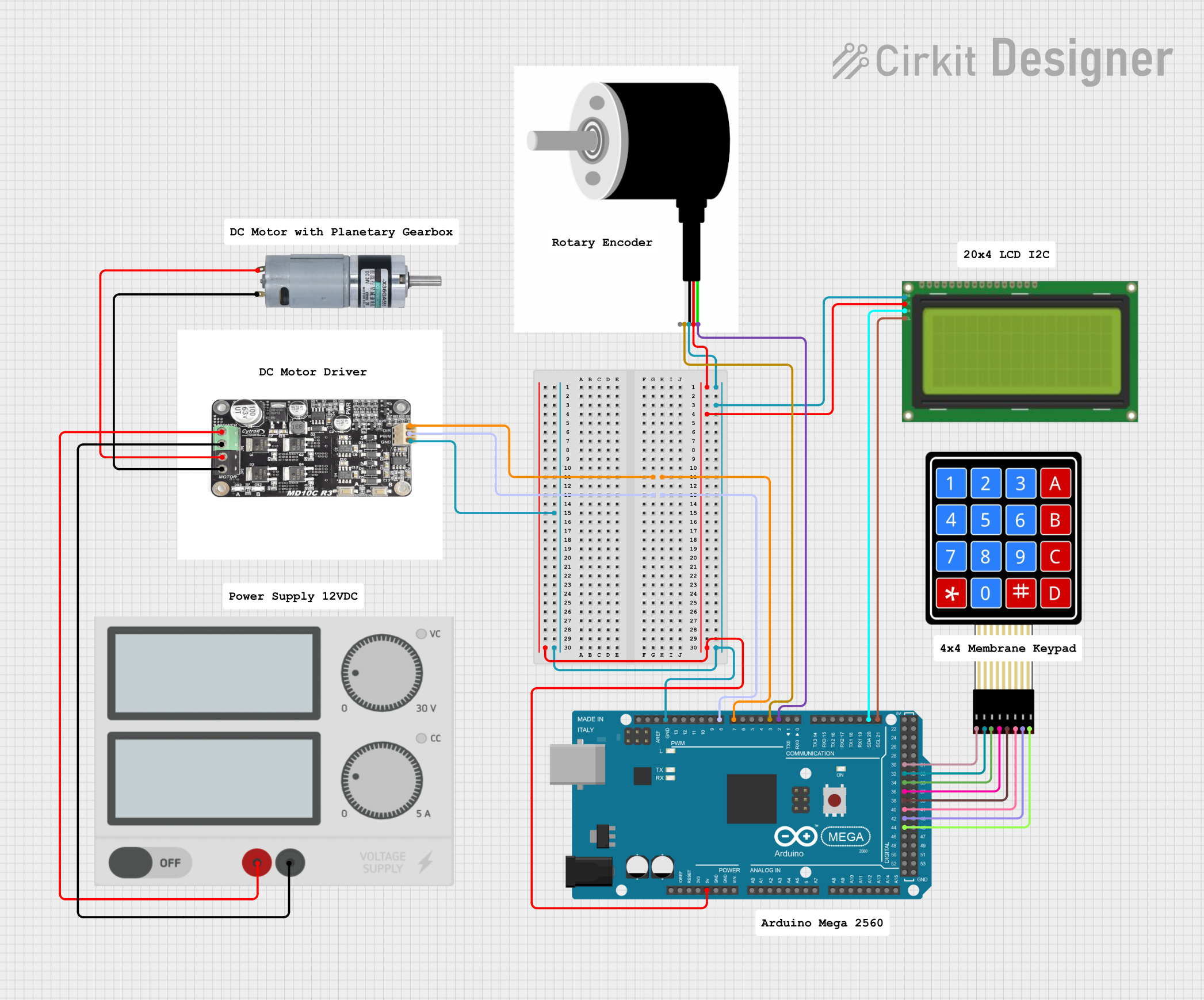

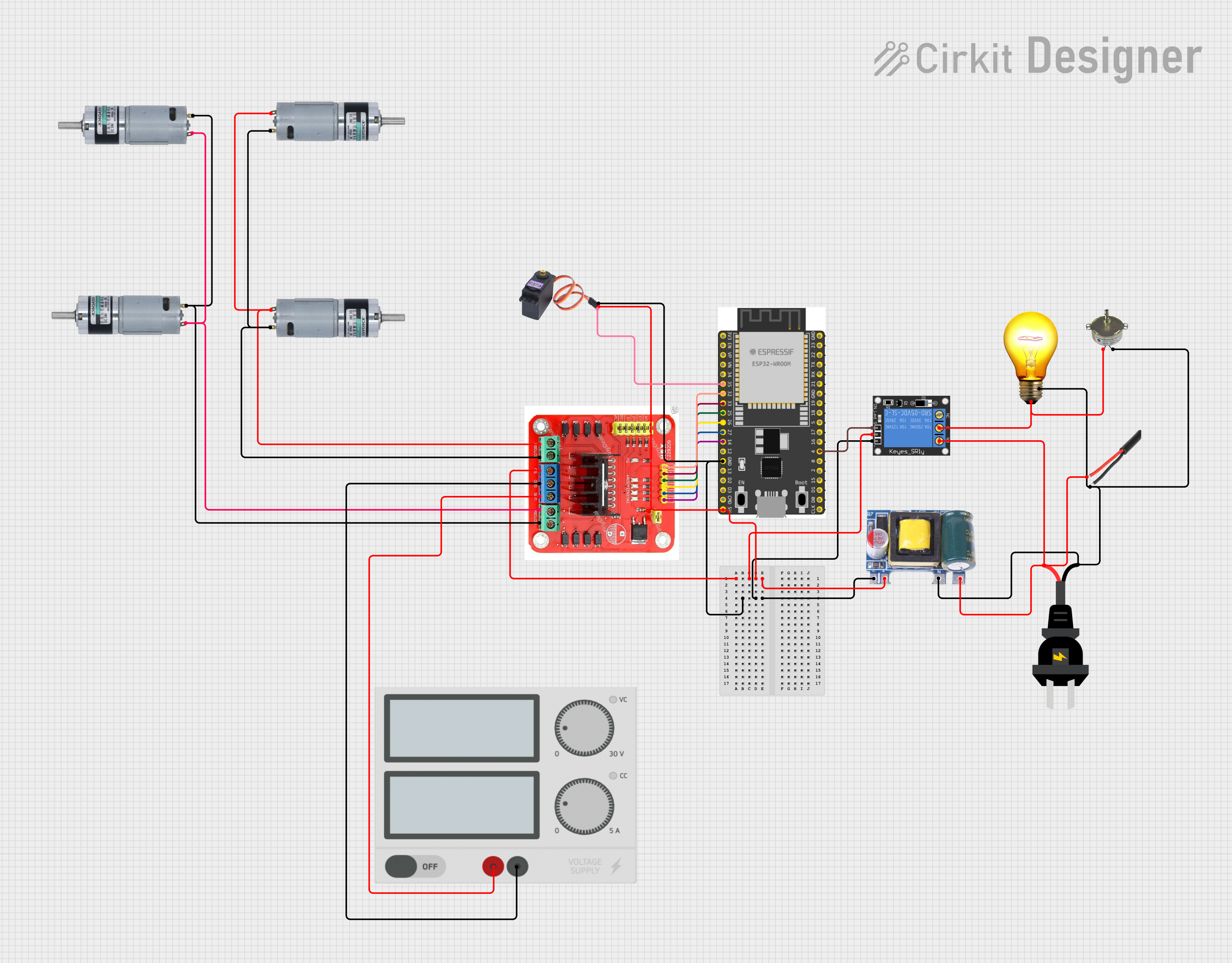

Explore Projects Built with MRB Planetary gearbox motor

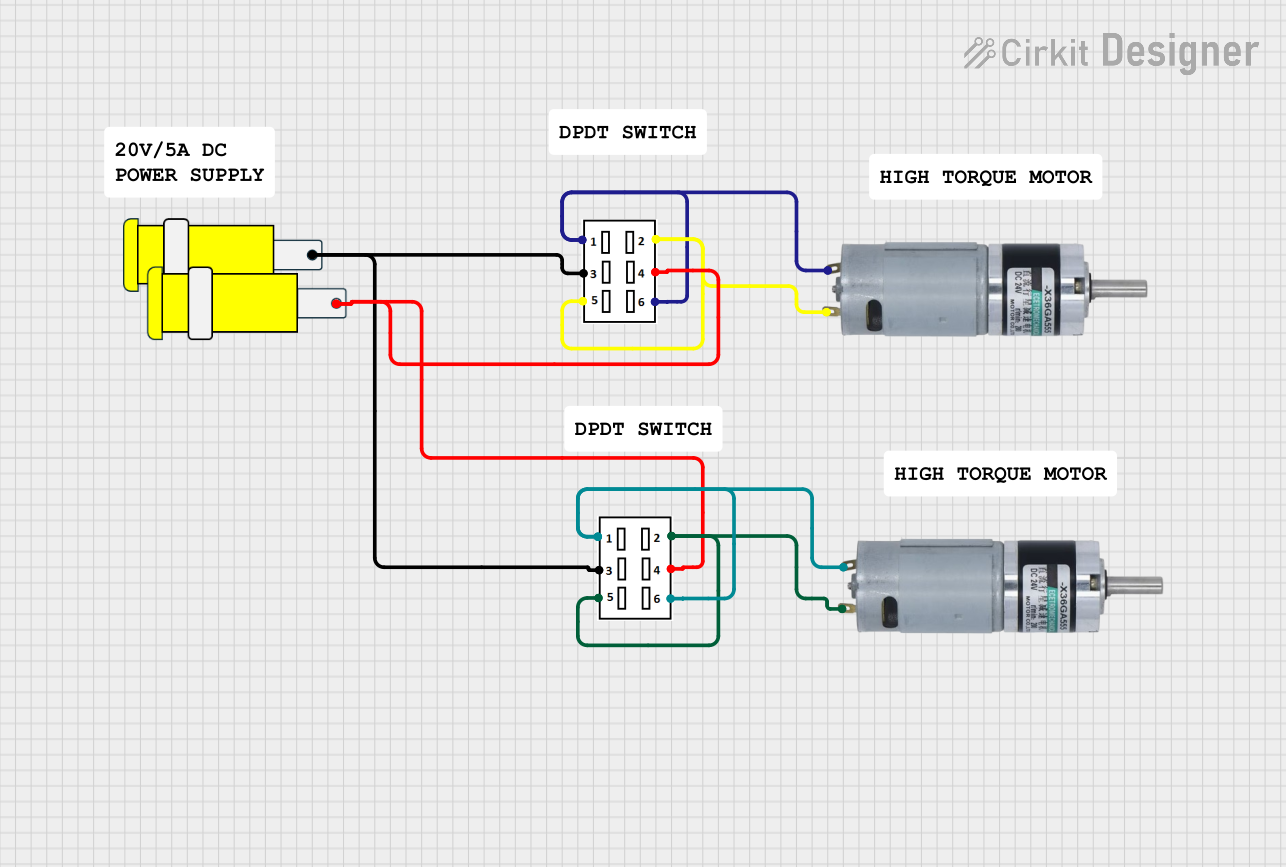

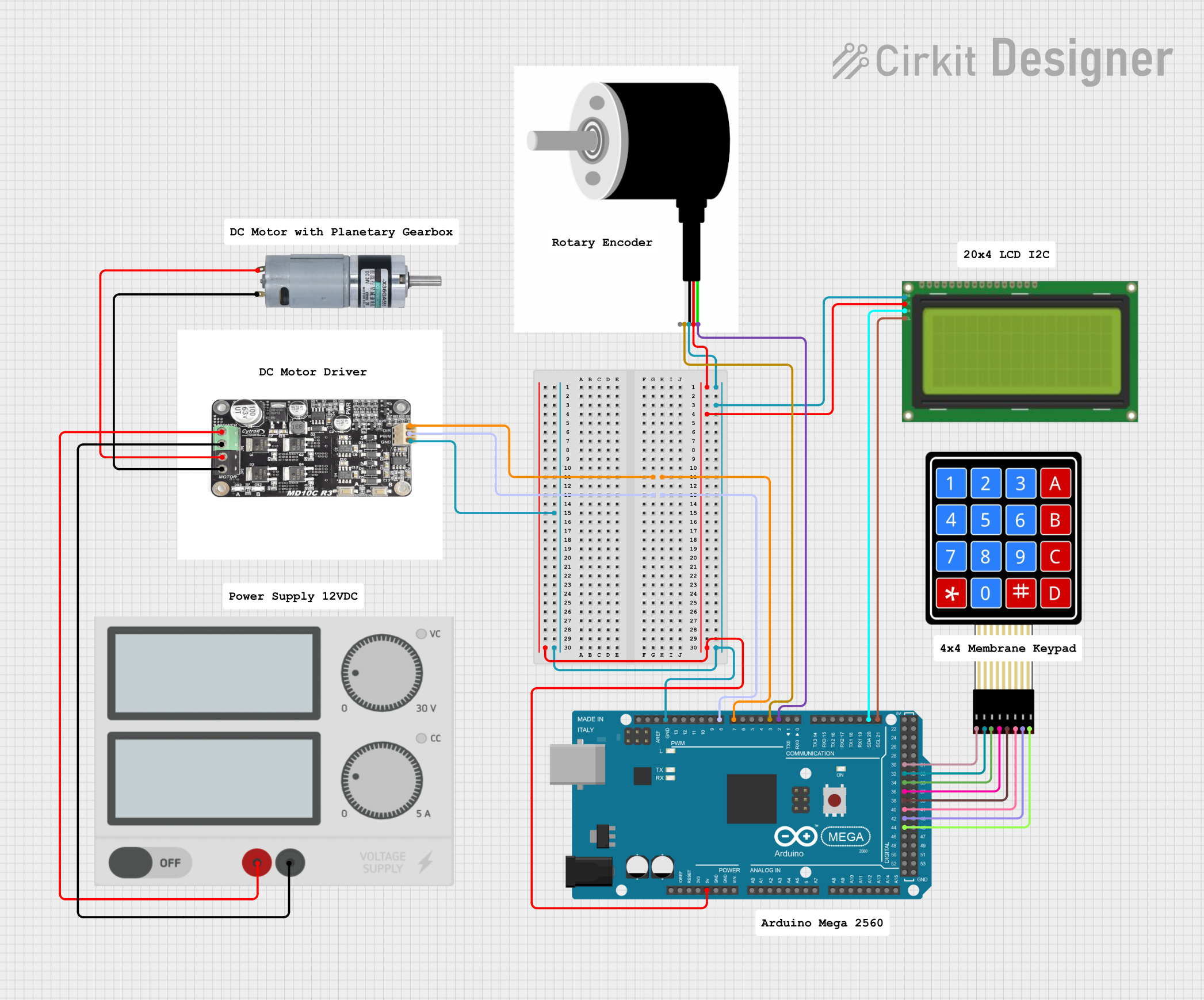

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with MRB Planetary gearbox motor

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications:

- Robotics (e.g., robotic arms, mobile robots)

- Automation systems

- CNC machines

- Conveyor systems

- Electric vehicles

- Precision positioning systems

Technical Specifications

Key Technical Details:

| Parameter | Value |

|---|---|

| Motor Type | DC Motor with Planetary Gearbox |

| Gearbox Type | Planetary |

| Input Voltage Range | 6V - 24V |

| Rated Torque | Up to 50 Nm (varies by model) |

| Gear Ratio Options | 4:1, 16:1, 64:1, etc. |

| No-Load Speed | 10 - 500 RPM (depending on model) |

| Efficiency | ≥ 85% |

| Shaft Diameter | 6 mm |

| Operating Temperature | -10°C to 60°C |

| Weight | ~500g (varies by model) |

Pin Configuration and Descriptions:

The MRB Planetary Gearbox Motor typically has two terminals for electrical connections. These are:

| Pin Name | Description |

|---|---|

| V+ | Positive terminal for power input |

| V- | Negative terminal for power input (ground) |

For models with an encoder, additional pins may be present:

| Pin Name | Description |

|---|---|

| A | Encoder output channel A |

| B | Encoder output channel B |

| Vcc | Power supply for the encoder (e.g., 5V) |

| GND | Ground for the encoder |

Usage Instructions

How to Use the MRB Planetary Gearbox Motor in a Circuit:

- Power Supply: Connect the motor's V+ and V- terminals to a DC power supply or motor driver. Ensure the voltage matches the motor's input voltage range (6V - 24V).

- Motor Driver: Use a motor driver (e.g., L298N or TB6612FNG) to control the motor's speed and direction. The driver should be capable of handling the motor's current requirements.

- Encoder (if available): If the motor includes an encoder, connect the encoder pins (A, B, Vcc, GND) to a microcontroller (e.g., Arduino) for speed and position feedback.

- Mounting: Secure the motor using appropriate brackets or mounts to prevent vibration and ensure alignment with the load.

Important Considerations and Best Practices:

- Gear Ratio Selection: Choose a gear ratio that balances speed and torque for your application.

- Current Rating: Ensure the power supply and motor driver can handle the motor's peak current.

- Heat Dissipation: Avoid prolonged operation at maximum torque to prevent overheating.

- Load Alignment: Misalignment of the motor shaft and load can cause excessive wear and reduce efficiency.

- Encoder Wiring: Use shielded cables for encoder connections to minimize noise interference.

Example: Connecting to an Arduino UNO

Below is an example of how to control the MRB Planetary Gearbox Motor with an Arduino UNO using a motor driver (e.g., L298N):

// Example code to control MRB Planetary Gearbox Motor with Arduino UNO

// Motor driver connections:

// IN1 -> Pin 9, IN2 -> Pin 10, ENA -> Pin 3 (PWM)

#define IN1 9 // Motor driver input 1

#define IN2 10 // Motor driver input 2

#define ENA 3 // Motor driver enable pin (PWM)

void setup() {

pinMode(IN1, OUTPUT); // Set IN1 as output

pinMode(IN2, OUTPUT); // Set IN2 as output

pinMode(ENA, OUTPUT); // Set ENA as output

}

void loop() {

// Rotate motor forward

digitalWrite(IN1, HIGH); // Set IN1 high

digitalWrite(IN2, LOW); // Set IN2 low

analogWrite(ENA, 128); // Set speed (0-255)

delay(2000); // Run for 2 seconds

// Rotate motor backward

digitalWrite(IN1, LOW); // Set IN1 low

digitalWrite(IN2, HIGH); // Set IN2 high

analogWrite(ENA, 128); // Set speed (0-255)

delay(2000); // Run for 2 seconds

// Stop motor

digitalWrite(IN1, LOW); // Set IN1 low

digitalWrite(IN2, LOW); // Set IN2 low

analogWrite(ENA, 0); // Set speed to 0

delay(2000); // Wait for 2 seconds

}

Notes:

- Adjust the

analogWritevalue to control the motor speed. - Ensure the motor driver is properly powered and can handle the motor's current.

Troubleshooting and FAQs

Common Issues and Solutions:

Motor Not Spinning:

- Check the power supply voltage and connections.

- Verify that the motor driver is functioning correctly.

- Ensure the motor is not overloaded or stalled.

Overheating:

- Reduce the load or operating time.

- Ensure proper ventilation and heat dissipation.

No Encoder Feedback:

- Verify encoder wiring and connections.

- Check for noise interference and use shielded cables.

Excessive Noise or Vibration:

- Inspect the motor and gearbox for damage or misalignment.

- Ensure the motor is securely mounted.

FAQs:

Q: Can the MRB Planetary Gearbox Motor be used with a battery?

A: Yes, the motor can be powered by a DC battery, provided the voltage and current ratings match the motor's requirements.

Q: How do I select the right gear ratio?

A: Choose a gear ratio based on the required torque and speed for your application. Higher gear ratios provide more torque but reduce speed.

Q: Can I use the motor without an encoder?

A: Yes, the motor can operate without an encoder, but you will lose speed and position feedback.

Q: What is the lifespan of the gearbox?

A: The lifespan depends on operating conditions, load, and maintenance. Proper alignment and avoiding excessive loads can extend its life.