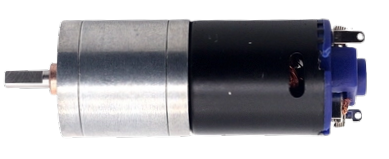

How to Use GM-25 370: Examples, Pinouts, and Specs

Design with GM-25 370 in Cirkit Designer

Design with GM-25 370 in Cirkit DesignerIntroduction

The GM-25 370, manufactured by Chihai Motor, is a gas meter designed for precise measurement of gas flow in residential and commercial applications. It utilizes a diaphragm mechanism to ensure accurate readings and is built to operate under a wide range of pressure conditions. This component is widely used in gas distribution systems, industrial gas monitoring, and utility metering.

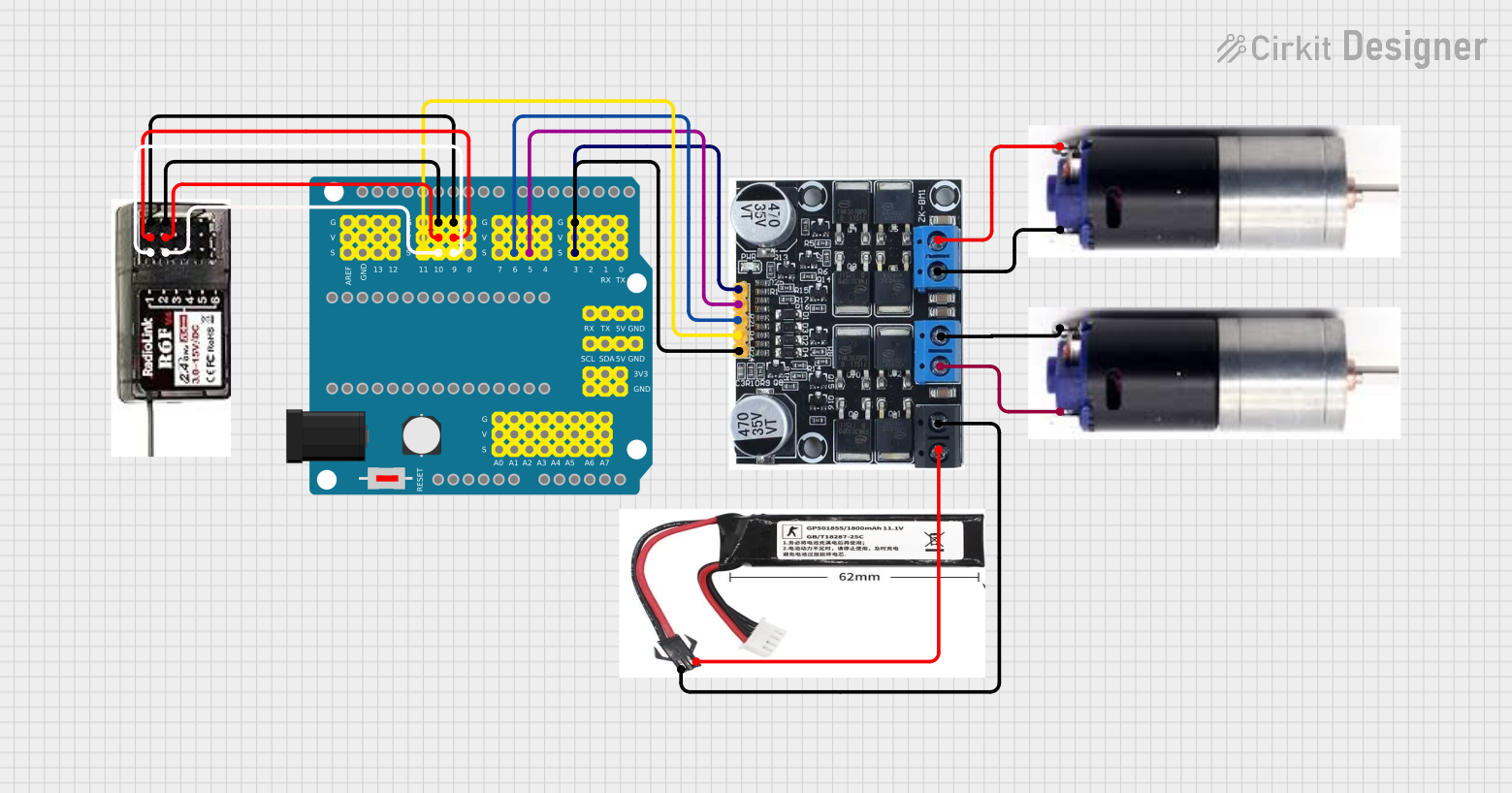

Explore Projects Built with GM-25 370

Open Project in Cirkit Designer

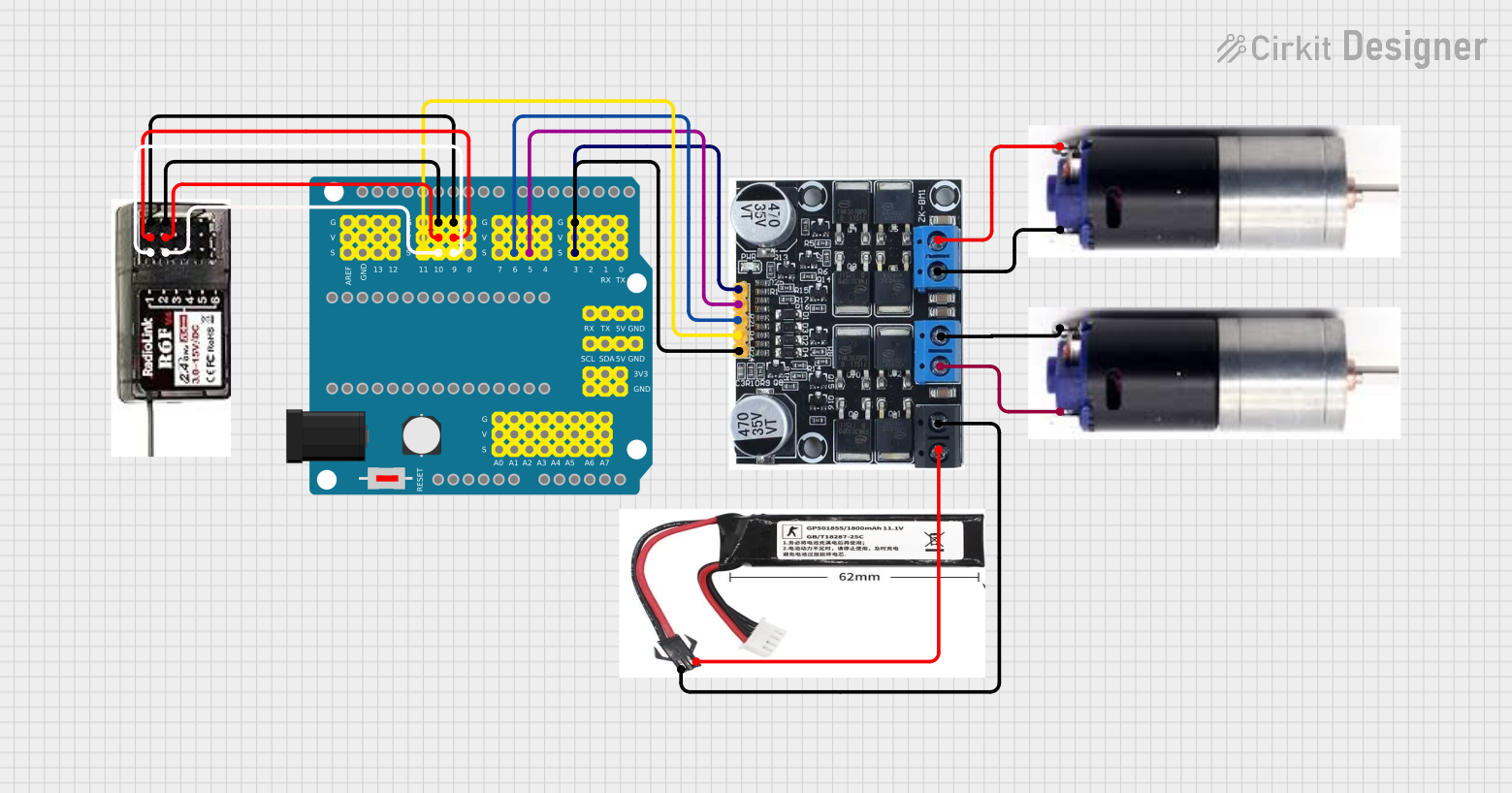

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with GM-25 370

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications and Use Cases

- Residential gas consumption monitoring

- Commercial gas flow measurement

- Industrial gas distribution systems

- Utility billing systems

- Gas leak detection and monitoring

Technical Specifications

The GM-25 370 gas meter is engineered for reliability and accuracy. Below are its key technical specifications:

General Specifications

| Parameter | Value |

|---|---|

| Manufacturer | Chihai Motor |

| Measurement Mechanism | Diaphragm |

| Application | Gas flow measurement |

| Operating Pressure Range | 0.5 kPa to 50 kPa |

| Flow Rate Range | 0.016 m³/h to 6 m³/h |

| Accuracy Class | ±1.5% |

| Operating Temperature | -20°C to 50°C |

| Material | Corrosion-resistant alloy |

| Weight | ~1.5 kg |

Pin Configuration and Descriptions

The GM-25 370 gas meter typically includes an electronic interface for data output. Below is the pin configuration for the electronic interface:

| Pin Number | Pin Name | Description |

|---|---|---|

| 1 | VCC | Power supply input (3.3V to 5V DC) |

| 2 | GND | Ground connection |

| 3 | Pulse Output | Outputs a digital pulse for each unit of gas flow measured (e.g., 1 pulse = 0.01 m³) |

| 4 | Data (Optional) | Optional data communication pin for advanced monitoring systems |

Usage Instructions

The GM-25 370 gas meter is straightforward to integrate into gas monitoring systems. Below are the steps and best practices for using this component:

How to Use the GM-25 370 in a Circuit

- Power Supply: Connect the VCC pin to a 3.3V or 5V DC power source and the GND pin to the ground of your circuit.

- Pulse Output: Connect the Pulse Output pin to a microcontroller or data acquisition system to count pulses and calculate gas flow.

- Data Communication (Optional): If your system supports advanced monitoring, connect the Data pin to the appropriate interface for real-time data transfer.

- Calibration: Ensure the meter is calibrated according to the manufacturer's guidelines for accurate measurements.

Important Considerations and Best Practices

- Pressure Compatibility: Verify that the operating pressure of the gas system is within the meter's specified range (0.5 kPa to 50 kPa).

- Pulse Counting: Use a microcontroller (e.g., Arduino UNO) to count pulses and calculate gas flow. Each pulse typically represents a fixed volume of gas (e.g., 0.01 m³).

- Environmental Conditions: Install the meter in a location protected from extreme temperatures, moisture, and physical damage.

- Safety: Ensure all connections are secure and comply with local safety regulations for gas systems.

Example Code for Arduino UNO

Below is an example of how to interface the GM-25 370 with an Arduino UNO to measure gas flow:

// GM-25 370 Gas Meter Example Code for Arduino UNO

// This code counts pulses from the gas meter and calculates the gas flow in m³.

const int pulsePin = 2; // Pin connected to the Pulse Output of the GM-25 370

volatile int pulseCount = 0; // Variable to store the pulse count

float gasFlow = 0.0; // Variable to store the calculated gas flow in m³

const float pulseToVolume = 0.01; // Volume of gas per pulse in m³

void setup() {

pinMode(pulsePin, INPUT_PULLUP); // Set the pulse pin as input with pull-up resistor

attachInterrupt(digitalPinToInterrupt(pulsePin), countPulse, FALLING);

// Attach an interrupt to count pulses on a falling edge

Serial.begin(9600); // Initialize serial communication for debugging

}

void loop() {

noInterrupts(); // Disable interrupts to safely read pulseCount

int currentPulseCount = pulseCount;

interrupts(); // Re-enable interrupts

// Calculate gas flow

gasFlow = currentPulseCount * pulseToVolume;

// Print the gas flow to the Serial Monitor

Serial.print("Gas Flow: ");

Serial.print(gasFlow);

Serial.println(" m³");

delay(1000); // Wait for 1 second before updating

}

// Interrupt Service Routine (ISR) to count pulses

void countPulse() {

pulseCount++;

}

Notes on the Code

- Ensure the

pulseToVolumeconstant matches the pulse-to-volume ratio of your specific GM-25 370 model. - Use a pull-up resistor if the Pulse Output pin does not have an internal pull-up.

Troubleshooting and FAQs

Common Issues and Solutions

No Pulse Output Detected

- Cause: Incorrect wiring or insufficient power supply.

- Solution: Verify all connections and ensure the VCC pin is receiving 3.3V to 5V DC.

Inaccurate Gas Flow Readings

- Cause: Calibration error or incorrect pulse-to-volume ratio.

- Solution: Recalibrate the meter and confirm the correct pulse-to-volume ratio.

Intermittent Data Output

- Cause: Electrical noise or unstable power supply.

- Solution: Use decoupling capacitors near the power supply pins and ensure a stable power source.

Physical Damage to the Meter

- Cause: Exposure to harsh environmental conditions or improper installation.

- Solution: Inspect the meter for damage and replace if necessary. Install in a protected location.

FAQs

Q: Can the GM-25 370 be used for liquids?

A: No, the GM-25 370 is specifically designed for gas flow measurement and is not suitable for liquids.

Q: How do I reset the pulse count?

A: You can reset the pulse count in your microcontroller code by setting the pulseCount variable to 0.

Q: Is the GM-25 370 compatible with wireless monitoring systems?

A: Yes, the Data pin can be interfaced with wireless modules for remote monitoring, depending on your system's capabilities.

Q: What is the lifespan of the GM-25 370?

A: The lifespan depends on usage and environmental conditions but typically exceeds 10 years with proper maintenance.

This documentation provides a comprehensive guide to using the GM-25 370 gas meter effectively. For further assistance, refer to the manufacturer's manual or contact Chihai Motor support.