How to Use Etamaster ECM motor: Examples, Pinouts, and Specs

Design with Etamaster ECM motor in Cirkit Designer

Design with Etamaster ECM motor in Cirkit DesignerIntroduction

The Etamaster ECM Motor (EM 125 EC 02), manufactured by Ruck, is an electronically commutated motor (ECM) known for its high efficiency and variable speed capabilities. ECM motors are widely used in HVAC systems due to their ability to provide precise control over motor speed and energy consumption, leading to significant energy savings and improved system performance.

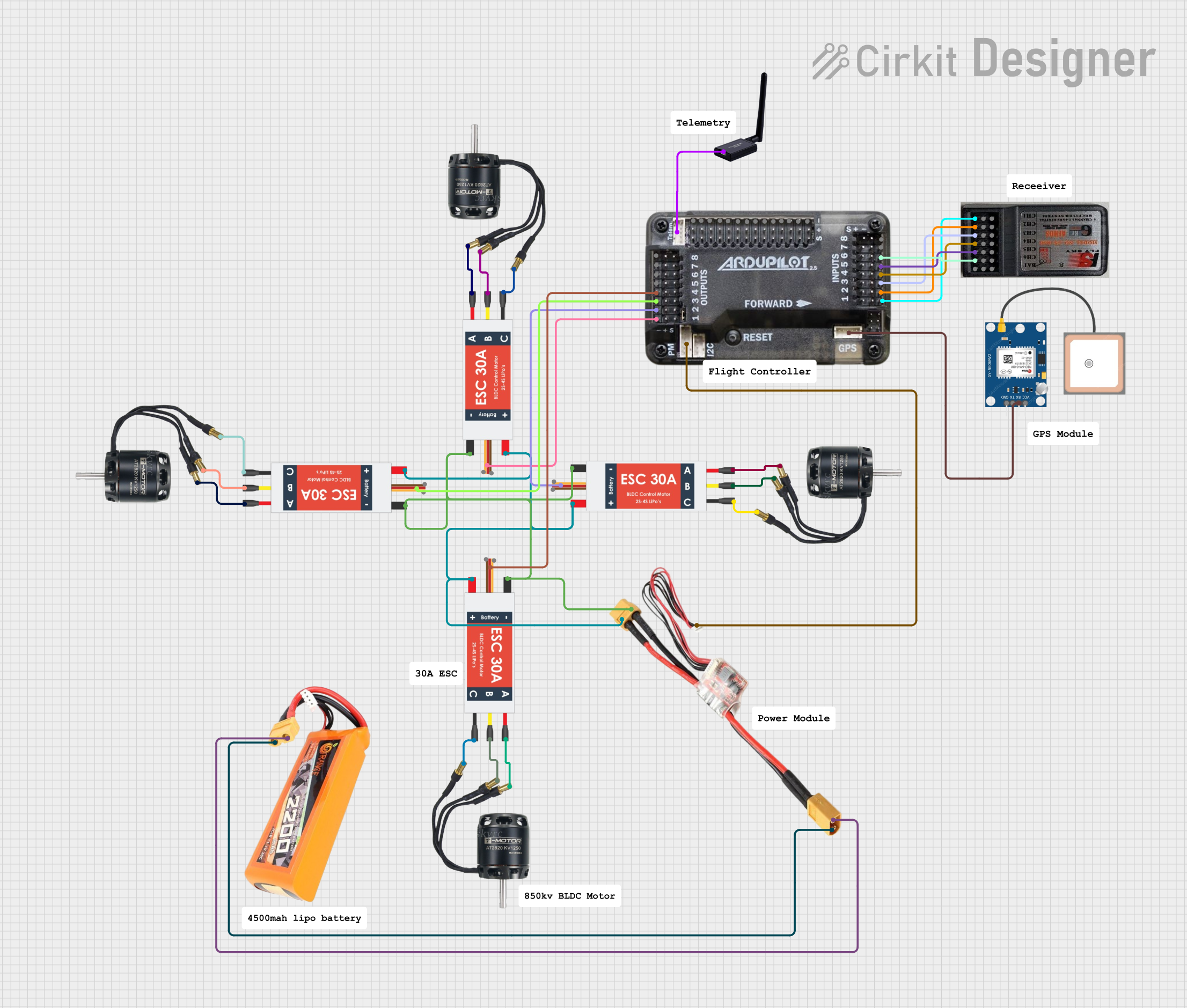

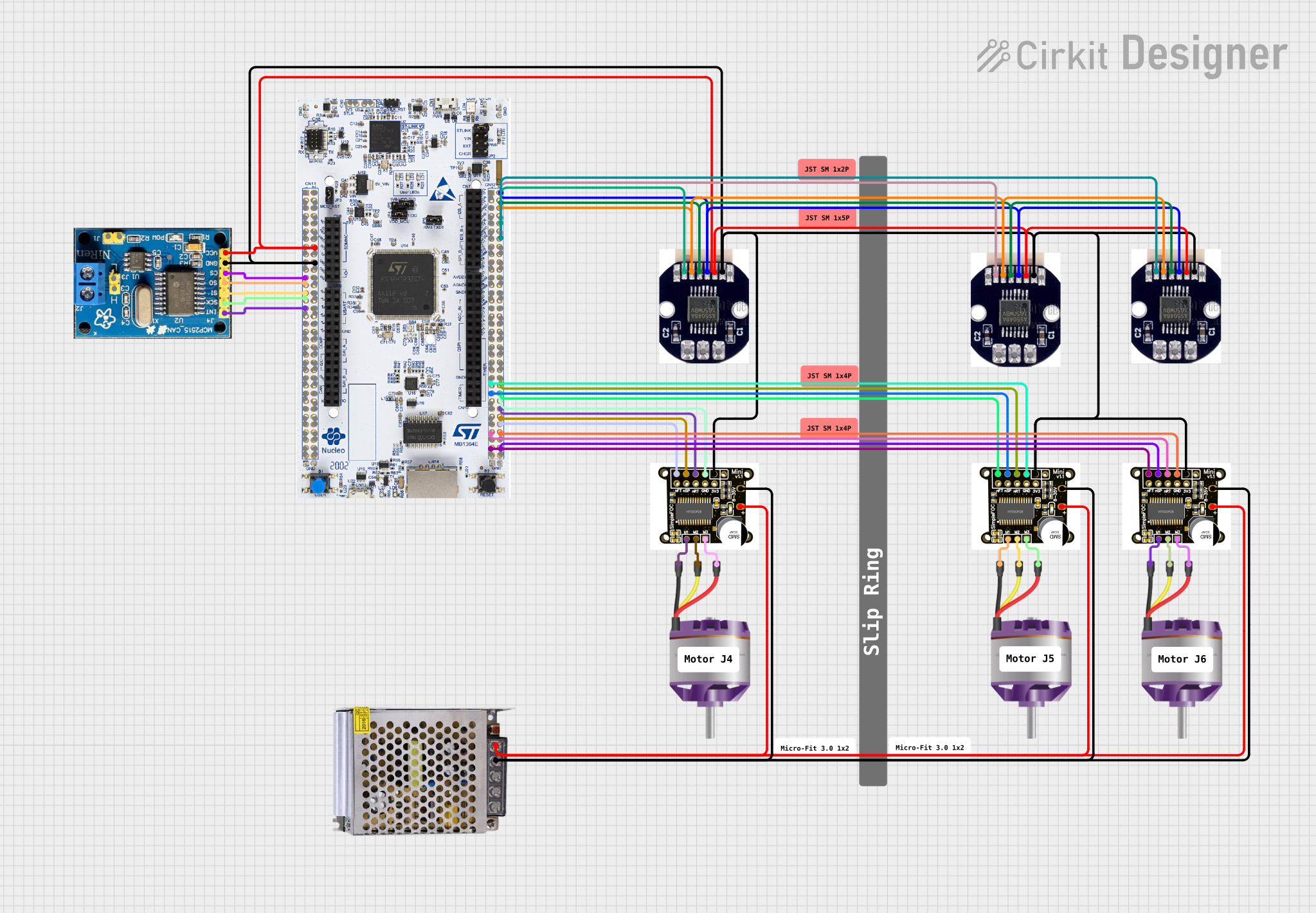

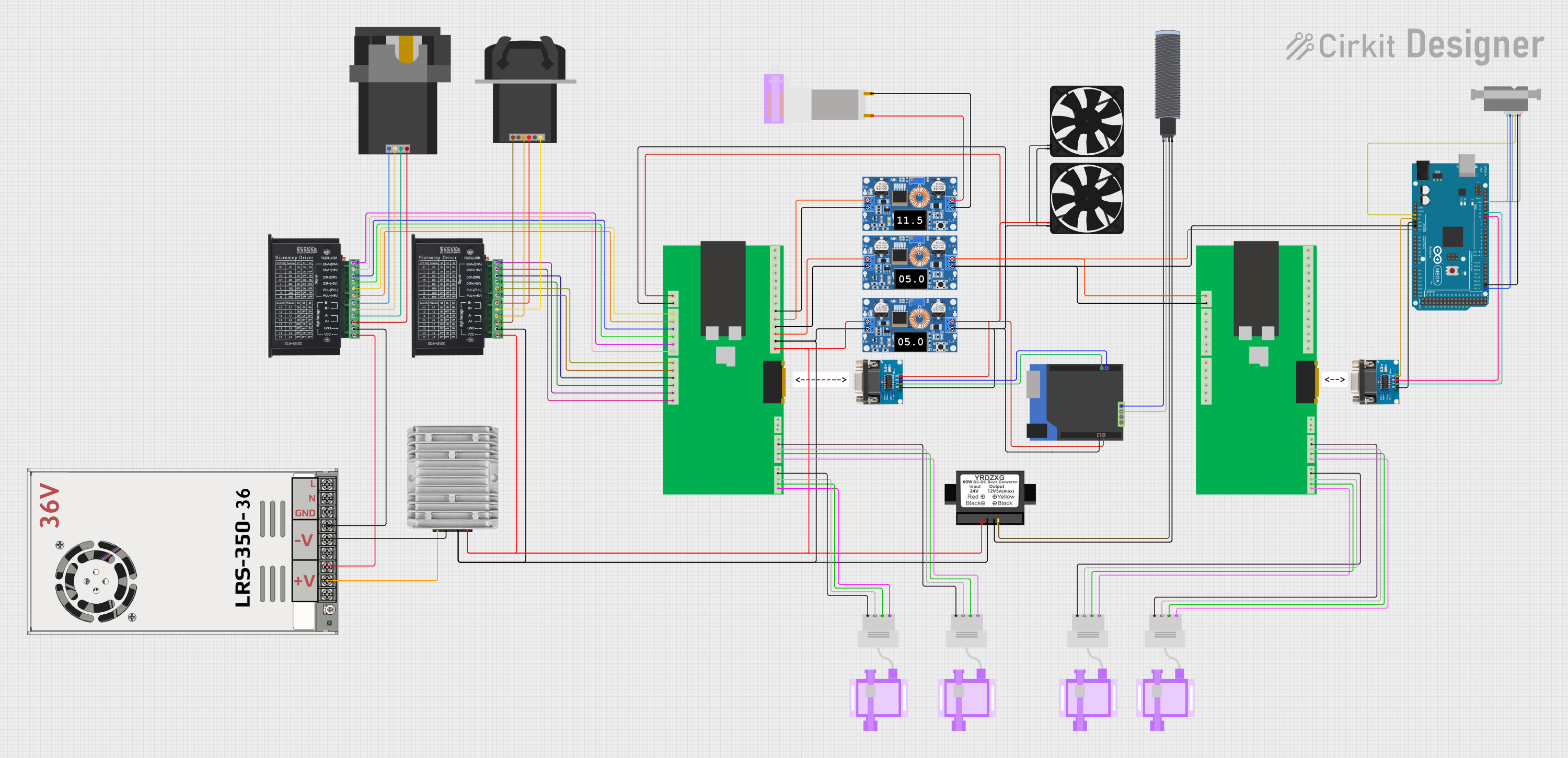

Explore Projects Built with Etamaster ECM motor

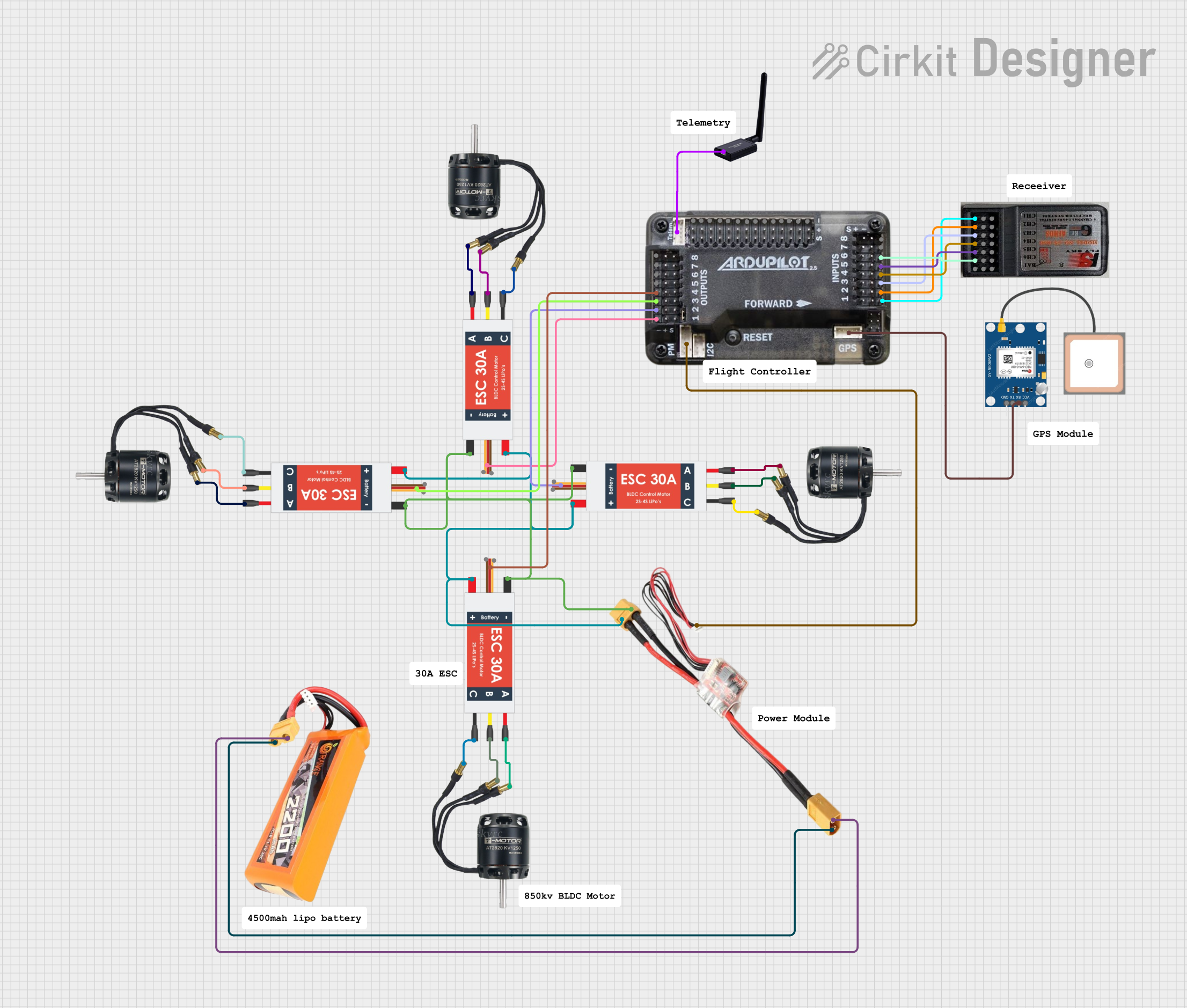

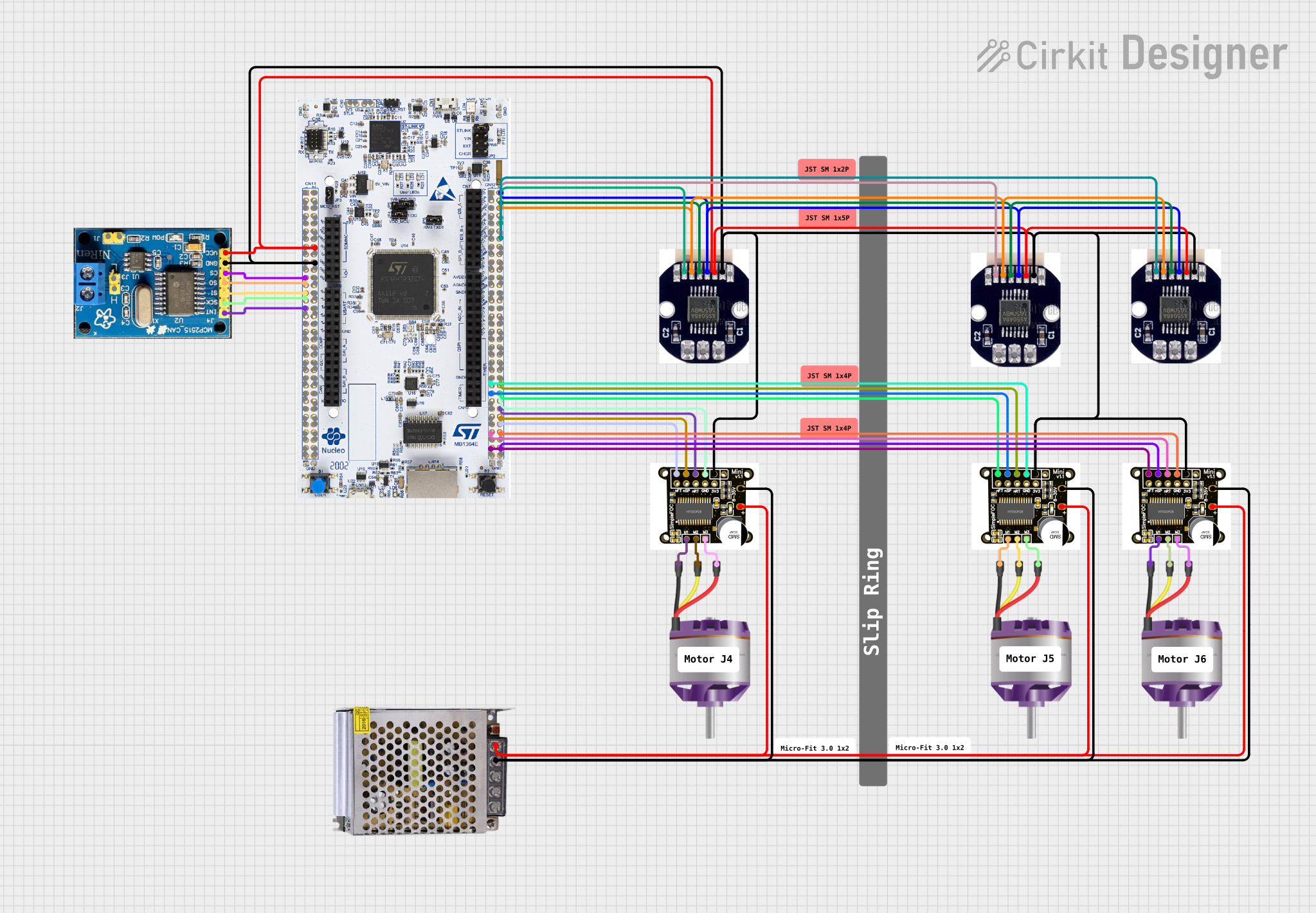

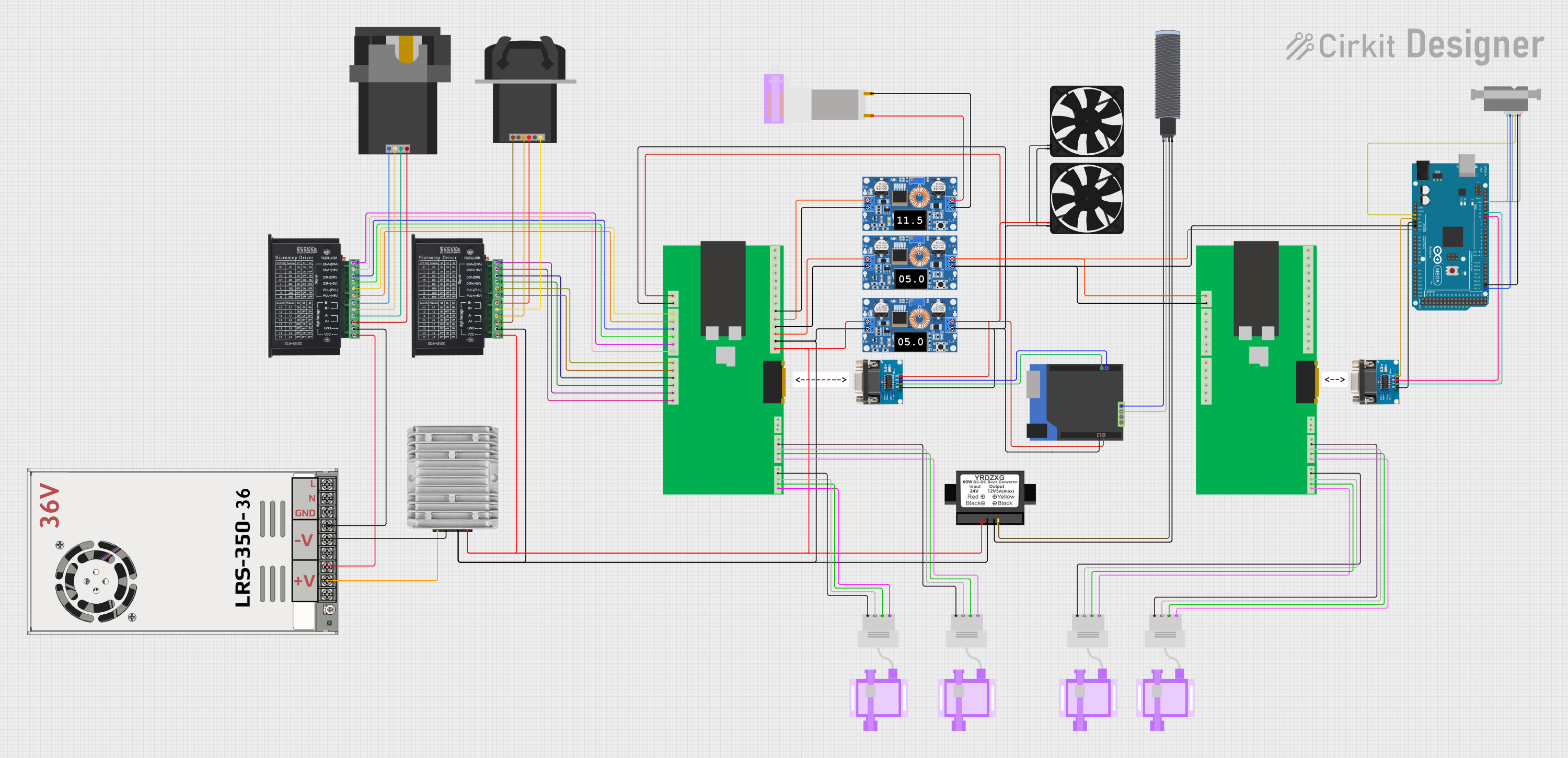

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with Etamaster ECM motor

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications and Use Cases

- HVAC Systems: Used in fans, blowers, and pumps for heating, ventilation, and air conditioning.

- Industrial Automation: Employed in conveyor systems and other machinery requiring variable speed control.

- Home Appliances: Found in high-efficiency washing machines, refrigerators, and other appliances.

- Renewable Energy Systems: Utilized in wind turbines and solar tracking systems.

Technical Specifications

Key Technical Details

| Parameter | Value |

|---|---|

| Manufacturer | Ruck |

| Part ID | EM 125 EC 02 |

| Voltage Range | 24V - 48V DC |

| Rated Power | 125W |

| Maximum Current | 5A |

| Speed Range | 0 - 3000 RPM |

| Efficiency | Up to 90% |

| Operating Temperature | -20°C to 60°C |

| Communication | PWM, Analog Input |

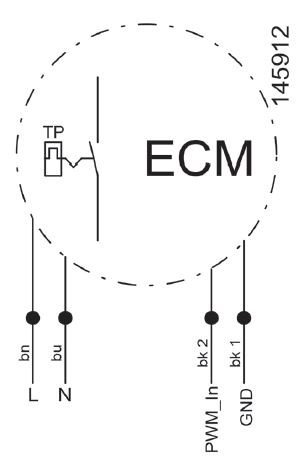

Pin Configuration and Descriptions

| Pin Number | Pin Name | Description |

|---|---|---|

| 1 | VCC | Power Supply (24V - 48V DC) |

| 2 | GND | Ground |

| 3 | PWM | Pulse Width Modulation Input for Speed Control |

| 4 | FG | Frequency Generator Output (Speed Feedback) |

| 5 | ANLG | Analog Input for Speed Control (0-10V) |

| 6 | NC | Not Connected |

Usage Instructions

How to Use the Component in a Circuit

- Power Supply: Connect the VCC pin to a DC power supply within the range of 24V to 48V. Connect the GND pin to the ground of the power supply.

- Speed Control:

- For PWM control, connect a PWM signal (0-5V) to the PWM pin.

- For analog control, connect a 0-10V analog signal to the ANLG pin.

- Speed Feedback: The FG pin provides a frequency output proportional to the motor speed, which can be used for monitoring and closed-loop control.

Important Considerations and Best Practices

- Power Supply: Ensure the power supply voltage is within the specified range to avoid damaging the motor.

- Heat Dissipation: Provide adequate ventilation or cooling to prevent overheating, especially in high-power applications.

- Signal Integrity: Use shielded cables for PWM and analog signals to minimize noise and ensure accurate speed control.

- Mounting: Securely mount the motor to prevent vibrations and mechanical stress.

Troubleshooting and FAQs

Common Issues and Solutions

Motor Does Not Start:

- Check Power Supply: Ensure the power supply is within the specified voltage range.

- Verify Connections: Confirm all connections are secure and correctly wired.

- Inspect Control Signals: Ensure the PWM or analog control signals are within the appropriate range.

Motor Overheats:

- Check Ventilation: Ensure adequate airflow around the motor.

- Reduce Load: Decrease the mechanical load on the motor.

- Verify Power Supply: Ensure the power supply is not exceeding the maximum current rating.

Inconsistent Speed:

- Check Signal Quality: Ensure the PWM or analog control signals are stable and free from noise.

- Inspect Feedback Loop: Verify the FG pin output and ensure the feedback loop is functioning correctly.

FAQs

Q: Can the ECM motor be controlled using an Arduino UNO?

A: Yes, the ECM motor can be controlled using an Arduino UNO. Below is an example code to control the motor speed using PWM:

// Define the PWM pin connected to the ECM motor

const int pwmPin = 9;

void setup() {

// Set the PWM pin as an output

pinMode(pwmPin, OUTPUT);

}

void loop() {

// Set motor speed to 50% duty cycle

analogWrite(pwmPin, 128); // 128 out of 255 is approximately 50%

delay(5000); // Run at this speed for 5 seconds

// Set motor speed to 75% duty cycle

analogWrite(pwmPin, 192); // 192 out of 255 is approximately 75%

delay(5000); // Run at this speed for 5 seconds

// Set motor speed to 25% duty cycle

analogWrite(pwmPin, 64); // 64 out of 255 is approximately 25%

delay(5000); // Run at this speed for 5 seconds

}

Q: What is the maximum speed of the ECM motor?

A: The maximum speed of the ECM motor is 3000 RPM.

Q: How can I monitor the motor speed?

A: The motor speed can be monitored using the FG pin, which provides a frequency output proportional to the motor speed. This signal can be read using a microcontroller or frequency counter.

This documentation provides a comprehensive overview of the Etamaster ECM Motor (EM 125 EC 02) by Ruck, including its technical specifications, usage instructions, and troubleshooting tips. Whether you are a beginner or an experienced user, this guide will help you effectively integrate and utilize this high-efficiency motor in your applications.