How to Use Fluxgate: Examples, Pinouts, and Specs

Design with Fluxgate in Cirkit Designer

Design with Fluxgate in Cirkit DesignerIntroduction

A fluxgate is a type of magnetic sensor used to measure the strength and direction of magnetic fields. It operates by utilizing a core material that becomes magnetized in response to an external magnetic field. This property allows for precise and reliable measurements, making fluxgate sensors ideal for applications such as navigation, geophysical surveys, and industrial monitoring. Their high sensitivity and ability to detect weak magnetic fields make them indispensable in scientific research and aerospace systems.

Explore Projects Built with Fluxgate

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with Fluxgate

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerTechnical Specifications

Below are the key technical details and pin configuration for a typical fluxgate sensor:

Key Technical Details

- Operating Voltage: 5V to 12V DC (varies by model)

- Current Consumption: 10mA to 50mA

- Measurement Range: ±100 µT to ±1 mT (microteslas to milliteslas)

- Resolution: 0.1 µT or better

- Frequency Response: DC to 1 kHz

- Output Signal: Analog voltage or digital signal (depending on the model)

- Operating Temperature: -40°C to +85°C

- Core Material: High-permeability ferromagnetic alloy

- Dimensions: Typically compact, e.g., 20mm x 20mm x 10mm (varies by model)

Pin Configuration and Descriptions

The pin configuration of a fluxgate sensor may vary depending on the manufacturer, but a common configuration is as follows:

| Pin Number | Pin Name | Description |

|---|---|---|

| 1 | VCC | Power supply input (5V to 12V DC). |

| 2 | GND | Ground connection. |

| 3 | Signal Output | Analog or digital output representing the measured magnetic field strength. |

| 4 | Enable/Control | Optional pin to enable or disable the sensor (not present on all models). |

Usage Instructions

How to Use the Fluxgate in a Circuit

- Power Supply: Connect the VCC pin to a stable DC power source (5V or 12V, depending on the sensor's specifications). Connect the GND pin to the ground of the power supply.

- Signal Output: Connect the Signal Output pin to an analog input pin of a microcontroller (e.g., Arduino) or to an oscilloscope for direct measurement.

- Enable/Control Pin: If the sensor has an Enable/Control pin, ensure it is connected to the appropriate logic level (e.g., HIGH to enable, LOW to disable).

- Magnetic Field Measurement: Place the fluxgate sensor in the environment where the magnetic field is to be measured. Ensure the sensor is oriented correctly to measure the desired field component (e.g., X, Y, or Z axis).

Important Considerations and Best Practices

- Shielding: Avoid placing the fluxgate sensor near strong magnetic sources or ferromagnetic materials, as these can interfere with measurements.

- Calibration: Periodically calibrate the sensor to ensure accurate readings, especially in environments with fluctuating magnetic fields.

- Temperature Effects: Be mindful of the operating temperature range, as extreme temperatures can affect the sensor's performance.

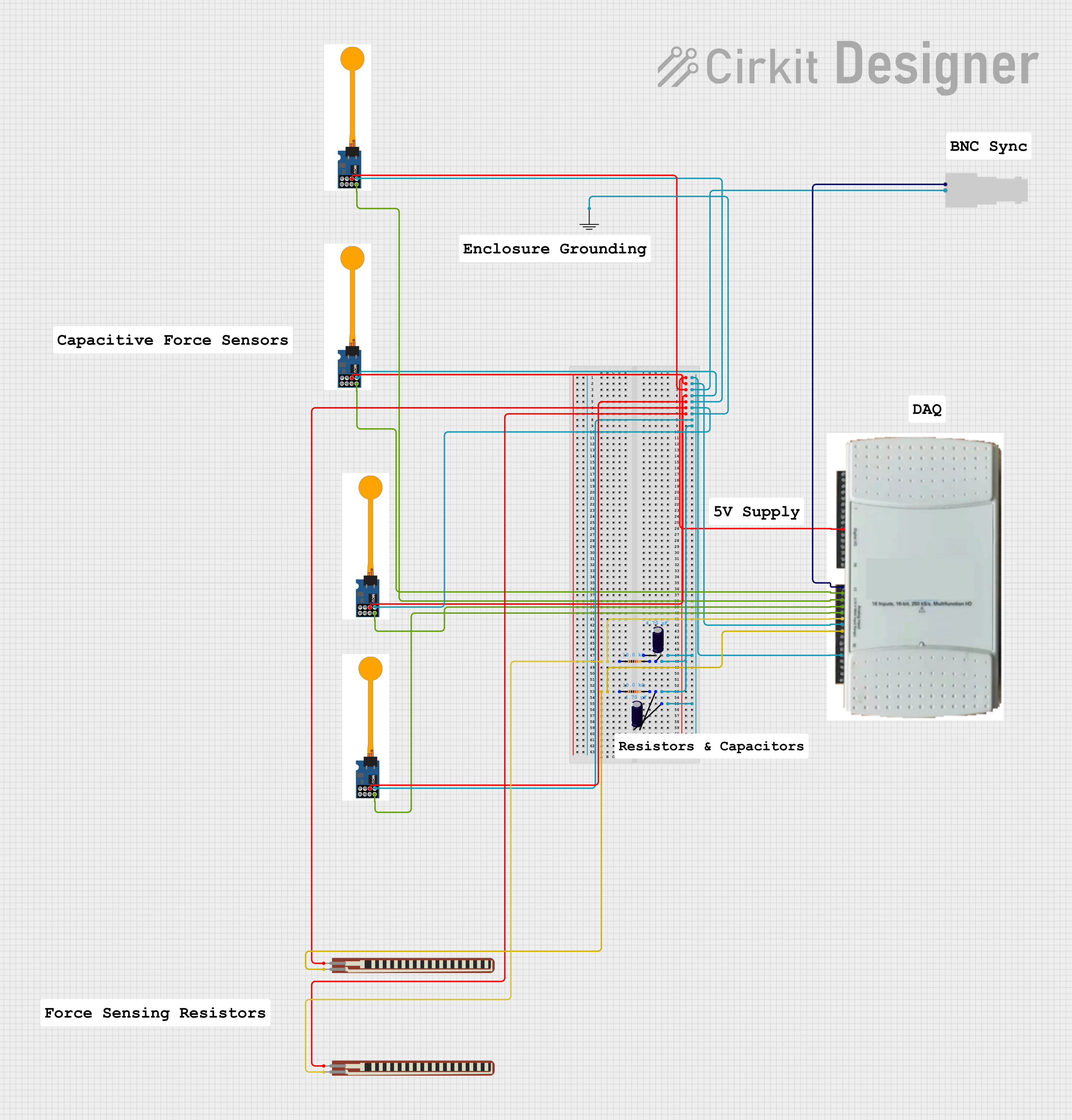

- Noise Filtering: Use appropriate filtering techniques (e.g., low-pass filters) to reduce noise in the output signal.

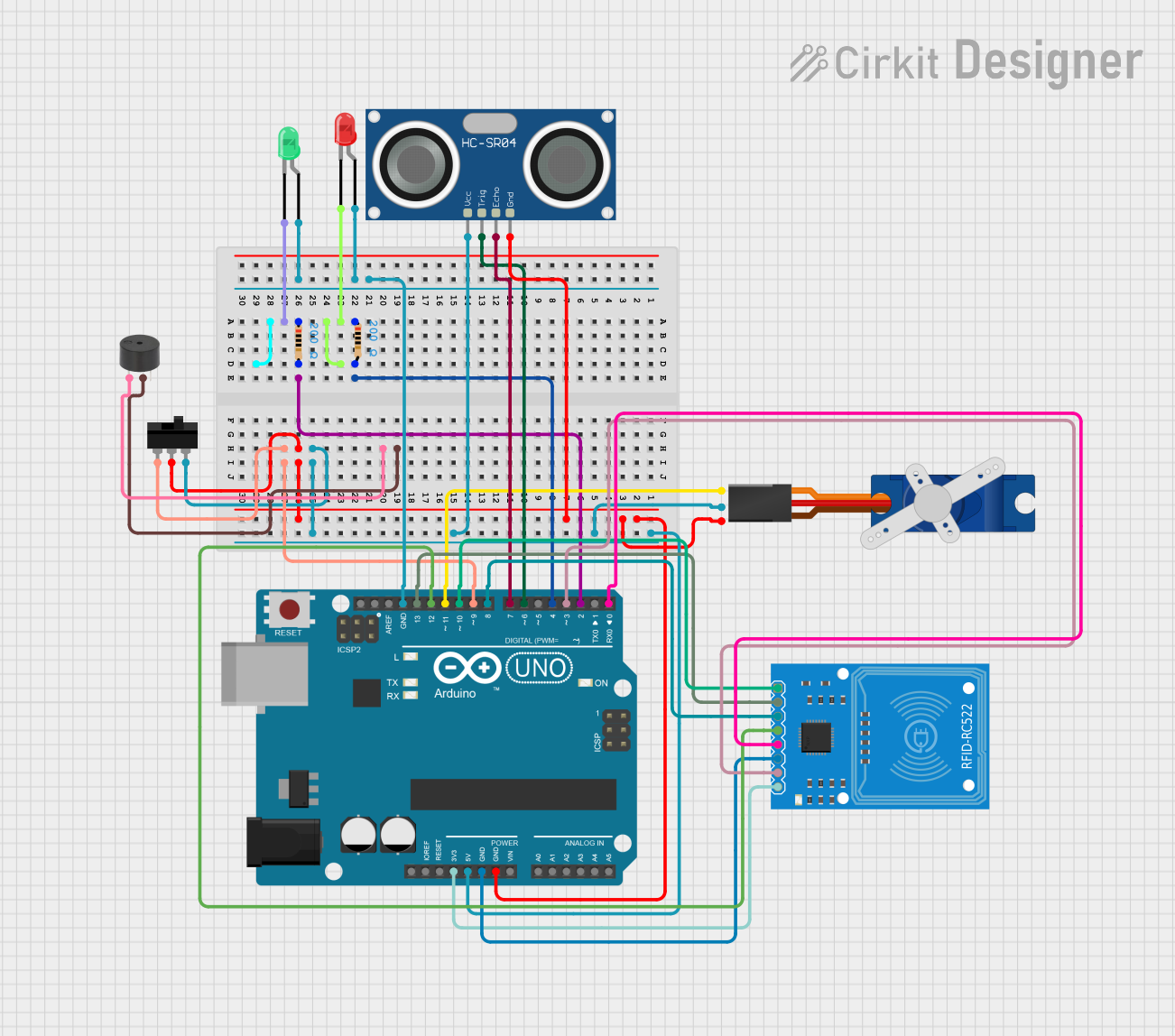

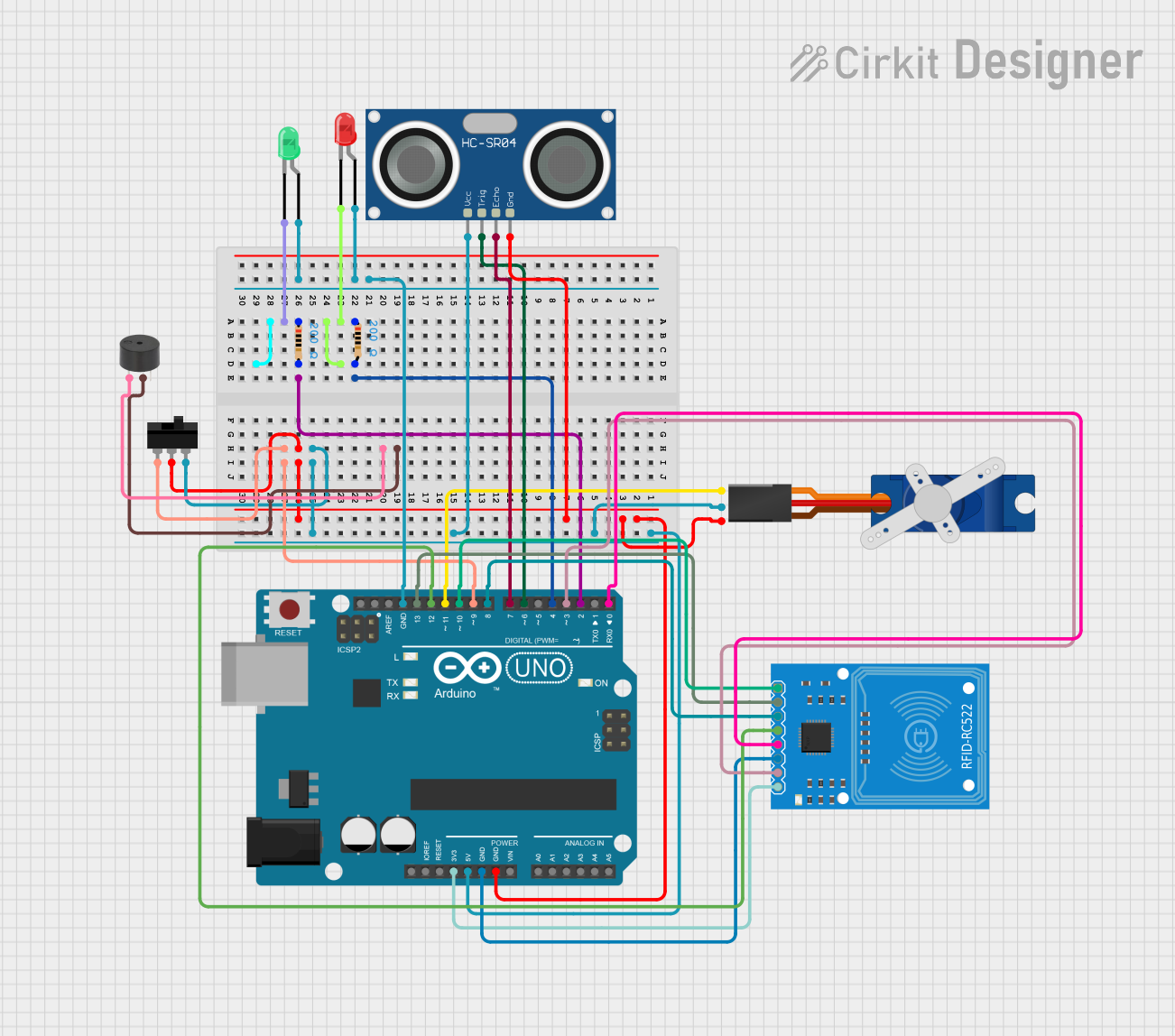

Example: Connecting a Fluxgate to an Arduino UNO

Below is an example of how to connect and read data from a fluxgate sensor using an Arduino UNO:

Circuit Diagram

- Connect the VCC pin of the fluxgate to the 5V pin on the Arduino.

- Connect the GND pin of the fluxgate to the GND pin on the Arduino.

- Connect the Signal Output pin of the fluxgate to the A0 analog input pin on the Arduino.

Arduino Code

// Fluxgate Sensor Example with Arduino UNO

// Reads the analog output of the fluxgate sensor and prints the value to the Serial Monitor.

const int fluxgatePin = A0; // Analog pin connected to the fluxgate's Signal Output

void setup() {

Serial.begin(9600); // Initialize serial communication at 9600 baud

pinMode(fluxgatePin, INPUT); // Set the fluxgate pin as input

}

void loop() {

int sensorValue = analogRead(fluxgatePin); // Read the analog value from the sensor

float voltage = sensorValue * (5.0 / 1023.0); // Convert the reading to voltage

// Print the voltage to the Serial Monitor

Serial.print("Fluxgate Voltage: ");

Serial.print(voltage);

Serial.println(" V");

delay(500); // Wait for 500ms before the next reading

}

Troubleshooting and FAQs

Common Issues and Solutions

No Output Signal:

- Cause: Incorrect wiring or insufficient power supply.

- Solution: Double-check all connections and ensure the power supply meets the sensor's requirements.

Inconsistent Readings:

- Cause: External magnetic interference or improper sensor orientation.

- Solution: Move the sensor away from magnetic sources and ensure it is properly aligned.

High Noise in Output:

- Cause: Electrical noise or lack of filtering.

- Solution: Add a low-pass filter to the output signal or use shielded cables.

Sensor Overheating:

- Cause: Operating outside the specified voltage or temperature range.

- Solution: Verify the power supply voltage and ensure the sensor is within the recommended temperature range.

FAQs

Q: Can the fluxgate sensor measure AC magnetic fields?

- A: Yes, fluxgate sensors can measure AC magnetic fields, but their frequency response is typically limited to around 1 kHz.

Q: How do I calibrate a fluxgate sensor?

- A: Calibration involves placing the sensor in a known magnetic field and adjusting the output to match the expected value. Refer to the manufacturer's guidelines for detailed calibration procedures.

Q: Can I use a fluxgate sensor underwater?

- A: Only if the sensor is specifically designed for waterproof or underwater applications. Check the product specifications before use.

Q: What is the lifespan of a fluxgate sensor?

- A: Fluxgate sensors are highly durable and can last for many years if used within their specified operating conditions.