How to Use Pump: Examples, Pinouts, and Specs

Design with Pump in Cirkit Designer

Design with Pump in Cirkit DesignerIntroduction

A pump is an electronic component designed to move fluids, such as liquids or gases, through mechanical action. Pumps are essential in various applications, including water circulation, chemical processing, air conditioning systems, and irrigation. They are also commonly used in hobbyist projects, such as automated plant watering systems, aquariums, and DIY fountains.

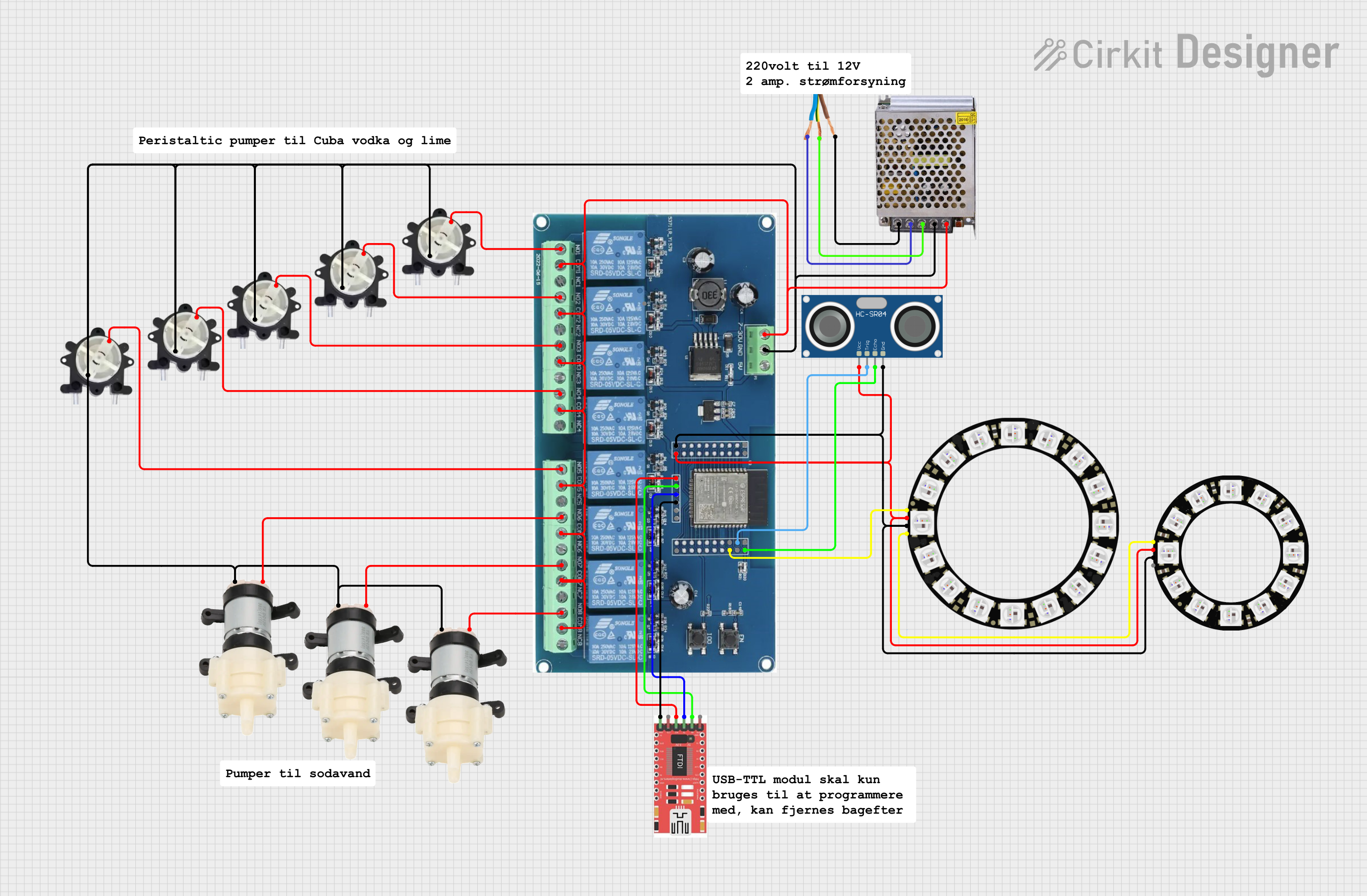

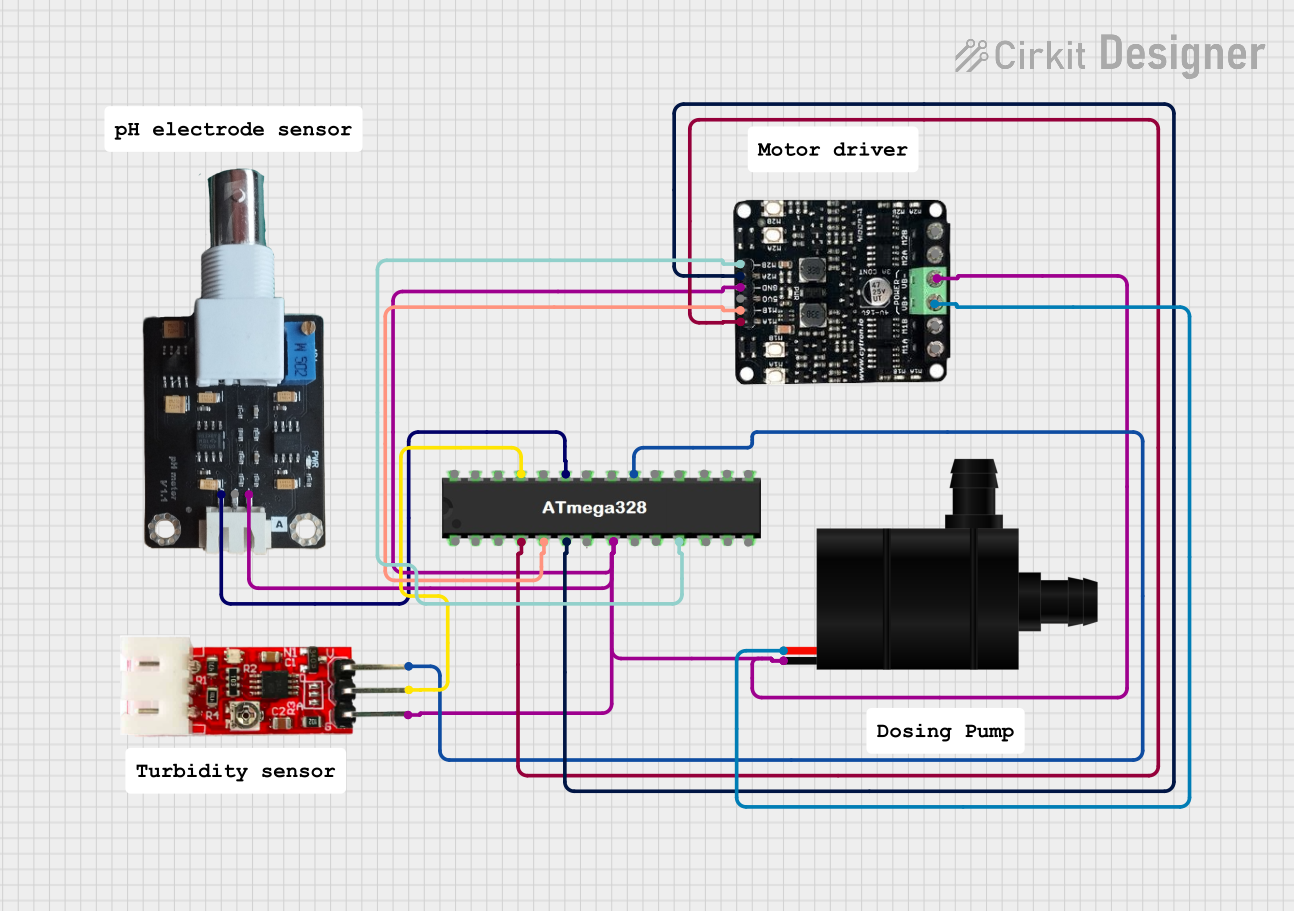

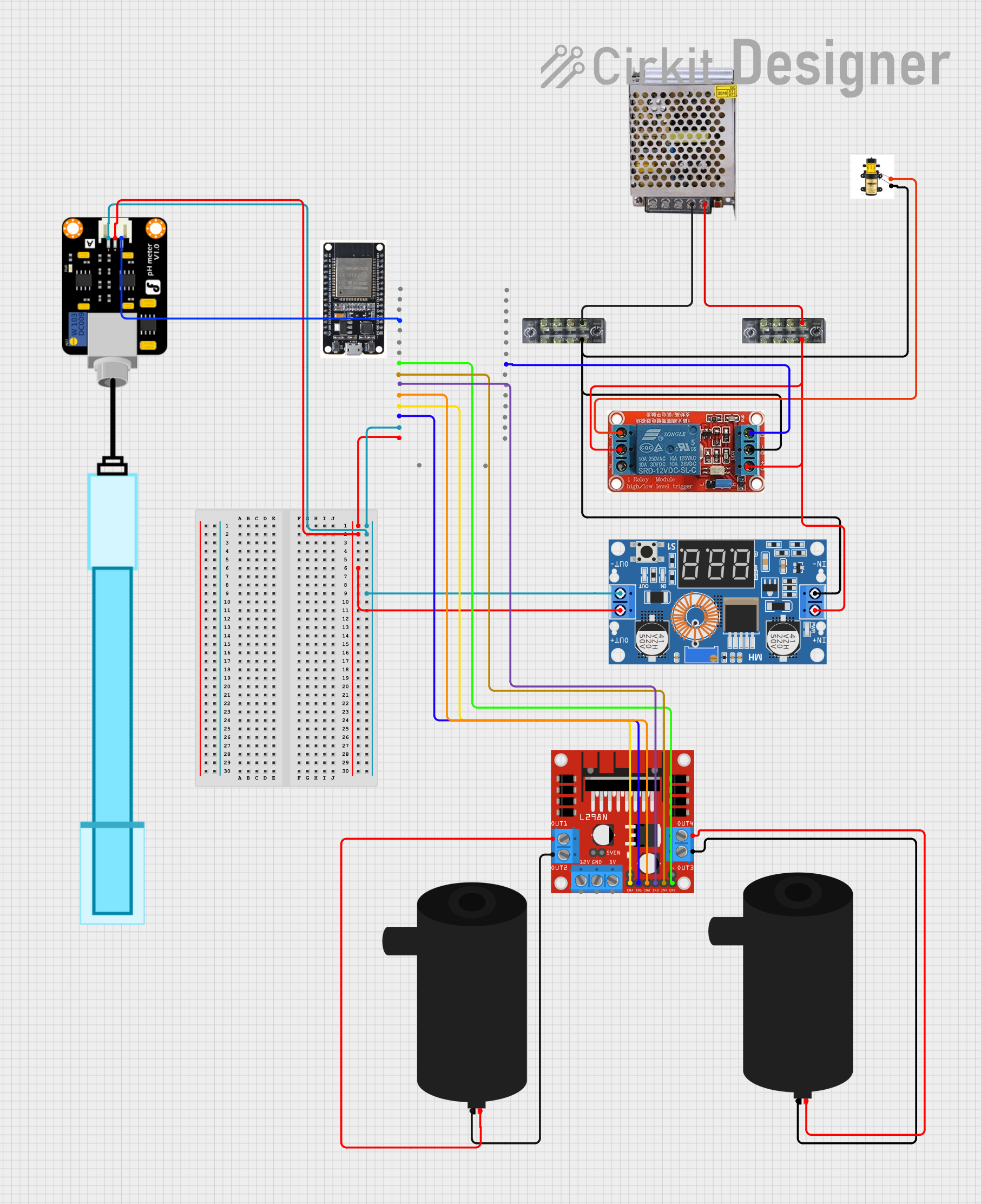

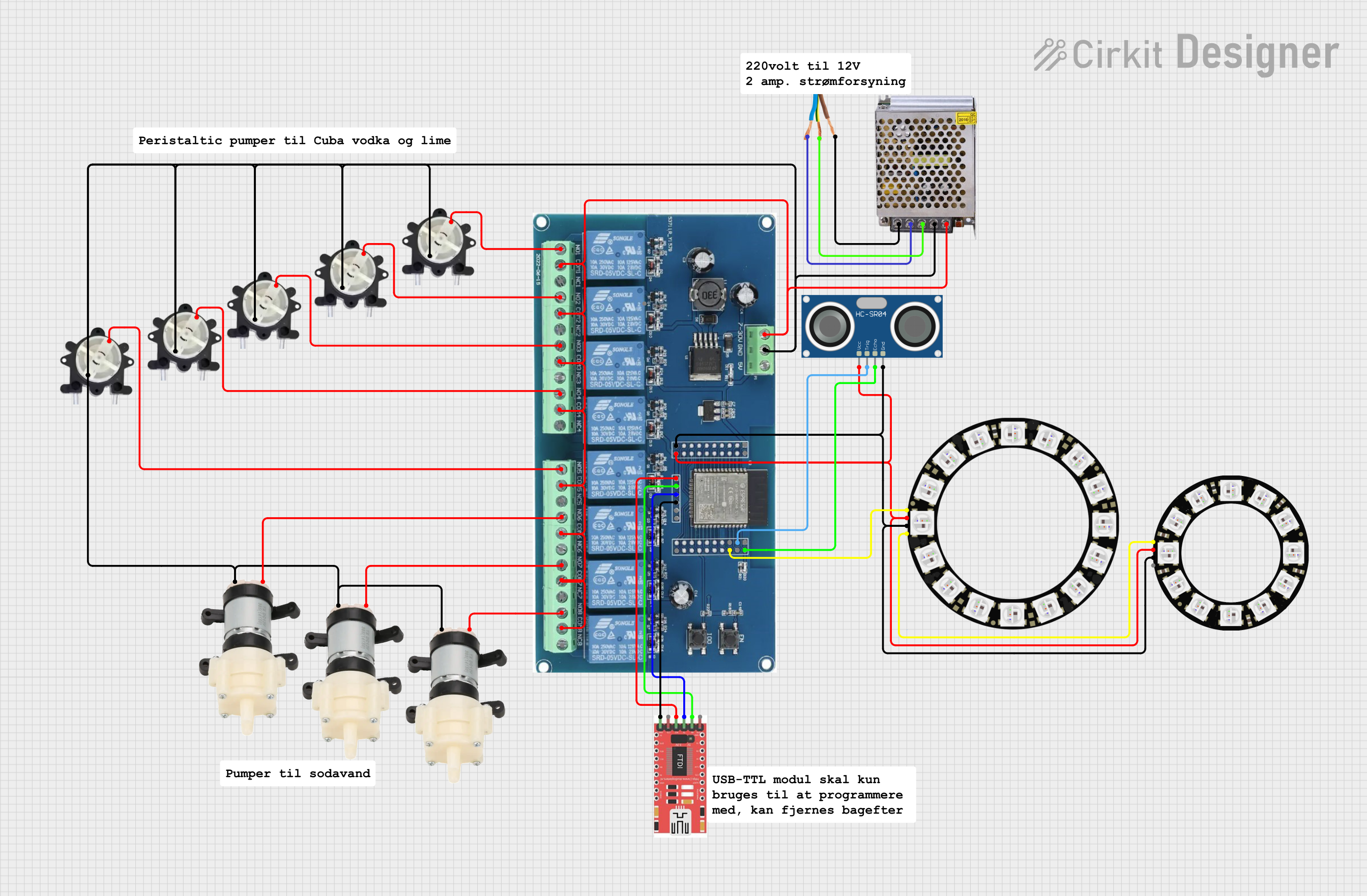

Explore Projects Built with Pump

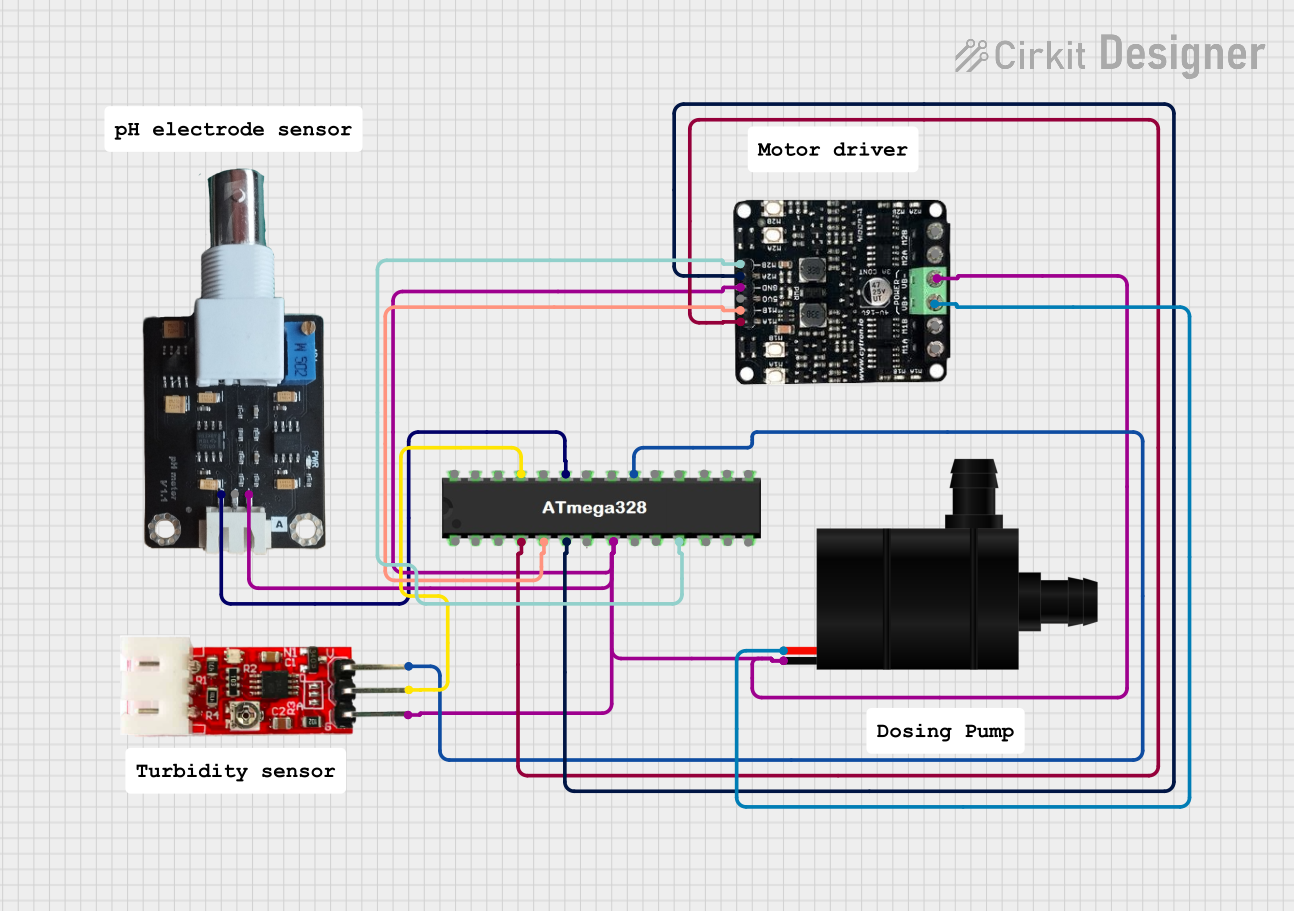

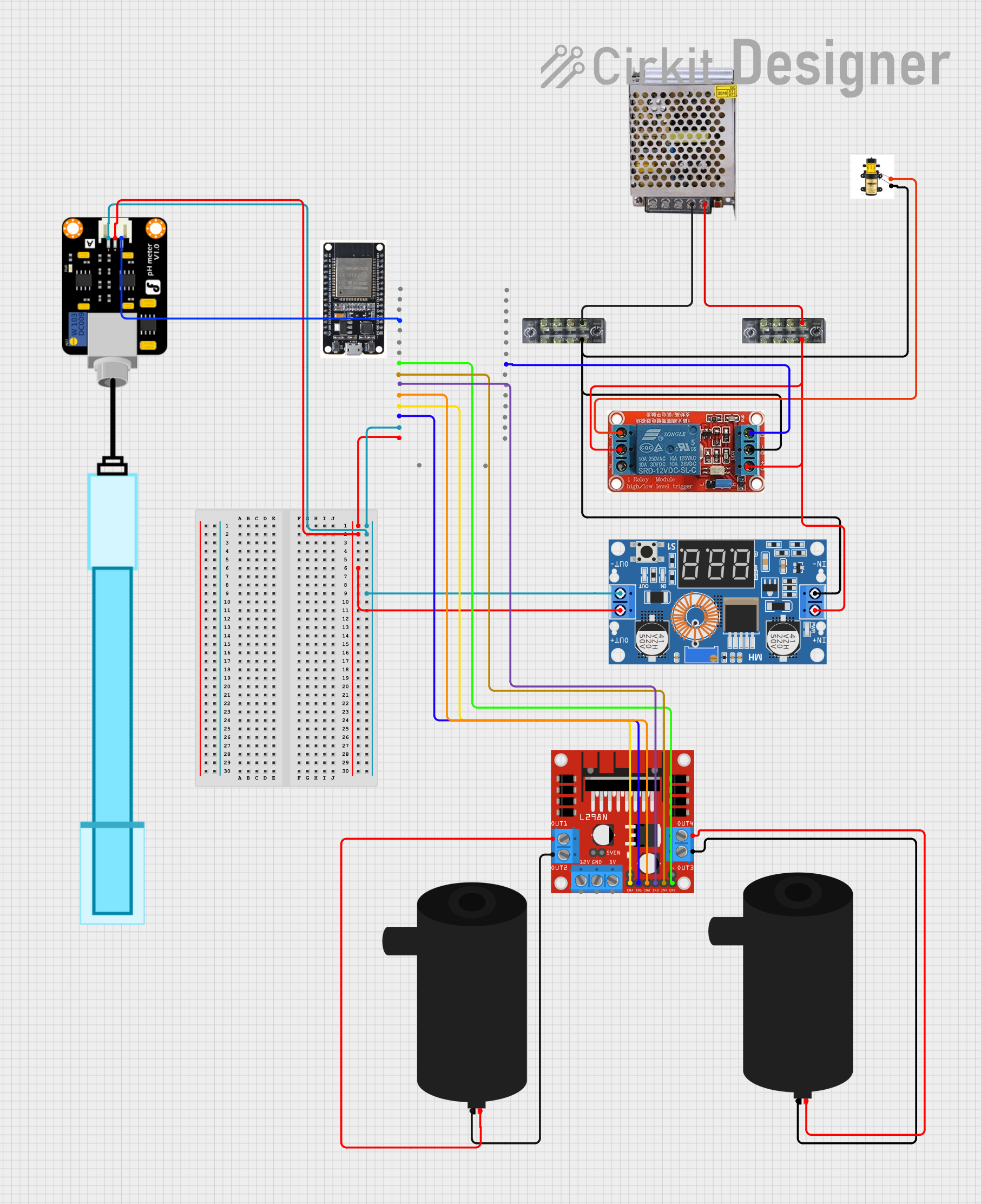

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with Pump

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerTechnical Specifications

General Specifications

- Type: Miniature Submersible/Non-submersible Pump

- Operating Voltage Range: 3V to 12V DC

- Rated Current: 100mA to 800mA (depending on model and voltage)

- Flow Rate: Up to 100-200 L/h (liters per hour)

- Max Head: 0.5 to 3 meters (pressure head)

- Operating Temperature: 0°C to 50°C

- Life Expectancy: 20,000 hours of continuous operation

- Material: Plastic (ABS for non-submersible, waterproof materials for submersible)

Pin Configuration and Descriptions

| Pin Number | Description | Notes |

|---|---|---|

| 1 | Positive Voltage (V+) | Connect to positive power supply |

| 2 | Ground (GND) | Connect to system ground |

Usage Instructions

Integration into a Circuit

Power Supply: Ensure that the pump is connected to a power supply that matches its voltage and current requirements. Overvoltage or excessive current can damage the pump.

Polarity: Connect the positive terminal of the power supply to the V+ pin and the negative terminal to the GND pin. Reversing the polarity may damage the pump.

Switching: Use a relay or a transistor to control the pump's operation from a microcontroller like an Arduino UNO. This allows for automated control of the pump.

Protection: Incorporate a diode in reverse bias across the pump's terminals to protect against voltage spikes when the pump is turned off (flyback diode).

Filtering: If the pump is submersible, ensure that the intake is filtered to prevent debris from damaging the pump's internal components.

Best Practices

- Avoid running the pump dry, as this can cause overheating and damage.

- Regularly check for any blockages or debris in the pump.

- Submerge the pump entirely if it is designed to be submersible to prevent damage.

- Use a fuse or a circuit breaker to protect against overcurrent conditions.

Example Arduino UNO Code

// Define the pump control pin

const int pumpPin = 7;

void setup() {

// Set the pump control pin as an output

pinMode(pumpPin, OUTPUT);

}

void loop() {

// Turn on the pump for 5 seconds

digitalWrite(pumpPin, HIGH);

delay(5000);

// Turn off the pump for 10 seconds

digitalWrite(pumpPin, LOW);

delay(10000);

}

Troubleshooting and FAQs

Common Issues

- Pump does not start: Check the power supply for proper voltage and current. Ensure that the connections are secure and the polarity is correct.

- Low flow rate: Verify that there are no blockages in the pump or the intake filter. Check that the pump is not running dry.

- Pump is noisy: Ensure that the pump is securely mounted and that there are no foreign objects inside the pump.

FAQs

Q: Can I run the pump continuously? A: Yes, but ensure that the operating conditions such as voltage, current, and temperature are within the specified limits.

Q: Is it necessary to use a relay with an Arduino? A: Yes, a relay or a transistor is necessary to control the high current required by the pump, which cannot be supplied directly by the Arduino's GPIO pins.

Q: How do I adjust the flow rate of the pump? A: The flow rate can be adjusted by changing the input voltage within the specified range or by using a flow control valve in the output line.

Q: Can the pump be used to pump hot liquids? A: The pump is typically rated for a certain temperature range. Exceeding this range can damage the pump and pose safety risks. Check the manufacturer's specifications.

Q: What maintenance does the pump require? A: Regular maintenance includes checking for blockages, ensuring the pump is not running dry, and replacing the intake filter as needed.