How to Use DC 12V PWM Speed Controller: Examples, Pinouts, and Specs

Design with DC 12V PWM Speed Controller in Cirkit Designer

Design with DC 12V PWM Speed Controller in Cirkit DesignerIntroduction

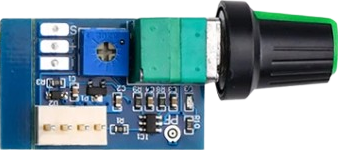

The DC 12V PWM Speed Controller is an electronic device designed to control the speed of a DC motor by modulating the power supplied to the motor. The controller uses Pulse Width Modulation (PWM) to adjust the duty cycle of the signal, effectively varying the voltage and thus the speed of the motor. This component is widely used in robotics, automation systems, DIY electronic projects, and anywhere precise motor speed control is required.

Explore Projects Built with DC 12V PWM Speed Controller

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with DC 12V PWM Speed Controller

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerTechnical Specifications

Key Technical Details

- Input Voltage: 12V DC

- Output Voltage: 0-12V DC (adjustable)

- Continuous Current Rating: Typically 2A-3A (varies by model)

- PWM Frequency: Typically around 20kHz (varies by model)

- Duty Cycle Adjustable Range: 0% - 100%

- Control Method: Potentiometer (variable resistor) or external PWM signal

Pin Configuration and Descriptions

| Pin Number | Description | Notes |

|---|---|---|

| 1 | V+ (Power Supply) | Connect to +12V DC power source |

| 2 | Motor Output + | Connect to DC motor positive lead |

| 3 | Motor Output - | Connect to DC motor negative lead |

| 4 | Ground | Connect to power supply ground |

| 5 | PWM Input (optional) | For external PWM signal input |

| 6 | Speed Control Knob | Built-in potentiometer |

Usage Instructions

How to Use the Component in a Circuit

Power Connections:

- Connect the

V+pin to the positive terminal of your 12V DC power supply. - Connect the

Groundpin to the negative terminal of your power supply.

- Connect the

Motor Connections:

- Connect the

Motor Output +pin to the positive lead of your DC motor. - Connect the

Motor Output -pin to the negative lead of your DC motor.

- Connect the

Speed Control:

- Turn the built-in

Speed Control Knobto adjust the motor speed. - Alternatively, apply an external PWM signal to the

PWM Inputpin for electronic control.

- Turn the built-in

Important Considerations and Best Practices

- Ensure that the power supply can handle the current requirements of both the motor and the speed controller.

- Do not exceed the maximum current rating of the controller to prevent damage.

- Use a heat sink if the controller is expected to handle currents near its maximum rating for extended periods.

- Keep the PWM frequency within the specified range for optimal performance.

- For noise-sensitive applications, consider adding a filter capacitor across the motor terminals.

Troubleshooting and FAQs

Common Issues

- Motor not turning: Check connections and power supply, ensure the potentiometer is not set to minimum.

- Controller overheating: Reduce the load or improve cooling with a heat sink or fan.

- Inconsistent motor speed: Verify that the PWM frequency is stable and within the specified range.

Solutions and Tips

- Double-check wiring and solder joints for any loose connections or shorts.

- Use a multimeter to verify the input voltage and the PWM signal.

- If using an external PWM signal, ensure it is within the 0-12V range and the frequency is correct.

FAQs

Q: Can I use this controller with motors rated for higher currents? A: It is not recommended as it may damage the controller. Always match the motor to the controller's specifications.

Q: How can I reverse the motor direction? A: To reverse the motor direction, you will need to reverse the motor connections or use a motor driver with direction control.

Q: Can I control multiple motors with one controller? A: Yes, as long as the combined current does not exceed the controller's rating.

Example Arduino Code

// Example code to control a DC motor speed using an Arduino and a DC 12V PWM Speed Controller

int pwmPin = 3; // PWM output pin that connects to PWM Input on the speed controller

int speedValue = 0; // Variable to store the speed value (0 to 255)

void setup() {

pinMode(pwmPin, OUTPUT); // Set the PWM pin as an output

}

void loop() {

for (speedValue = 0; speedValue <= 255; speedValue++) {

analogWrite(pwmPin, speedValue); // Ramp up the speed

delay(10);

}

for (speedValue = 255; speedValue >= 0; speedValue--) {

analogWrite(pwmPin, speedValue); // Ramp down the speed

delay(10);

}

}

Note: The analogWrite function on Arduino uses PWM to control the pin output. The speedValue ranges from 0 (0% duty cycle, motor off) to 255 (100% duty cycle, full speed). Adjust the speedValue as needed for your application.