How to Use NEMA23: Examples, Pinouts, and Specs

Design with NEMA23 in Cirkit Designer

Design with NEMA23 in Cirkit DesignerIntroduction

The NEMA 23 stepper motor is a high-torque, precision motor commonly used in CNC machines, 3D printers, and robotics. With a 2.3 x 2.3 inch faceplate, this motor offers high resolution and accuracy, making it ideal for applications requiring precise control of movement.

Explore Projects Built with NEMA23

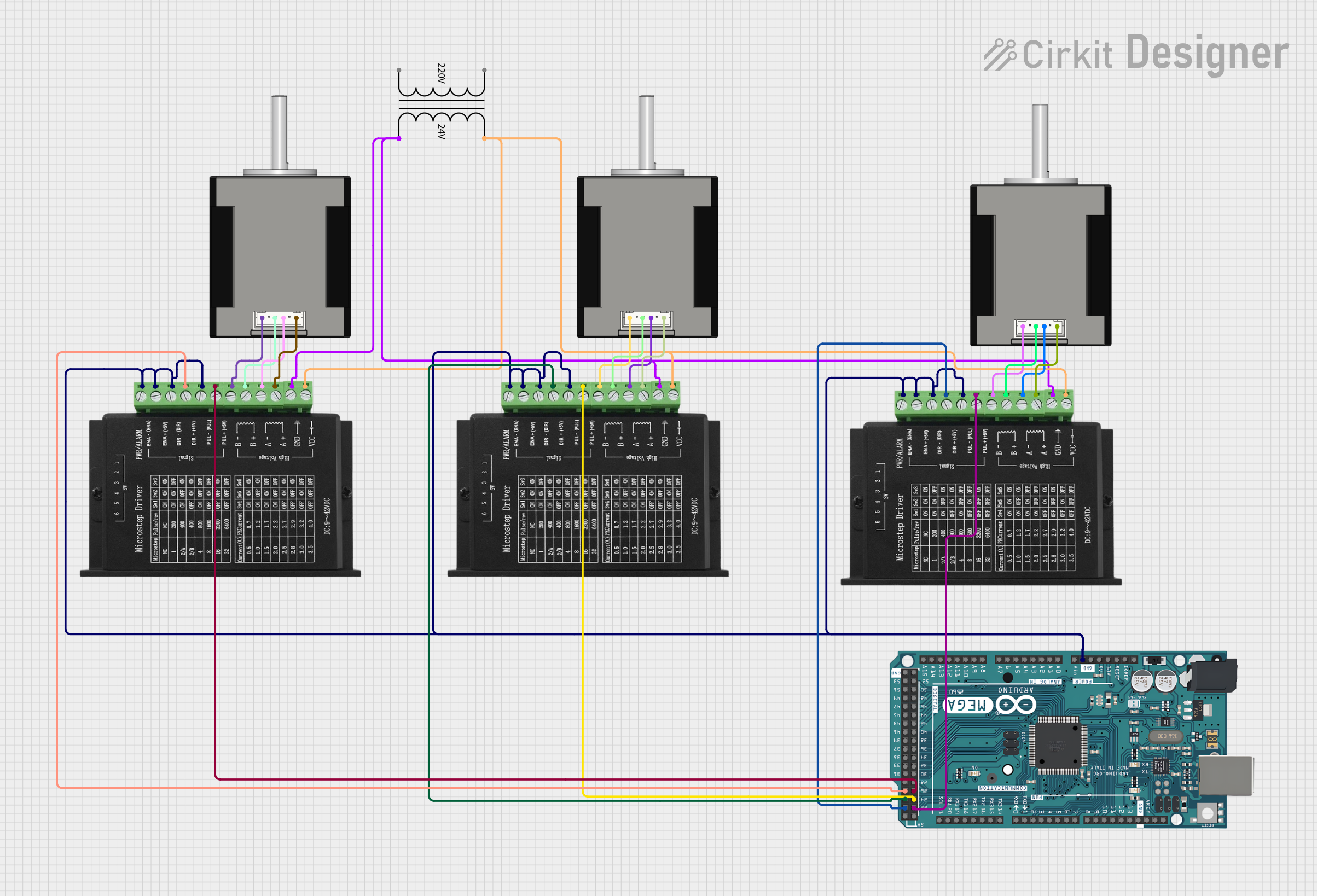

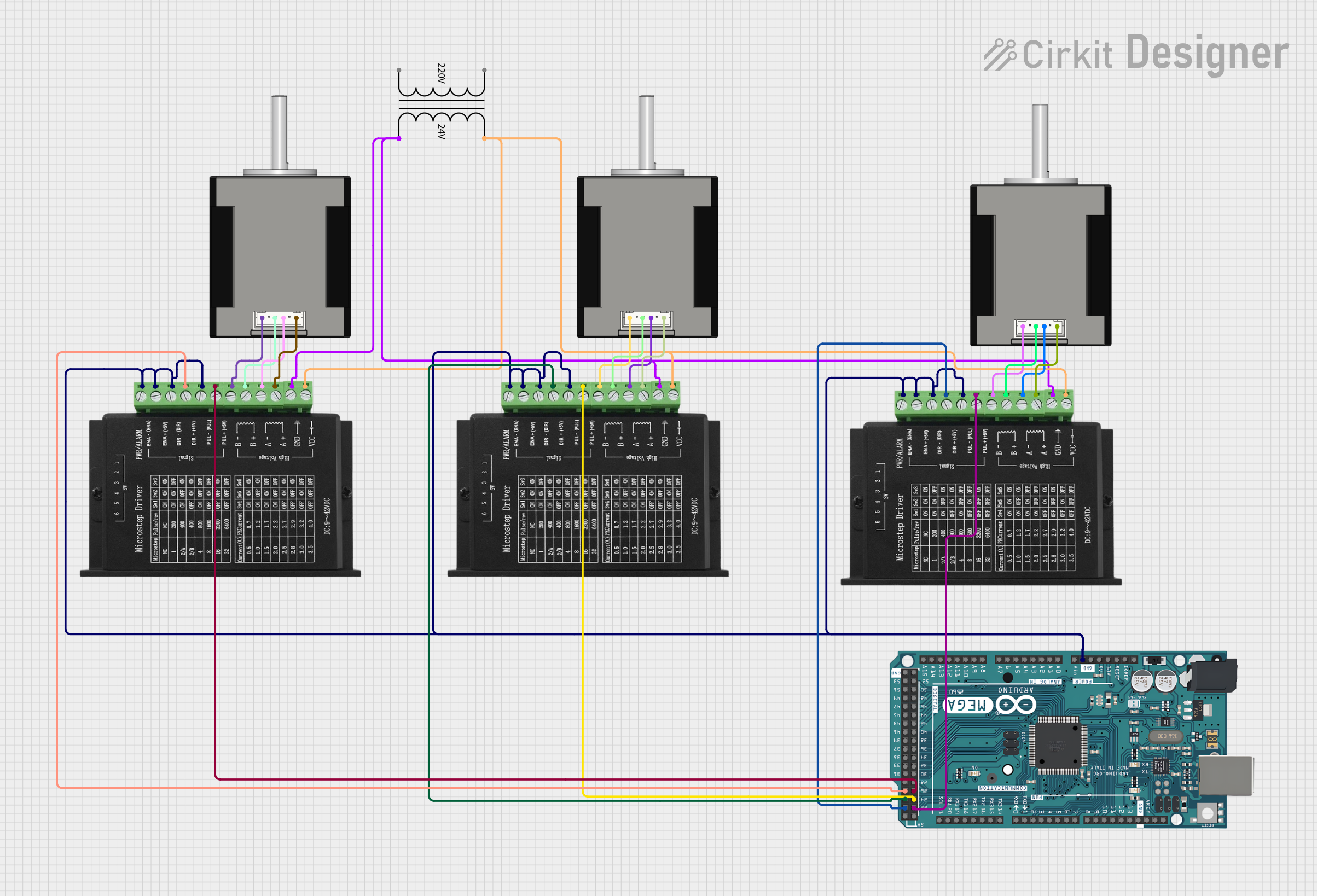

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with NEMA23

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications

- CNC Machines

- 3D Printers

- Robotics

- Automated Manufacturing Systems

- Laser Cutters

Technical Specifications

Key Technical Details

| Parameter | Value |

|---|---|

| Frame Size | 2.3 x 2.3 inches (57 x 57 mm) |

| Step Angle | 1.8° |

| Holding Torque | 1.26 Nm - 3.18 Nm |

| Rated Current | 2.8 A - 3.5 A |

| Voltage | 2.8 V - 4.2 V |

| Resistance | 0.9 Ω - 1.4 Ω |

| Inductance | 2.5 mH - 5.0 mH |

| Shaft Diameter | 6.35 mm |

| Number of Leads | 4, 6, or 8 |

Pin Configuration and Descriptions

4-Wire Configuration

| Pin | Color | Description |

|---|---|---|

| 1 | Red | Coil A |

| 2 | Blue | Coil A' |

| 3 | Green | Coil B |

| 4 | Black | Coil B' |

6-Wire Configuration

| Pin | Color | Description |

|---|---|---|

| 1 | Red | Coil A |

| 2 | Blue | Coil A' |

| 3 | Yellow | Center Tap A |

| 4 | Green | Coil B |

| 5 | Black | Coil B' |

| 6 | White | Center Tap B |

8-Wire Configuration

| Pin | Color | Description |

|---|---|---|

| 1 | Red | Coil A |

| 2 | Blue | Coil A' |

| 3 | Yellow | Coil A Center Tap |

| 4 | White | Coil A Center Tap |

| 5 | Green | Coil B |

| 6 | Black | Coil B' |

| 7 | Brown | Coil B Center Tap |

| 8 | Orange | Coil B Center Tap |

Usage Instructions

How to Use the NEMA 23 Stepper Motor in a Circuit

- Power Supply: Ensure you have a suitable power supply that matches the voltage and current ratings of the motor.

- Driver: Use a stepper motor driver compatible with the NEMA 23 motor. Common drivers include the A4988, DRV8825, and TB6600.

- Connections: Connect the motor leads to the driver according to the pin configuration. For example, in a 4-wire configuration, connect Coil A and Coil A' to the respective driver outputs.

- Control Signals: Connect the control signals (step and direction) from your microcontroller (e.g., Arduino UNO) to the driver.

Important Considerations and Best Practices

- Current Limiting: Set the current limit on the driver to match the rated current of the motor to prevent overheating.

- Microstepping: Enable microstepping on the driver for smoother and more precise control.

- Cooling: Ensure adequate cooling for both the motor and driver, especially in high-torque applications.

- Wiring: Double-check wiring connections to avoid short circuits or incorrect connections.

Example Code for Arduino UNO

// Include the AccelStepper library

#include <AccelStepper.h>

// Define stepper motor connections and motor interface type

#define dirPin 2

#define stepPin 3

#define motorInterfaceType 1

// Create a new instance of the AccelStepper class

AccelStepper stepper = AccelStepper(motorInterfaceType, stepPin, dirPin);

void setup() {

// Set the maximum speed and acceleration

stepper.setMaxSpeed(1000);

stepper.setAcceleration(500);

}

void loop() {

// Move the motor to 1000 steps

stepper.moveTo(1000);

stepper.runToPosition();

// Move the motor back to 0 steps

stepper.moveTo(0);

stepper.runToPosition();

}

Troubleshooting and FAQs

Common Issues and Solutions

Motor Not Moving:

- Solution: Check power supply connections and ensure the driver is receiving power. Verify control signal connections from the microcontroller to the driver.

Motor Overheating:

- Solution: Ensure the current limit on the driver is set correctly. Provide adequate cooling and ventilation.

Inconsistent Movement:

- Solution: Enable microstepping on the driver. Check for loose or faulty wiring connections.

Vibrations and Noise:

- Solution: Use microstepping to reduce vibrations. Ensure the motor is securely mounted.

FAQs

Q1: Can I use a different driver with the NEMA 23 stepper motor?

- A1: Yes, as long as the driver is compatible with the motor's voltage and current ratings.

Q2: How do I determine the correct wiring configuration for my motor?

- A2: Refer to the motor's datasheet or use a multimeter to identify the coils and their respective leads.

Q3: What is microstepping and why is it important?

- A3: Microstepping divides each full step into smaller steps, providing smoother and more precise motor control.

Q4: Can I run the NEMA 23 stepper motor at higher speeds?

- A4: Yes, but ensure the driver and power supply can handle the increased current and voltage requirements.

By following this documentation, users can effectively integrate and utilize the NEMA 23 stepper motor in their projects, ensuring reliable and precise performance.