How to Use Water Pump: Examples, Pinouts, and Specs

Design with Water Pump in Cirkit Designer

Design with Water Pump in Cirkit DesignerIntroduction

The Maruf M_02 Water Pump is a versatile and efficient device designed to move water from one location to another. It is commonly used in applications such as irrigation systems, drainage solutions, water supply systems, and small-scale DIY projects. With its compact design and reliable performance, the M_02 is suitable for both hobbyists and professionals.

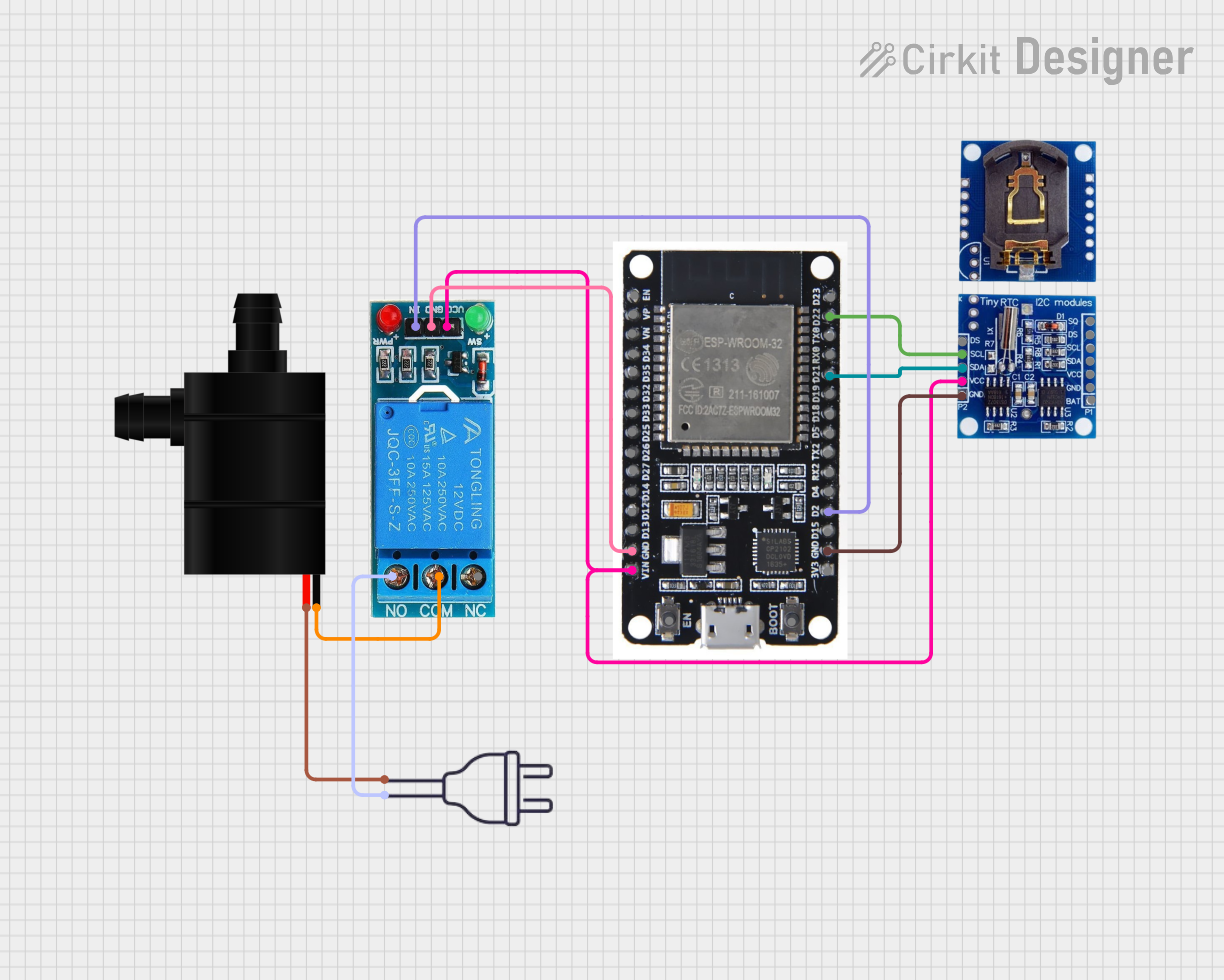

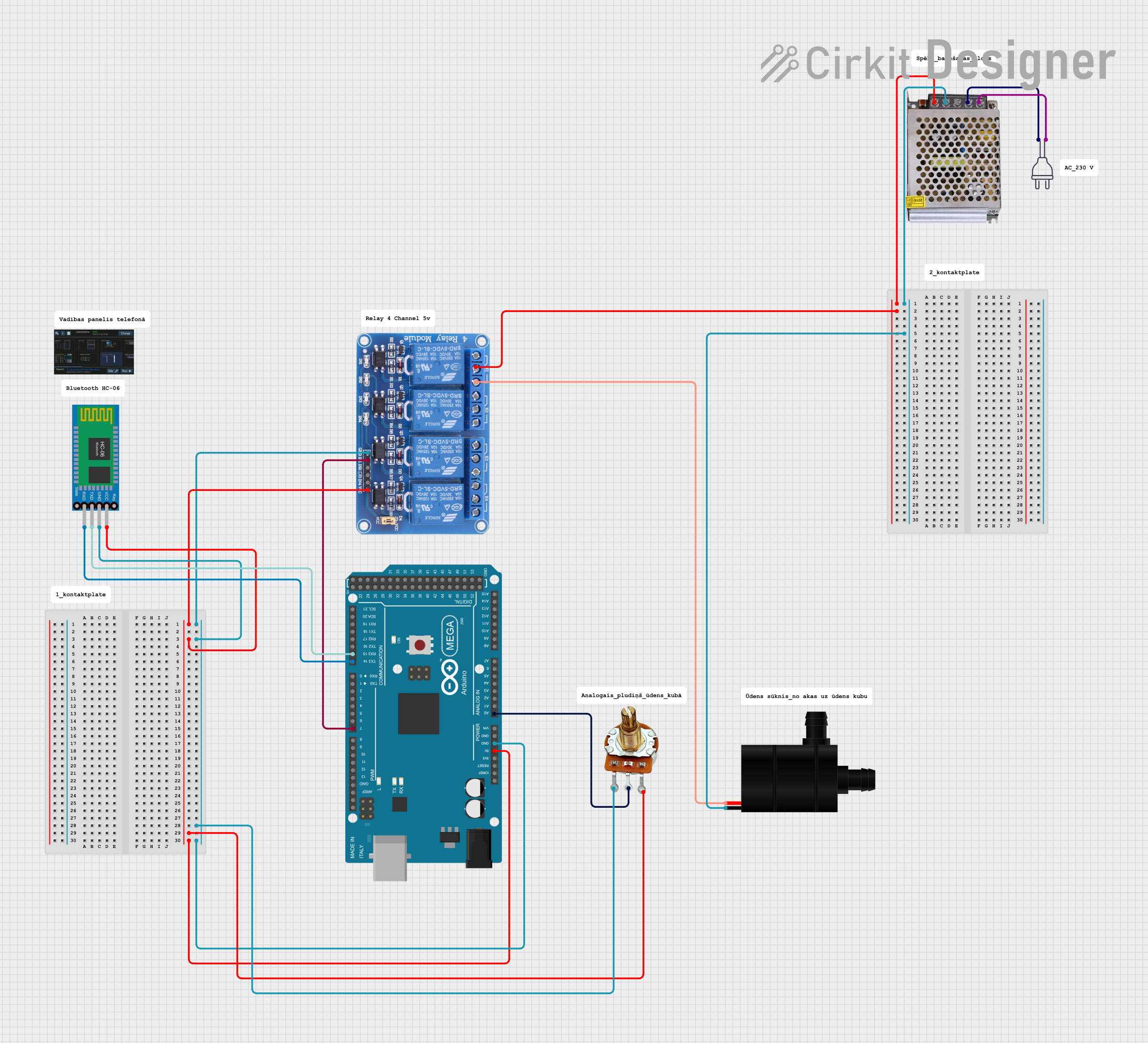

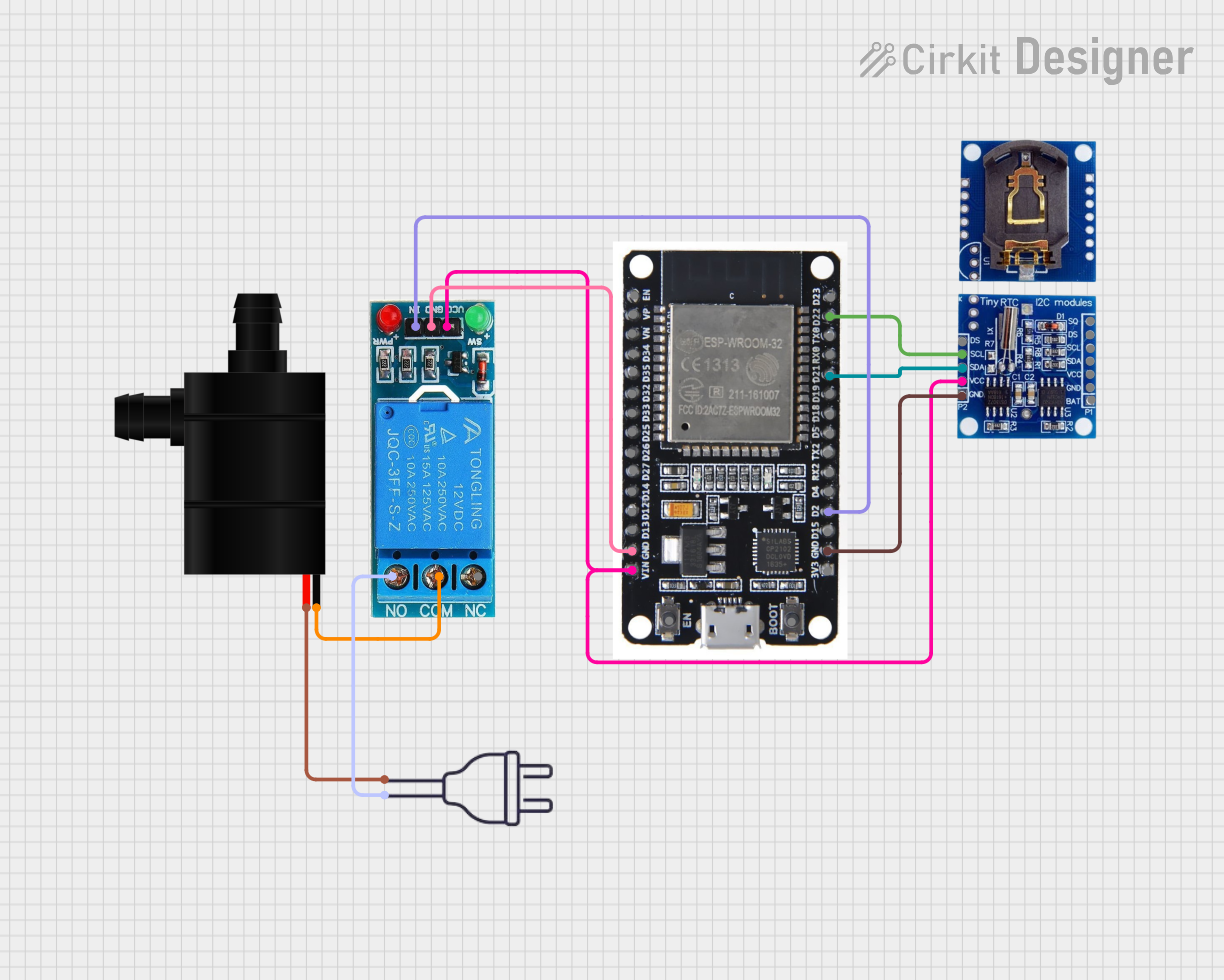

Explore Projects Built with Water Pump

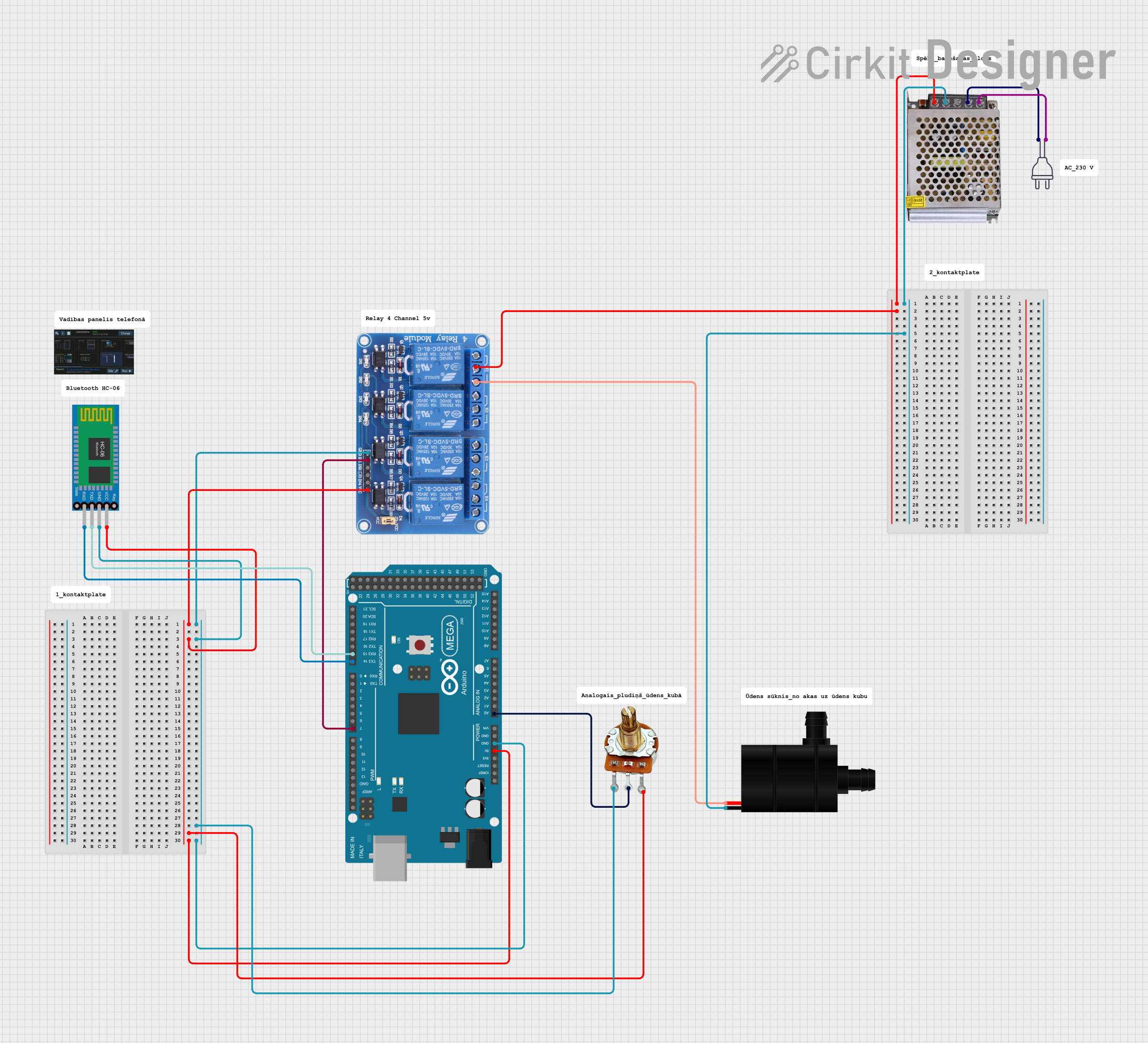

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with Water Pump

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerTechnical Specifications

Below are the key technical details and pin configuration for the Maruf M_02 Water Pump:

Key Technical Details

| Parameter | Specification |

|---|---|

| Manufacturer | Maruf |

| Part ID | M_02 |

| Operating Voltage | 6V - 12V DC |

| Operating Current | 0.5A - 1.2A |

| Maximum Flow Rate | 240 liters per hour (L/h) |

| Maximum Lift Height | 3 meters |

| Inlet/Outlet Diameter | 8 mm |

| Material | Plastic (ABS) |

| Weight | 150 grams |

| Operating Temperature | 0°C to 50°C |

Pin Configuration and Descriptions

The Maruf M_02 Water Pump has two electrical connections for operation:

| Pin Name | Description |

|---|---|

| V+ | Positive terminal for DC power input (6V - 12V) |

| GND | Ground terminal for DC power input |

Usage Instructions

How to Use the Component in a Circuit

- Power Supply: Connect the V+ pin to a DC power source (6V to 12V) and the GND pin to the ground of the power source. Ensure the power supply can provide sufficient current (at least 1.2A for peak performance).

- Water Connections: Attach hoses or pipes to the inlet and outlet ports of the pump. Ensure the connections are secure to prevent leaks.

- Mounting: Secure the pump in a stable position to minimize vibration during operation.

- Control: Optionally, you can control the pump using a relay module or a transistor circuit connected to a microcontroller like an Arduino UNO.

Important Considerations and Best Practices

- Voltage Range: Do not exceed the specified voltage range (6V - 12V) to avoid damaging the pump.

- Dry Run Prevention: Ensure the pump is always primed with water before operation. Running the pump dry can cause overheating and damage.

- Filtration: Use a filter at the inlet to prevent debris from entering the pump and causing blockages.

- Polarity: Double-check the polarity of the power connections to avoid reverse polarity damage.

- Cooling: Operate the pump within the recommended temperature range (0°C to 50°C) to ensure optimal performance.

Example: Controlling the Pump with an Arduino UNO

Below is an example of how to control the Maruf M_02 Water Pump using an Arduino UNO and a relay module:

// Example: Controlling the Maruf M_02 Water Pump with Arduino UNO

// This code turns the pump ON for 5 seconds and then OFF for 5 seconds in a loop.

const int relayPin = 7; // Pin connected to the relay module

void setup() {

pinMode(relayPin, OUTPUT); // Set the relay pin as an output

digitalWrite(relayPin, LOW); // Ensure the pump is OFF initially

}

void loop() {

digitalWrite(relayPin, HIGH); // Turn the pump ON

delay(5000); // Keep the pump ON for 5 seconds

digitalWrite(relayPin, LOW); // Turn the pump OFF

delay(5000); // Keep the pump OFF for 5 seconds

}

Note: Ensure the relay module is rated for the pump's voltage and current requirements.

Troubleshooting and FAQs

Common Issues and Solutions

| Issue | Possible Cause | Solution |

|---|---|---|

| Pump does not start | Incorrect wiring or insufficient power | Verify wiring and ensure power supply meets |

| voltage and current requirements. | ||

| Low water flow rate | Blocked inlet or outlet | Check for debris and clean the inlet/outlet. |

| Ensure hoses are not kinked or obstructed. | ||

| Pump overheats | Running dry or excessive voltage | Ensure the pump is primed with water and |

| operate within the specified voltage range. | ||

| Noise or vibration | Loose mounting or air in the system | Secure the pump and ensure proper priming. |

FAQs

Can the pump be used with liquids other than water?

The Maruf M_02 is designed for water only. Using other liquids may damage the pump or reduce its lifespan.What is the maximum distance the pump can lift water?

The pump can lift water up to a maximum height of 3 meters.Can the pump be submerged in water?

No, the Maruf M_02 is not a submersible pump. It must be used in a dry environment.How do I control the pump speed?

The pump speed can be controlled by varying the input voltage within the specified range (6V - 12V). However, ensure the voltage does not drop below 6V to maintain proper operation.

By following this documentation, you can effectively integrate and operate the Maruf M_02 Water Pump in your projects.