How to Use Big Easy Driver ROB-11876: Examples, Pinouts, and Specs

Design with Big Easy Driver ROB-11876 in Cirkit Designer

Design with Big Easy Driver ROB-11876 in Cirkit DesignerIntroduction

The Big Easy Driver (BED) ROB-11876 is a full-featured stepper motor driver board designed to control bipolar stepper motors. Based on the Allegro A4988 microstepping driver, the BED allows for fine control of stepper motors with an adjustable current output and seven different step resolutions. It is an ideal choice for applications requiring precise motion control such as 3D printers, CNC machines, and robotics.

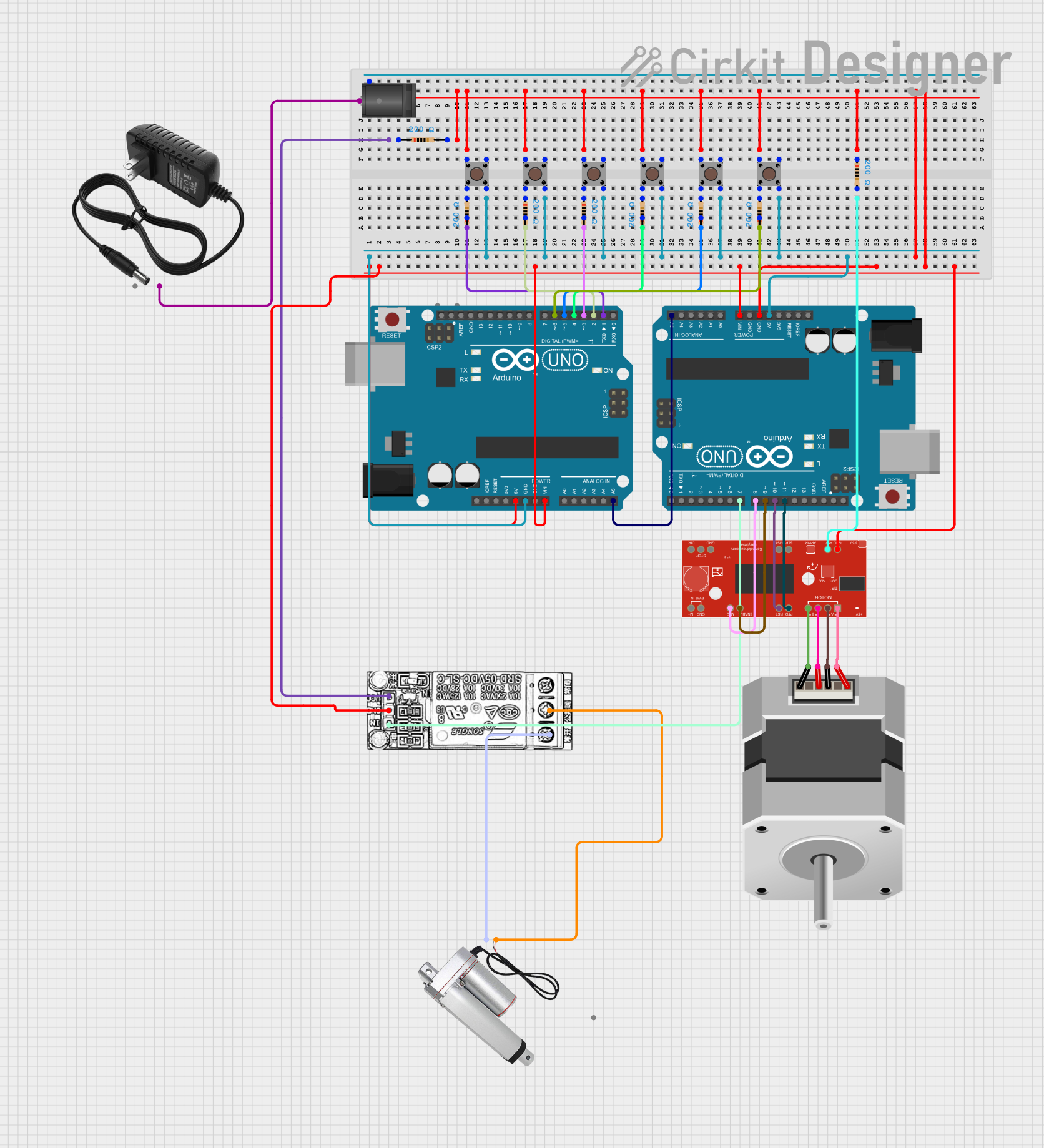

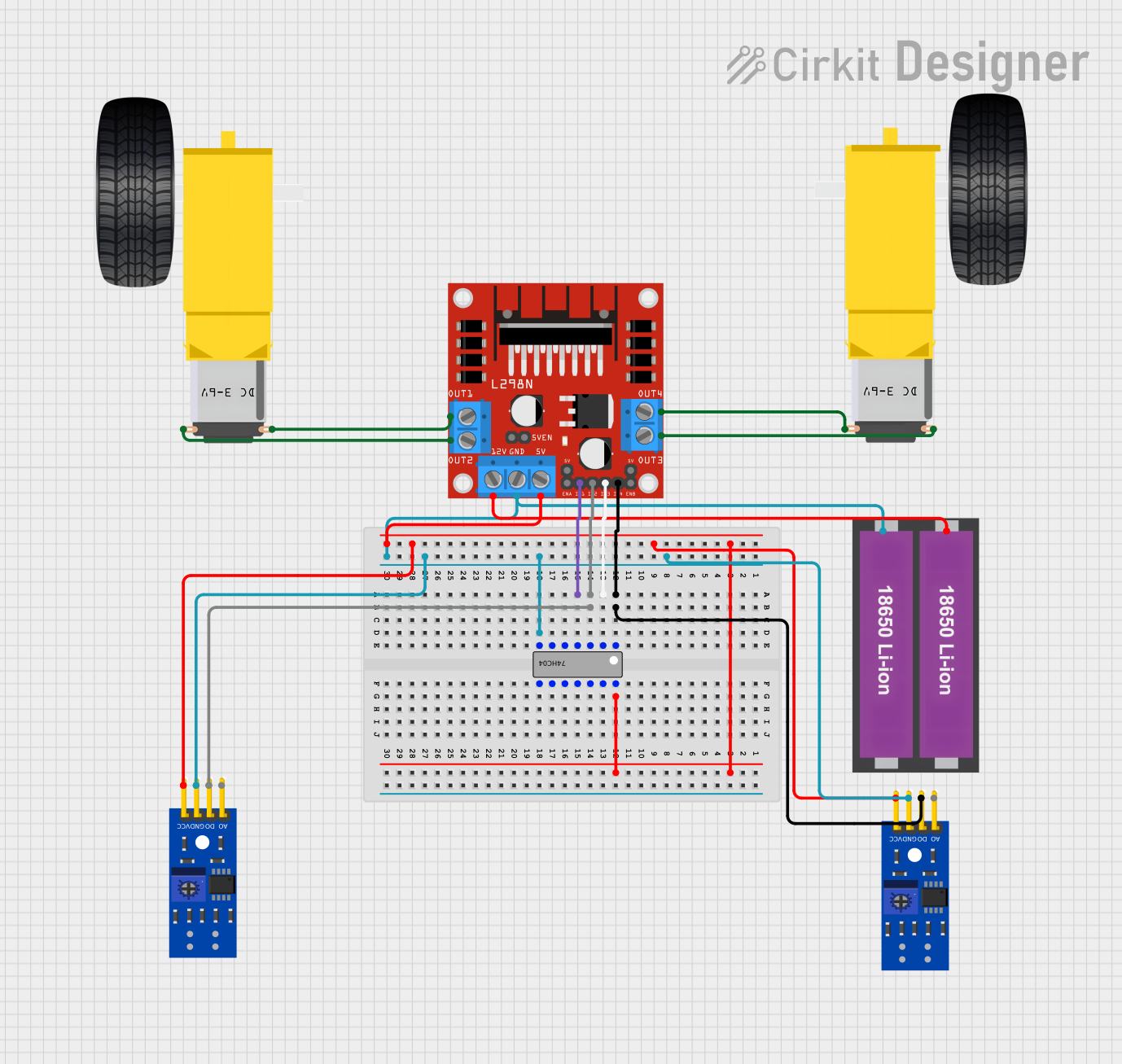

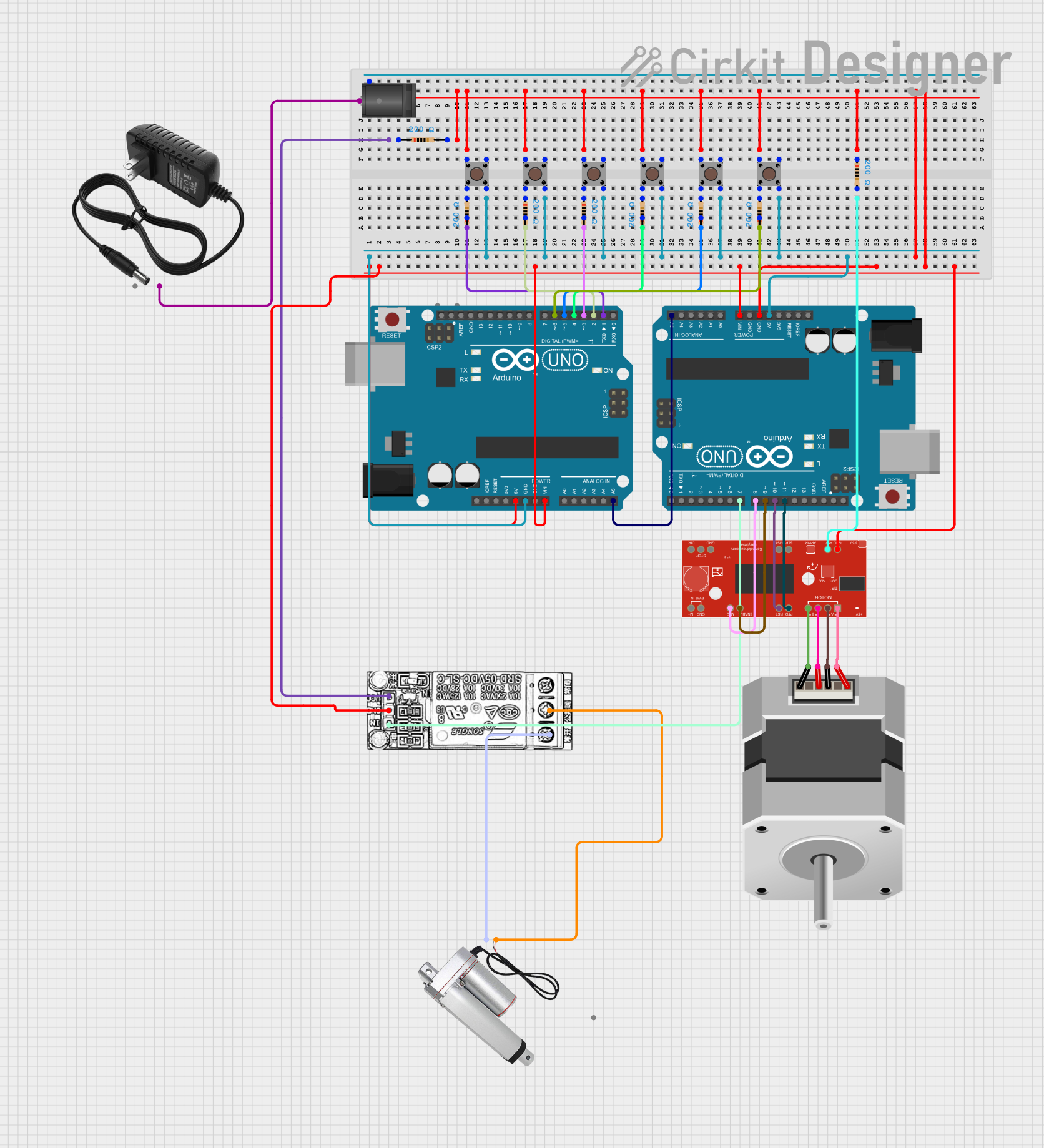

Explore Projects Built with Big Easy Driver ROB-11876

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with Big Easy Driver ROB-11876

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications and Use Cases

- 3D Printers

- CNC Machines

- Robotic Arms

- Precision Positioning Systems

- Automated Equipment

Technical Specifications

Key Technical Details

- Maximum Current: 2A per phase (with sufficient additional cooling)

- Voltage Range: 8V to 35V

- Logic Input Voltage Range: 3V to 5.5V

- Step Resolutions: Full, 1/2, 1/4, 1/8, 1/16, 1/32

- Dimensions: 1.35in x 1.95in (34.3mm x 49.5mm)

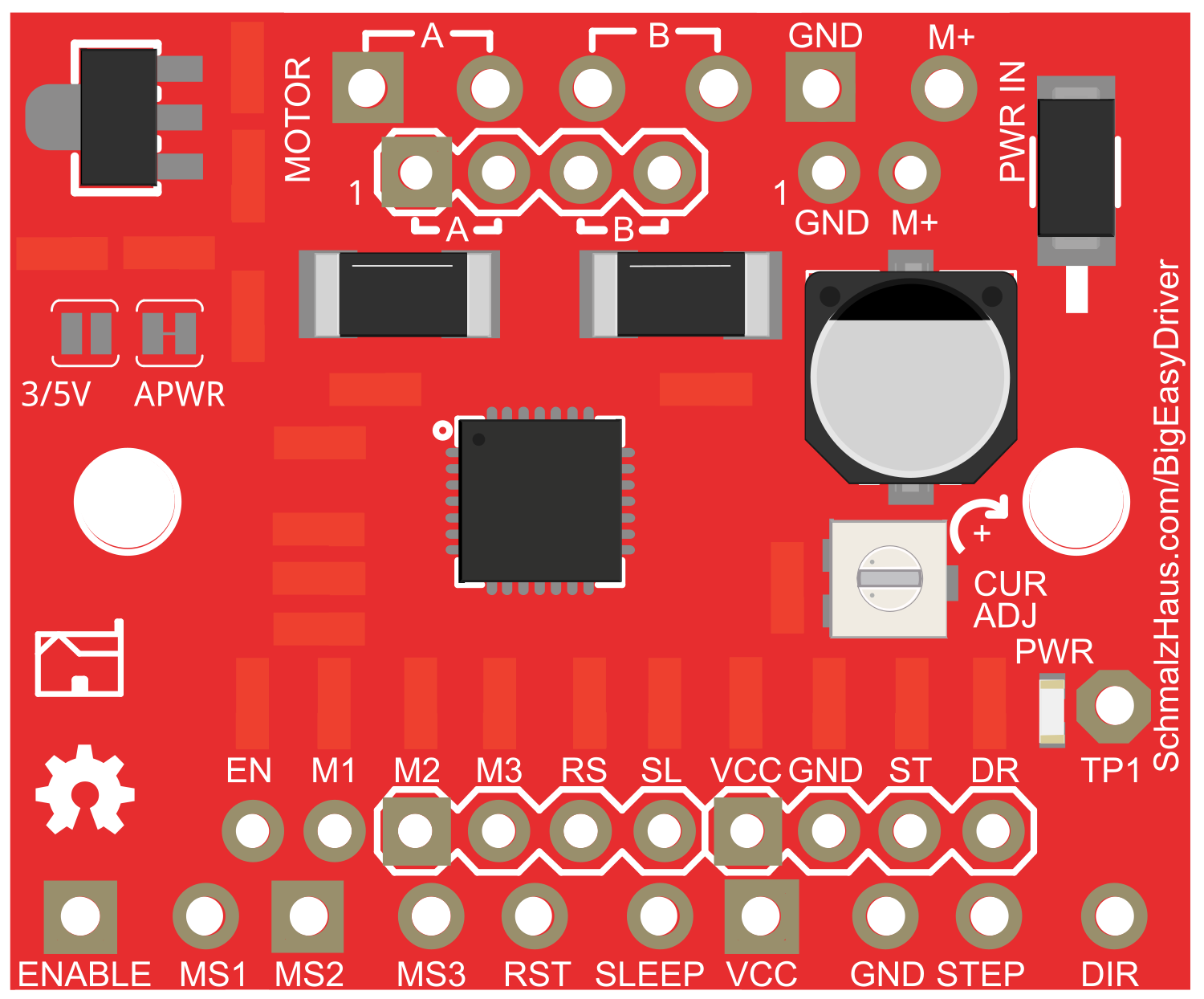

Pin Configuration and Descriptions

| Pin Name | Description |

|---|---|

| GND | Ground connection |

| M+ | Motor power supply (8V to 35V) |

| AOUT1/AOUT2 | Motor coil A connections |

| BOUT1/BOUT2 | Motor coil B connections |

| STEP | Step input (pulses from the controller) |

| DIR | Direction input (high for one direction, low for the other) |

| MS1, MS2, MS3 | Microstep resolution select inputs |

| ENABLE | Enables (low) or disables (high) the FET outputs |

| SLEEP | Logic low puts the board into low power sleep mode |

| RESET | Logic low resets the internal translator and disables all outputs |

| PFD | Sets the percentage of fast decay in mixed decay mode |

| VDD | Logic supply voltage (should be the same as the logic input voltage) |

| 5VOUT | Regulated 5V output (up to 50mA for powering logic circuitry) |

Usage Instructions

How to Use the Component in a Circuit

Power Connections:

- Connect the motor power supply to the M+ and GND pins.

- Ensure that the power supply voltage is within the specified range (8V to 35V).

Motor Connections:

- Connect the stepper motor coils to the AOUT1/AOUT2 and BOUT1/BOUT2.

Control Connections:

- Connect the STEP and DIR pins to the appropriate outputs from your microcontroller.

- Set the MS1, MS2, and MS3 pins to the desired microstepping resolution.

Logic Power:

- Provide 3V to 5.5V to the VDD pin for the logic power supply.

Enable and Sleep Modes:

- Use the ENABLE pin to turn the driver on and off.

- Use the SLEEP pin to put the driver into a low power state when not in use.

Important Considerations and Best Practices

- Always ensure the power supply is turned off before making any connections.

- Use a heatsink if the current setting is above 1A to prevent overheating.

- Adjust the current limit to match the specifications of your stepper motor.

- Avoid disconnecting the motor while the driver is powered to prevent damage.

- Use decoupling capacitors close to the board to minimize voltage spikes.

Example Code for Arduino UNO

// Define step and direction pins

#define STEP_PIN 2

#define DIR_PIN 3

void setup() {

pinMode(STEP_PIN, OUTPUT);

pinMode(DIR_PIN, OUTPUT);

}

void loop() {

digitalWrite(DIR_PIN, HIGH); // Set direction

for (int i = 0; i < 200; i++) { // Move 200 steps in one direction

digitalWrite(STEP_PIN, HIGH);

delay(1);

digitalWrite(STEP_PIN, LOW);

delay(1);

}

delay(1000); // Wait for a second

digitalWrite(DIR_PIN, LOW); // Change direction

for (int i = 0; i < 200; i++) { // Move 200 steps in the other direction

digitalWrite(STEP_PIN, HIGH);

delay(1);

digitalWrite(STEP_PIN, LOW);

delay(1);

}

delay(1000); // Wait for a second

}

Troubleshooting and FAQs

Common Issues

- Motor not moving: Check power supply, connections, and ensure the ENABLE pin is set correctly.

- Overheating: Ensure proper current limit setting and use a heatsink if necessary.

- Inconsistent movement: Verify microstep settings and that the power supply can handle the current draw.

Solutions and Tips for Troubleshooting

- Double-check wiring against the pinout table.

- Use a multimeter to verify the voltage at the motor and logic power supply.

- If the motor vibrates but does not turn, check for a misconnection in the motor wiring.

- Ensure the firmware on the microcontroller is correctly configured for the step resolution.

FAQs

Q: Can I use the Big Easy Driver with a 5V stepper motor? A: Yes, as long as the motor's voltage rating is within the BED's voltage range and the current limit is properly set.

Q: How do I adjust the current limit? A: Turn the potentiometer on the board while measuring the voltage on the REF pin, or follow the detailed instructions in the BED datasheet.

Q: What is the maximum step frequency for the BED? A: The maximum step frequency depends on the motor and power supply, but the A4988 chip can handle up to 200kHz under ideal conditions.

Q: Can I run two stepper motors off one BED? A: No, the BED is designed to control one bipolar stepper motor. Use one driver per motor.