How to Use pressure sensor: Examples, Pinouts, and Specs

Design with pressure sensor in Cirkit Designer

Design with pressure sensor in Cirkit DesignerIntroduction

A pressure sensor is a device that measures the pressure of gases or liquids and converts the physical pressure into an electrical signal for monitoring and control applications. These sensors are widely used in various industries, including automotive, medical, aerospace, and industrial automation. They play a critical role in systems that require precise pressure monitoring, such as HVAC systems, fluid control systems, and weather monitoring equipment.

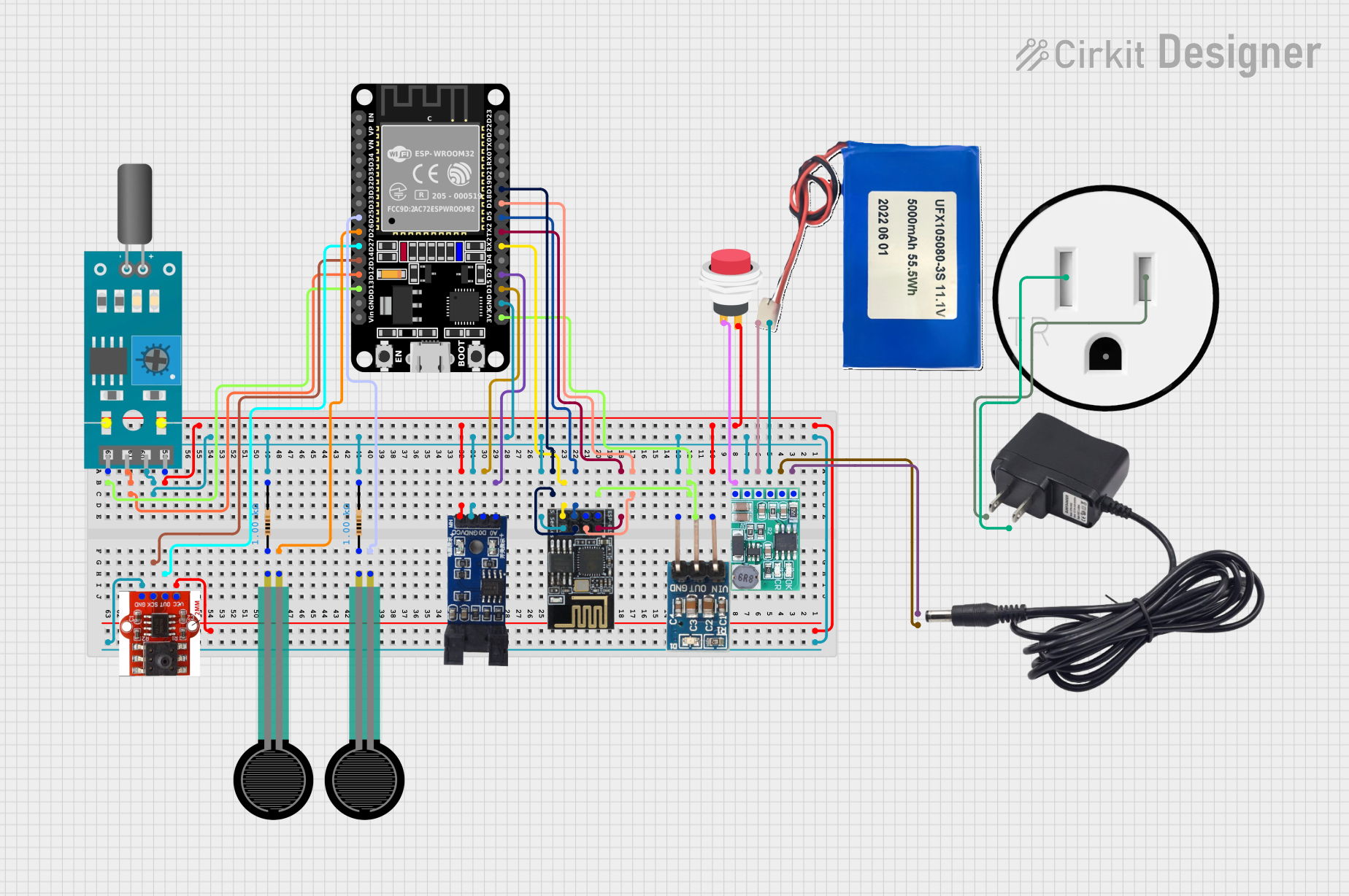

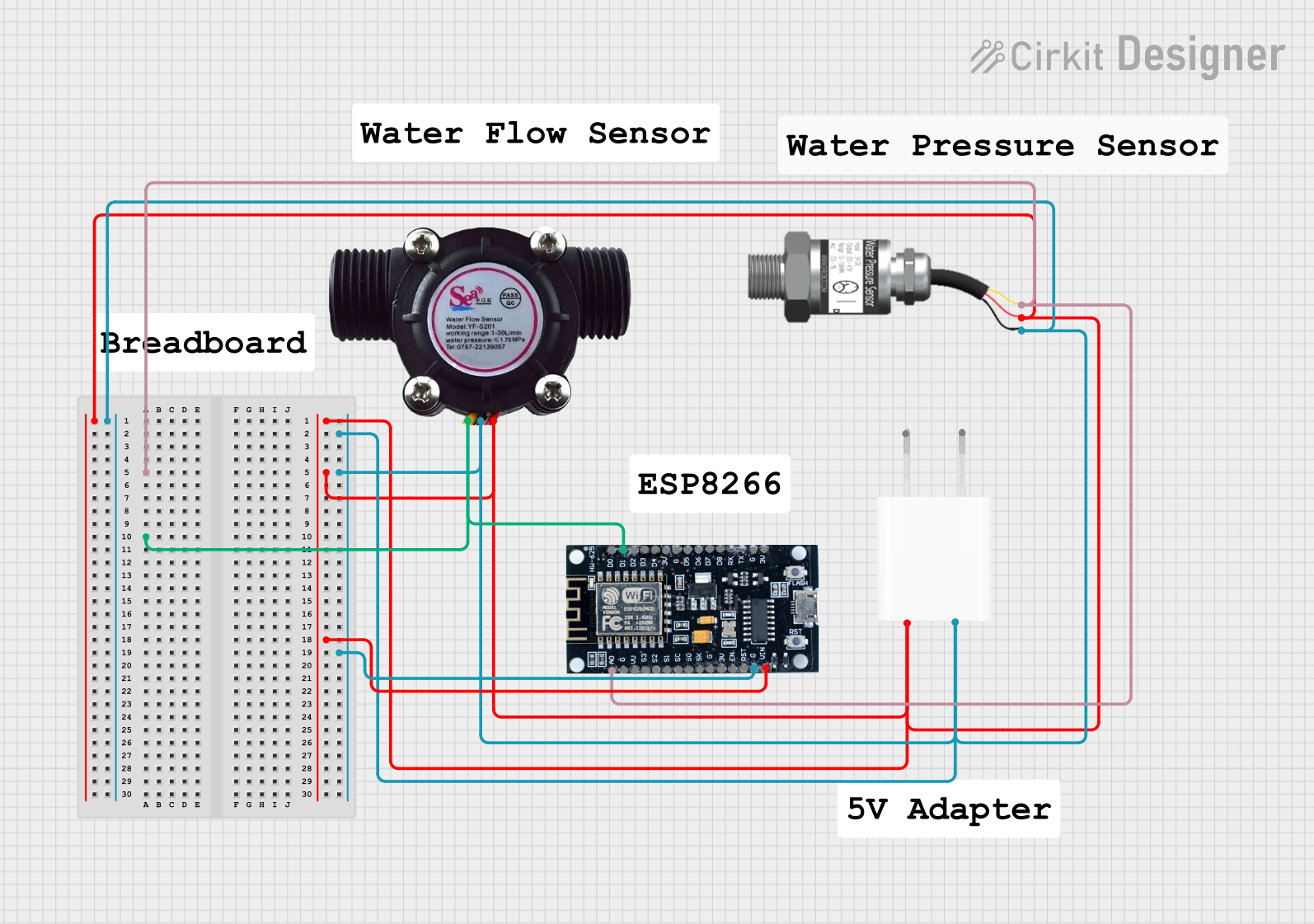

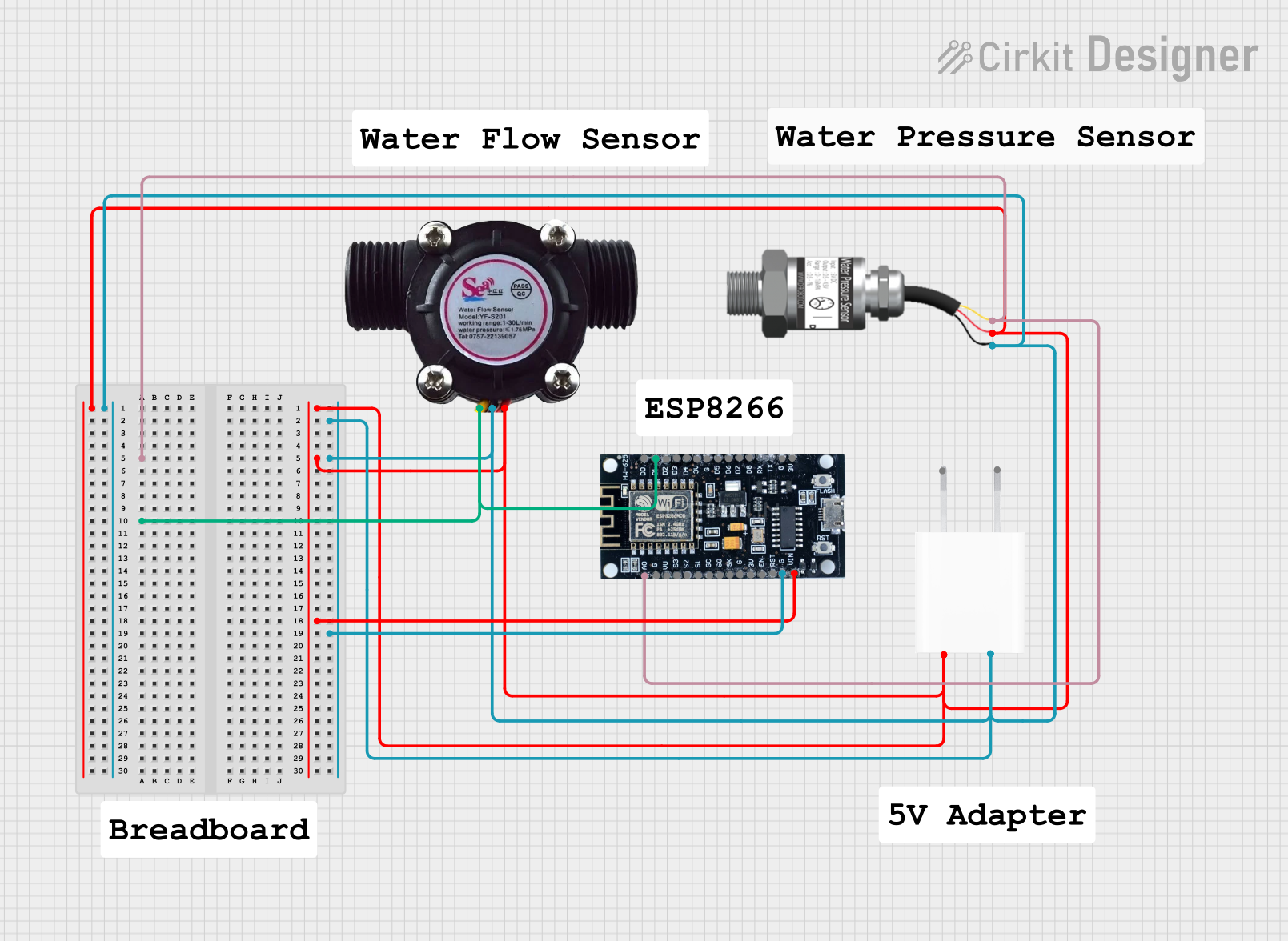

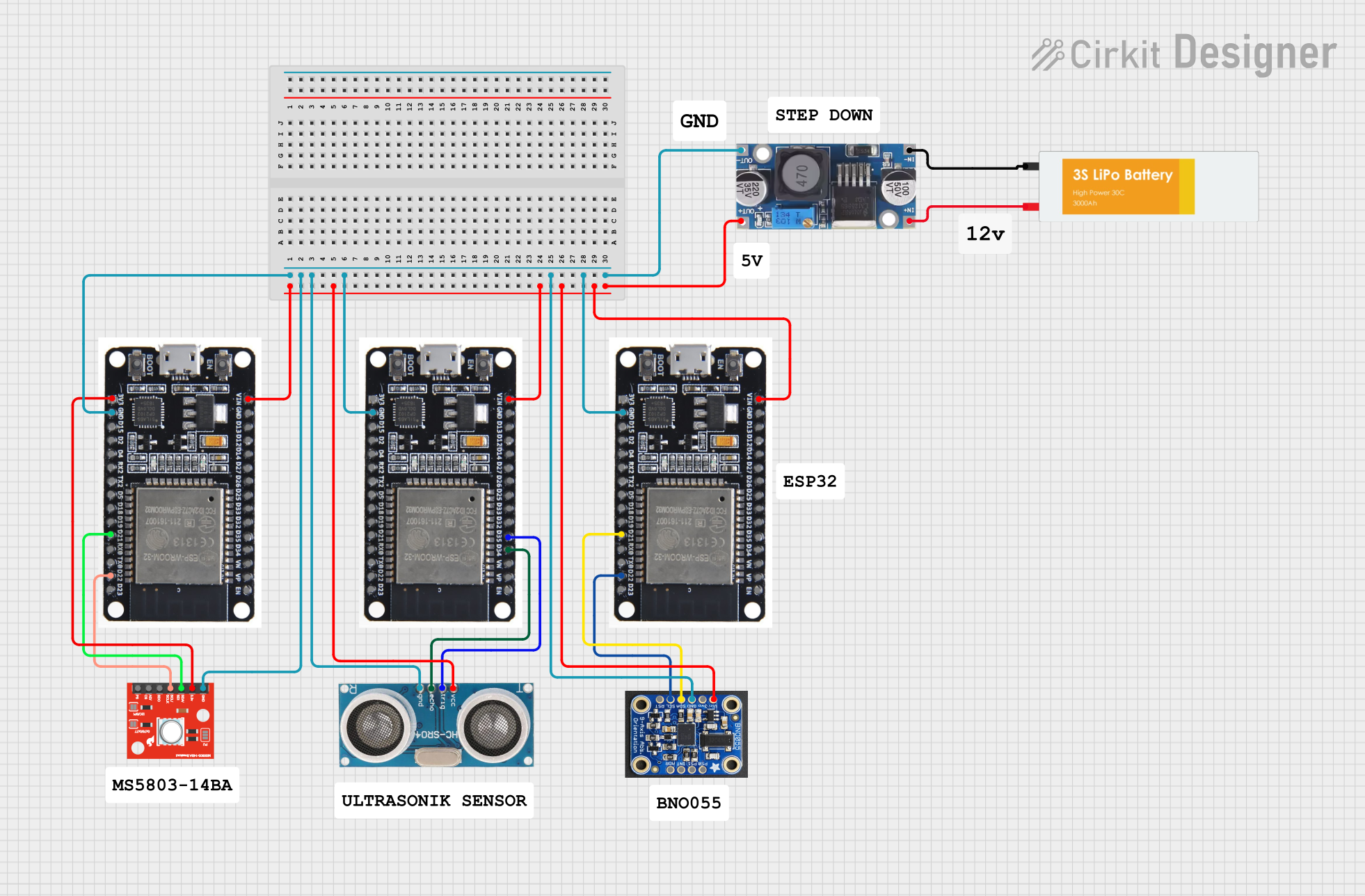

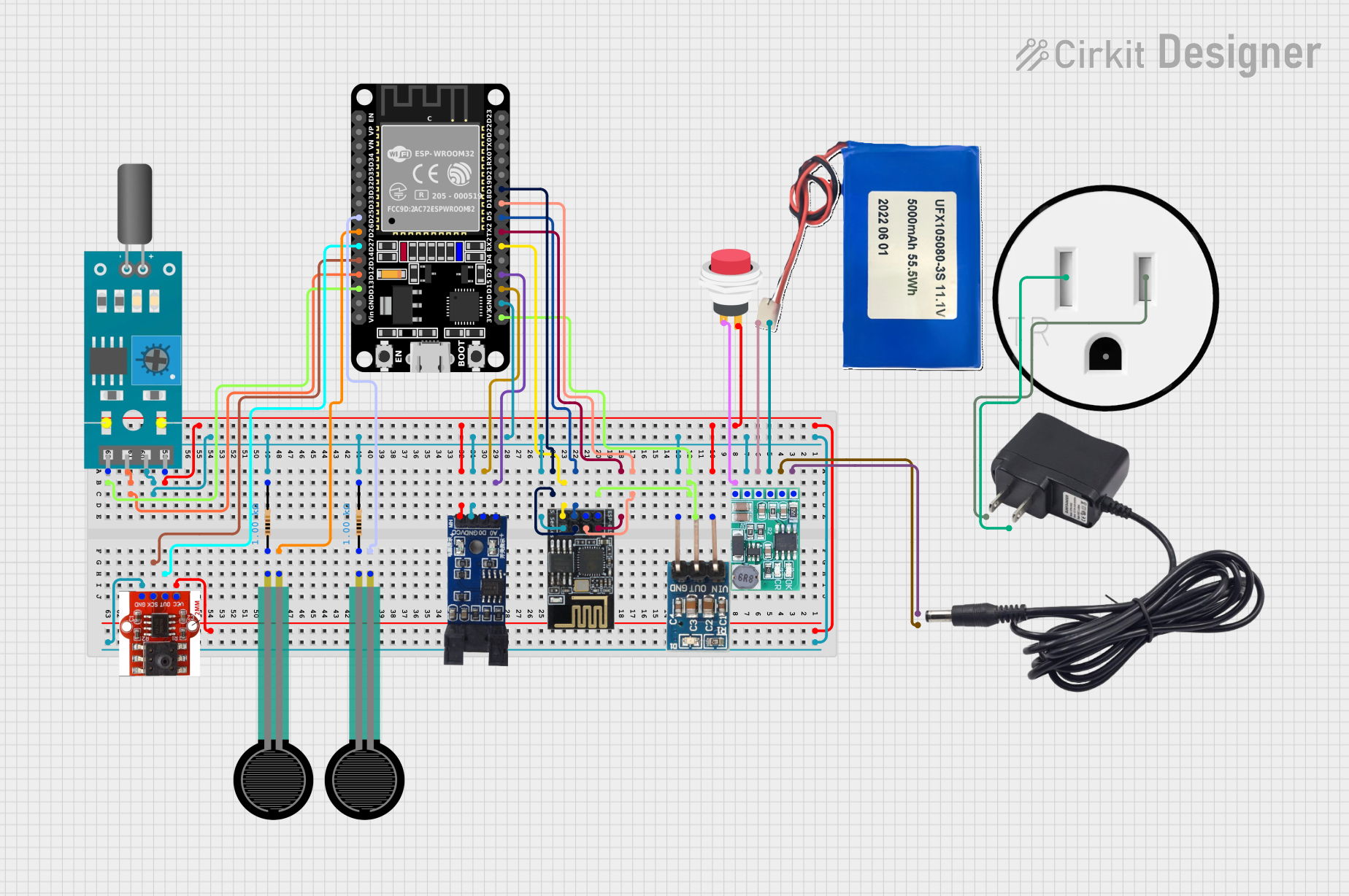

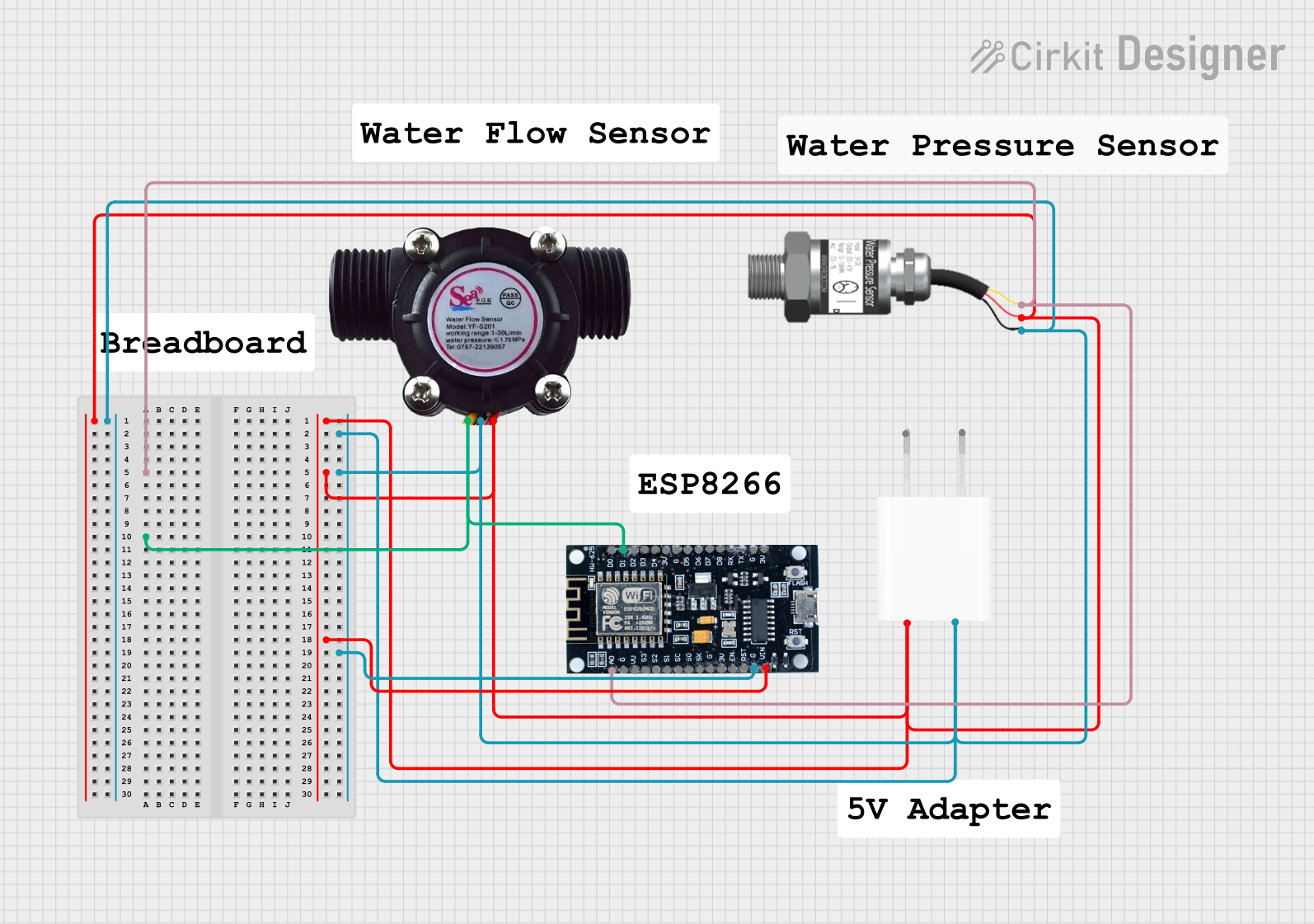

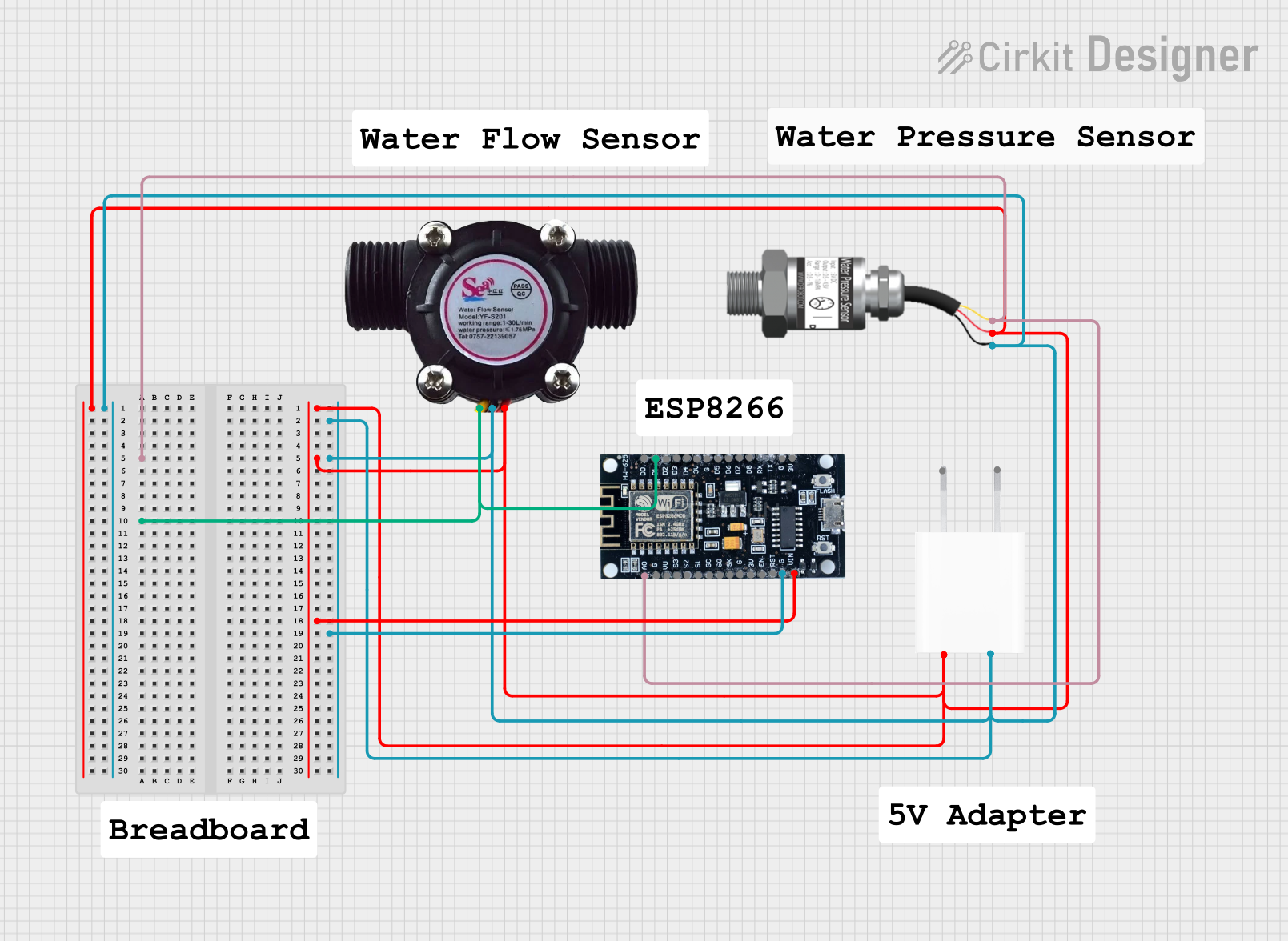

Explore Projects Built with pressure sensor

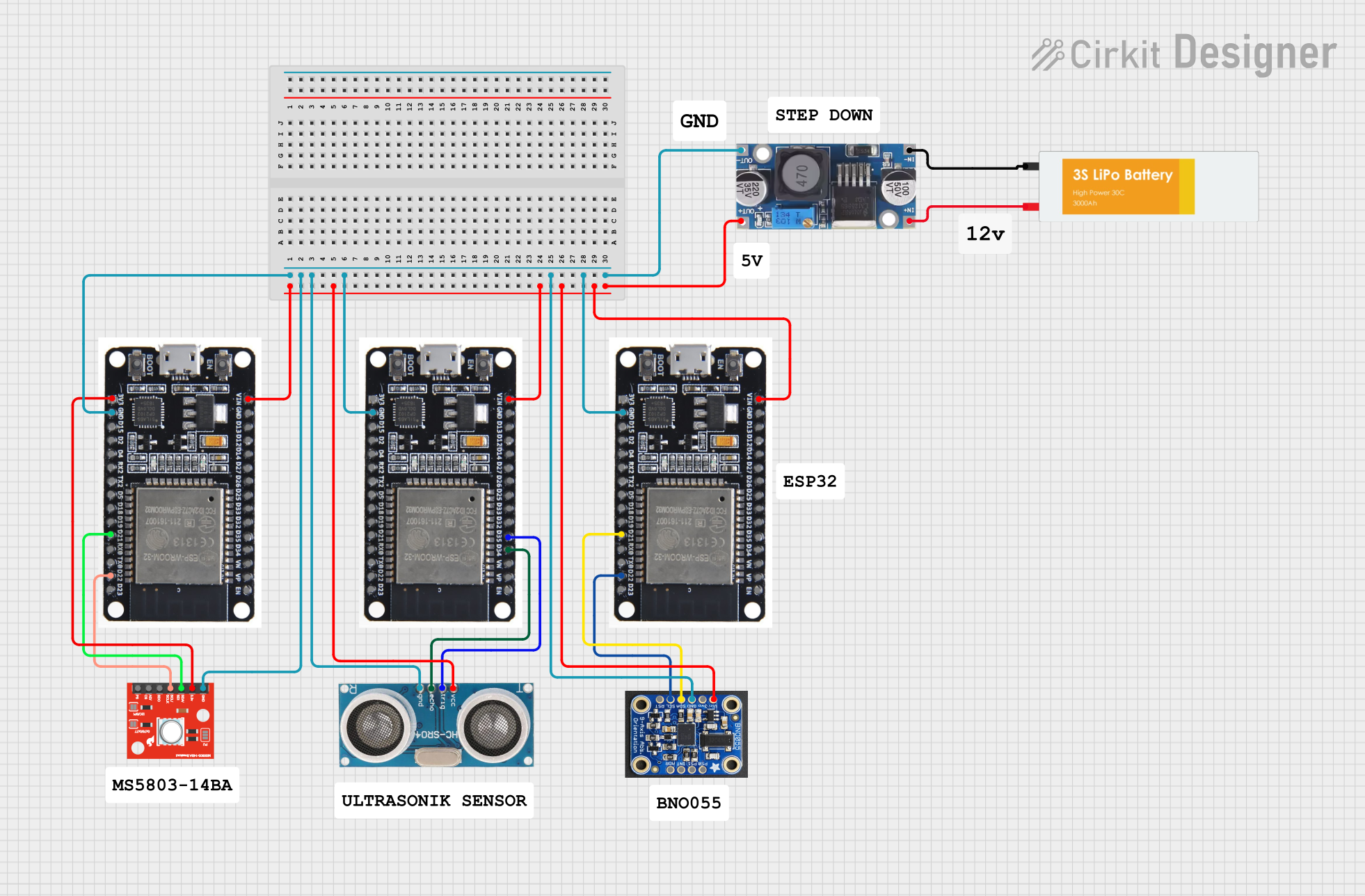

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with pressure sensor

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications and Use Cases

- Automotive: Tire pressure monitoring systems (TPMS), engine control systems.

- Medical: Blood pressure monitors, respiratory devices.

- Industrial: Hydraulic and pneumatic systems, leak detection.

- Aerospace: Altitude measurement, cabin pressure monitoring.

- Consumer Electronics: Weather stations, barometric pressure sensors in smartphones.

Technical Specifications

Below are the general technical specifications for a typical pressure sensor. Note that specific models may vary, so always refer to the datasheet of the sensor you are using.

Key Technical Details

- Pressure Range: 0 to 100 psi (varies by model)

- Output Signal: Analog (e.g., 0.5V to 4.5V) or Digital (e.g., I2C, SPI)

- Supply Voltage: 3.3V or 5V

- Accuracy: ±1% of full scale

- Operating Temperature: -40°C to 125°C

- Response Time: <1 ms

- Media Compatibility: Air, non-corrosive gases, and liquids

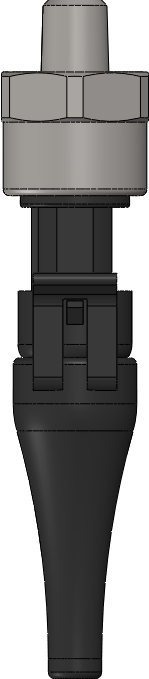

Pin Configuration and Descriptions

The pin configuration for a typical 3-pin analog pressure sensor is as follows:

| Pin | Name | Description |

|---|---|---|

| 1 | VCC | Power supply input (3.3V or 5V, depending on model) |

| 2 | OUT | Analog output signal proportional to pressure |

| 3 | GND | Ground connection |

For a digital pressure sensor with I2C communication, the pin configuration may look like this:

| Pin | Name | Description |

|---|---|---|

| 1 | VCC | Power supply input (3.3V or 5V, depending on model) |

| 2 | SDA | Serial Data Line for I2C communication |

| 3 | SCL | Serial Clock Line for I2C communication |

| 4 | GND | Ground connection |

Usage Instructions

How to Use the Component in a Circuit

- Power the Sensor: Connect the VCC pin to a 3.3V or 5V power source, depending on the sensor's specifications. Connect the GND pin to the ground of your circuit.

- Read the Output:

- For analog sensors, connect the OUT pin to an analog input pin of your microcontroller (e.g., Arduino).

- For digital sensors, connect the SDA and SCL pins to the corresponding I2C pins on your microcontroller.

- Calibrate the Sensor: Some sensors may require calibration to ensure accurate readings. Refer to the sensor's datasheet for calibration instructions.

- Process the Data: Use the microcontroller to read and process the pressure data. For analog sensors, convert the voltage reading to pressure using the sensor's transfer function. For digital sensors, use the appropriate communication protocol to retrieve the pressure data.

Important Considerations and Best Practices

- Power Supply: Ensure the sensor is powered with the correct voltage to avoid damage.

- Media Compatibility: Verify that the sensor is compatible with the gas or liquid being measured.

- Noise Reduction: Use decoupling capacitors near the sensor to reduce electrical noise.

- Environmental Protection: If the sensor is used in harsh environments, consider using a protective enclosure.

- Wiring: Keep the wiring short and shielded to minimize signal interference.

Example: Using a Pressure Sensor with Arduino UNO

Below is an example of how to use an analog pressure sensor with an Arduino UNO:

// Define the analog pin connected to the pressure sensor

const int pressurePin = A0;

// Variable to store the sensor reading

int sensorValue = 0;

void setup() {

// Initialize serial communication for debugging

Serial.begin(9600);

}

void loop() {

// Read the analog value from the pressure sensor

sensorValue = analogRead(pressurePin);

// Convert the analog value to voltage (assuming 5V reference)

float voltage = sensorValue * (5.0 / 1023.0);

// Convert the voltage to pressure (example: 0.5V = 0 psi, 4.5V = 100 psi)

float pressure = (voltage - 0.5) * (100.0 / (4.5 - 0.5));

// Print the pressure value to the Serial Monitor

Serial.print("Pressure: ");

Serial.print(pressure);

Serial.println(" psi");

// Wait for 500 milliseconds before the next reading

delay(500);

}

Troubleshooting and FAQs

Common Issues and Solutions

- No Output Signal:

- Check the power supply voltage and connections.

- Ensure the sensor is properly grounded.

- Inaccurate Readings:

- Verify the sensor calibration.

- Check for electrical noise and add decoupling capacitors if necessary.

- Ensure the sensor is compatible with the media being measured.

- Intermittent Output:

- Inspect the wiring for loose connections.

- Use shielded cables to reduce interference.

- Sensor Damage:

- Avoid exposing the sensor to pressures beyond its rated range.

- Ensure the sensor is not exposed to corrosive or incompatible media.

FAQs

Q: Can I use a pressure sensor with a 3.3V microcontroller?

A: Yes, as long as the sensor supports a 3.3V power supply and the output signal is within the input range of the microcontroller.

Q: How do I know if my sensor is analog or digital?

A: Check the sensor's datasheet. Analog sensors typically have an output pin labeled "OUT," while digital sensors have communication pins like SDA and SCL.

Q: Can I measure negative pressure (vacuum) with a pressure sensor?

A: Some pressure sensors are designed to measure both positive and negative pressures. Look for sensors labeled as "gauge" or "differential" pressure sensors.

Q: What is the lifespan of a pressure sensor?

A: The lifespan depends on the operating conditions and the sensor's quality. Many sensors are rated for millions of pressure cycles. Always refer to the manufacturer's specifications.