How to Use Engine with gearbox 6VDC 200rpm side: Examples, Pinouts, and Specs

Design with Engine with gearbox 6VDC 200rpm side in Cirkit Designer

Design with Engine with gearbox 6VDC 200rpm side in Cirkit DesignerIntroduction

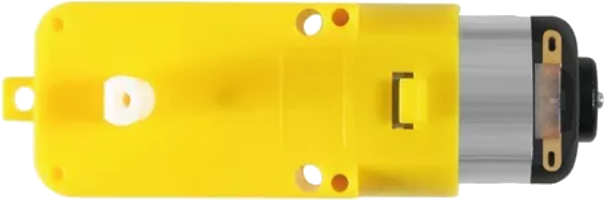

The Engine with Gearbox 6VDC 200RPM Side is a compact and efficient DC motor equipped with a built-in gearbox. The gearbox reduces the motor's speed to 200 revolutions per minute (RPM), significantly increasing torque output. This makes it ideal for applications requiring precise, low-speed, high-torque motion. The motor operates at 6V DC, making it compatible with a wide range of power sources, including batteries and microcontroller-based systems.

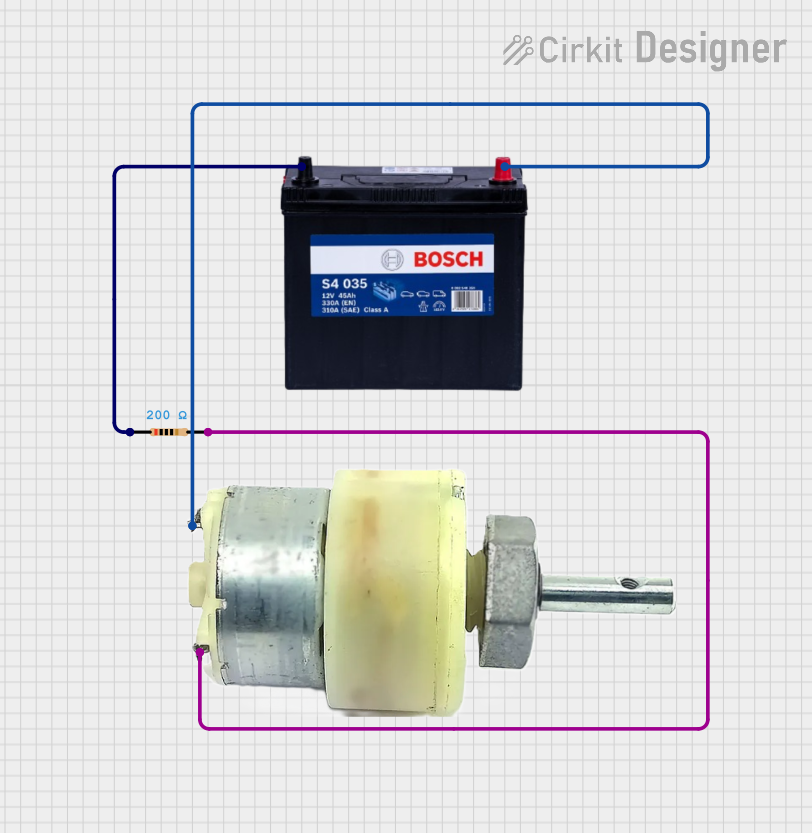

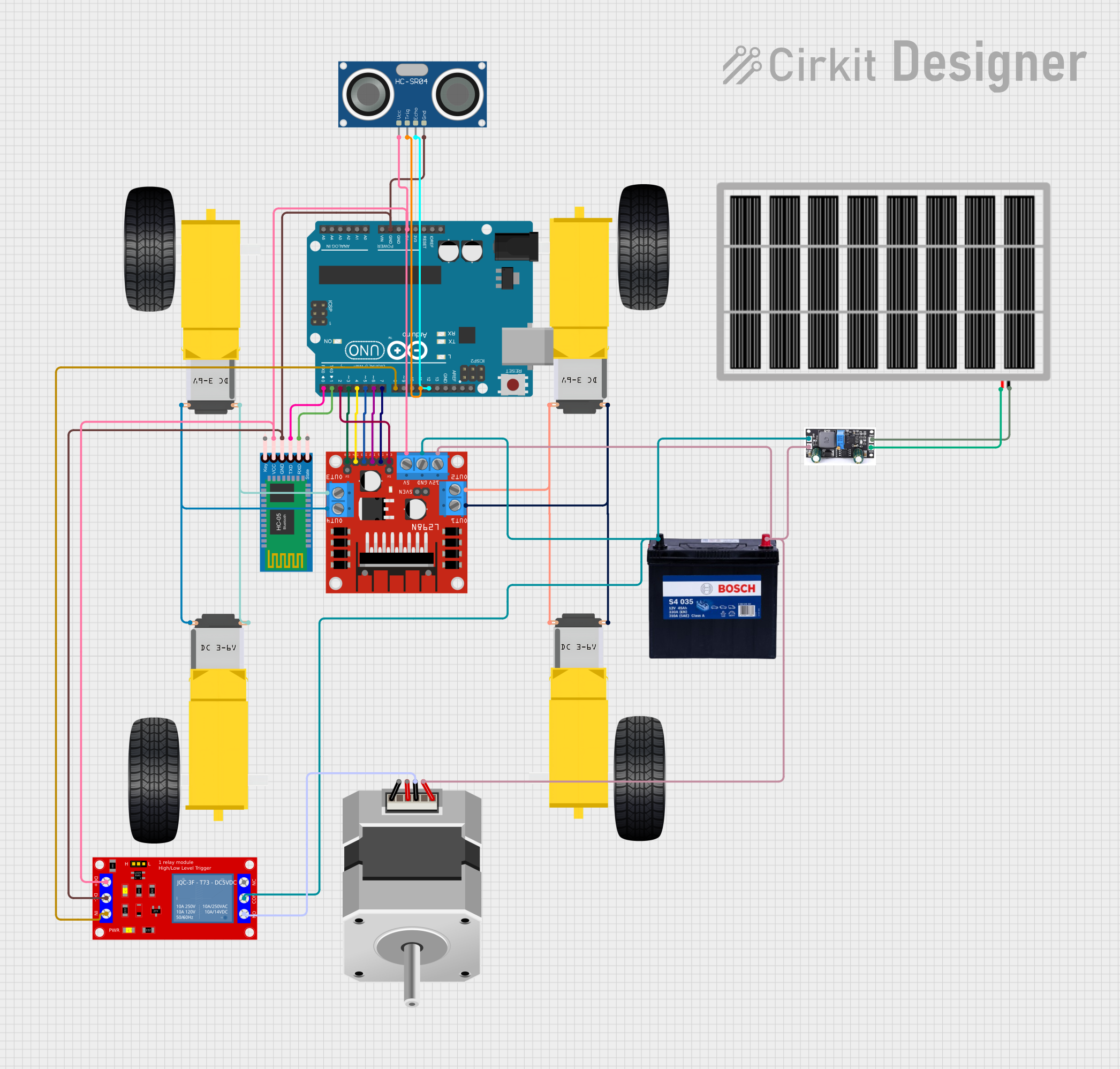

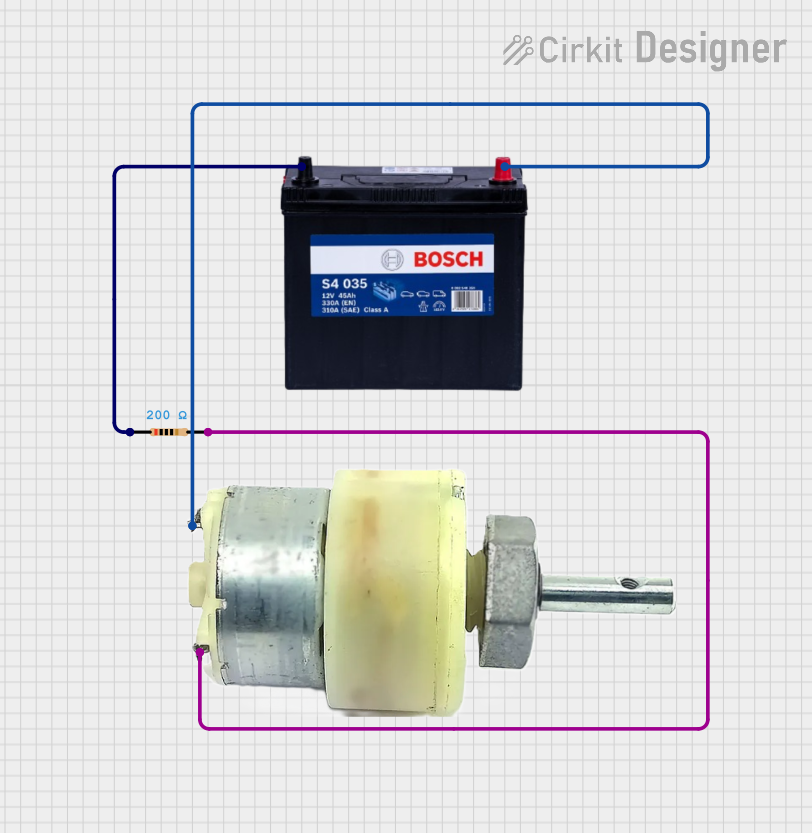

Explore Projects Built with Engine with gearbox 6VDC 200rpm side

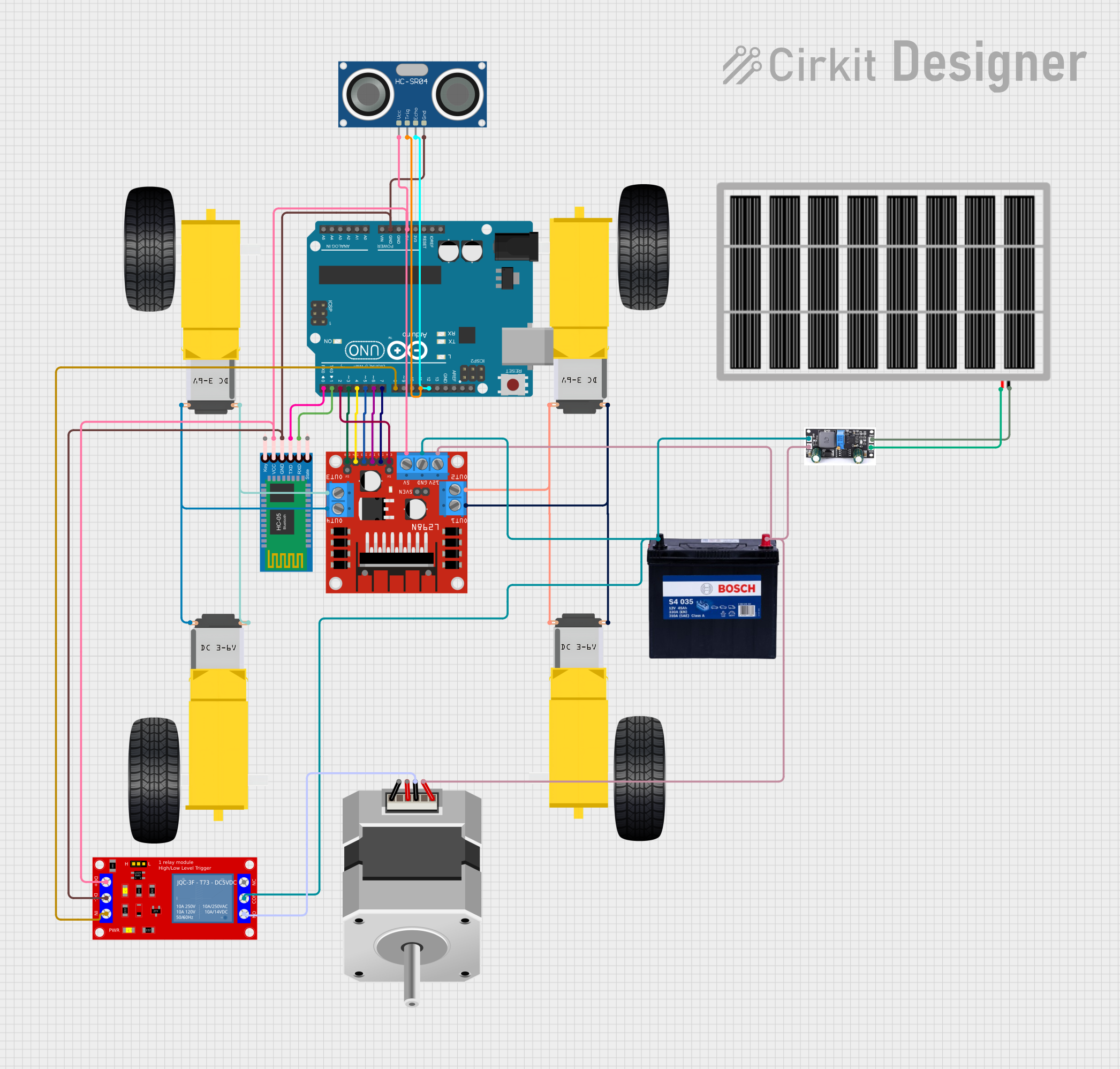

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with Engine with gearbox 6VDC 200rpm side

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications and Use Cases

- Robotics: Driving wheels, arms, or other mechanical components.

- Conveyor belts: Providing controlled motion for small-scale systems.

- Automated systems: Used in vending machines, door openers, and other mechanisms.

- DIY projects: Ideal for hobbyists building motorized models or tools.

Technical Specifications

Below are the key technical details of the Engine with Gearbox 6VDC 200RPM Side:

| Parameter | Value |

|---|---|

| Operating Voltage | 6V DC |

| No-Load Speed | 200 RPM |

| Gearbox Ratio | 1:30 |

| Stall Torque | ~2.5 kg·cm |

| No-Load Current | ~120 mA |

| Stall Current | ~1.2 A |

| Shaft Diameter | 6 mm |

| Motor Dimensions | 70 mm x 30 mm x 25 mm |

| Weight | ~100 g |

Pin Configuration and Descriptions

The motor has two terminals for electrical connections:

| Pin | Description |

|---|---|

| + | Positive terminal for 6V DC input |

| - | Negative terminal (ground) for 6V DC |

Usage Instructions

How to Use the Component in a Circuit

- Power Supply: Connect the motor's terminals to a 6V DC power source. Ensure the power supply can provide sufficient current (at least 1.2 A for stall conditions).

- Polarity Control: Reversing the polarity of the connections will reverse the motor's rotation direction.

- Motor Driver: For microcontroller-based systems (e.g., Arduino), use an H-bridge motor driver (e.g., L298N or L293D) to control the motor's speed and direction.

- Mounting: Secure the motor using screws or brackets to prevent movement during operation.

Important Considerations and Best Practices

- Avoid Overloading: Do not exceed the motor's stall torque, as this can damage the gearbox or motor windings.

- Heat Management: Prolonged operation at high currents may cause the motor to overheat. Allow cooling periods if necessary.

- Power Supply: Use a regulated power supply to avoid voltage spikes that could damage the motor.

- Noise Suppression: Add a capacitor (e.g., 0.1 µF) across the motor terminals to reduce electrical noise.

Example: Connecting to an Arduino UNO

Below is an example of how to control the motor using an Arduino UNO and an L298N motor driver:

// Example: Controlling a 6V DC motor with Arduino and L298N motor driver

// Define motor control pins

const int motorPin1 = 9; // IN1 on L298N

const int motorPin2 = 10; // IN2 on L298N

const int enablePin = 11; // ENA on L298N (PWM control)

void setup() {

// Set motor control pins as outputs

pinMode(motorPin1, OUTPUT);

pinMode(motorPin2, OUTPUT);

pinMode(enablePin, OUTPUT);

}

void loop() {

// Rotate motor forward

digitalWrite(motorPin1, HIGH); // Set IN1 high

digitalWrite(motorPin2, LOW); // Set IN2 low

analogWrite(enablePin, 128); // Set speed (0-255, 128 = ~50% speed)

delay(2000); // Run for 2 seconds

// Stop motor

analogWrite(enablePin, 0); // Set speed to 0

delay(1000); // Wait for 1 second

// Rotate motor backward

digitalWrite(motorPin1, LOW); // Set IN1 low

digitalWrite(motorPin2, HIGH); // Set IN2 high

analogWrite(enablePin, 128); // Set speed (0-255, 128 = ~50% speed)

delay(2000); // Run for 2 seconds

// Stop motor

analogWrite(enablePin, 0); // Set speed to 0

delay(1000); // Wait for 1 second

}

Troubleshooting and FAQs

Common Issues and Solutions

Motor Does Not Spin:

- Cause: Insufficient power supply or loose connections.

- Solution: Check the power source and ensure all connections are secure.

Motor Spins in the Wrong Direction:

- Cause: Polarity of the connections is reversed.

- Solution: Swap the + and - connections to reverse the direction.

Motor Overheats:

- Cause: Prolonged operation at high current or excessive load.

- Solution: Reduce the load or allow the motor to cool periodically.

Excessive Noise or Vibration:

- Cause: Loose mounting or worn-out gearbox.

- Solution: Secure the motor properly and inspect the gearbox for damage.

FAQs

Can I use a higher voltage than 6V?

- No, exceeding 6V may damage the motor or gearbox.

What is the maximum weight the motor can handle?

- The motor can handle loads up to ~2.5 kg·cm of torque. Ensure the load does not exceed this limit.

Can I control the speed without a motor driver?

- Yes, by using a variable resistor or PWM circuit, but a motor driver is recommended for precise control.

Is the motor waterproof?

- No, the motor is not waterproof. Avoid exposing it to water or moisture.