How to Use MINI560: Examples, Pinouts, and Specs

Design with MINI560 in Cirkit Designer

Design with MINI560 in Cirkit DesignerIntroduction

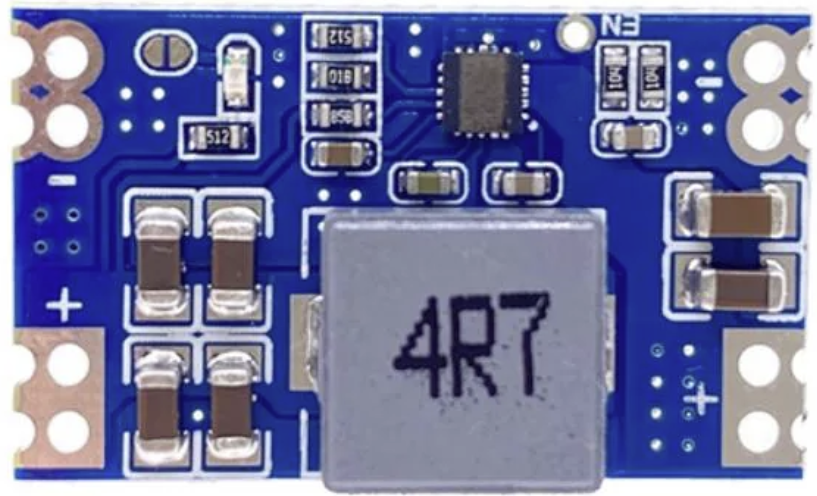

The MINI560 is a compact, high-performance DC-DC buck converter designed for efficient voltage regulation in small electronic devices. It is ideal for applications requiring a stable and adjustable output voltage from a wide input voltage range. The MINI560 is commonly used in battery-powered devices, IoT modules, portable electronics, and embedded systems. Its built-in protection features, such as overcurrent and thermal shutdown, ensure reliable operation in various environments.

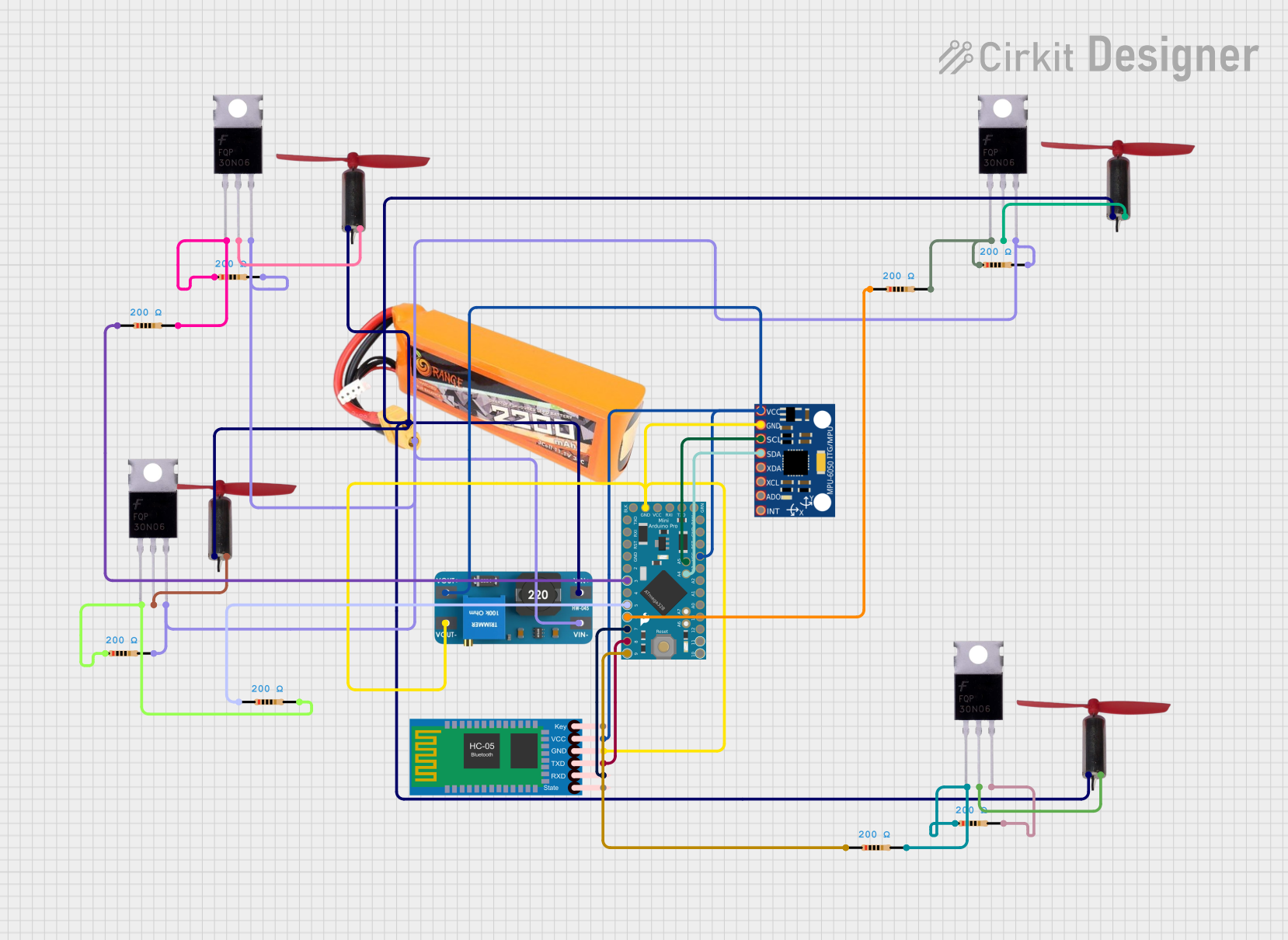

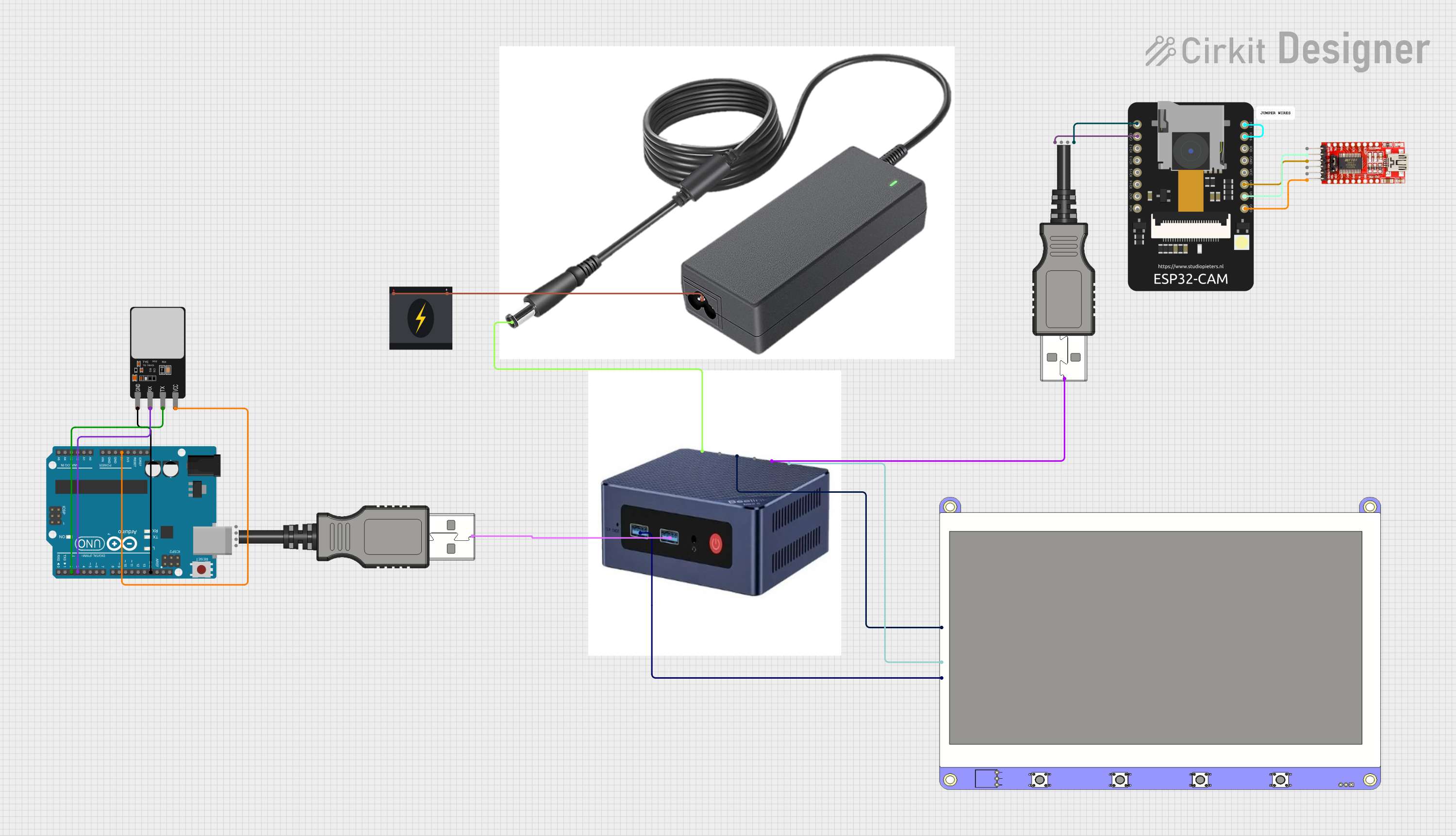

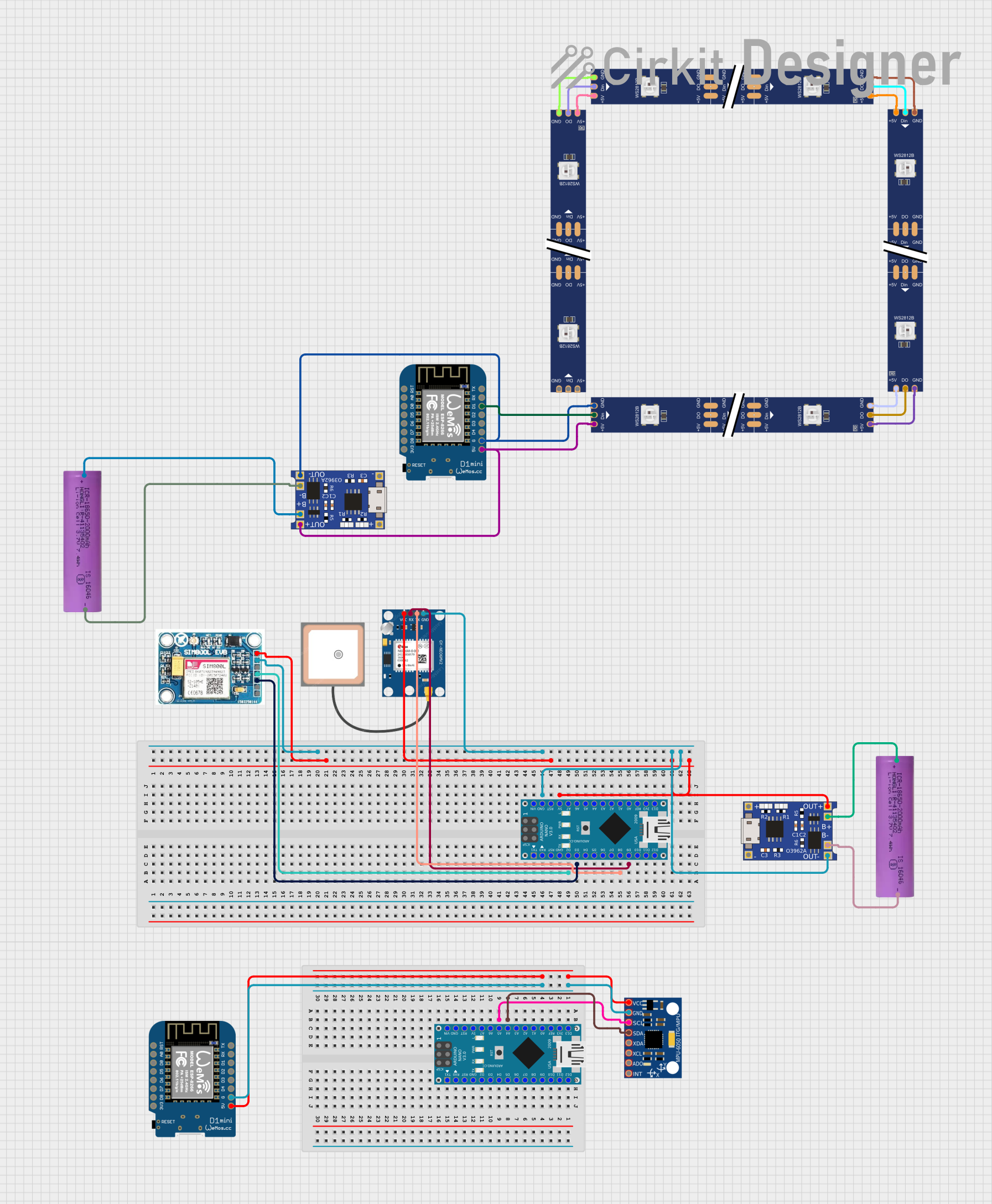

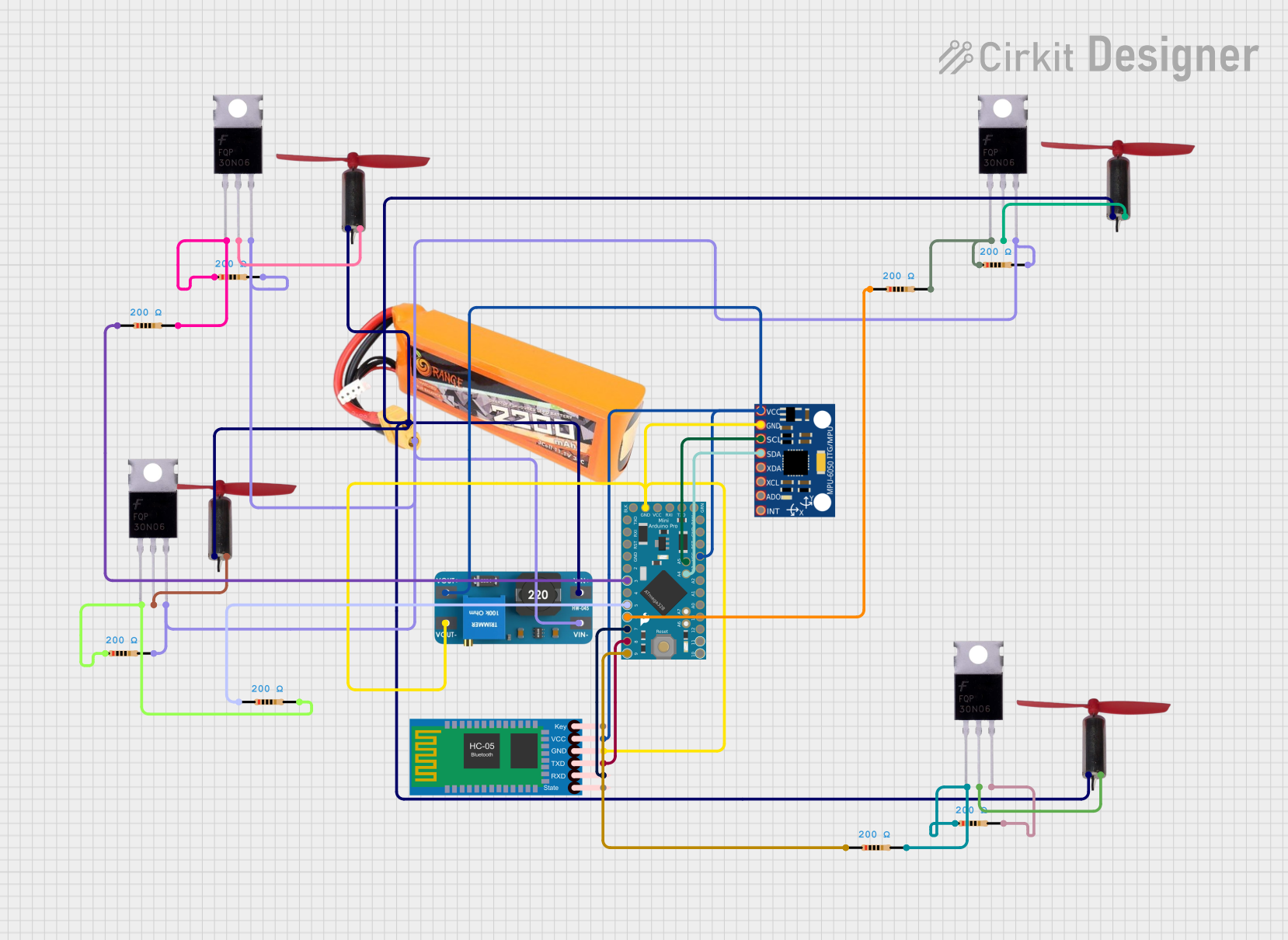

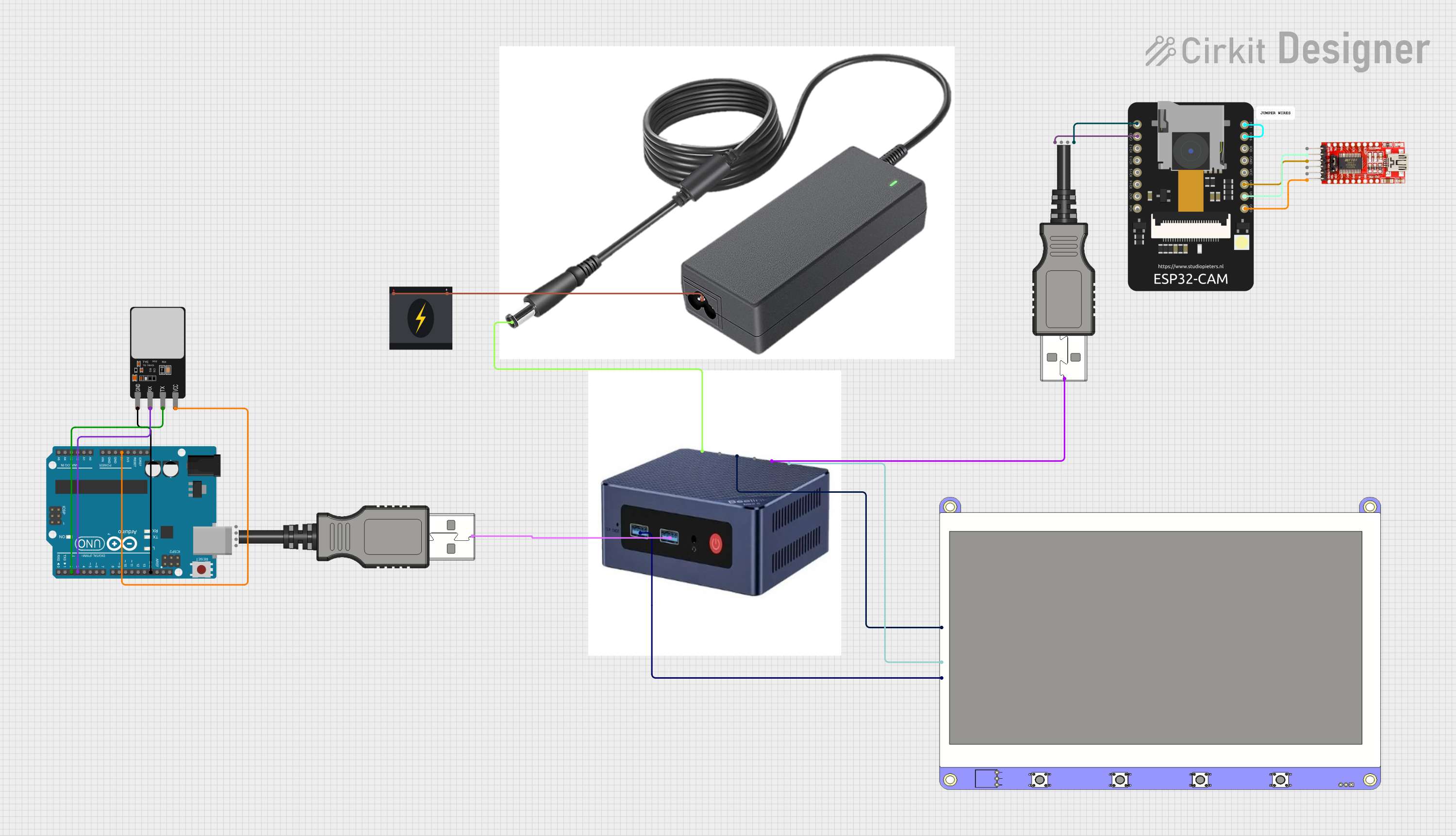

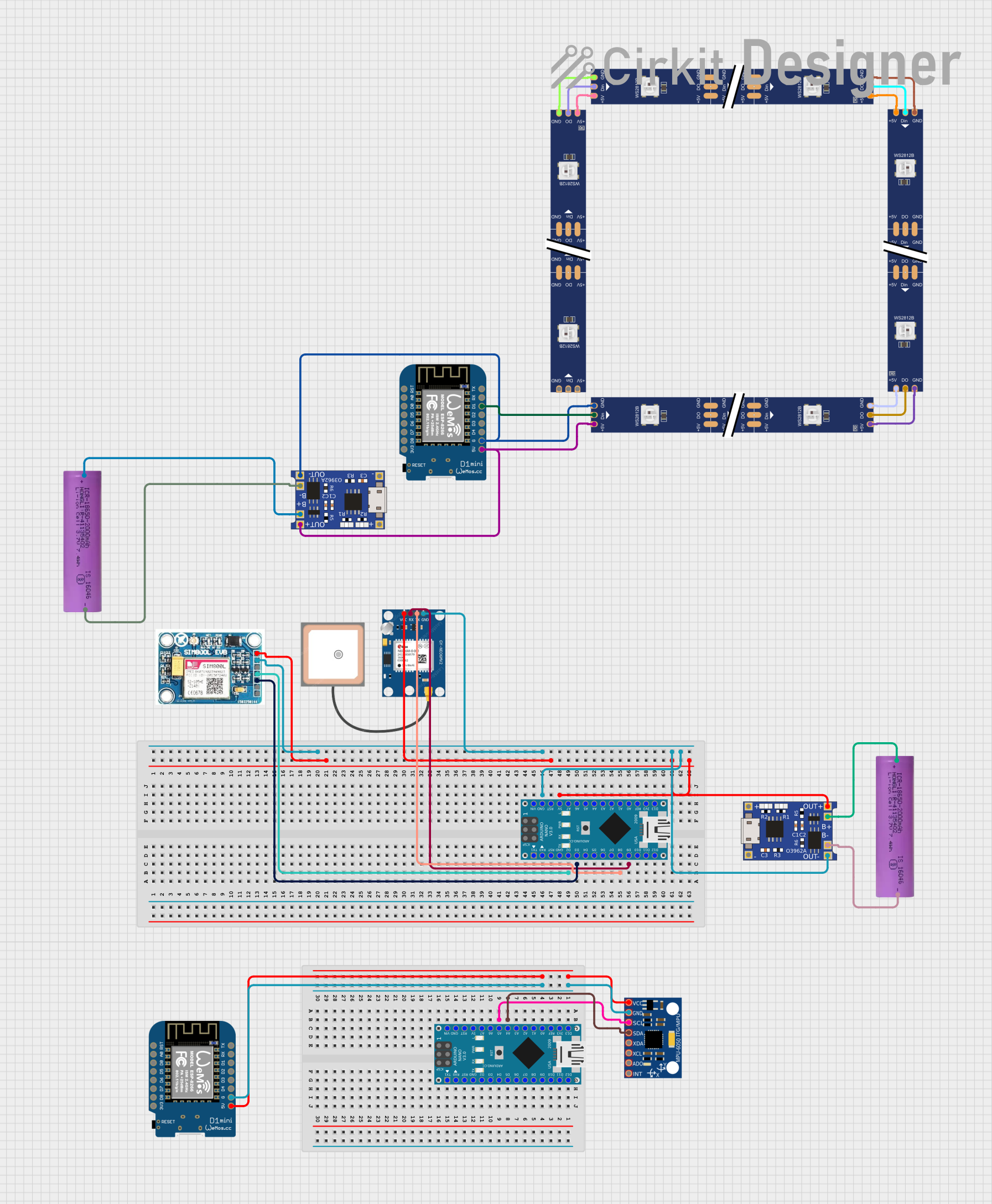

Explore Projects Built with MINI560

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with MINI560

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerTechnical Specifications

The MINI560 offers robust performance and flexibility for a variety of applications. Below are its key technical specifications:

General Specifications

- Input Voltage Range: 4.5V to 28V

- Output Voltage Range: 0.8V to 20V (adjustable via external resistors)

- Maximum Output Current: 3A

- Efficiency: Up to 95% (depending on input/output conditions)

- Switching Frequency: 1.2 MHz

- Operating Temperature Range: -40°C to +85°C

- Protection Features: Overcurrent protection, thermal shutdown, and short-circuit protection

Pin Configuration and Descriptions

The MINI560 is typically available in a 6-pin SOT-23 package. Below is the pinout and description:

| Pin Number | Pin Name | Description |

|---|---|---|

| 1 | VIN | Input voltage pin. Connect to the power source (4.5V to 28V). |

| 2 | GND | Ground pin. Connect to the system ground. |

| 3 | SW | Switching output pin. Connect to the inductor and diode in the buck circuit. |

| 4 | FB | Feedback pin. Connect to a resistor divider to set the output voltage. |

| 5 | EN | Enable pin. Drive high to enable the converter, or low to disable it. |

| 6 | NC | No connection. Leave this pin unconnected or grounded. |

Usage Instructions

How to Use the MINI560 in a Circuit

- Input Voltage: Connect the VIN pin to a DC power source within the range of 4.5V to 28V. Use a decoupling capacitor (e.g., 10µF) close to the VIN pin to reduce noise.

- Output Voltage Adjustment: Use a resistor divider network connected to the FB pin to set the desired output voltage. The output voltage can be calculated using the formula: [ V_{OUT} = V_{REF} \times \left(1 + \frac{R1}{R2}\right) ] where ( V_{REF} ) is typically 0.8V.

- Inductor and Diode Selection: Choose an appropriate inductor and Schottky diode based on the desired output current and voltage. For example, a 10µH inductor and a 3A-rated diode are commonly used.

- Enable Pin: Drive the EN pin high (e.g., connect to VIN) to enable the converter. Pull it low to disable the output.

- Output Capacitor: Place a low-ESR capacitor (e.g., 22µF) at the output to stabilize the voltage and reduce ripple.

Important Considerations and Best Practices

- Ensure proper heat dissipation, especially when operating at high currents. Use a PCB with good thermal management (e.g., thermal vias or copper planes).

- Keep the feedback resistor network and output capacitor close to the FB pin to minimize noise and improve stability.

- Avoid exceeding the maximum input voltage (28V) or output current (3A) to prevent damage to the component.

- Use a proper layout to minimize EMI. Keep the high-current paths (e.g., VIN, SW, and GND) as short and wide as possible.

Example: Using the MINI560 with an Arduino UNO

The MINI560 can be used to power an Arduino UNO by stepping down a higher voltage (e.g., 12V) to 5V. Below is an example circuit and Arduino code to demonstrate its usage:

Circuit Setup

- Connect a 12V DC power source to the VIN pin of the MINI560.

- Set the output voltage to 5V using a resistor divider network.

- Connect the output of the MINI560 to the 5V pin of the Arduino UNO.

- Ensure proper grounding between the MINI560 and the Arduino UNO.

Arduino Code

// Example code to read a sensor and print data to the Serial Monitor

// The MINI560 is used to power the Arduino UNO at 5V

const int sensorPin = A0; // Analog pin connected to the sensor

int sensorValue = 0; // Variable to store the sensor reading

void setup() {

Serial.begin(9600); // Initialize serial communication at 9600 baud

pinMode(sensorPin, INPUT); // Set the sensor pin as input

}

void loop() {

sensorValue = analogRead(sensorPin); // Read the sensor value

Serial.print("Sensor Value: ");

Serial.println(sensorValue); // Print the sensor value to the Serial Monitor

delay(1000); // Wait for 1 second before the next reading

}

Troubleshooting and FAQs

Common Issues and Solutions

No Output Voltage

- Cause: The EN pin is not properly connected.

- Solution: Ensure the EN pin is driven high (e.g., connected to VIN).

Output Voltage is Unstable

- Cause: Insufficient output capacitance or poor PCB layout.

- Solution: Use a low-ESR capacitor (e.g., 22µF) and ensure proper grounding.

Excessive Heat

- Cause: High output current or poor thermal management.

- Solution: Use a heatsink or improve PCB thermal design (e.g., add copper planes).

Output Voltage is Incorrect

- Cause: Incorrect resistor values in the feedback network.

- Solution: Verify the resistor values and recalculate the output voltage using the formula.

FAQs

Q: Can the MINI560 be used with a 3.3V output?

- A: Yes, the MINI560 can be configured for a 3.3V output by selecting appropriate feedback resistors.

Q: What is the maximum efficiency of the MINI560?

- A: The MINI560 can achieve up to 95% efficiency, depending on the input and output voltage conditions.

Q: Is the MINI560 suitable for battery-powered applications?

- A: Yes, its high efficiency and wide input voltage range make it ideal for battery-powered devices.

Q: Can I use the MINI560 without an external diode?

- A: No, an external Schottky diode is required for proper operation in the buck converter circuit.

This concludes the documentation for the MINI560. For further assistance, refer to the manufacturer's datasheet or contact technical support.