How to Use Bilge Pump 12V: Examples, Pinouts, and Specs

Design with Bilge Pump 12V in Cirkit Designer

Design with Bilge Pump 12V in Cirkit DesignerIntroduction

A Bilge Pump 12V is an essential component in marine applications, designed to evacuate water from the bilge, the lowest compartment inside a boat's hull. This electric pump is specifically tailored for use in a 12-volt DC electrical system, which is standard in most small to medium-sized vessels. The bilge pump's primary role is to ensure that the boat remains afloat by preventing water accumulation that can lead to instability and potential sinking.

Explore Projects Built with Bilge Pump 12V

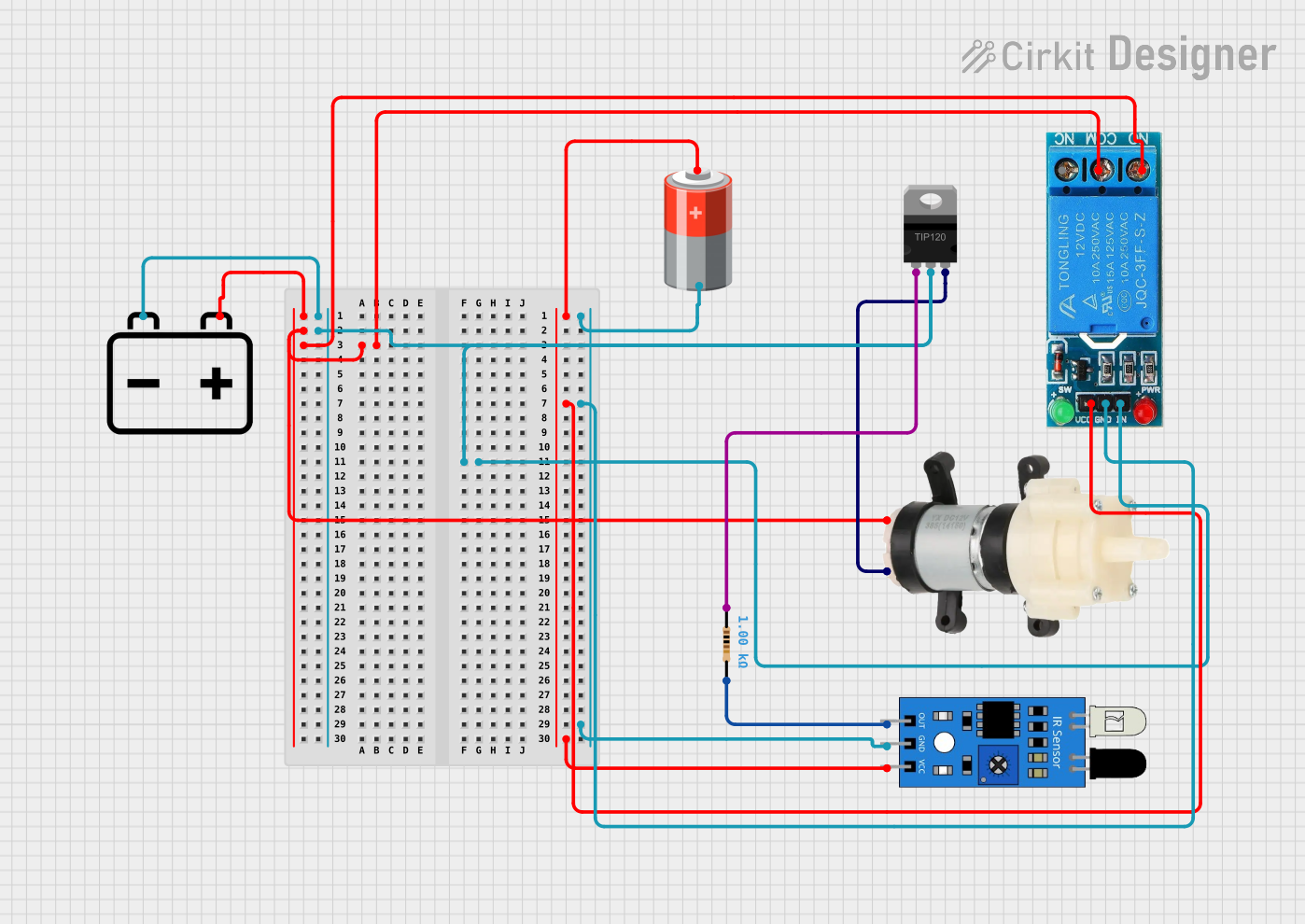

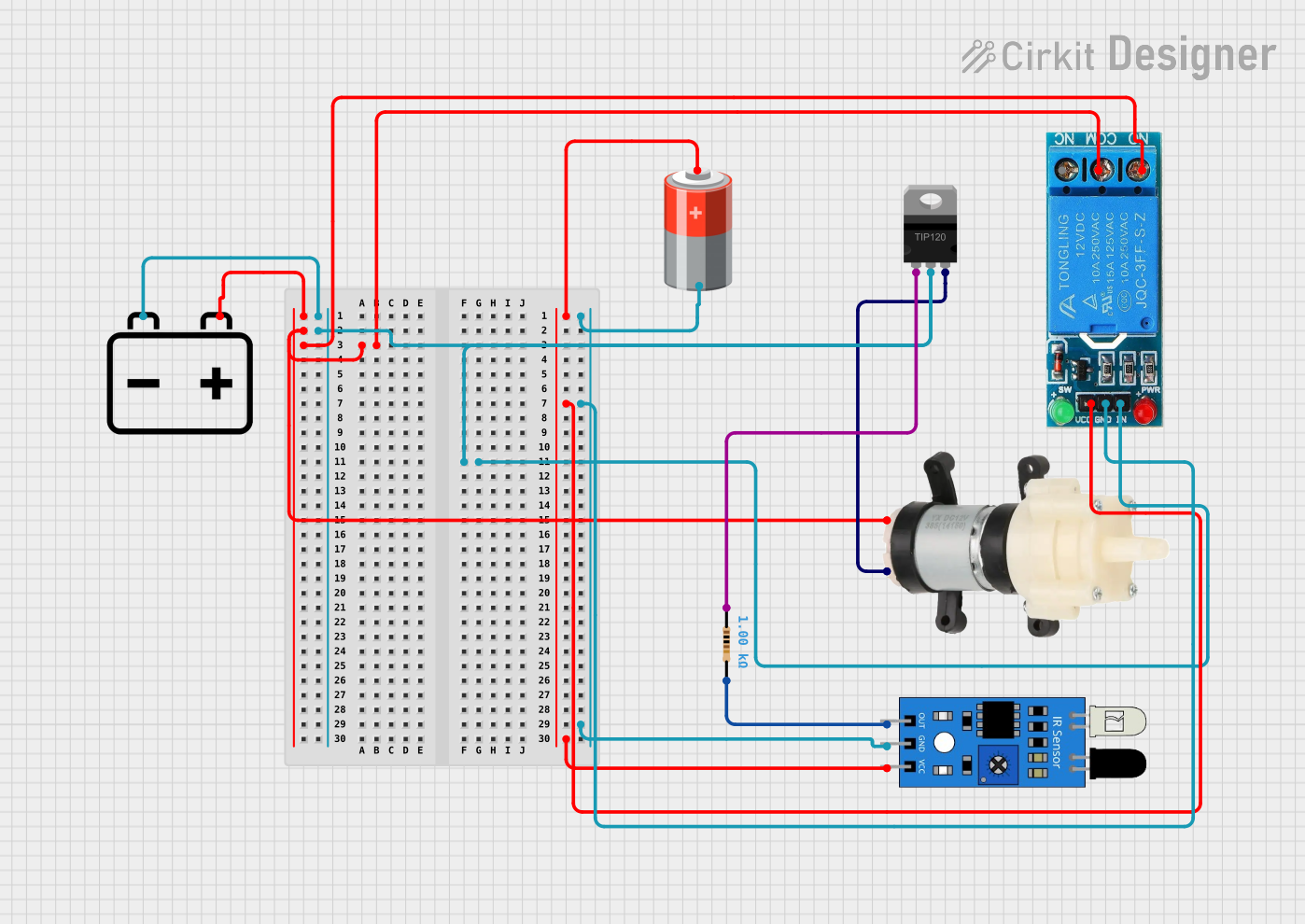

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with Bilge Pump 12V

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications and Use Cases

- Removing accumulated water from the bilge of boats and ships

- Employed in emergency situations to mitigate flooding

- Used in conjunction with float switches for automatic water level management

- Can be used in non-marine applications where water transfer is needed

Technical Specifications

Key Technical Details

| Specification | Value | Description |

|---|---|---|

| Operating Voltage | 12V DC | The voltage at which the pump is designed to operate efficiently |

| Power Consumption | Varies by model | Typically measured in watts (W) |

| Flow Rate | Varies by model | The volume of water the pump can move, usually measured in gallons per hour (GPH) or liters per hour (LPH) |

| Outlet Diameter | Varies by model | The diameter of the pump's outlet port, typically in inches or millimeters |

| Maximum Head | Varies by model | The maximum height to which the pump can lift water |

| Fuse Size | Varies by model | Recommended fuse size to protect the pump from overcurrent |

| Material | Marine-grade materials | Construction materials designed to withstand harsh marine environments |

Pin Configuration and Descriptions

Since a bilge pump typically has only two wires for power and ground, there is no pin configuration in the traditional sense. However, the wire connections are as follows:

| Wire Color | Connection Type | Description |

|---|---|---|

| Red | Positive (+) | Connects to the positive terminal of the power source |

| Black | Negative (−) | Connects to the negative terminal of the power source or ground |

Usage Instructions

How to Use the Component in a Circuit

Power Source Connection: Connect the red wire of the bilge pump to the positive terminal of a 12V battery or power supply. Connect the black wire to the negative terminal or a grounding point.

Switch Integration: It is advisable to integrate a switch into the circuit to control the operation of the bilge pump manually. This switch should be placed in series with the red wire.

Fuse Installation: Install an appropriate fuse inline with the red wire close to the power source to protect against overcurrent situations.

Float Switch (Optional): For automatic operation, a float switch can be connected to the circuit. The float switch will turn the pump on when the water level rises and off when it is lowered.

Important Considerations and Best Practices

- Ensure that the bilge pump is securely mounted at the lowest point of the bilge.

- Use marine-grade wire and waterproof connectors to prevent corrosion and ensure longevity.

- Regularly inspect the pump and its components for debris or damage that may impede operation.

- Test the pump and float switch operation periodically to ensure functionality in case of an emergency.

- Follow the manufacturer's guidelines for maintenance and replacement intervals.

Troubleshooting and FAQs

Common Issues Users Might Face

- Pump Not Operating: Check the power supply, fuse, and connections. Ensure the switch and float switch (if used) are functioning correctly.

- Low Flow Rate: Inspect for blockages in the inlet or outlet. Verify that the pump is not air-locked and that the impeller is not damaged.

- Pump Running Continuously: Ensure the float switch is not stuck in the "on" position and that it is mounted correctly.

Solutions and Tips for Troubleshooting

- No Power: Confirm that the battery is charged and that all connections are secure and free from corrosion.

- Pump Clogs: Regularly clean the pump and surrounding area to prevent clogs. Check the manufacturer's manual for cleaning instructions.

- Automatic Operation Issues: Adjust the float switch to ensure it activates and deactivates at the correct water levels.

FAQs

Q: Can I use the bilge pump with a solar panel? A: Yes, as long as the solar panel system is capable of providing a stable 12V output.

Q: How do I know what size fuse to use? A: The fuse size is typically specified by the pump manufacturer. If not, a general rule is to use a fuse rated slightly higher than the pump's maximum current draw.

Q: Is it necessary to use a float switch? A: While not strictly necessary, a float switch is highly recommended for automatic operation and to prevent the pump from running dry.

Q: How often should the bilge pump be tested? A: It is advisable to test the pump at least once a month and after any significant weather events.

Q: Can the bilge pump be used for other liquids? A: Bilge pumps are designed for water. Using them for other liquids, especially flammable or corrosive ones, is not recommended and could be unsafe.

For any further assistance or detailed product support, please refer to the manufacturer's documentation or contact their customer service department.