How to Use Bipolar Stepper Motor (NEMA 17): Examples, Pinouts, and Specs

Design with Bipolar Stepper Motor (NEMA 17) in Cirkit Designer

Design with Bipolar Stepper Motor (NEMA 17) in Cirkit DesignerIntroduction

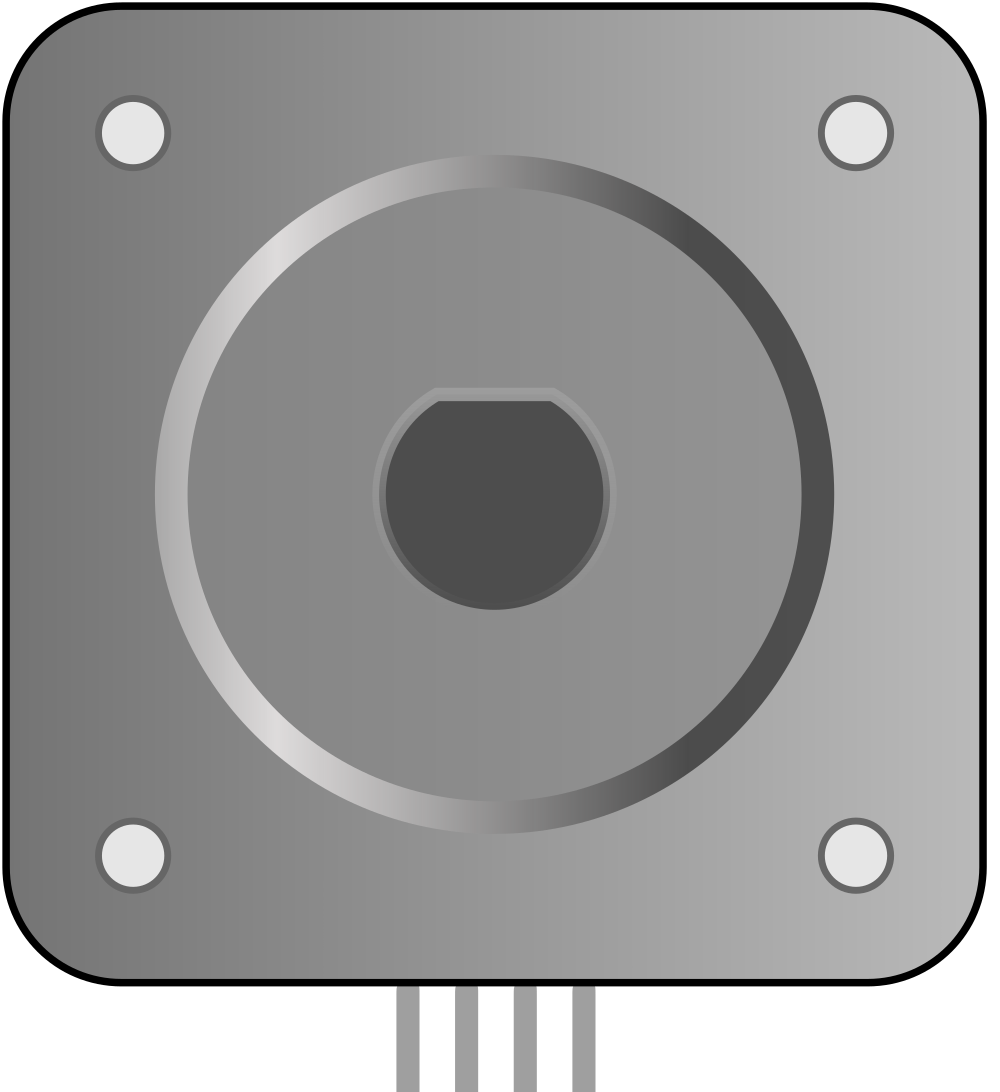

The Bipolar Stepper Motor (NEMA 17) is a type of stepper motor that uses two coils to generate magnetic fields, enabling precise control of rotation and position. The "NEMA 17" designation refers to the motor's faceplate dimensions, which measure 1.7 inches (43.2 mm) on each side. This motor is widely used in applications requiring accurate positioning, such as 3D printers, CNC machines, robotics, and automated systems. Its compact size, high torque, and reliability make it a popular choice for both hobbyists and professionals.

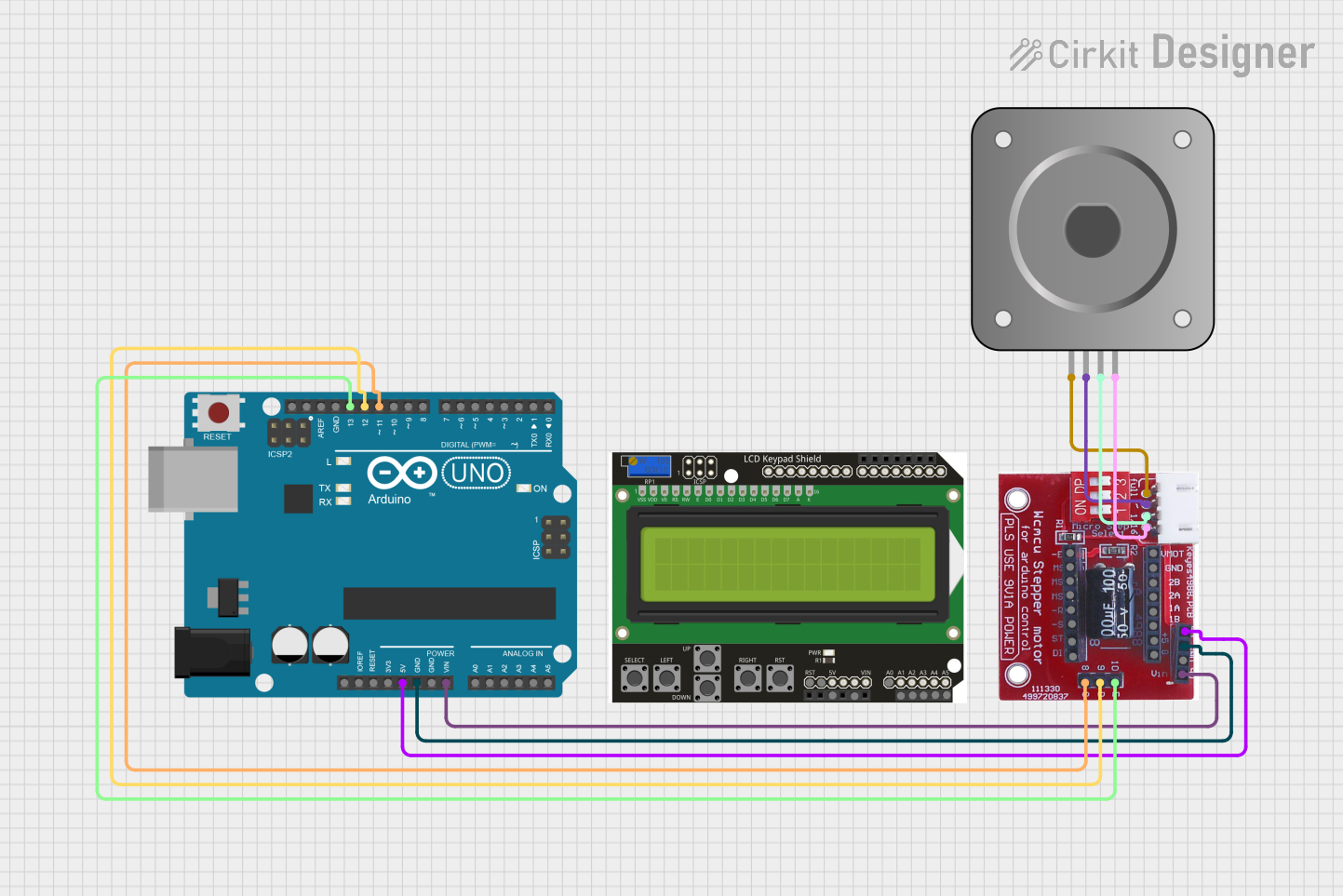

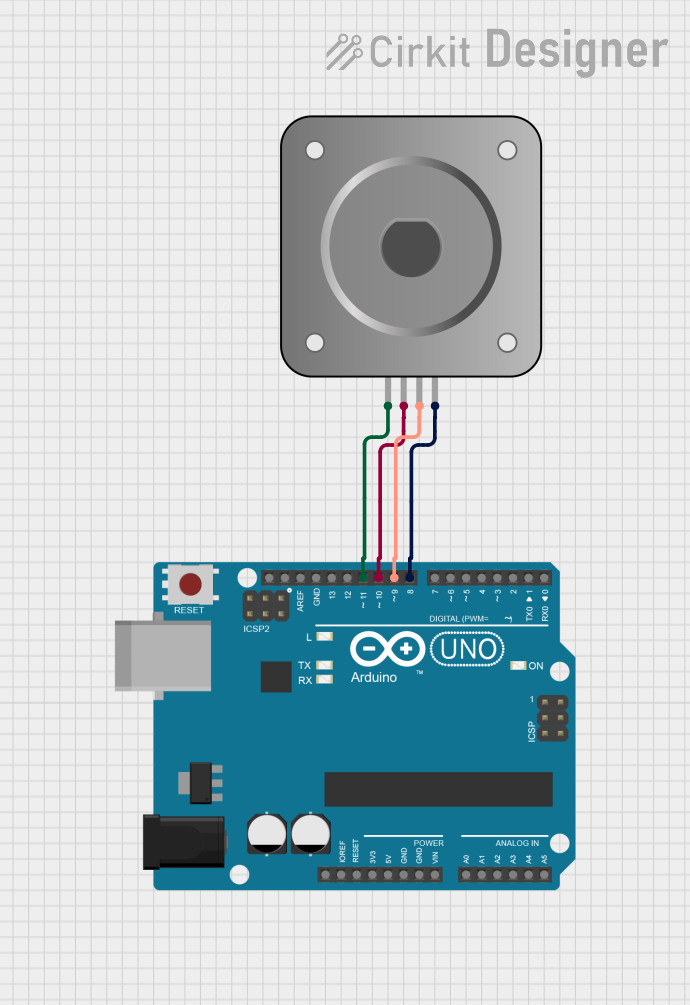

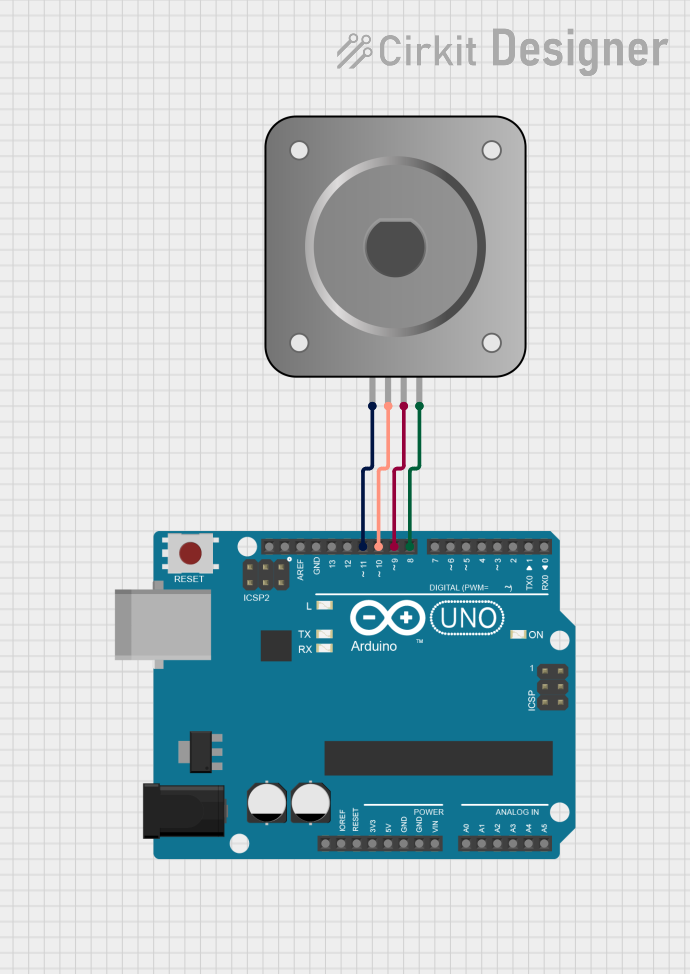

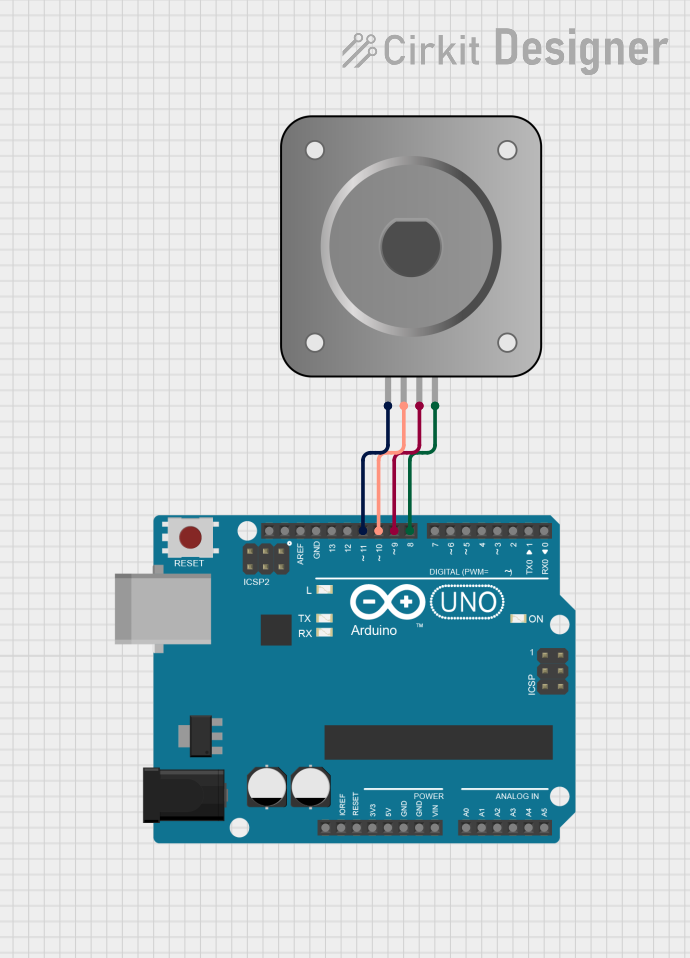

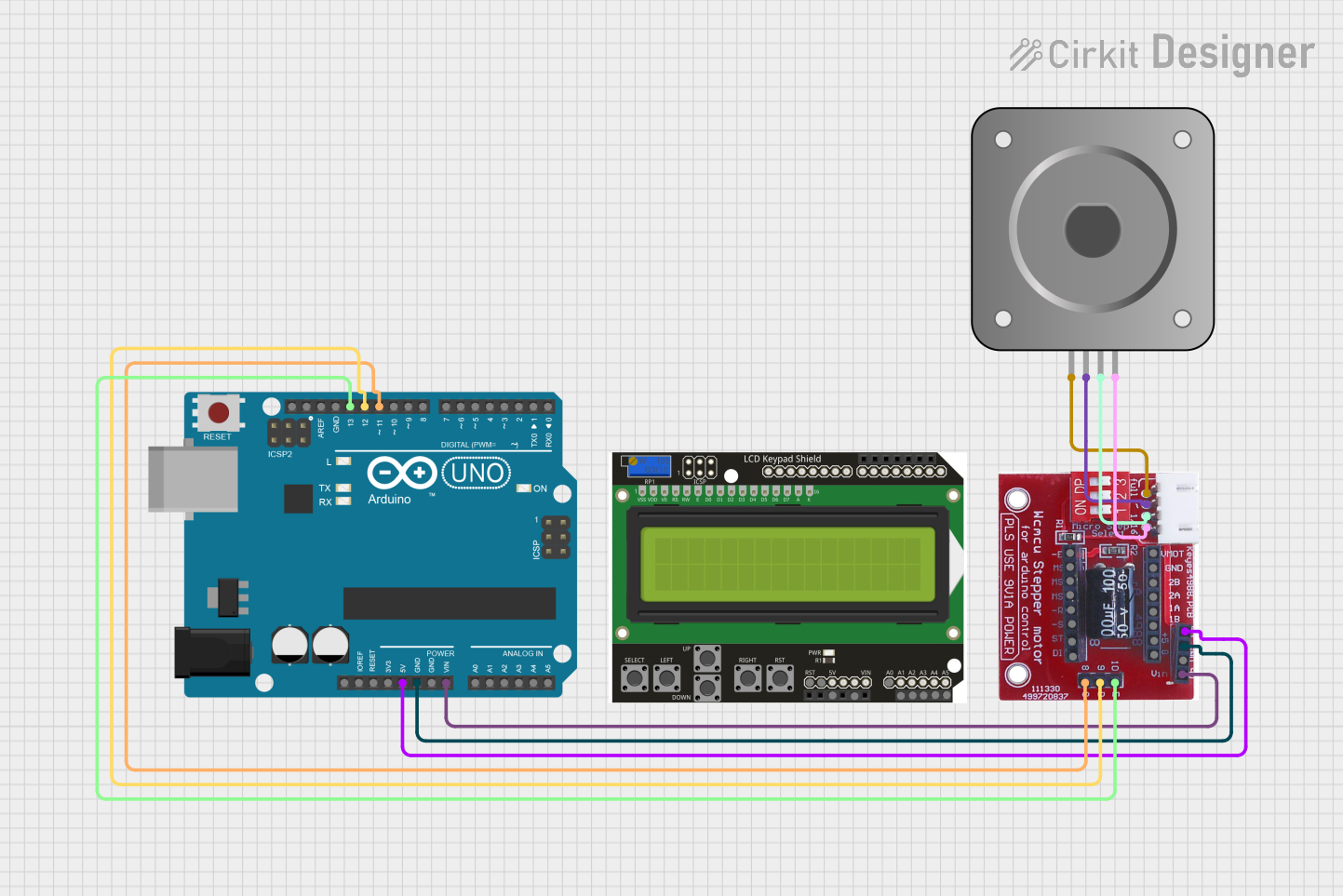

Explore Projects Built with Bipolar Stepper Motor (NEMA 17)

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with Bipolar Stepper Motor (NEMA 17)

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerTechnical Specifications

Below are the key technical details for a typical NEMA 17 Bipolar Stepper Motor. Note that specific models may vary slightly, so always refer to the datasheet for your particular motor.

General Specifications

- Step Angle: 1.8° (200 steps per revolution)

- Rated Voltage: 2.8 V (varies by model)

- Rated Current: 1.2 A per phase

- Holding Torque: 40 N·cm to 70 N·cm (varies by model)

- Number of Phases: 2

- Resistance per Phase: ~2.4 Ω

- Inductance per Phase: ~3.2 mH

- Shaft Diameter: 5 mm

- Body Dimensions: 42.3 mm x 42.3 mm x 47 mm (typical)

Pin Configuration and Descriptions

The NEMA 17 Bipolar Stepper Motor has four wires, corresponding to the two coils. The table below describes the pinout:

| Wire Color | Function | Description |

|---|---|---|

| Red | Coil A (Positive) | Connects to one end of Coil A |

| Blue | Coil A (Negative) | Connects to the other end of Coil A |

| Green | Coil B (Positive) | Connects to one end of Coil B |

| Black | Coil B (Negative) | Connects to the other end of Coil B |

Note: Wire colors may vary depending on the manufacturer. Use a multimeter to verify coil pairs by checking continuity.

Usage Instructions

How to Use the NEMA 17 in a Circuit

- Identify Coil Pairs: Use a multimeter to identify the two coil pairs. Check for continuity between wires to determine which wires belong to the same coil.

- Connect to a Stepper Driver: The NEMA 17 requires a stepper motor driver (e.g., A4988 or DRV8825) to control its operation. Connect the motor wires to the driver as follows:

- Coil A wires (e.g., Red and Blue) to the A+ and A- terminals.

- Coil B wires (e.g., Green and Black) to the B+ and B- terminals.

- Power the Driver: Provide the appropriate voltage and current to the stepper driver. Ensure the power supply matches the motor's specifications.

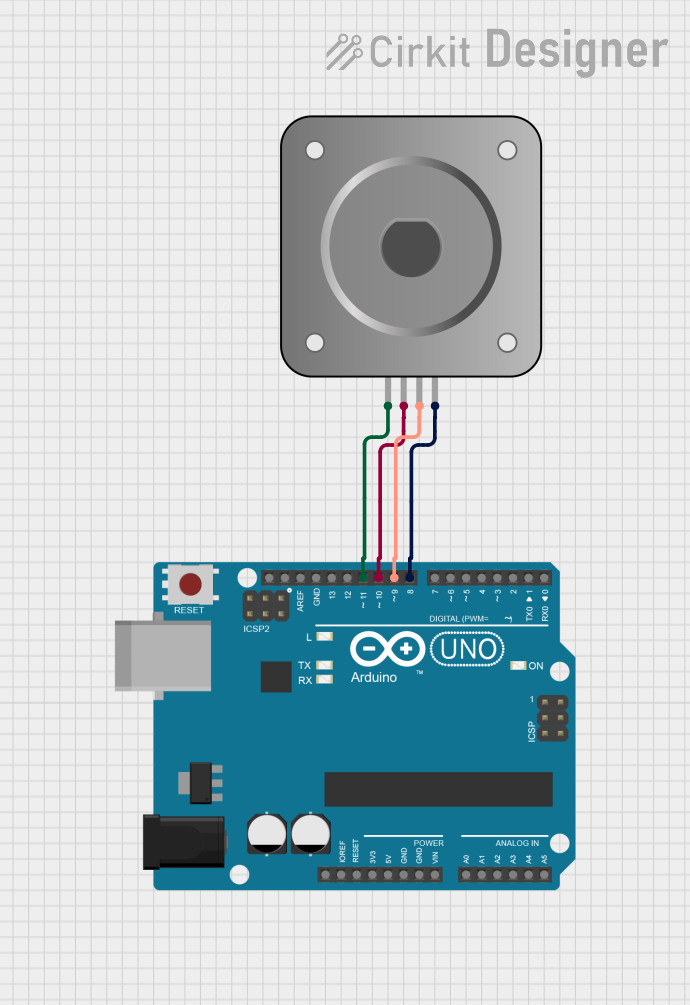

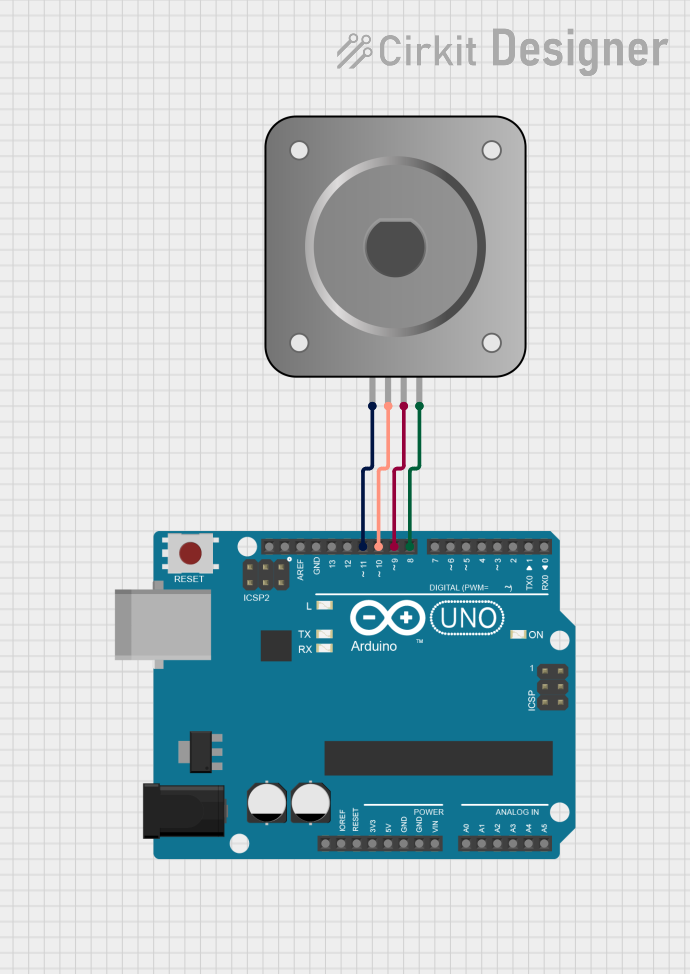

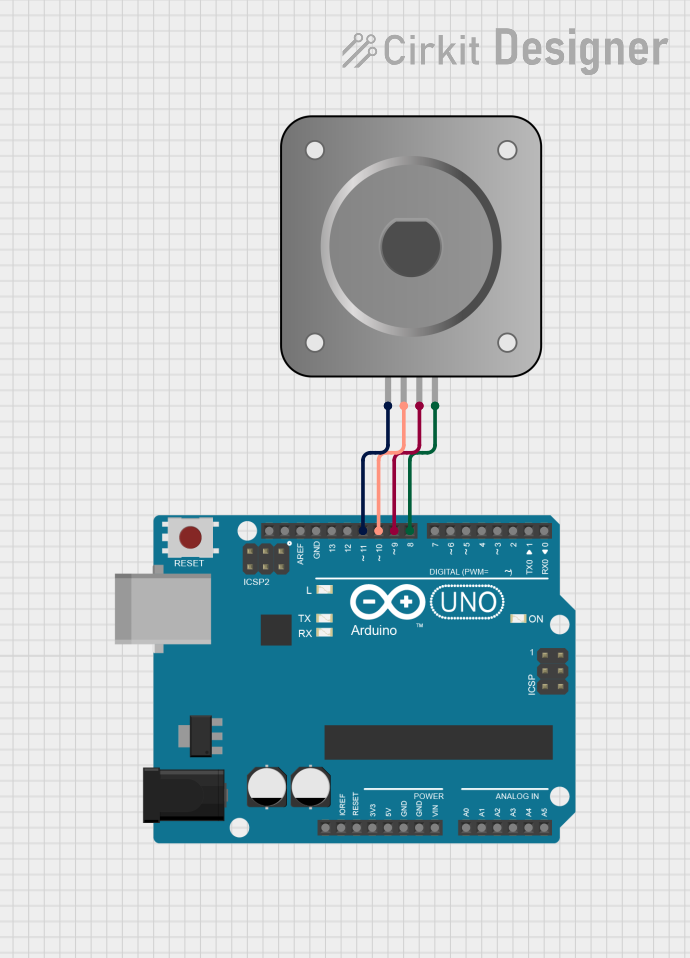

- Control with a Microcontroller: Use a microcontroller (e.g., Arduino UNO) to send step and direction signals to the driver.

Arduino UNO Example Code

Below is an example of how to control a NEMA 17 motor using an A4988 driver and an Arduino UNO:

// Define pin connections

const int stepPin = 3; // Pin for step signal

const int dirPin = 4; // Pin for direction signal

void setup() {

pinMode(stepPin, OUTPUT); // Set step pin as output

pinMode(dirPin, OUTPUT); // Set direction pin as output

digitalWrite(dirPin, HIGH); // Set initial direction (HIGH = clockwise)

}

void loop() {

// Generate step pulses to rotate the motor

for (int i = 0; i < 200; i++) { // 200 steps = 1 full revolution

digitalWrite(stepPin, HIGH); // Step signal HIGH

delayMicroseconds(500); // Wait 500 µs

digitalWrite(stepPin, LOW); // Step signal LOW

delayMicroseconds(500); // Wait 500 µs

}

delay(1000); // Pause for 1 second

// Change direction

digitalWrite(dirPin, !digitalRead(dirPin)); // Toggle direction

}

Important Considerations and Best Practices

- Current Limiting: Adjust the current limit on the stepper driver to match the motor's rated current. This prevents overheating and ensures optimal performance.

- Microstepping: Enable microstepping on the driver (if supported) for smoother motion and higher resolution.

- Power Supply: Use a power supply with sufficient voltage and current capacity. A higher voltage (within the driver's limits) can improve motor performance.

- Cooling: If the motor or driver becomes excessively hot, consider adding a heatsink or fan for cooling.

Troubleshooting and FAQs

Common Issues and Solutions

Motor Not Moving

- Cause: Incorrect wiring or loose connections.

- Solution: Double-check the wiring and ensure all connections are secure.

Motor Vibrates but Doesn't Rotate

- Cause: Coil pairs are incorrectly identified or swapped.

- Solution: Verify coil pairs using a multimeter and reconnect correctly.

Driver Overheating

- Cause: Current limit set too high or insufficient cooling.

- Solution: Adjust the current limit on the driver and add cooling if necessary.

Motor Skipping Steps

- Cause: Insufficient torque or excessive load.

- Solution: Reduce the load or increase the current limit (within safe limits).

Motor Makes Noise

- Cause: Low microstepping setting or resonance.

- Solution: Enable higher microstepping on the driver and secure the motor to reduce vibrations.

FAQs

Q: Can I run the NEMA 17 without a driver?

A: No, a stepper driver is required to control the motor's operation and provide the necessary current.Q: What is the maximum speed of the NEMA 17?

A: The maximum speed depends on the driver, power supply, and load. Typically, it can achieve up to 1000 RPM under optimal conditions.Q: How do I reverse the motor's direction?

A: Toggle the direction pin on the driver or swap the connections of one coil.Q: Can I use the NEMA 17 with a 12V power supply?

A: Yes, but ensure the stepper driver regulates the current to prevent overheating the motor.

By following this documentation, you can effectively use the NEMA 17 Bipolar Stepper Motor in your projects.