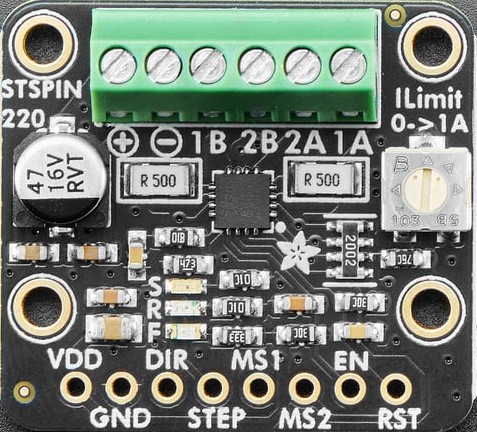

How to Use Adafruit STSPIN220 Stepper Motor Driver Breakout Board: Examples, Pinouts, and Specs

Design with Adafruit STSPIN220 Stepper Motor Driver Breakout Board in Cirkit Designer

Design with Adafruit STSPIN220 Stepper Motor Driver Breakout Board in Cirkit DesignerIntroduction

The Adafruit STSPIN220 Stepper Motor Driver Breakout Board (Manufacturer Part ID: 6353) is a compact and efficient stepper motor driver designed for precise control of stepper motors. It features adjustable current control, microstepping capabilities, and seamless integration with microcontrollers, making it ideal for a wide range of applications.

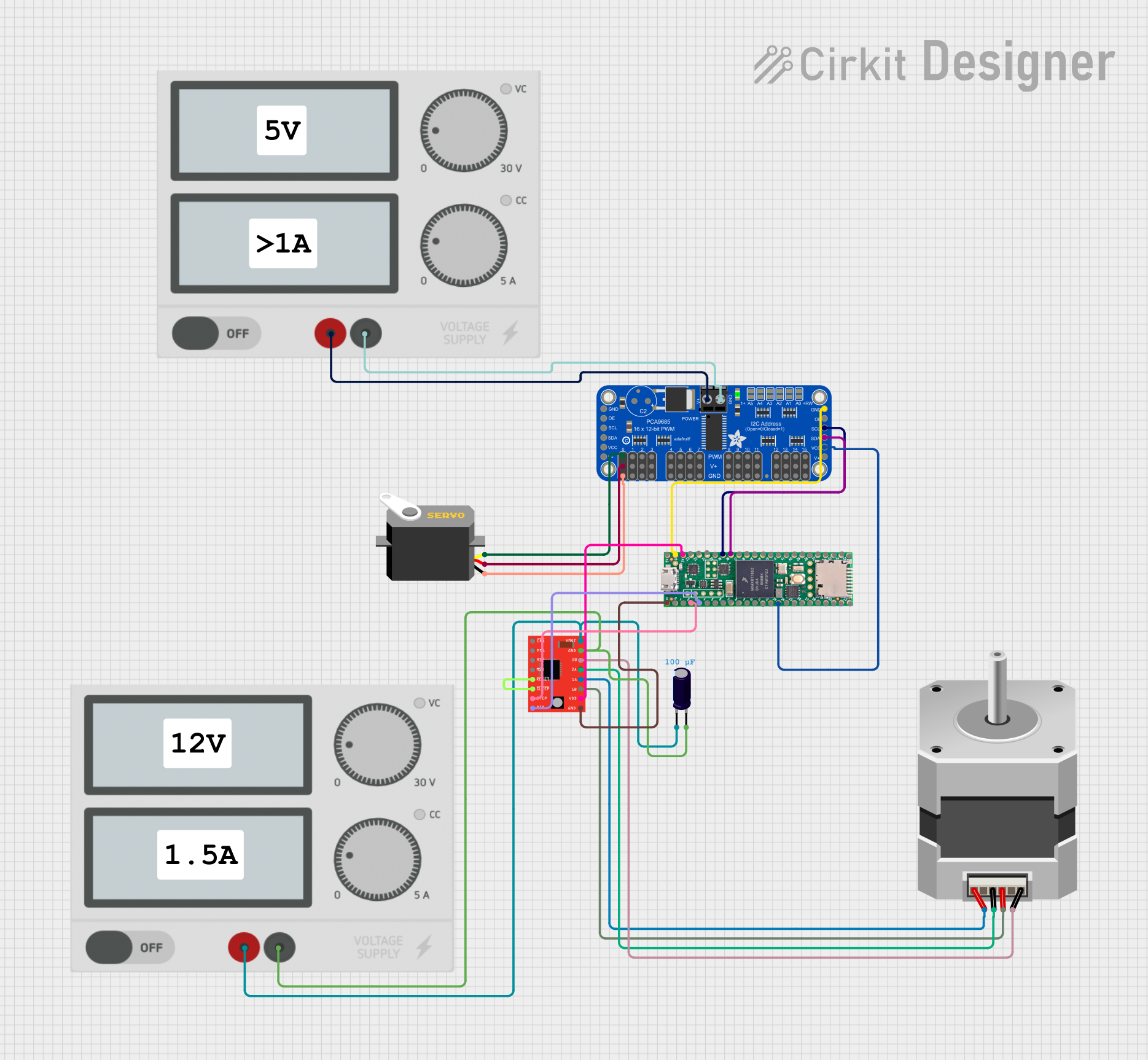

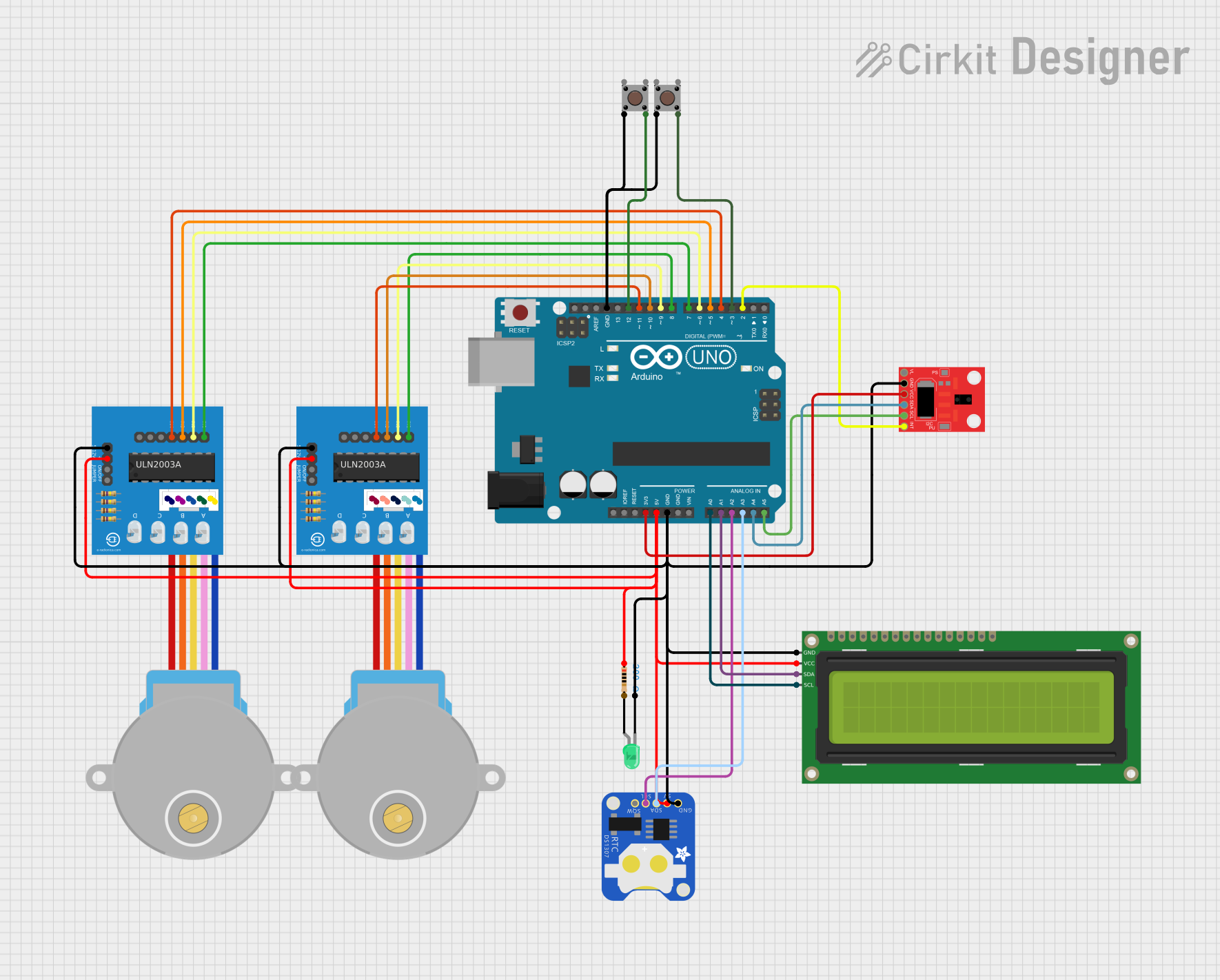

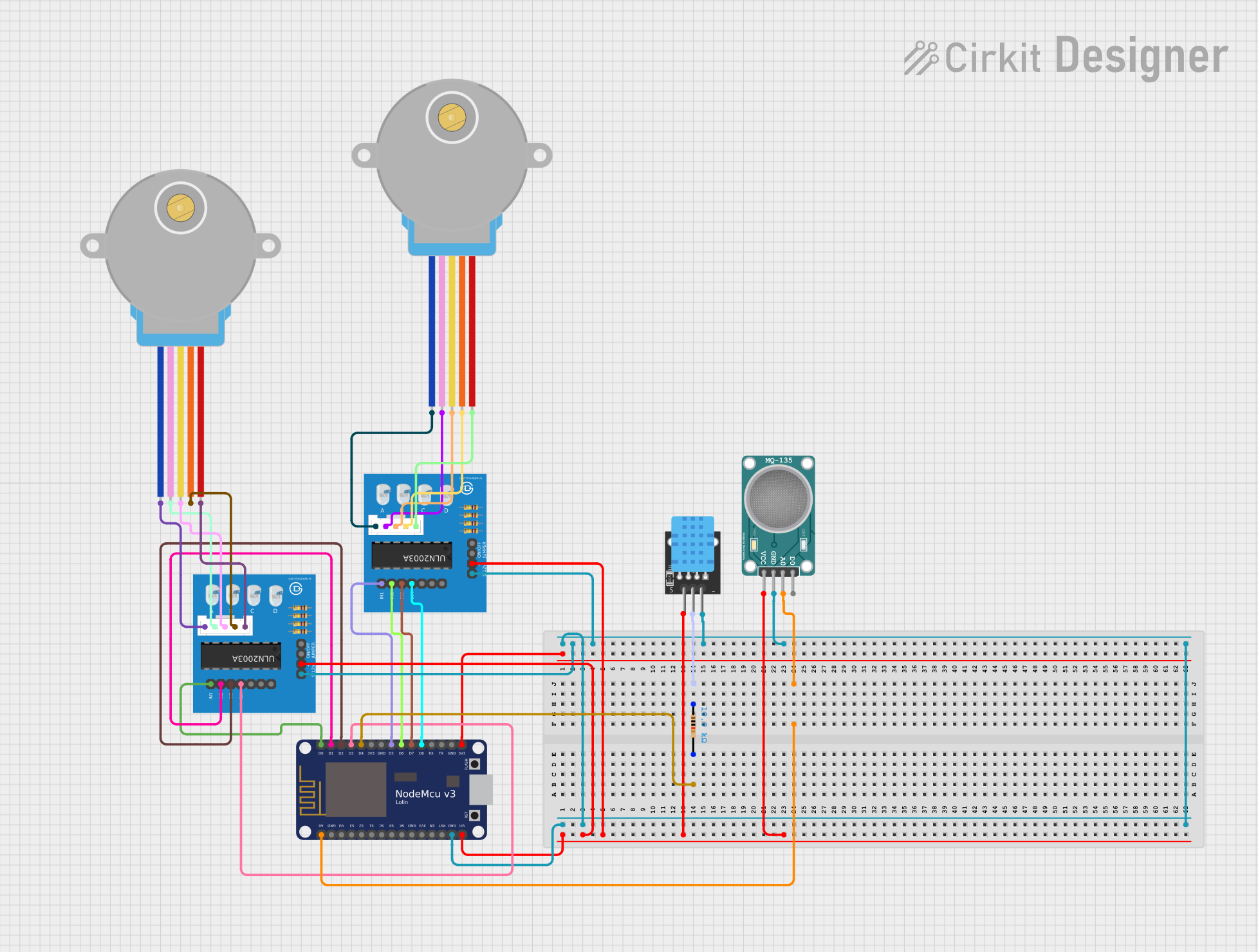

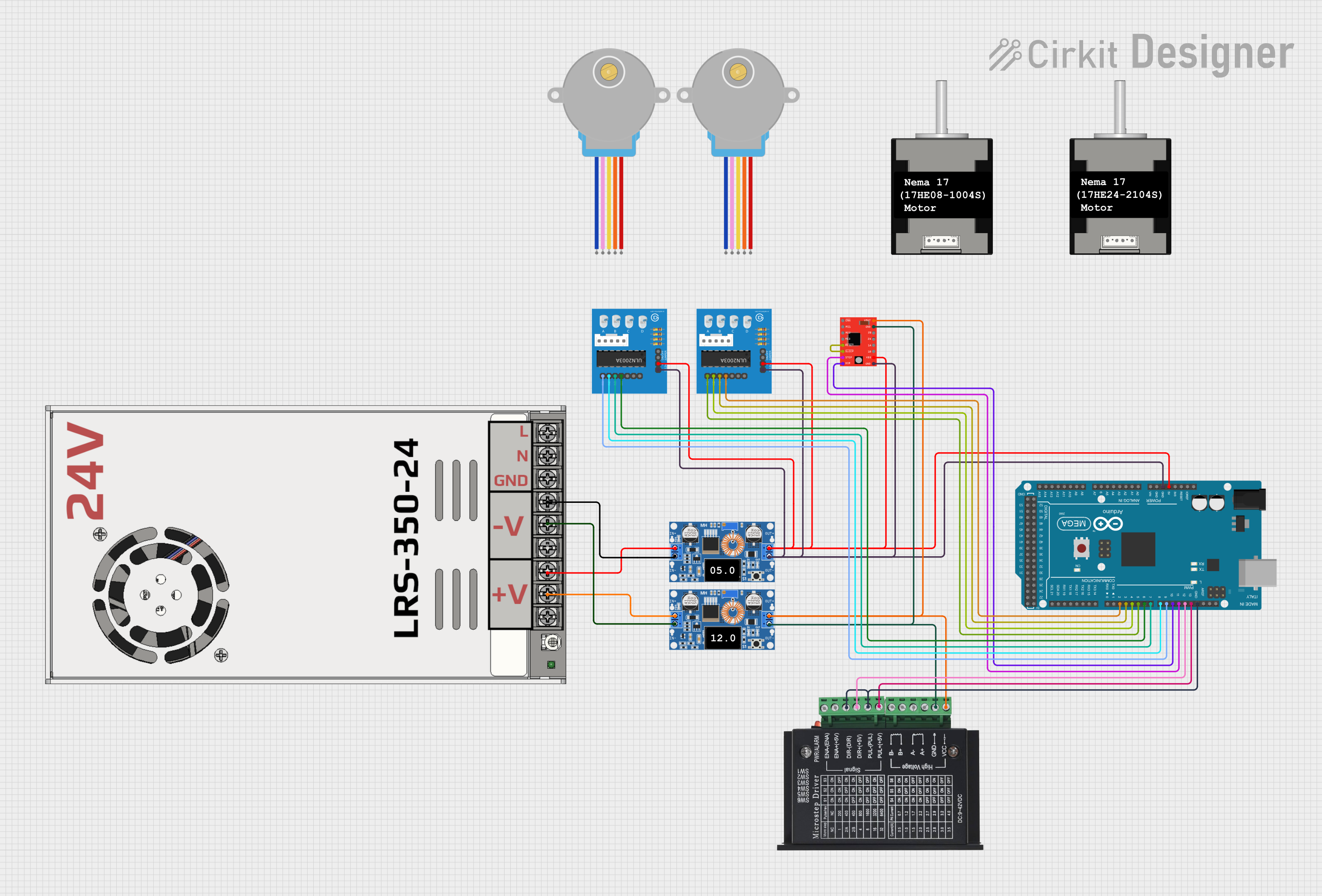

Explore Projects Built with Adafruit STSPIN220 Stepper Motor Driver Breakout Board

Open Project in Cirkit Designer

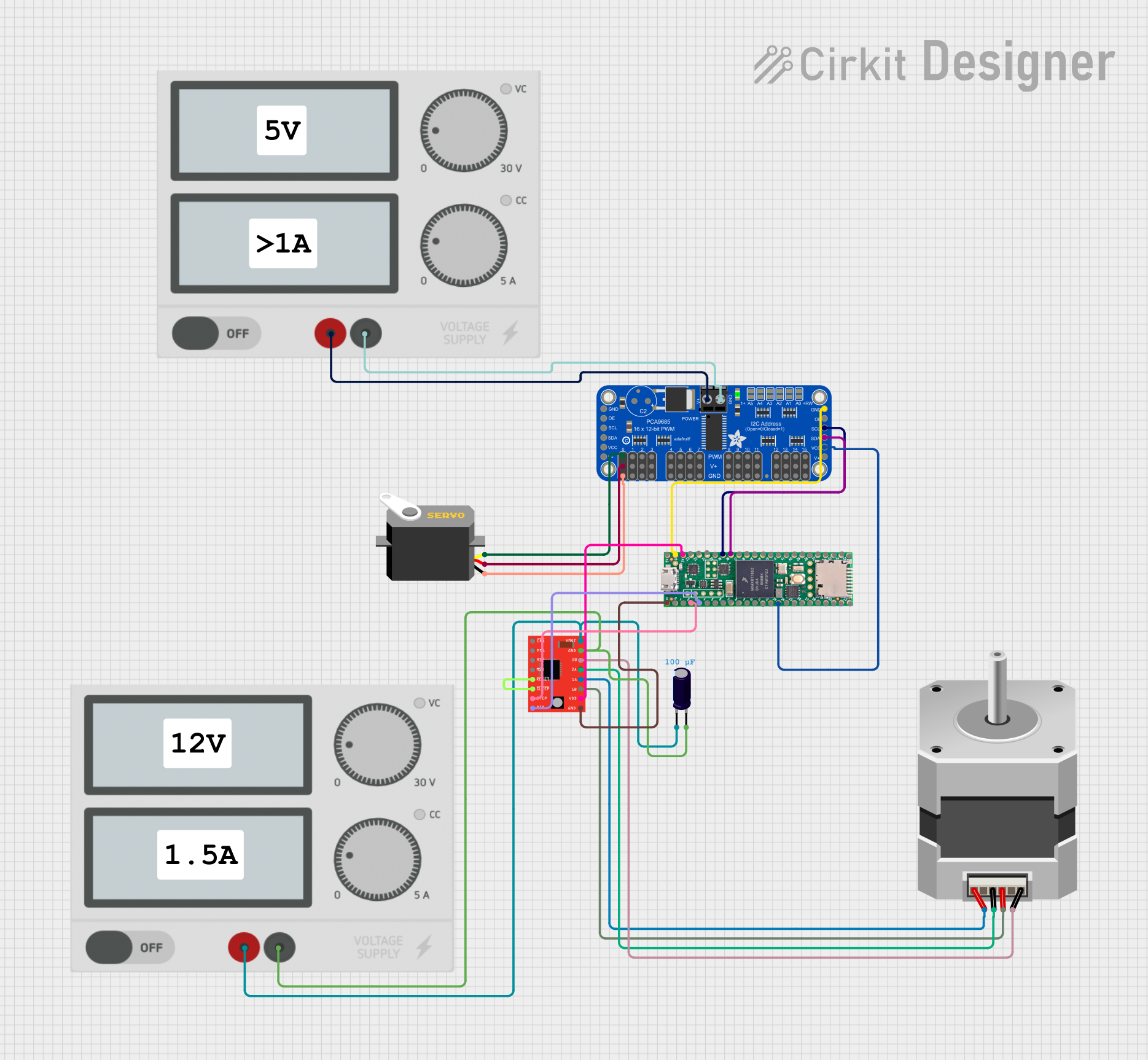

Open Project in Cirkit Designer

Open Project in Cirkit Designer

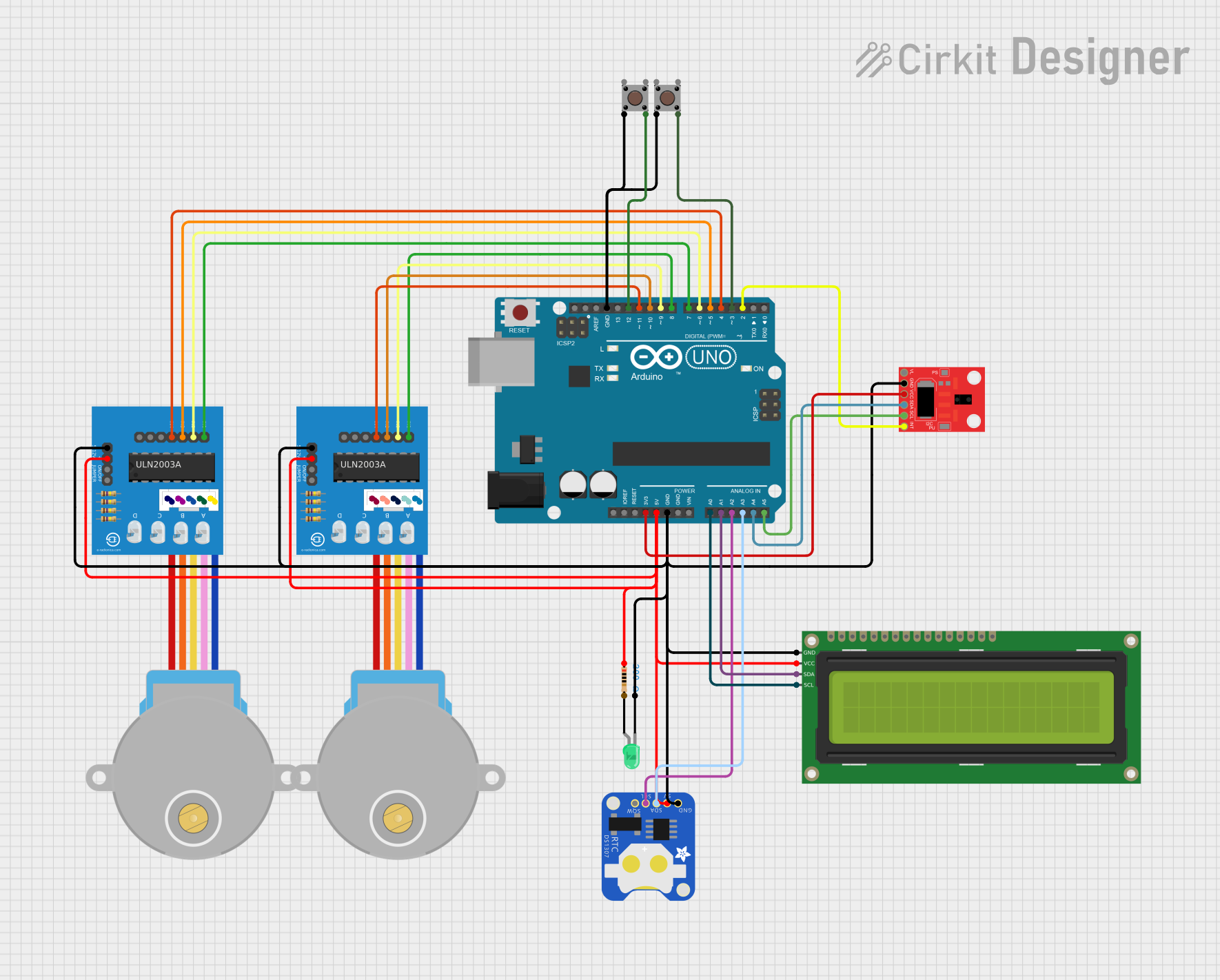

Open Project in Cirkit Designer

Open Project in Cirkit Designer

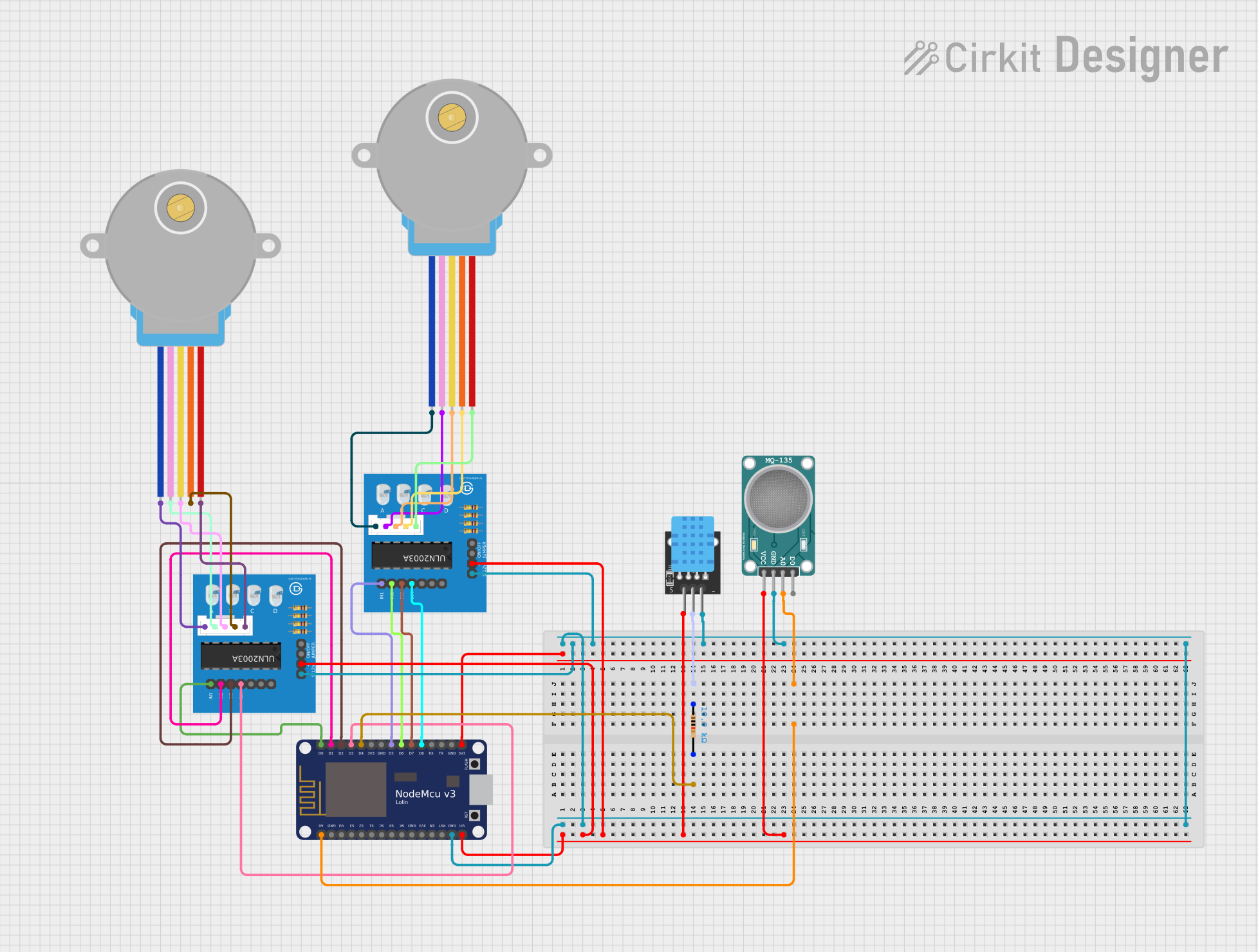

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with Adafruit STSPIN220 Stepper Motor Driver Breakout Board

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications and Use Cases

- Robotics and automation systems

- 3D printers and CNC machines

- Camera sliders and gimbals

- Precision positioning systems

- DIY electronics and prototyping projects

Technical Specifications

The Adafruit STSPIN220 is built for high performance and flexibility. Below are its key technical details:

| Parameter | Value |

|---|---|

| Operating Voltage (Vcc) | 3.0V to 10.0V |

| Motor Voltage (VM) | 1.8V to 10.0V |

| Maximum Motor Current | 1.3A RMS (1.8A peak) |

| Microstepping Modes | Full-step, 1/2, 1/4, 1/8, 1/16, 1/32, 1/64, 1/128 |

| Logic Voltage | 3.3V or 5V compatible |

| Control Interface | Step/Direction pins |

| Dimensions | 20mm x 20mm x 4mm |

| Thermal Shutdown | Yes |

| Overcurrent Protection | Yes |

Pin Configuration and Descriptions

The breakout board has 10 pins, as described in the table below:

| Pin Name | Type | Description |

|---|---|---|

| VIN | Power Input | Main power supply for the motor (1.8V to 10.0V). |

| GND | Ground | Ground connection for the motor and logic circuits. |

| VCC | Power Input | Logic voltage supply (3.0V to 10.0V). |

| STEP | Input | Step signal input for controlling motor steps. |

| DIR | Input | Direction signal input to set motor rotation direction. |

| ENABLE | Input | Enable/disable the motor driver (active low). |

| MODE0 | Input | Microstepping mode selection (see datasheet for mode combinations). |

| MODE1 | Input | Microstepping mode selection (see datasheet for mode combinations). |

| MODE2 | Input | Microstepping mode selection (see datasheet for mode combinations). |

| FAULT | Output | Fault indicator pin (active low when a fault occurs, e.g., overcurrent). |

Usage Instructions

How to Use the Component in a Circuit

Power Connections:

- Connect the motor power supply to the

VINpin (1.8V to 10.0V). - Connect the logic power supply to the

VCCpin (3.0V to 10.0V). - Ensure all grounds (

GND) are connected.

- Connect the motor power supply to the

Control Signals:

- Use the

STEPpin to send pulses for each motor step. - Use the

DIRpin to set the motor's rotation direction (HIGH for one direction, LOW for the other). - Set the

ENABLEpin LOW to activate the driver and HIGH to disable it.

- Use the

Microstepping Configuration:

- Configure the

MODE0,MODE1, andMODE2pins to select the desired microstepping mode. Refer to the datasheet for the specific pin combinations.

- Configure the

Motor Connections:

- Connect the stepper motor's two coils to the motor output terminals on the breakout board.

Fault Monitoring:

- Monitor the

FAULTpin for any errors. If the pin goes LOW, check for issues such as overcurrent or thermal shutdown.

- Monitor the

Important Considerations and Best Practices

- Current Limiting: Adjust the current limit using the onboard potentiometer to match your motor's rated current. This prevents overheating and ensures optimal performance.

- Power Supply: Use a stable power supply within the specified voltage range to avoid damage to the driver or motor.

- Heat Dissipation: Ensure proper ventilation or add a heatsink if the driver operates at high currents for extended periods.

- Signal Integrity: Use short and shielded wires for control signals to minimize noise and interference.

Example: Using with Arduino UNO

Below is an example of how to control the STSPIN220 with an Arduino UNO:

// Define pin connections

#define STEP_PIN 3 // Connect to STEP pin on STSPIN220

#define DIR_PIN 4 // Connect to DIR pin on STSPIN220

#define ENABLE_PIN 5 // Connect to ENABLE pin on STSPIN220

void setup() {

// Set pin modes

pinMode(STEP_PIN, OUTPUT);

pinMode(DIR_PIN, OUTPUT);

pinMode(ENABLE_PIN, OUTPUT);

// Enable the motor driver

digitalWrite(ENABLE_PIN, LOW); // LOW to enable the driver

// Set initial direction

digitalWrite(DIR_PIN, HIGH); // HIGH for one direction, LOW for the other

}

void loop() {

// Generate step pulses

digitalWrite(STEP_PIN, HIGH); // Step pulse HIGH

delayMicroseconds(500); // Wait 500 microseconds

digitalWrite(STEP_PIN, LOW); // Step pulse LOW

delayMicroseconds(500); // Wait 500 microseconds

}

Troubleshooting and FAQs

Common Issues and Solutions

Motor Not Moving:

- Ensure the

ENABLEpin is set to LOW. - Verify the

STEPandDIRsignals are being sent correctly. - Check the motor connections and ensure the coils are connected properly.

- Ensure the

Overheating:

- Reduce the current limit using the onboard potentiometer.

- Ensure proper ventilation or add a heatsink.

FAULT Pin is LOW:

- Check for overcurrent or thermal shutdown conditions.

- Verify the power supply voltage is within the specified range.

Motor Vibrates but Doesn't Rotate:

- Verify the microstepping mode configuration.

- Check the

DIRsignal and ensure it is set correctly.

FAQs

Q: Can I use a 12V power supply with this driver?

A: No, the maximum motor voltage (VIN) is 10.0V. Using a higher voltage may damage the driver.

Q: How do I set the microstepping mode?

A: Use the MODE0, MODE1, and MODE2 pins to configure the microstepping mode. Refer to the datasheet for the specific combinations.

Q: What happens if the motor draws more current than the limit?

A: The driver has built-in overcurrent protection and will shut down to prevent damage. Adjust the current limit to match your motor's specifications.

Q: Can I use this driver with a 5V logic microcontroller?

A: Yes, the STSPIN220 is compatible with both 3.3V and 5V logic levels.