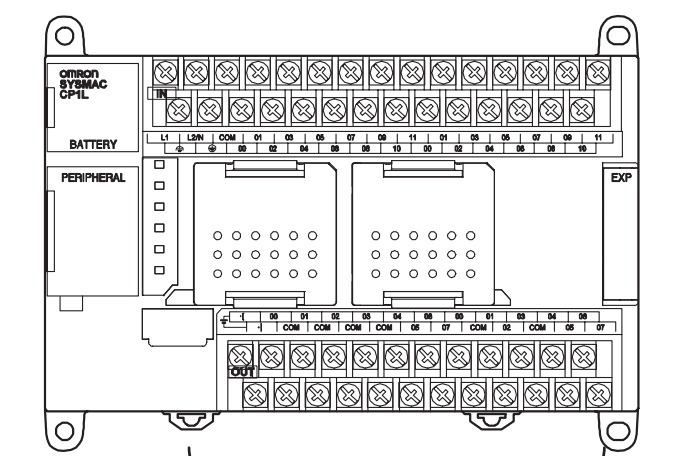

How to Use PLC OMRON CP1L: Examples, Pinouts, and Specs

Design with PLC OMRON CP1L in Cirkit Designer

Design with PLC OMRON CP1L in Cirkit DesignerIntroduction

The OMRON CP1L series is a range of compact Programmable Logic Controllers (PLCs) designed for high-speed, high-performance control in various industrial automation applications. These PLCs are known for their ease of use, reliability, and versatility, making them suitable for a wide array of applications including packaging, food processing, and manufacturing.

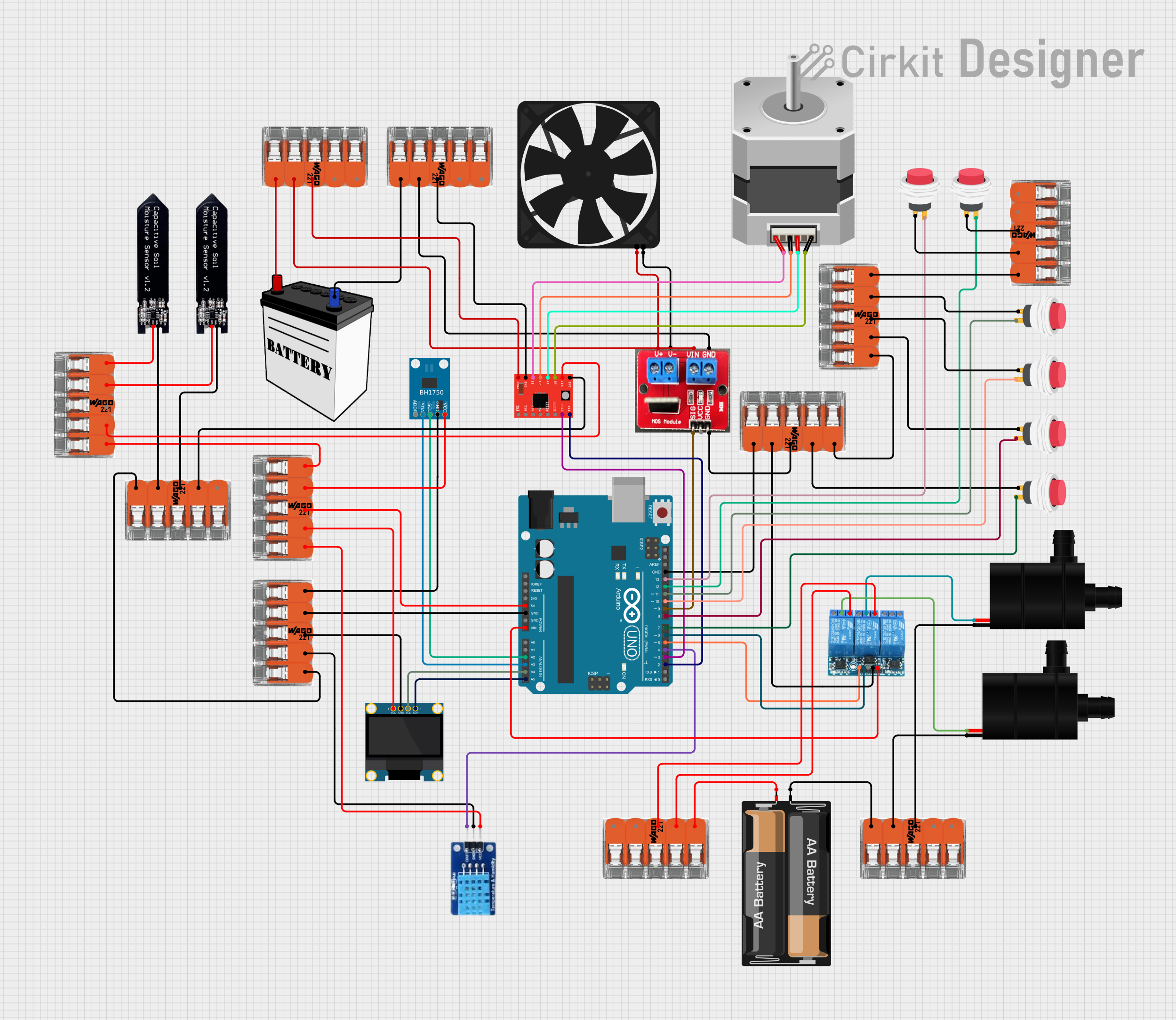

Explore Projects Built with PLC OMRON CP1L

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

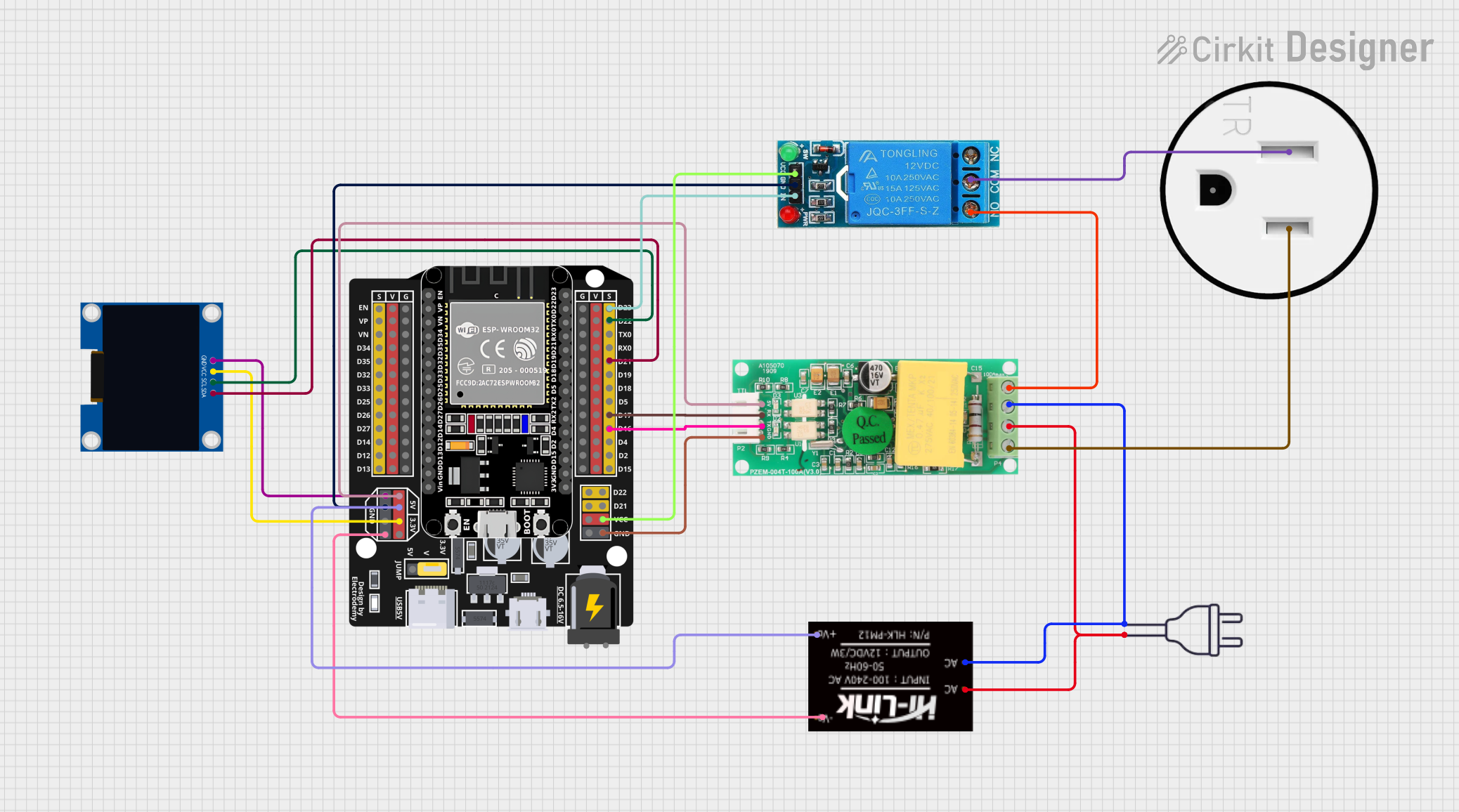

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with PLC OMRON CP1L

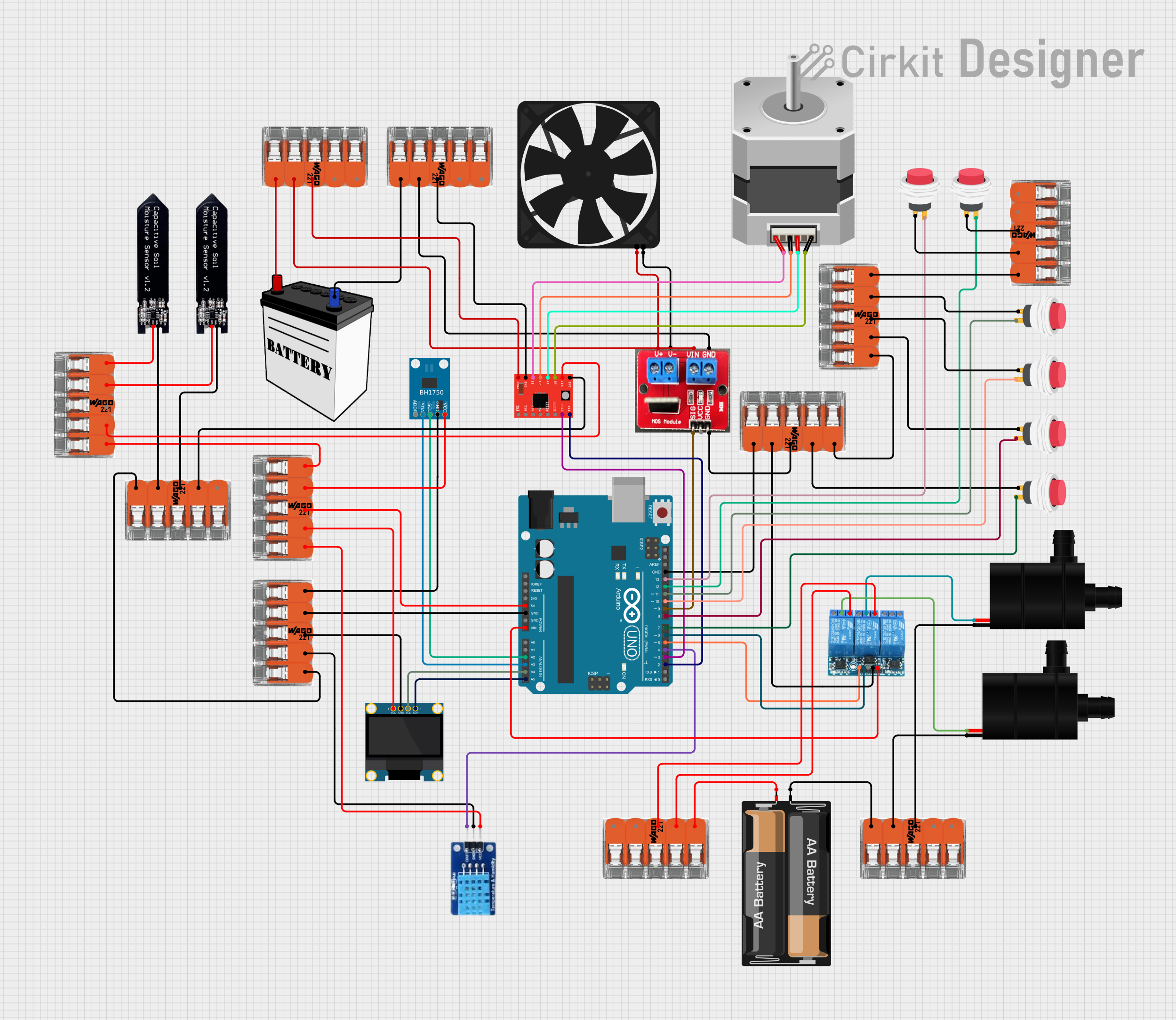

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications and Use Cases

- Automated production lines

- Machine control systems

- Material handling systems

- Process control in manufacturing

- Remote monitoring and control

Technical Specifications

Key Technical Details

- Power Supply: 100-240 VAC or 24 VDC

- Input/Output Range: 10 to 40 points

- Program Capacity: 10K steps

- Data Memory: 32K words

- High-Speed Counters: 100 kHz

- Pulse Outputs: Up to 100 kHz

- Communication Ports: USB, RS-232C, Ethernet (varies by model)

- Expansion Options: Available with various expansion modules

Pin Configuration and Descriptions

The CP1L series PLCs come in different models with varying I/O configurations and features. Below is a general representation of the pin configuration for a typical CP1L PLC. For specific pinout details, refer to the datasheet of the particular CP1L model you are using.

| Pin No. | Description | Type |

|---|---|---|

| 1 | Input 0 | Digital |

| 2 | Input 1 | Digital |

| ... | ... | ... |

| n | Input n-1 | Digital |

| n+1 | Output 0 | Digital |

| n+2 | Output 1 | Digital |

| ... | ... | ... |

| m | Output m-1 | Digital |

| COM | Common Terminal | - |

| V+ | Power Supply Voltage | - |

| 0V | Ground | - |

Note: 'n' and 'm' will vary based on the specific model of the CP1L series PLC.

Usage Instructions

How to Use the Component in a Circuit

- Power Supply Connection: Ensure that the PLC is powered with the correct voltage as per the model's requirement.

- Input/Output Wiring: Connect sensors, switches, and actuators to the respective input and output terminals.

- Programming: Use OMRON's CX-Programmer or other compatible software to write, simulate, and download logic programs to the PLC.

- Testing: Perform a test run to ensure that the PLC operates as intended.

Important Considerations and Best Practices

- Always follow the manufacturer's installation and wiring guidelines.

- Use proper shielding and grounding techniques to minimize electrical noise and interference.

- Regularly back up your PLC programs and maintain version control.

- Implement safety measures to protect against unintended operations.

Troubleshooting and FAQs

Common Issues Users Might Face

- PLC not powering on: Check power supply connections and fuses.

- Inputs/Outputs not responding: Verify wiring, check for short circuits, and ensure proper configuration in the program.

- Communication errors: Confirm the correct communication settings and cable connections.

Solutions and Tips for Troubleshooting

- Always refer to the diagnostic indicators on the PLC for quick troubleshooting.

- Use the programming software's debugging tools to monitor and test I/O status.

- Regularly update the PLC firmware to the latest version to address known issues.

FAQs

Q: Can I expand the I/O capacity of my CP1L PLC? A: Yes, the CP1L series supports expansion modules to increase the number of I/O points.

Q: What programming languages can be used with the CP1L? A: The CP1L can be programmed using Ladder Logic and, in some cases, Structured Text or Function Block Diagrams, depending on the software used.

Q: How do I connect my CP1L PLC to a computer for programming? A: You can connect via USB, RS-232C, or Ethernet, depending on the model and available ports.

Q: Is it possible to remotely monitor the CP1L PLC? A: Yes, with the appropriate communication modules and software, remote monitoring and control are possible.

Note: This documentation provides a general overview of the OMRON CP1L series PLCs. For detailed instructions and advanced configurations, always refer to the specific model's user manual and datasheet.