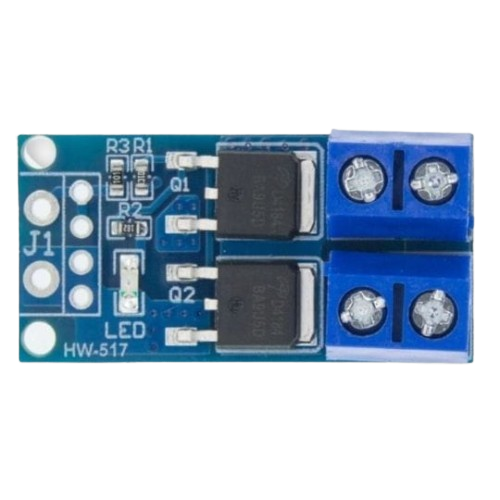

How to Use HW-517: Examples, Pinouts, and Specs

Design with HW-517 in Cirkit Designer

Design with HW-517 in Cirkit DesignerIntroduction

The HW-517 is a versatile electronic component widely used in signal processing, control systems, and other electronic applications. Its compact design ensures easy integration into circuit boards, making it a popular choice for engineers and hobbyists alike. Known for its reliability and efficiency, the HW-517 is ideal for projects requiring consistent performance and durability.

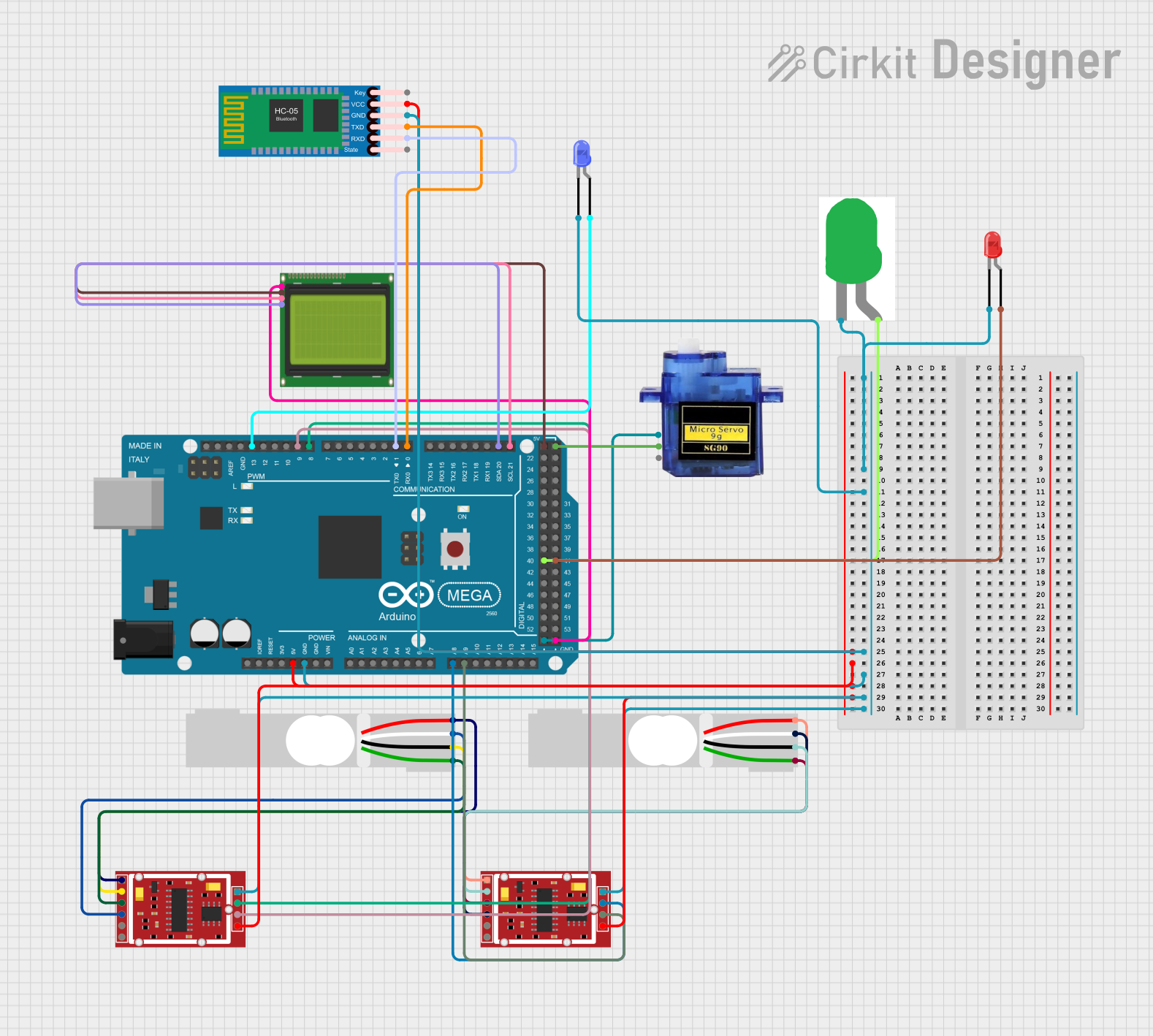

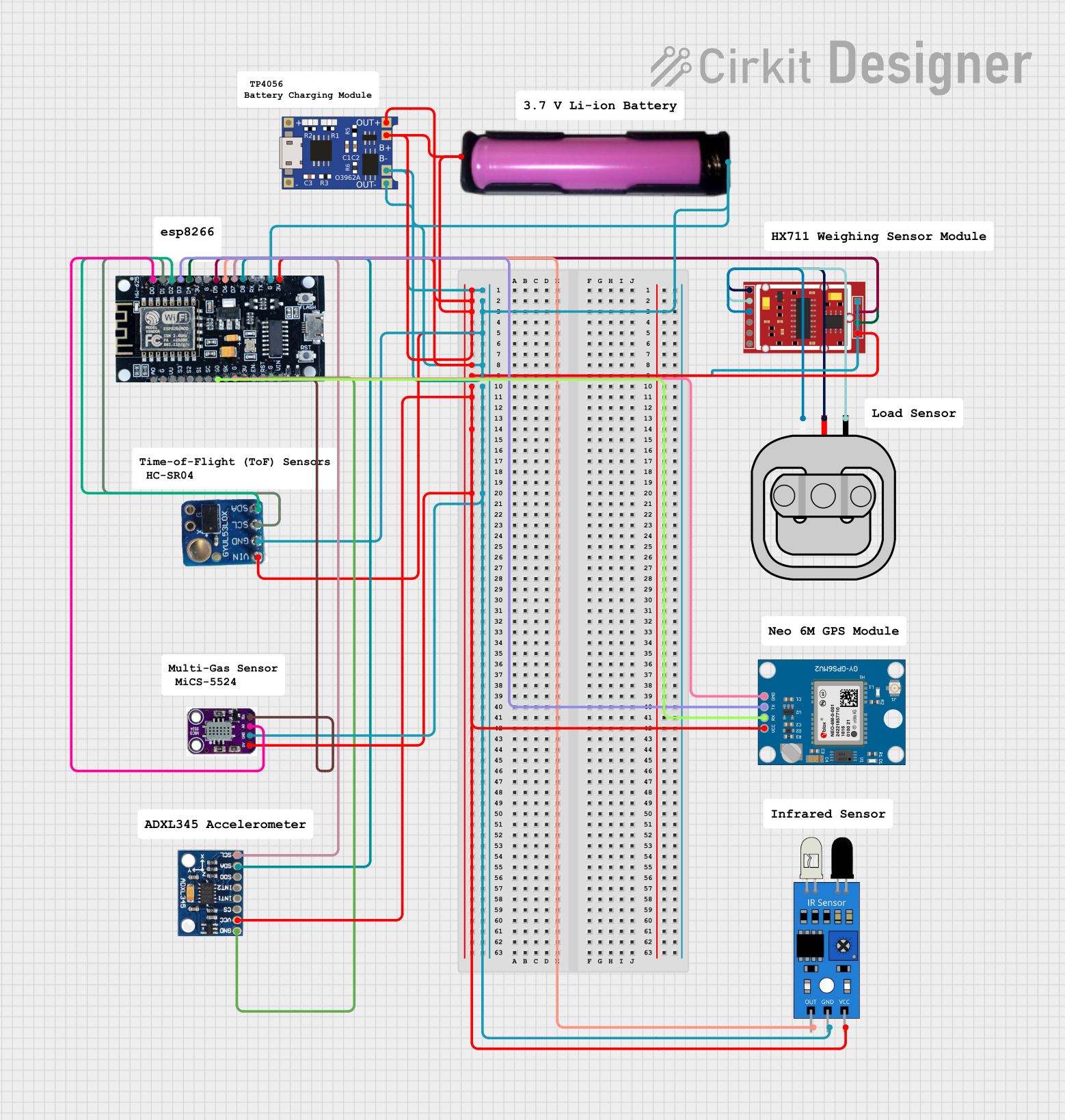

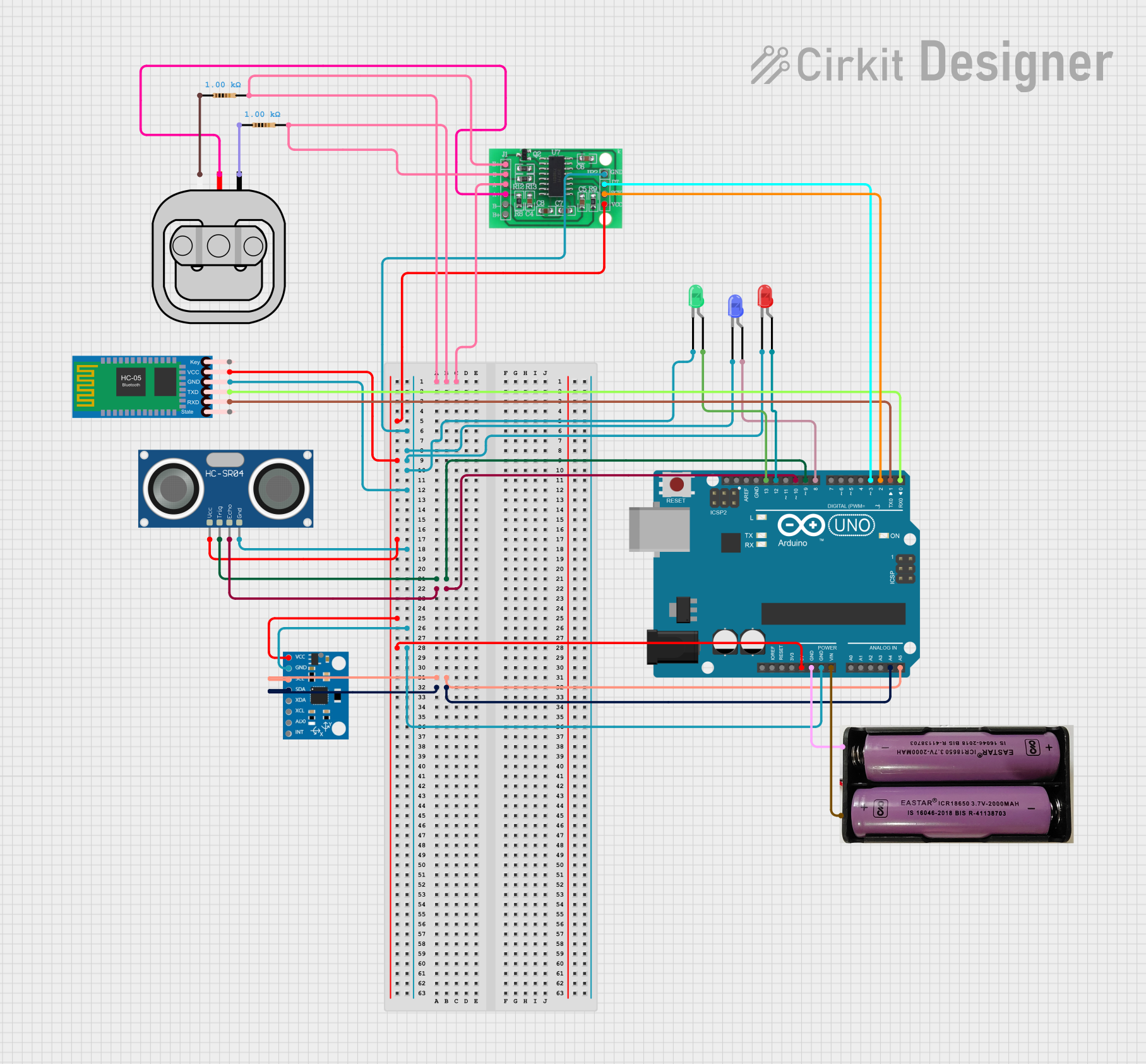

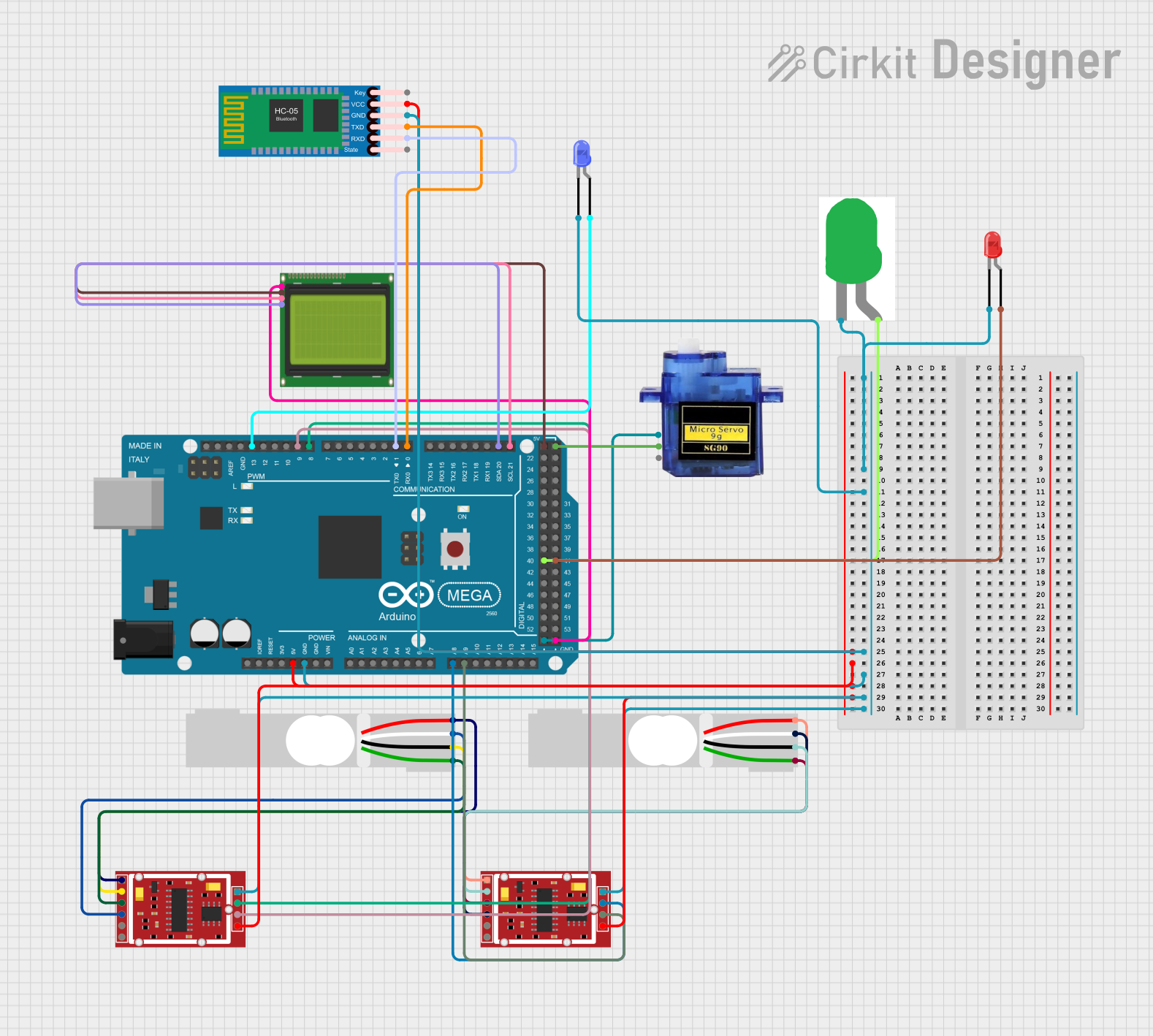

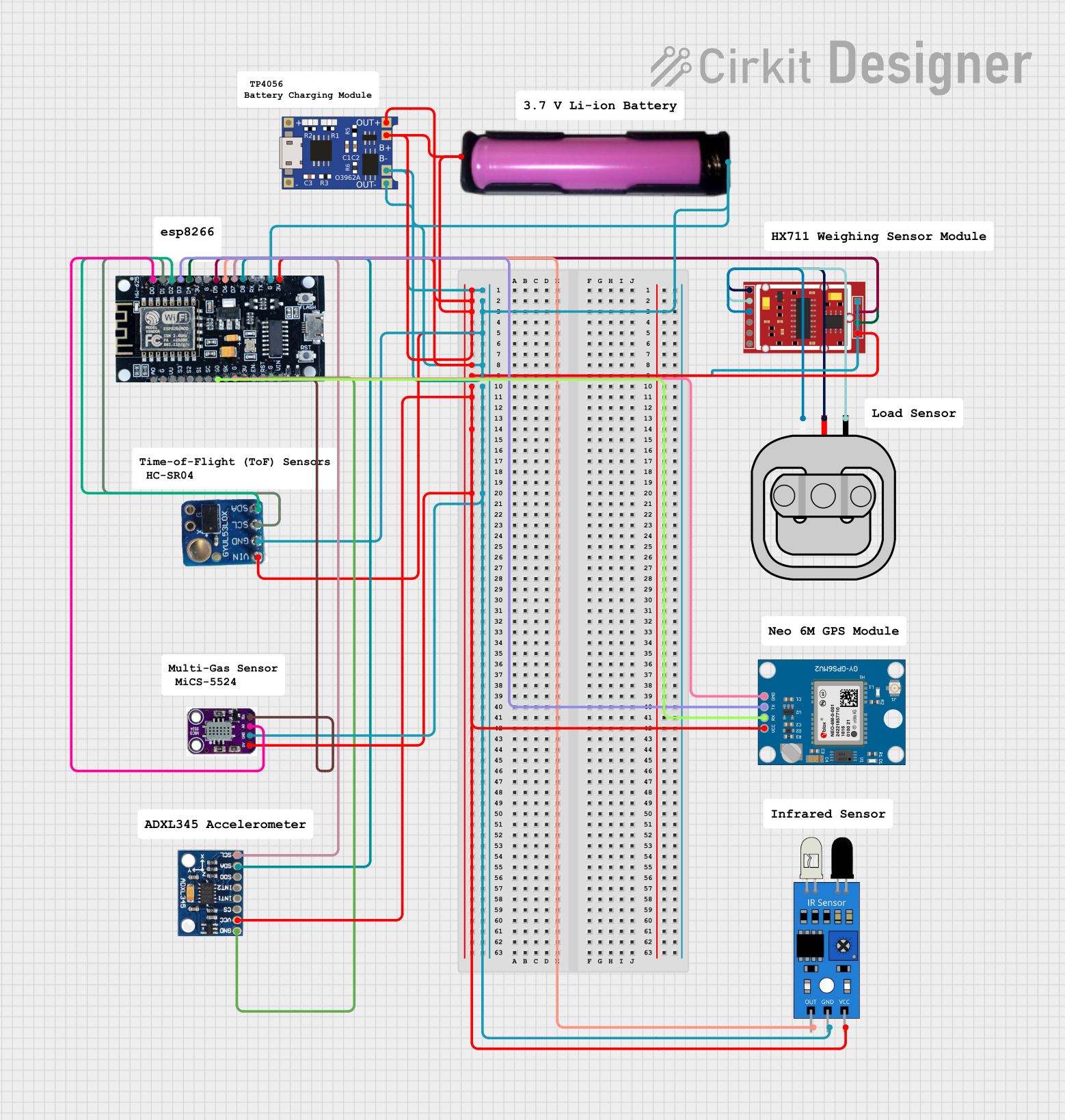

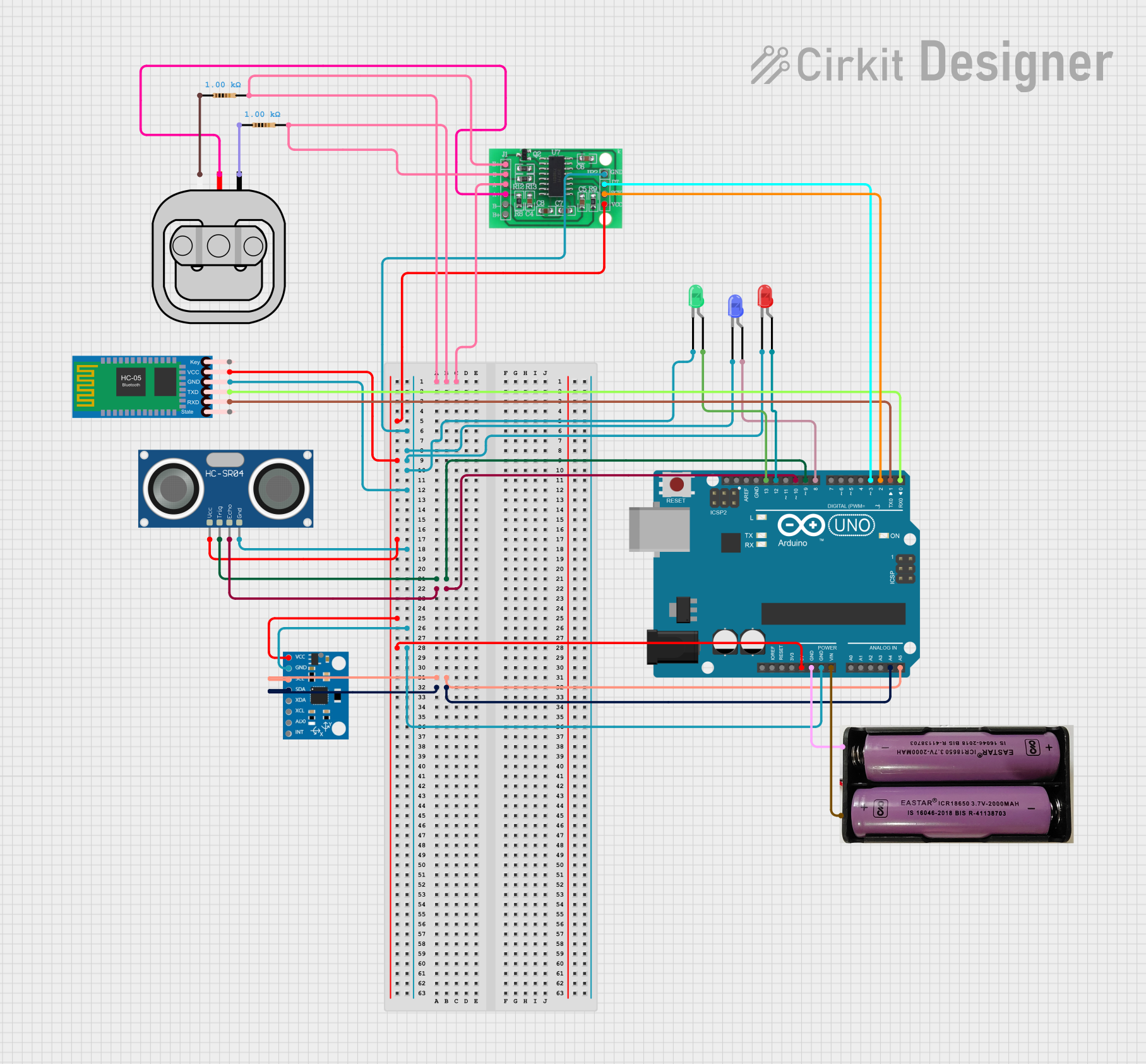

Explore Projects Built with HW-517

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with HW-517

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications

- Signal amplification and processing

- Control systems in automation

- Sensor interfacing and data acquisition

- General-purpose electronic circuits

Technical Specifications

The HW-517 is designed to deliver reliable performance under a range of operating conditions. Below are its key technical specifications:

| Parameter | Value |

|---|---|

| Operating Voltage | 3.3V to 5V |

| Operating Current | 10mA (typical) |

| Signal Input Range | 0V to 5V |

| Output Voltage Range | 0V to 5V |

| Operating Temperature | -40°C to 85°C |

| Dimensions | 25mm x 15mm x 5mm |

Pin Configuration

The HW-517 features a simple pinout for easy integration. Below is the pin configuration:

| Pin | Name | Description |

|---|---|---|

| 1 | VCC | Power supply input (3.3V to 5V) |

| 2 | GND | Ground connection |

| 3 | Signal Input | Input pin for the signal to be processed |

| 4 | Signal Output | Output pin for the processed signal |

Usage Instructions

The HW-517 is straightforward to use in a variety of circuits. Follow the steps below to integrate it into your project:

Basic Circuit Connection

- Power Supply: Connect the

VCCpin to a 3.3V or 5V power source and theGNDpin to the ground of your circuit. - Signal Input: Connect the signal source (e.g., a sensor or microcontroller) to the

Signal Inputpin. - Signal Output: Connect the

Signal Outputpin to the next stage of your circuit, such as an ADC (Analog-to-Digital Converter) or another processing module.

Important Considerations

- Ensure the input signal voltage does not exceed the operating range (0V to 5V) to avoid damage.

- Use decoupling capacitors (e.g., 0.1µF) near the

VCCpin to reduce noise and improve stability. - If using the HW-517 with an Arduino UNO, ensure the power supply matches the Arduino's logic level (5V).

Example: Using HW-517 with Arduino UNO

Below is an example of how to connect and use the HW-517 with an Arduino UNO to read and process a signal:

Circuit Diagram

- Connect

VCCto the Arduino's5Vpin. - Connect

GNDto the Arduino'sGNDpin. - Connect the

Signal Inputto an analog sensor output. - Connect the

Signal Outputto an analog input pin on the Arduino (e.g.,A0).

Arduino Code

// Example code to read and display the HW-517 output using Arduino UNO

const int signalOutputPin = A0; // HW-517 Signal Output connected to A0

void setup() {

Serial.begin(9600); // Initialize serial communication at 9600 baud

pinMode(signalOutputPin, INPUT); // Set A0 as input

}

void loop() {

int signalValue = analogRead(signalOutputPin); // Read the signal value

float voltage = (signalValue / 1023.0) * 5.0; // Convert to voltage (0-5V range)

// Print the signal value and voltage to the Serial Monitor

Serial.print("Signal Value: ");

Serial.print(signalValue);

Serial.print(" | Voltage: ");

Serial.println(voltage);

delay(500); // Wait for 500ms before the next reading

}

Best Practices

- Use proper grounding techniques to minimize noise in the circuit.

- Avoid exposing the HW-517 to extreme temperatures or humidity to ensure long-term reliability.

- Test the component in a breadboard setup before finalizing the design.

Troubleshooting and FAQs

Common Issues

No Output Signal:

- Cause: Incorrect power supply or loose connections.

- Solution: Verify that the

VCCandGNDpins are properly connected and the power supply is within the specified range.

Output Signal is Noisy:

- Cause: Insufficient decoupling or external interference.

- Solution: Add a 0.1µF capacitor near the

VCCpin and ensure proper grounding.

Signal Output is Clipped:

- Cause: Input signal exceeds the specified range (0V to 5V).

- Solution: Ensure the input signal is within the acceptable range or use a voltage divider to scale it down.

FAQs

Q1: Can the HW-517 operate at 3.3V?

A1: Yes, the HW-517 is designed to operate at both 3.3V and 5V, making it compatible with a wide range of systems.

Q2: Is the HW-517 suitable for high-frequency signals?

A2: The HW-517 is optimized for general-purpose applications. For high-frequency signals, verify its performance in your specific use case.

Q3: Can I use the HW-517 with a Raspberry Pi?

A3: Yes, the HW-517 can be used with a Raspberry Pi. Ensure the VCC pin is connected to a 3.3V power source, as the Raspberry Pi operates at 3.3V logic levels.

By following this documentation, you can effectively integrate and troubleshoot the HW-517 in your projects.