How to Use water pump 12v: Examples, Pinouts, and Specs

Design with water pump 12v in Cirkit Designer

Design with water pump 12v in Cirkit DesignerIntroduction

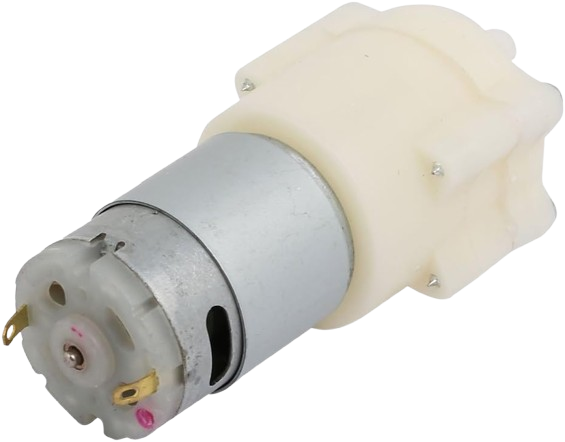

A 12V water pump is an electromechanical device designed to move water through pumping action, powered by a 12-volt DC power supply. These pumps are widely used in applications such as aquariums, fountains, hydroponic systems, and small-scale irrigation setups due to their compact size, efficiency, and ease of use.

Explore Projects Built with water pump 12v

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with water pump 12v

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerTechnical Specifications

General Specifications

- Operating Voltage: 12V DC

- Max Flow Rate: X liters per minute (l/min) (specify based on model)

- Max Head: X meters (specify based on model)

- Power Consumption: X watts (specify based on model)

- Operating Current: X amperes (specify based on model)

- Inlet/Outlet Diameter: X mm (specify based on model)

- Operating Temperature Range: X°C to Y°C (specify based on model)

- Material: Suitable for water (e.g., ABS plastic, stainless steel)

Pin Configuration and Descriptions

| Pin Number | Description | Notes |

|---|---|---|

| 1 | Positive (V+) | Connect to 12V power supply |

| 2 | Negative (GND) | Connect to ground of power supply |

Usage Instructions

Connecting the Pump to a Circuit

- Power Supply: Ensure you have a 12V DC power supply that can provide sufficient current for the pump's operation.

- Wiring: Connect the positive terminal of the pump to the positive output of the power supply, and the negative terminal to the ground.

- Tubing: Attach the appropriate water tubing to the inlet and outlet ports, ensuring a secure fit to prevent leaks.

- Priming: Before turning on the pump, fill the inlet tube with water to prime the pump and avoid running it dry, which can cause damage.

- Switching: Use a switch or relay to control the power to the pump. For automated control, you can use a microcontroller like an Arduino UNO.

Best Practices

- Avoid running the pump dry as it can lead to overheating and damage.

- Ensure the pump is securely mounted to avoid vibrations and noise.

- Use a fuse or circuit breaker to protect against overcurrent situations.

- Regularly clean the pump and check for obstructions to maintain performance.

Example Arduino UNO Code

// Define the pump control pin

const int pumpPin = 7; // Connect pump control to digital pin 7

void setup() {

pinMode(pumpPin, OUTPUT); // Set the pump pin as an output

}

void loop() {

digitalWrite(pumpPin, HIGH); // Turn on the pump

delay(10000); // Run the pump for 10 seconds

digitalWrite(pumpPin, LOW); // Turn off the pump

delay(20000); // Wait for 20 seconds

}

Note: The above code assumes the use of a relay module connected to pin 7 to control the 12V water pump.

Troubleshooting and FAQs

Common Issues

- Pump not starting: Check power supply and connections. Ensure the pump is primed with water.

- Low flow rate: Verify that there are no blockages and the tubing is not kinked. Check if the filter (if any) is clean.

- Noise or vibration: Make sure the pump is securely mounted and not touching any surfaces that could amplify noise.

FAQs

Q: Can I run the pump continuously? A: It depends on the pump's design. Some models are designed for intermittent use, while others can run continuously. Check the manufacturer's specifications.

Q: Is it safe to use the pump with non-water liquids? A: This depends on the pump's material compatibility. Check the manufacturer's recommendations for the types of liquids your pump can handle.

Q: How do I control the flow rate of the pump? A: Some pumps have an adjustable flow rate. If not, you can control the flow using a valve on the outlet or by adjusting the voltage with a PWM controller.

Q: What should I do if the pump is overheating? A: Turn off the pump immediately and check for any obstructions or reasons for the pump to work harder than normal. Ensure it is not running dry and that the ambient temperature is within the operating range.

For further assistance, consult the manufacturer's technical support.